Attic ventilation thermodynamics is the application of building science principles to regulate heat transfer and airflow within the attic envelope, directly impacting the longevity of a roof system. An improperly ventilated attic creates a chaotic thermal environment. This environment actively works against the primary function of your roof: providing stable protection against sunlight, extremes of temperature, and moisture. Most roofing contractors address ventilation with assumptions, not calculations. This is a recipe for premature roof failure, material degradation, and voided manufacturer warranties. It is the direct cause of the chaos homeowners dread.

We operate differently. Our approach is based on quantitative analysis and predictable systems. If your primary goal is the absolute lowest bid, we are not the right fit for your project. Our process is designed for meticulous homeowners who understand that a properly engineered system is the only way to protect their investment and ensure peace of mind.

The Foundational Principles of Attic Thermodynamics

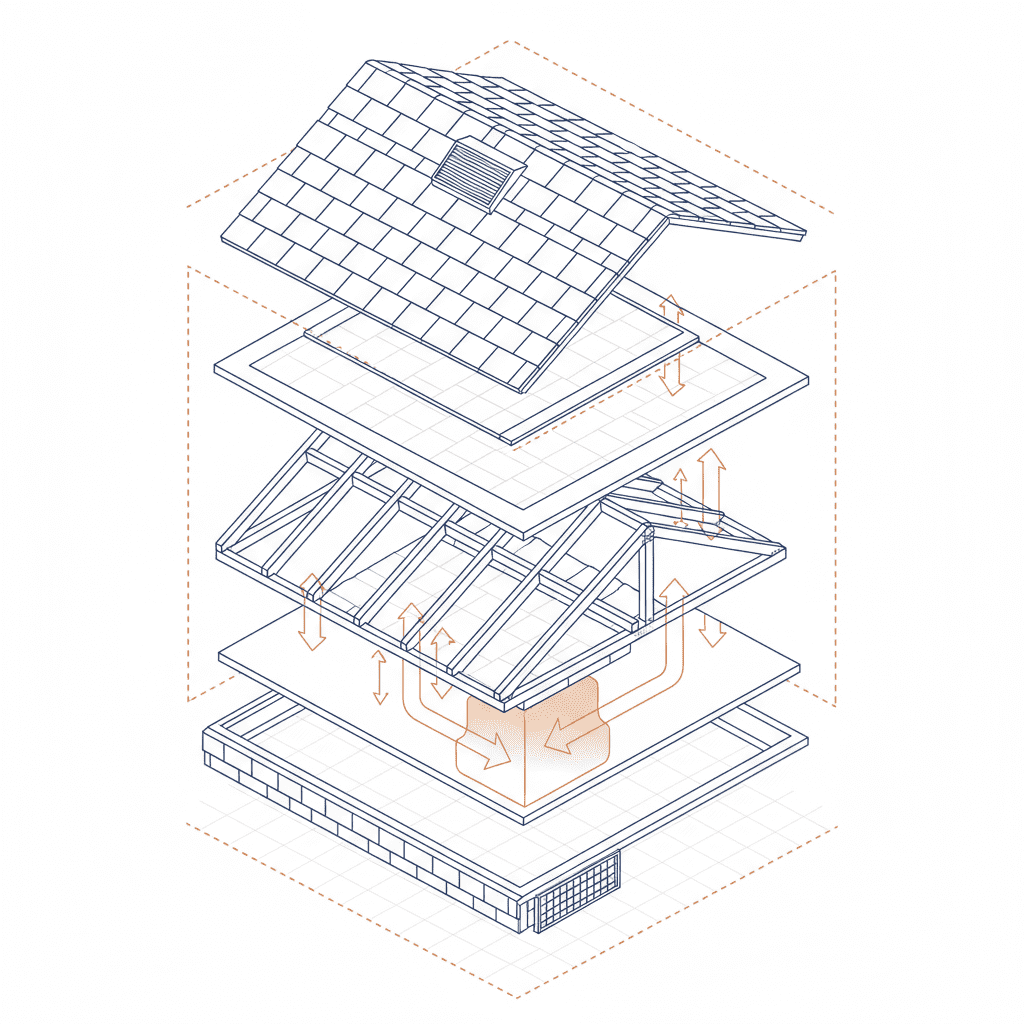

A roof is not a static cover; it is a dynamic system governed by the immutable laws of physics. Understanding attic ventilation begins with the fundamental principles of thermal dynamics. These principles are not optional. They dictate how heat and moisture behave within your home’s uppermost structure—the attic—which supports the entire roof covering and its related constructions.

