A roof is the top covering of a building, including all materials and constructions necessary to support it on the walls of the building. Its primary function is to provide protection against rain, snow, sunlight, extremes of temperature, and wind. This is not a component to be left to chance. It is a critical defense system for your most significant asset. The standard roofing industry, however, often treats it as a commodity, creating a process defined by chaos: vague estimates, unpredictable timelines, poor communication, and disorganized job sites. This is unacceptable.

The RocStout Method is the antidote to this chaos. We have engineered a systematic, transparent, and predictable process for homeowners who value clarity and control. Our methodology is a blueprint for execution, designed to eliminate surprises and deliver a superior result. We operate on a foundation of clear communication, meticulous planning, and uncompromising standards.

A point of clarity is required before proceeding. If your selection criteria for a roofing contractor is based primarily on securing the lowest possible price, RocStout is not the right fit for your project. Our process is intentionally rigorous, using superior materials and dedicated project management to ensure a predictable outcome. This commitment to quality and order is an investment in certainty, not a bid in a race to the bottom. For the meticulous homeowner, this is the only logical approach.

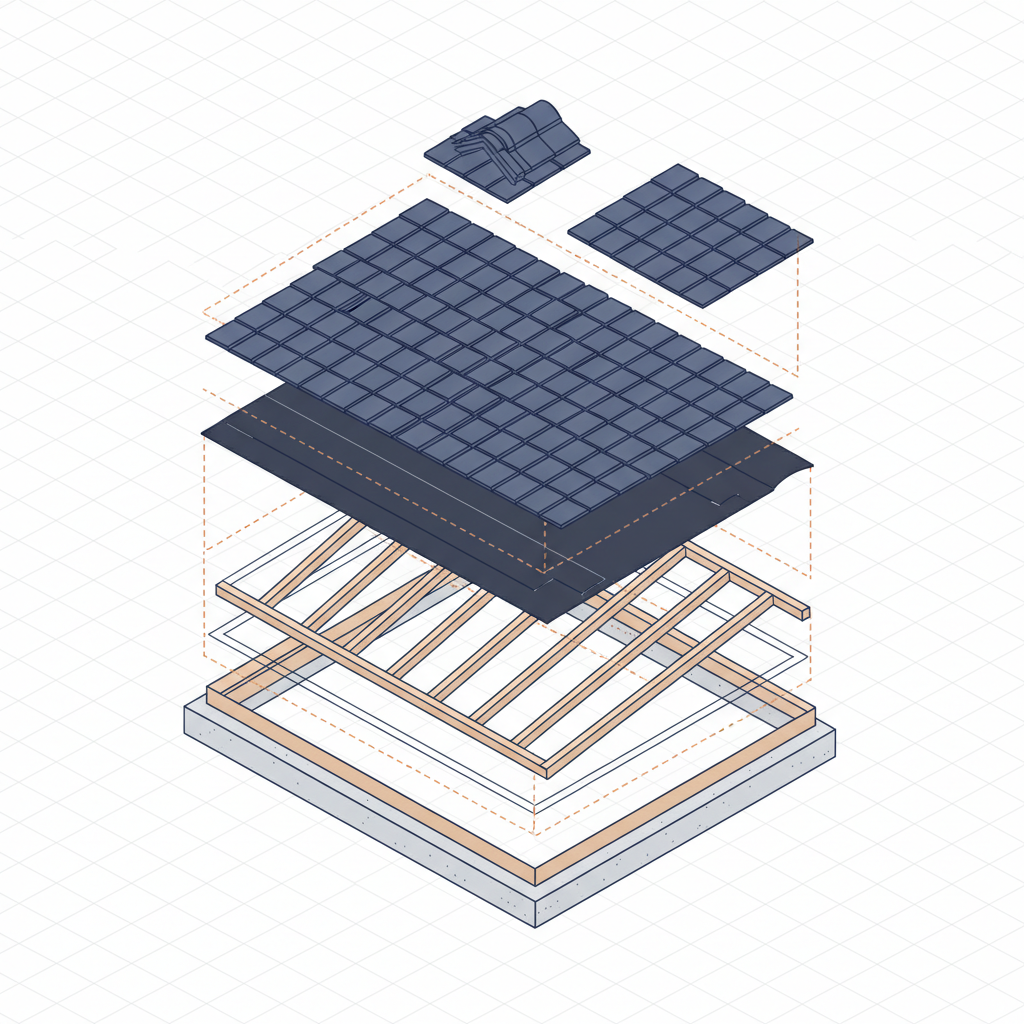

Deconstructing the Roof System: The Anatomy of Protection

A roof is not a single entity. It is a complex, integrated system of components, each engineered to perform a specific function. Understanding this anatomy is the first step in mitigating risk and ensuring long-term performance. Every layer and component contributes to the primary functions of weather protection and structural support, shielding the building from the five primary environmental threats: water, wind, snow, solar radiation, and temperature fluctuations.

Structural Support: The Role of Decking and Trusses on Walls

The foundation of any roof system is its structural framework. This begins with the trusses, the engineered wooden structures that create the roof’s slope and transfer the load of the entire system down to the building’s load-bearing walls. Affixed to the trusses is the roof deck, typically made of oriented strand board (OSB) or plywood sheathing. The deck serves two critical functions: it provides a solid, continuous surface for the attachment of all subsequent roofing materials and it contributes to the overall structural rigidity of the roof. A compromised deck, suffering from rot or inadequate fastening, invalidates the performance of every other component installed on top of it. It is a non-negotiable point of failure.

The Waterproofing Layer: Underlayment and Barriers for Rain & Snow

The primary covering of a roof is its first line of defense, but the waterproofing layer is the failsafe. This layer consists of two primary materials. First, an ice and water shield is applied directly to the decking at the most vulnerable areas: the eaves, valleys, and around any penetrations like chimneys or vents. This is a self-adhering membrane that seals around fasteners, providing a robust waterproof barrier against ice dams and wind-driven rain. Second, the rest of the roof deck is covered with underlayment. This material, either traditional roofing felt or modern synthetic fabric, acts as a secondary moisture barrier, protecting the sheathing from any water that might penetrate the primary covering. This layer is the system’s insurance policy against water intrusion.

