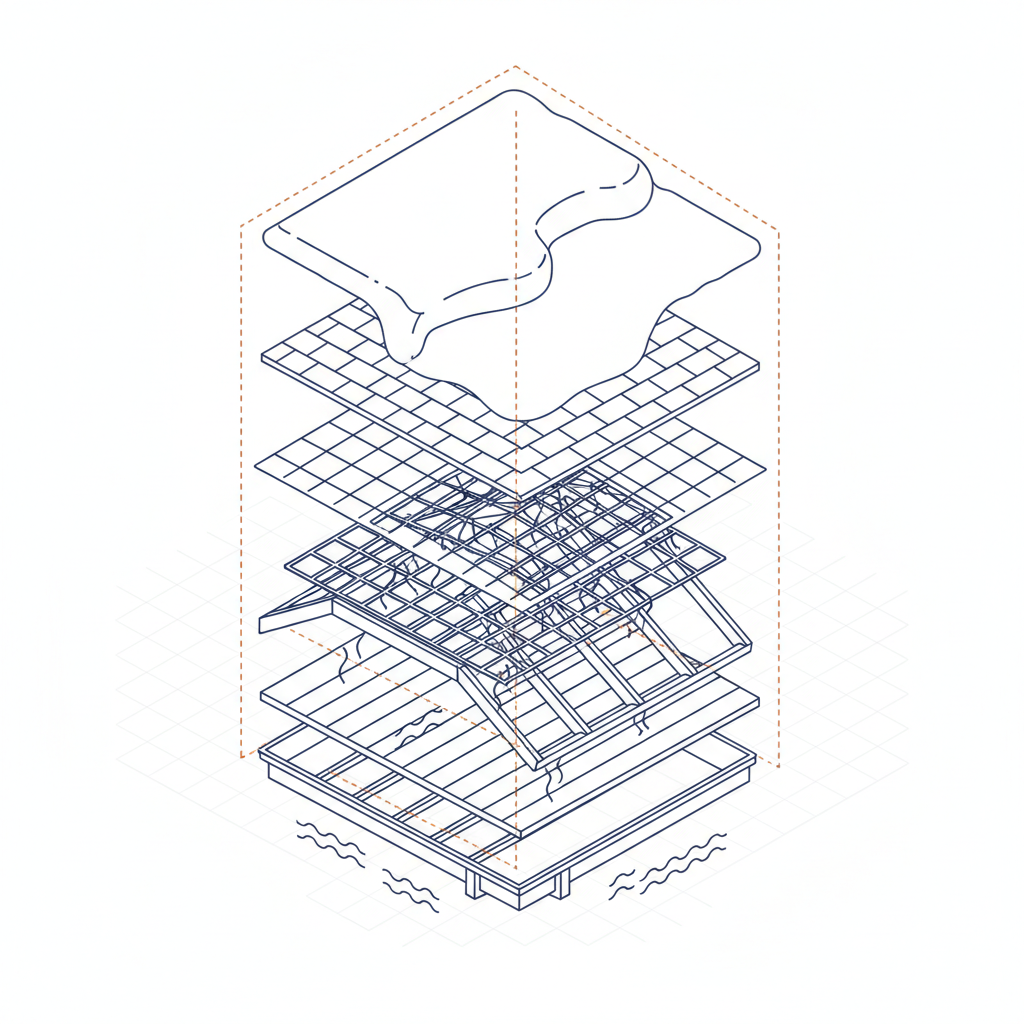

An ice dam is a ridge of ice that forms at the edge of a roof and prevents melting snow from draining properly. A roof is a complete system engineered to provide protection against environmental loads, including snow, sunlight, and extremes of temperature. The formation of an ice dam represents a critical failure of this system, specifically its inability to manage thermal differentials across the building envelope. This failure allows pooled water to breach the primary water-shedding layer, leading to structural rot, insulation damage, and interior water intrusion. Understanding the mechanics of this failure is the first step in engineering a permanent solution.

Ice Dam Formation: A Roof System Failure Analysis

Ice dam formation is not a random event; it is the predictable result of a flawed roofing system interacting with specific weather conditions. The process is a direct consequence of uneven roof surface temperatures. When the upper sections of a roof are above 32°F (0°C) and the lower eaves are below freezing, the conditions are set for damming. This temperature imbalance is almost always caused by heat escaping from the conditioned living space into the attic.

