Roofing material science is the engineering discipline concerned with the composition, performance characteristics, and systematic integration of materials used for a building’s top covering. A roof is a complete system, not a single product. It consists of all materials and constructions necessary to support it on the building’s walls or uprights. Its primary function is providing absolute protection against rain, snow, sunlight, extreme temperatures, and wind. This analysis provides a quantitative framework for selecting the optimal system for your home, treating the decision not as a commodity purchase but as a capital investment in your property’s long-term structural integrity and resilience.

The process of selecting a roof is an exercise in risk mitigation. A miscalculation in material science or installation methodology introduces unacceptable variables. The goal is a predictable outcome. If your primary objective is securing the lowest possible bid, we are not the right partner for your project. Our process is designed for homeowners who understand that the true cost of a roof includes its performance longevity and the absence of chaotic, unmanaged project execution. We eliminate chaos through a rigorously defined, transparent process.

Establishing Your Roof’s Performance Mandate

A roof’s performance mandate is its specific set of operational requirements, dictated by local climate and building codes. This mandate defines the environmental forces the system must withstand throughout its service life. These forces are quantifiable and non-negotiable. Defining this mandate is the first step in engineering a successful roofing solution. It is a process of identifying the specific threats—wind, water, and solar radiation—that will act upon your building’s primary protective layer.

Assessing Wind and Uplift Resistance Requirements

Wind uplift is the primary aerodynamic force that seeks to detach a roof from its structure. This force does not push; it pulls. As wind flows over a roof’s surface, it creates a pressure differential, resulting in a suction or lifting effect. A roof system’s ability to resist this force is its most critical structural attribute. This resistance is not arbitrary; it is a measurable standard.

The key metric is the ASTM D7158 wind resistance test, which assigns a class rating (Class F, G, or H) to asphalt shingles based on their ability to withstand specific wind speeds. Class H, for example, denotes resistance to wind speeds up to 150 mph. The system’s performance, however, depends on more than the shingle itself. The selection and pattern of fasteners are critical. The integrity of the underlying roof deck, or sheathing, provides the anchor point for these fasteners. If the sheathing is compromised, the fastener has no purchase, and the system’s wind rating is void. Local building codes dictate the minimum wind resistance required for your specific geographic location, establishing a baseline performance standard that must be met or exceeded.

Evaluating Water and Snow Load Management

Water infiltration is the most insidious threat to a building’s structure. The roof system functions as the primary defense, managing water in both its liquid and solid states. The system must be engineered to handle the maximum anticipated volume and state of precipitation. This includes managing static loads from accumulated snow and dynamic loads from heavy rain.

Snow load refers to the downward force exerted by accumulated snow and ice. This is a structural engineering calculation, measured in pounds per square foot (PSF), and is mandated by local building codes. Beyond the static weight, the formation of ice damming presents a severe risk. An ice dam is a ridge of ice that forms at the roof’s edge, preventing melting snow from draining properly. This pooled water can then migrate under roofing materials and cause catastrophic water penetration. A properly designed system mitigates this risk through a multi-layered defense: robust, code-compliant flashing at all penetrations and transitions, and a high-quality, self-adhering ice and water shield underlayment applied at eaves, valleys, and other critical areas. The underlayment acts as a redundant, impermeable barrier should any moisture bypass the primary roofing material.

Analyzing Sunlight and Thermal Performance (UV & IR)

Sunlight, composed of ultraviolet (UV) and infrared (IR) radiation, is a constant source of material degradation and thermal stress. UV radiation chemically breaks down organic materials like the bitumen in asphalt shingles, causing brittleness and granule loss over time. Infrared radiation is absorbed as heat, increasing the roof’s surface temperature and, by extension, the building’s cooling load. This constant expansion and contraction from daily heating and cooling cycles is known as thermal shock, which stresses fasteners, sealants, and the materials themselves.

A roof’s thermal performance is directly related to its energy efficiency. The concept of a ‘cool roof’ refers to a system with high solar reflectance. This property allows the roof to reflect a significant portion of incoming solar radiation rather than absorbing it as heat. The Solar Reflectance Index (SRI) is the standard measure, combining a material’s solar reflectance with its thermal emittance (its ability to radiate absorbed heat). A higher SRI value indicates a cooler roof, leading to lower attic temperatures, reduced HVAC energy consumption, and an extended lifespan for the roofing materials by mitigating sunlight degradation and thermal shock.