The Primary Covering: Materials Engineered for Durability

This is the most visible component of the roof system, the top covering that directly confronts the elements. The choice of material is an engineering decision based on desired longevity, aesthetic, budget, and local climate conditions. Architectural asphalt shingles are a common choice, offering a layered, durable surface with granules that protect the asphalt from solar degradation. Standing seam metal panels provide exceptional longevity and superior resistance to wind and snow-shedding capabilities. Roof tiles, whether clay or concrete, offer significant thermal mass and a very long service life. Each material is a distinct choice with a specific performance profile; the correct specification is critical to the system’s success.

System Integrity: The Function of Flashings, Vents, and Ridge Caps

A roof system’s integrity is only as strong as its weakest points. These are typically the transitions and penetrations. Flashings are pieces of metal engineered to direct water away from joints, such as where a roof meets a wall, a chimney, or a skylight. Without correct flashing installation, these areas are guaranteed points of water entry. Ventilation components, like ridge vents and soffit vents, are equally critical. They create a balanced airflow system that removes super-heated, moist air from the attic space. This process prevents condensation in the winter, which can lead to mold and rot, and reduces heat buildup in the summer, which can accelerate shingle aging and increase cooling costs. Finally, ridge caps cover the peak of the roof, protecting the hip and ridge lines from weather and completing the integrated defense system.

Assessing Critical Failure Points: A Data-Driven Roof Inspection

A RocStout roof inspection is not a sales estimate. It is a forensic analysis of an existing system to identify and quantify points of failure. We approach this process with a data-driven methodology, focusing on the specific forces that degrade a roof over its lifespan. The objective is to produce a precise diagnosis, not a vague quote. This allows for the engineering of a solution that addresses root causes, rather than merely treating symptoms.

Quantifying Water Intrusion Risks from Rain and Snow Melt

Water is the primary adversary of any building covering. Our inspection systematically identifies all potential vectors for water penetration. We analyze the condition of flashings at all transition points, the integrity of seals around pipe boots and vents, and the state of the underlayment. We look for evidence of moisture ingress in the attic, such as stained decking or damp insulation, which indicates a breach in the waterproofing envelope. In regions with snow, we specifically assess the eaves for evidence of ice damming, a critical failure point that can force water uphill and underneath the primary covering. Each potential leak is documented and its risk quantified to inform the replacement scope.