The Causal Chain: How Heat Loss Breaches Your Roof’s Defenses

The development of an ice dam follows a precise sequence of events driven by heat transfer. The entire process is a function of a temperature gradient between your heated attic and the cold exterior. The system fails when this gradient is not properly managed.

Warm air from the living space escapes into the attic through air leaks and inadequate insulation. This heats the underside of the roof sheathing.

The warm roof sheathing conducts heat to the overlying snowpack, causing it to melt from the bottom up, even when the ambient air temperature is below freezing.

Meltwater flows down the roof surface until it reaches the cold eaves and gutters, which extend beyond the building’s heated envelope. Here, the water refreezes.

Ice accumulates, forming a dam. Subsequent meltwater pools behind it, submerging the lower courses of shingles in a standing pool of water.

Component Failure 1: Inadequate Attic Insulation

Insulation’s primary function within the building envelope is to resist the transfer of heat. Inadequate insulation on the attic floor is a primary contributor to ice dams. The effectiveness of insulation is measured by its R-value, which quantifies its resistance to heat flow. When the R-value is too low for the climate zone, heat conducts easily from the living space into the attic. Furthermore, gaps in insulation, compressed areas, or thermal bridging through ceiling joists create localized hot spots on the roof, initiating the melting process. Insulation must be thick, continuous, and correctly installed to maintain the thermal barrier between the house and the attic.

Component Failure 2: Improper Roof Ventilation

Roof ventilation is the second critical component. Its purpose is to use exterior air to keep the attic space and the underside of the roof sheathing as close to the outdoor temperature as possible. A properly functioning ventilation system continuously flushes out any warm, moist air that enters the attic. This requires a balanced system of intake vents (at the lowest point of the roof, typically soffits) and exhaust vents (at the highest point, the ridge). When ventilation is blocked, insufficient, or unbalanced, warm air stagnates in the attic. This stagnant air warms the roof deck and guarantees snow will melt, regardless of insulation levels.

System Diagnostics: Assessing Your Building’s Vulnerability

A proper diagnosis of your home’s vulnerability to ice dams is a technical assessment, not guesswork. It involves a systematic inspection of the integrated roof, insulation, and ventilation systems to identify specific points of failure. This forensic approach is required to develop a corrective plan that addresses the root cause, not just the symptoms.

Visual Inspection Points: Eaves, Gutters, and Soffits

The exterior of your home provides clear evidence of system failure. The presence of large, numerous icicles along the eaves is the most obvious indicator. While small icicles can form on any home, thick columns of ice growing from the gutter edge indicate a significant refreezing cycle is underway. Check for ice overflowing the gutters and ice buildup on the siding below. Stains or peeling paint on soffits and fascia boards are signs of persistent water overflow, pointing to a history of ice damming and potential water damage to the underlying wood structure.

Interior Analysis: Mapping Heat Loss Sources in Your Attic

The most critical data is found inside the attic. This space must be analyzed to identify specific pathways for heat and air leakage from the conditioned home below. Common sources of failure include:

- Unsealed Attic Hatch: A thin, uninsulated, and un-weatherstripped attic hatch is a massive thermal leak.

- Recessed Lighting: Older recessed can lights that are not rated for insulation contact (non-IC) require a clearance around them, creating a chimney for heat to pour directly into the attic.

- Penetrations: Gaps around plumbing vents, electrical wiring, and bathroom exhaust fans that penetrate the ceiling create direct pathways for warm air.

- Improperly Vented Fans: Bathroom or kitchen exhaust fans that terminate inside the attic dump warm, moisture-laden air directly into the space, contributing to both heat gain and potential moisture problems.

Each of these points represents a breach in the building envelope that must be sealed to control heat loss.

Evaluating Airflow: A Quantitative Look at Your Ventilation System

Visual inspection must be paired with quantitative analysis of the ventilation system. The goal is to achieve a Net Free Vent Area (NFVA) that meets or exceeds building code, typically a 1/300 ratio (1 square foot of ventilation for every 300 square feet of attic floor space). This total NFVA must be balanced, with approximately 50% dedicated to intake and 50% to exhaust. An imbalance, such as having a ridge vent with blocked or non-existent soffit vents, can render the system ineffective or even depressurize the attic, pulling more conditioned air from the house.

| Attic Floor Area (sq. ft.) | Total Required NFVA (sq. in.) | Required Intake NFVA (sq. in.) | Required Exhaust NFVA (sq. in.) |

|---|---|---|---|

| 1,200 | 576 | 288 | 288 |

| 1,500 | 720 | 360 | 360 |

| 2,000 | 960 | 480 | 480 |

Proactive Prevention: Engineering a Resilient Roof System

Preventing ice dams is not about quick fixes like heated cables or hammering ice off your eaves. These are temporary measures that treat a symptom. The only permanent solution is to engineer a resilient roof system that controls heat flow and manages moisture correctly. This is a multi-layered defense designed to keep the entire roof deck uniformly cold during winter.