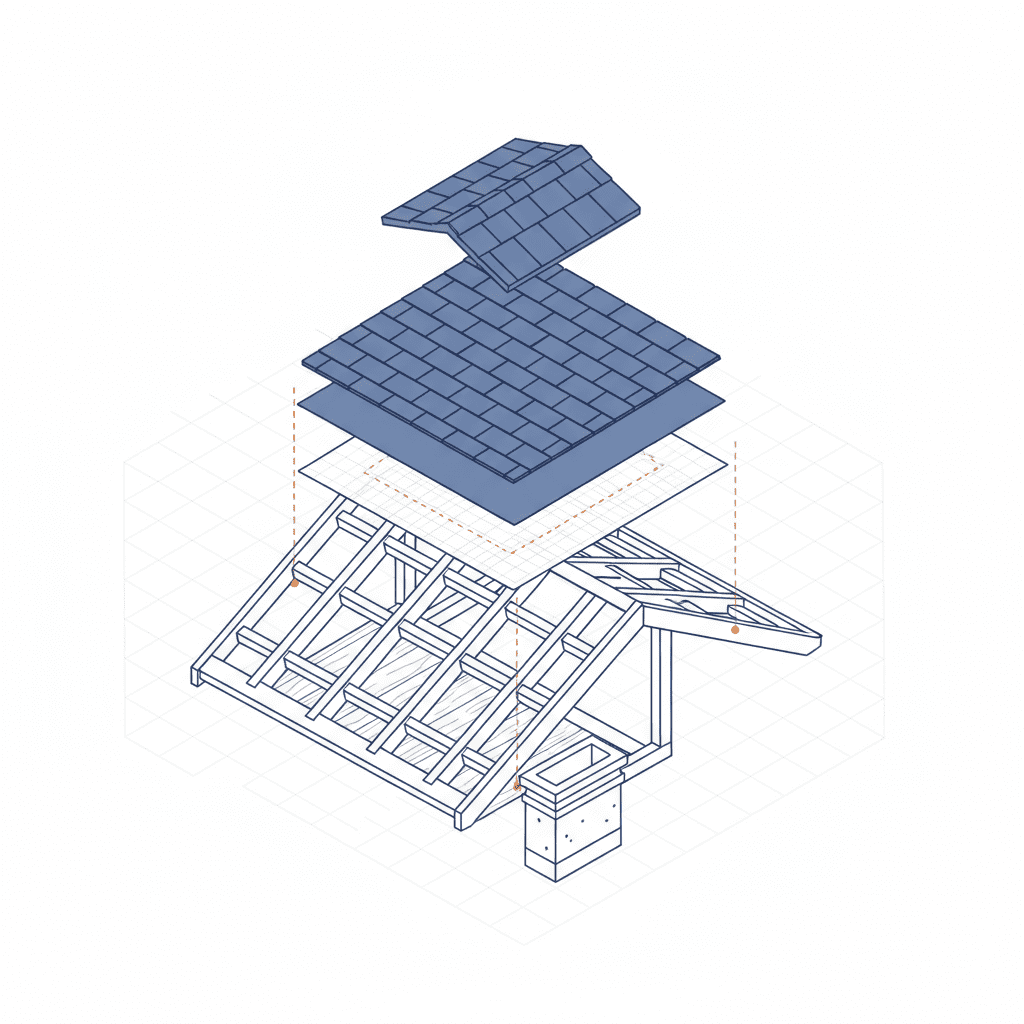

Deconstructing the Complete Roof System

A roof is an integrated assembly of components, each serving a distinct, non-redundant function. The failure of a single component compromises the entire system. Understanding this layered construction is essential for diagnosing issues and specifying a replacement that guarantees performance. The system begins with the structural supports and builds outward to the final weather-exposed surface. Its effectiveness is determined by how well these layers are integrated, not just the quality of the surface material.

Structural Foundation: The Role of Decking and Trusses

The structural integrity of any roof system begins with its foundation: the truss system and the roof deck. Trusses are pre-engineered wooden structures that form the roof’s slope and span the building’s width, transferring all loads to the exterior walls. The roof deck, or sheathing, is fastened to these trusses. This deck is almost always made of either Oriented Strand Board (OSB) or plywood panels. It serves two non-negotiable functions: it provides a continuous, solid surface for the attachment of underlayment and roofing materials, and it acts as a diaphragm, bracing the roof structure against lateral forces like wind.

The debate of OSB vs. Plywood is a matter of engineering trade-offs. Plywood is manufactured from thin layers of wood veneer glued together, offering superior dimensional stability and water resistance. OSB is made from compressed wood strands and resin, providing high shear strength at a lower cost. However, OSB is more susceptible to swelling and degradation when exposed to moisture. A pre-installation inspection of the deck is mandatory. Any rotten, delaminated, or damaged panels must be replaced to ensure adequate fastener pull-out strength and maintain the roof’s structural integrity.

The Weatherproofing Barrier: Underlayment and Flashing

The underlayment is the roof’s secondary, and arguably most critical, water barrier. It protects the roof deck from water that may penetrate the primary roofing material due to wind-driven rain, ice damming, or material failure. Obsolete asphalt-saturated felt has been supplanted by modern synthetic underlayment. These synthetics are lighter, stronger, more tear-resistant, and offer superior water repellency and UV stability during installation.