Conduction, Convection, & Radiation: The Three Modes of Heat Transfer Impacting Your Roof

Three distinct mechanisms of heat transfer dictate the thermal load on your attic and roof. A functional ventilation system is designed to manage all three.

- Solar Radiation: This is the primary source of heat. Sunlight directly strikes the roof’s covering material (shingles), transferring thermal energy. Darker shingles absorb more radiant heat.

- Conduction: The absorbed heat travels through solid materials. It conducts from the shingles, through the underlayment, and into the roof sheathing, warming the air inside the attic.

- Convection: This is the transfer of heat through the movement of fluids, in this case, air. As the attic air is heated via conduction, it becomes less dense and more buoyant. This lighter air rises, creating a natural convective loop that is the engine of a passive ventilation system.

Stack Effect vs. Wind Effect: The Natural Forces Driving Airflow

Natural ventilation relies on two forces to create a continuous exchange of air. A properly designed system leverages both without mechanical assistance.

- The Stack Effect: This is the primary driver of airflow on calm, hot days. The buoyant, hot air rises to the highest point of the attic, creating a positive pressure zone at the peak and a negative pressure zone at the lowest point (the eaves). This pressure differential pulls cooler, denser replacement air in through the intake vents.

- The Wind Effect: Wind flowing over the roof’s peak creates a negative pressure area. This acts like a vacuum, actively pulling the hot, moist air out of the exhaust vents and enhancing the natural convective flow initiated by the stack effect.

Calculating Net Free Vent Area (NFVA): The System’s Critical Specification

Effective ventilation is a matter of mathematics, not guesswork. The critical variable is Net Free Vent Area (NFVA), which refers to the total unobstructed area through which air can pass through a vent. It is the system’s core specification.

The International Residential Code (IRC) provides a minimum standard: the 1/300 rule. This rule mandates a minimum of 1 square foot of total NFVA for every 300 square feet of attic floor space. Crucially, this NFVA must be perfectly balanced between intake and exhaust.

| Parameter | Calculation | Result |

|---|---|---|

| Total Required NFVA (1/300 Rule) | 1,500 sq. ft. / 300 | 5 sq. ft. (or 720 sq. inches) |

| Required Intake NFVA (50%) | 720 sq. in. / 2 | 360 sq. inches |

| Required Exhaust NFVA (50%) | 720 sq. in. / 2 | 360 sq. inches |

An imbalance, particularly insufficient intake, negates the entire system and is the root cause of most ventilation-related roof failures.

How Unregulated Temperatures Degrade Your Roof System

An unbalanced ventilation system exposes your roof—a construction designed for protection—to the very elements it should defend against. This is not a cosmetic issue; it is a direct assault on the structural and material integrity of your home, actively shortening the life of its most critical asset.

Accelerated Material Aging: The Impact of Extreme Heat on Shingles and Underlayment

An inadequately ventilated attic in a sunny climate can reach temperatures exceeding 150°F (65°C). This extreme heat ‘bakes’ the asphalt shingles from below, a process known as thermal cycling. This constant, high heat accelerates the loss of volatile oils that keep the shingles flexible. The result is a brittle roof covering that is susceptible to cracking and premature granule loss, drastically reducing its ability to provide protection against sunlight and rain.

Moisture and Condensation: The Threat to Structural Sheathing and Rafters

Warm, moist air from the home’s living areas naturally rises and enters the attic. In a poorly ventilated system, this moisture is trapped. During cooler nights, when the roof sheathing temperature drops below the dew point of the trapped air, condensation occurs. This persistent moisture saturates the wood sheathing and rafters, creating ideal conditions for wood rot and mold growth. This process directly undermines the support structure of the roof itself.

Winter Ice Damming: Analyzing the Consequence of Poor Thermal Gradients

Ice dams are a classic symptom of a failed thermal boundary and poor ventilation. Heat escaping from the living space warms the underside of the roof deck, melting the blanket of snow above it. This meltwater flows down the roof until it reaches the cold eaves, which are not heated from below. Here, the water refreezes, forming a dam of ice. Water pools behind this dam, backing up under the shingles and infiltrating the roof system. This defeats the roof’s fundamental purpose of providing protection against snow and water infiltration.

System Components for Controlled Attic Ventilation

A functional ventilation system is an assembly of specific components, each with a defined, non-negotiable role. The system’s integrity depends on the correct selection, calculation, and installation of these parts. Improvisation or substitution by an installer inevitably leads to systemic failure.