Layer 1: Air Sealing and Insulation to Control Temperature Extremes

The absolute first priority is to stop uncontrolled air leakage from your home into the attic. This is the source of the heat that starts the entire process. An air barrier must be established at the ceiling plane. This is accomplished by meticulously sealing all penetrations: gaps around pipes, wires, chimneys, and light fixtures. The attic hatch must be insulated and weatherstripped. Once the air barrier is complete, insulation can be added to achieve the recommended R-value for your climate zone (e.g., R-49 to R-60). Materials like blown-in cellulose or fiberglass are effective because they fill voids and create a seamless thermal blanket.

Layer 2: Re-engineering Ventilation for a Consistently Cold Roof Deck

With heat loss controlled, the ventilation system can perform its function: removing any residual heat and moisture. This often requires re-engineering the existing system. Baffles must be installed at the eaves to ensure that the new, deep insulation does not block the soffit intake vents. Intake ventilation must be confirmed as clear and sufficient. For exhaust, a continuous ridge vent is the most effective solution, as it allows warm air to exit along the entire peak of the roof. Power vents are an inferior mechanical solution to a problem that a properly designed passive system solves more reliably.

Layer 3: Installing High-Performance Ice and Water Shield Underlayment

The final layer of defense is a failsafe. Even with perfect insulation and ventilation, extreme weather can create unpredictable conditions. An ice and water shield is a self-adhered, waterproof membrane installed directly on the roof sheathing before the shingles. It seals around the shanks of roofing fasteners, creating a waterproof barrier. Building codes mandate its use at the eaves, extending at least 24 inches inside the interior warm wall line. For maximum asset protection, especially on lower-pitched roofs or in areas with severe weather, extending this membrane further up the roof deck provides an exceptional level of resilience against water intrusion from wind-driven rain and the most severe ice damming events.

The Methodology for Predictable Outcomes vs. Industry Chaos

The standard roofing industry experience is often defined by chaos. Vague quotes, fluctuating timelines, poor communication, and a focus on the cheapest, fastest installation. This approach is incompatible with solving a complex building science problem like ice damming. An ice dam is a system failure. Fixing it requires a systematic, engineering-based methodology. This is the only way to produce a predictable, permanent result.

Our Diagnostic Process: Data-Driven Plans, Not Contractor Guesses

We do not guess. Our process begins with a comprehensive diagnostic audit of your home’s thermal envelope and roof system. We use this data to perform a root cause analysis that identifies the specific failures in insulation, air sealing, and ventilation. This analysis forms the basis of a detailed, fixed-price proposal that outlines a precise scope of work. You receive a clear plan with defined outcomes, not a vague estimate based on square footage. This systematic approach eliminates surprises and ensures the solution is engineered to solve your specific problem.

Why Our Process Is Not for the Bargain Hunter

Our methodology is meticulous, our materials are premium, and our technicians are highly skilled. This level of service is not, and cannot be, the cheapest option. If your primary decision-making criterion is the lowest possible price, RocStout is not the right partner for your project. We make this clear upfront to ensure we work with clients who, like us, prioritize long-term value, asset protection, and the peace of mind that comes from a project executed correctly the first time. Our pricing is a direct reflection of a process designed to eliminate the chaos and hidden costs common in the industry.

Your Project Plan: Executing a Permanent Solution with Zero Surprises

When you engage with us, you are not just buying a roof; you are investing in a predictable process. Every project is managed by a dedicated project manager who is your single point of contact. You receive a detailed project timeline and a clear communication plan, so you are always informed of progress. Our quality control is rigorous, culminating in a final inspection to verify that every component of the system has been installed to manufacturer specifications and building science principles. The result is a permanent solution, a comprehensive warranty, and a stress-free experience from start to finish.”