Wind Uplift and Fastener Failure Analysis

Wind does not damage a roof by direct force alone; it creates a differential pressure known as uplift. This force attempts to lift the covering materials from the deck. Our analysis focuses on the system’s resistance to this force. We examine the nailing pattern of existing shingles—improperly placed or under-driven fasteners are a primary cause of shingle blow-off. For older roofs, we assess fastener pull-out potential by evaluating the condition of the underlying deck. Every component must be secured according to manufacturer specifications and local building codes, which dictate specific requirements based on regional wind speed data. We verify these fastening schedules to ensure the new system will meet or exceed these critical standards.

Thermal Variance Analysis: Mitigating Damage from Temperature Extremes

A roof system is subjected to constant thermal stress, expanding in the summer heat and contracting in the winter cold. This movement can degrade materials and compromise seals over time. The most critical element in mitigating this damage is a balanced attic ventilation system. Our inspection measures the net free area of existing intake (soffit) and exhaust (ridge/gable) vents. An imbalanced or inadequate system traps heat and moisture, leading to premature shingle aging, ice dam formation, and condensation that can destroy the roof deck from below. Our analysis provides the data needed to engineer a ventilation system that regulates attic temperature and humidity, extending the life of the entire roof assembly.

Solar Degradation Assessment: UV Impact of Sunlight on Materials

Constant exposure to ultraviolet (UV) radiation is a primary factor in the aging of roofing materials, particularly asphalt shingles. The ceramic granules on the shingle surface serve as a protective shield against UV rays. Our assessment quantifies the extent of granule loss. As granules erode and wash into the gutters, the underlying asphalt is exposed, becoming brittle and prone to cracking. We also assess the condition of sealant strips, which can harden and fail under prolonged sun exposure, compromising the shingles’ wind resistance. This analysis helps determine the remaining effective lifespan of the roof and informs the urgency of replacement.

Material Specification: Engineering a Roof for Decades of Performance

Selecting roofing materials is not a decorative choice; it is an engineering decision. Every component, from the underlayment to the fasteners, must be specified to work as an integrated system that meets the specific performance demands of your home and climate. We adhere strictly to building codes and manufacturer specifications to engineer a roof system built for longevity and resilience, not just code-minimum compliance.

Asphalt Shingles vs. Metal Roofing: A Performance Matrix

The two most common primary covering choices for residential properties are architectural asphalt shingles and standing seam metal panels. Each has a distinct profile of costs, benefits, and performance characteristics. The selection process must be a logical evaluation of these factors against your project goals.

| Attribute | Architectural Asphalt Shingles | Standing Seam Metal |

|---|---|---|

| Expected Lifespan | 25-30 years | 50+ years |

| Wind Resistance | Typically rated for 110-130 MPH | Typically rated for 140+ MPH |

| Impact Resistance | Good (Class 3 or 4 available) | Excellent (Resists hail, but can dent) |

| Initial Cost | Moderate | High |

| Maintenance | Minimal; periodic inspection for damage. | Virtually none; periodic inspection of sealants. |

| Energy Efficiency | Standard; ‘cool roof’ options available. | High; reflective properties reduce cooling loads. |

Synthetic vs. Felt Underlayment: A Technical Comparison for Waterproofing

The underlayment is the critical secondary water barrier. For decades, asphalt-saturated felt was the standard. Modern roofing technology, however, has produced synthetic underlayments that offer superior performance across key metrics. While felt is a viable, code-compliant product, we specify synthetic underlayment for its significant advantages in durability and water resistance.

| Attribute | Asphalt-Saturated Felt | Synthetic Underlayment |

|---|---|---|

| Tear Resistance | Low. Can tear easily during installation. | Very High. Resists tearing from wind and foot traffic. |

| Water Absorption | Can absorb moisture, leading to wrinkling. | Hydrophobic. Does not absorb water. |

| UV Resistance | Low. Degrades quickly if left exposed. | High. Can be left exposed for weeks or months. |

| Traction | Poor, especially when wet. | Excellent. Engineered non-slip surface. |