Intake Vents (Soffit): The Foundation for Balanced Airflow

Intake vents, correctly located in the soffits or at the eaves, are the system’s foundation. Their sole function is to provide a controlled, unobstructed entry point for cool, dry air from outside. Without adequate intake NFVA to balance the exhaust, the entire system is starved and will fail. This is the most critical and most frequently ignored component in residential roofing.

Exhaust Vents (Ridge, Gable, Turbine): Evaluating System Endpoints

Exhaust vents allow hot, moist air to exit the attic at or near the roof’s highest point. The selection of the exhaust vent type is critical, as mixing types will disrupt airflow.

- Ridge Vents: Considered the most effective solution. Installed along the entire peak of the roof, they allow hot air to escape at the absolute highest point, maximizing the stack effect.

- Gable Vents: Installed in the gable end walls. They are less effective because they are not at the highest point and can short-circuit the system by pulling air from each other rather than from the soffits.

- Turbine Vents: Wind-driven vents that use spinning vanes to pull air out. Their performance is dependent on wind speed and they require roof penetrations that can be a source of future leaks.

Baffles and Air Channels: Ensuring Unobstructed Pathways from Eave to Ridge

Baffles are chutes made of plastic or cardboard installed between the rafters at the eave line, directly above the intake vents. Their function is singular and essential: to maintain a clear channel for air to flow past the attic insulation. Without baffles, blown-in or batt insulation can shift and block the soffit vents, completely cutting off the system’s air intake and rendering the ventilation system useless.

Common Misconfigurations: A Root Cause Analysis of System Failure

Ventilation system failure is rarely a random event. It is the predictable outcome of design flaws and improper installation—the chaos introduced by contractors who lack a systematic, science-based approach. Understanding these common errors is the first step toward preventing them.

Mixing Vent Types: Why It Disrupts Convective Flow and Creates Dead Zones

A common error is combining different types of exhaust vents, such as a ridge vent and gable vents, on the same roof. This creates a pressure imbalance. Air, like water, follows the path of least resistance. The ridge vent, being higher, will often pull its intake air from the nearby gable vents instead of making the long journey from the soffits. This short-circuiting action leaves the majority of the attic with stagnant, super-heated air, completely defeating the purpose of the system.

Insufficient Intake: The Most Frequent Point of System Failure

This is the most common and destructive error in the roofing industry. An exhaust-heavy system with inadequate intake creates significant negative pressure inside the attic. To satisfy this pressure imbalance, the system will actively pull air from the easiest available source: your conditioned living space. It pulls this air—along with humidity, dust, and allergens—through any available ceiling penetration, such as light fixtures, bathroom fans, and attic hatches. It creates the very moisture problem it was meant to prevent.

Power Vents: A Costly Band-Aid for Systemic Design Flaws

A powered attic ventilator (PAV) is a mechanical fan installed on the roof to forcibly exhaust air. These devices are an attempt to use brute force to correct a fundamental design flaw in a passive system. They consume energy, are a common point of failure and leaks, and can create extreme negative pressure. This depressurization aggressively pulls conditioned air from your home, increasing utility bills and potentially back-drafting combustion appliances. A PAV is a loud, expensive symptom of a broken system, not a solution.

Our Protocol for Attic Ventilation: A Predictable, Systems-Based Solution

Chaos is the enemy. Predictability is the solution. We do not guess about your home’s ventilation requirements. We use a documented, repeatable protocol to diagnose, design, and implement a system that functions precisely according to the laws of building science. This is the only sane method for managing a critical component of your home’s building envelope.

Step 1: Quantitative Diagnostic and Airflow Modeling

We begin with data, not assumptions. Our process starts with a full attic inspection to measure attic floor area, identify existing vent types, calculate current NFVA, and assess insulation levels and baffle integrity.

Step 2: The Ventilation Blueprint – A Clear, Actionable Plan

Based on the diagnostic data, we engineer a balanced system and create a detailed Ventilation Blueprint. This document specifies the exact type, quantity, and placement of all required components, along with a fixed price. You see the entire plan and cost before work begins, eliminating the financial anxiety common to home improvement projects.

Our certified technicians execute the blueprint with precision. Post-installation, we verify airflow and ensure the system performs as designed, providing you with a predictable, warrantied outcome.

Why a Process-Driven Approach is Non-Negotiable for Your Home

Your home is a complex, interacting system. A roofing project should reduce complexity, not introduce chaos. A process-driven methodology is the only way to guarantee a predictable outcome, ensure your new roof performs as designed, and keep your manufacturer’s warranty fully intact. This level of detail and planning is not the industry standard, and it is not the cheapest option. It is, however, the only approach that respects the magnitude of your investment and delivers a truly professional, stress-free experience. We provide order. We eliminate chaos.