Ventilation Systems: Balancing Airflow and Weather Protection

A ventilation system is not an optional accessory. It is a fundamental component required to regulate temperature and moisture within the attic assembly. A properly engineered system creates continuous airflow from the intake vents (at the lowest part of the roof, the soffits) to the exhaust vents (at the highest part, the ridge). This balanced system prevents the formation of ice dams in winter and reduces the roof surface temperature in summer. The calculation for required ventilation, known as Net Free Area, is dictated by building codes. We perform this calculation precisely to specify a system that provides the correct volume of airflow without creating vulnerabilities for weather intrusion.

The Installation Process: A Step-by-Step Execution Plan

A superior roof system is the product of a superior installation process. The RocStout Method transforms the typical chaos of a construction site into a predictable, step-by-step execution plan. Each phase is clearly defined, with specific protocols and quality control checkpoints to ensure nothing is left to chance. This is our blueprint for a chaos-free project.

Before any work begins, your property is systematically protected. We deploy tarps over landscaping, cover sensitive areas like AC units, and establish clear material staging and debris removal zones. This protocol minimizes disruption and protects your assets.

The old roof is removed in manageable sections. As each section of decking is exposed, it is inspected for wood rot, delamination, or fastener pull-through. Any compromised sheathing is identified, documented, and replaced to ensure a solid, structurally sound nailing surface.

With a sound deck established, the new system is built. This starts with drip edge installation, followed by ice and water shield at all eaves and valleys. Synthetic underlayment is then installed, and all new flashings and pipe boots are meticulously integrated to create a complete, sealed waterproof barrier.

The primary covering is installed according to strict manufacturer specifications for fastener placement and exposure. This is a critical quality control point. Once the field is complete, the ridge caps and ventilation system are installed. The project concludes only after a final, multi-point inspection by the Project Manager.

Our Protocol: A Roofing Process Engineered to Eliminate Chaos

The difference between a stressful roofing project and a seamless one is not the materials. It is the process. The standard industry experience is reactive, disorganized, and opaque. Our protocol is the opposite: proactive, systematic, and completely transparent. We have engineered chaos out of the equation. This is our commitment to every client who values order and predictability.

Your Dedicated Project Manager: A Single Point of Contact and Control

Your project will not be handed off to an anonymous crew foreman. From start to finish, you will have a dedicated RocStout Project Manager who is your single point of contact. This individual is responsible for the project plan, logistics, quality control, and communication. You will have their direct contact information. Any question or concern is directed to one person who has complete oversight and accountability. This structure eliminates the confusion and frustration of dealing with multiple contacts and ensures clear, consistent communication.

The Daily Progress Log: Total Transparency, Zero Surprises

Uncertainty is a primary source of homeowner anxiety. We eliminate it with our Daily Progress Log. At the end of each workday, your Project Manager will send you a concise update summarizing the work completed, the tasks planned for the next day, and photo documentation of the progress. You will never have to wonder what is happening on your property. This transparent communication provides a verifiable record of progress and ensures you are always informed and in control of the project timeline.

Itemized, Fixed-Price Quoting: What We Quote is What You Pay. Always.

Vague estimates and surprise charges are hallmarks of a chaotic process. Our approach is different. We provide a detailed, itemized proposal that clearly defines the full scope of work, including material specifications and labor. Unless the scope of work is changed at your request, the price we quote is the price you pay. For potential issues like deck replacement, we establish a fixed, per-sheet price in advance. This creates financial predictability and eliminates the risk of hidden fees or inflated final invoices. Our pricing is a guarantee, not an estimate.

Our Commitment to Order: The Clean Site Guarantee

We view your property as a home, not just a job site. Our commitment to order extends to meticulous site management. Debris is managed and removed systematically throughout the day, not left to accumulate. At the end of the project, we perform a thorough cleanup, including a magnetic sweep of the entire perimeter to collect stray fasteners. The project is not considered complete until you have signed off on a final walkthrough, confirming that your property has been returned to its original condition. This respect for your property is a non-negotiable part of our process.