In critical areas, standard underlayment is insufficient. An ice and water shield, a self-adhering membrane made of polymer-modified bitumen, must be installed. This membrane seals directly to the roof deck and, critically, seals around the shanks of fasteners, preventing water from migrating through nail holes. It is required by code at eaves, in valleys, and around all roof penetrations (pipes, vents, skylights). Flashing, typically fabricated from aluminum or galvanized steel, is the final component of this barrier. It directs water away from the most vulnerable joints and intersections. Step flashing is used where a roof meets a vertical wall, and valley flashing protects the channels where two roof planes intersect. Proper integration of underlayment and flashing, sealed with high-grade elastomeric sealant, is the hallmark of a correctly installed, water-tight system.

System Longevity: The Critical Function of Ventilation

A roof system must breathe. Proper attic ventilation is a critical, often-overlooked component that directly impacts system longevity and home energy efficiency. A balanced ventilation system consists of intake vents (typically soffit vents under the eaves) and exhaust vents (such as a ridge vent at the peak of the roof). This creates a continuous, passive airflow path that manages temperature and moisture levels within the attic space.

In the summer, ventilation expels the immense heat buildup that radiates from the sun-baked roof deck. Unchecked heat buildup can cook asphalt shingles from below, drastically shortening their lifespan, and increase the load on your air conditioning system. In the winter, ventilation removes moisture that migrates into the attic from the living spaces below. Without proper exhaust, this warm, moist air condenses on the cold underside of the roof deck, leading to wood rot, mold growth, and saturated insulation. Effective moisture control is paramount to preserving the structural integrity of the entire roof assembly, from rafters to sheathing.

Material Analysis: Architectural Asphalt Shingles

Architectural asphalt shingles are a composite material engineered to provide reliable, cost-effective protection. They represent the baseline standard for residential roofing in North America. Their structure consists of a core fiberglass mat, which provides dimensional stability and fire resistance. This mat is coated with weather-grade asphalt (bitumen) for waterproofing and adhesion. The top surface is embedded with a layer of dense ceramic granules that shield the asphalt from UV radiation, provide color, and contribute to fire resistance. Understanding this composition is key to evaluating durability and performance claims.

Composition and Durability Factors

Modern architectural shingles are also known as dimensional or laminated shingles. Unlike older 3-tab shingles, which are a single flat layer, architectural shingles are constructed with two or more layers laminated together. This creates a thicker, more durable product with a varied, textured appearance that mimics natural materials like wood shake or slate. This laminated construction significantly enhances wind resistance and durability.

Key durability factors to analyze include algae resistance and granule loss. Algae resistance is achieved by infusing the surface granules with copper, which prevents the growth of unsightly black streaks (Gloeocapsa magma). Granule loss is a primary indicator of shingle aging. As the shingle weathers, these protective granules are shed, exposing the underlying bitumen to UV degradation and accelerating failure. The quality of the manufacturer’s warranty, particularly its non-prorated period, is a direct reflection of their confidence in the shingle’s composition and long-term durability against these factors.

Performance Profile: Wind, Fire, and Impact Ratings

Asphalt shingles are rated according to standardized tests to provide an objective measure of their protective capabilities. These ratings are not marketing terms; they are empirical data points for comparison.

- Fire Rating: The vast majority of fiberglass-based asphalt shingles carry a Class A fire rating, the highest available. This indicates they are effective against severe fire exposure from external sources.

- Wind Rating: Wind resistance is tested via ASTM D3161 (a pass/fail test at 60 mph) and, more importantly, ASTM D7158 (which tests resistance up to 150 mph). Ratings like ‘Class H’ correspond to this higher standard. A manufacturer’s wind warranty will specify a maximum wind speed, but this warranty is contingent upon exact installation according to their fastening specifications. The shingle sealant strip, a thermally activated asphalt adhesive, is critical for bonding the shingles together into a single, monolithic unit.

- Impact Rating: The UL 2218 test classifies materials based on their resistance to impact from objects like hail. A Class 4 impact rating is the highest, signifying that the shingle did not crack when struck twice in the same spot by a 2-inch steel ball. This rating can often result in homeowner insurance premium discounts.

Lifecycle Cost and Maintenance Projections

The total cost of an asphalt shingle roof extends beyond the initial installation price. A lifecycle cost analysis considers the cost per square (a 10’x10′ area), installation labor, and projected future expenses. While the initial investment for architectural shingles is relatively low, their expected lifespan is typically 20 to 30 years, requiring replacement sooner than premium materials. Repairability is a key advantage; individual shingles can be replaced by a skilled technician without disturbing large sections of the roof. Homeowner maintenance is minimal but critical: it involves keeping the roof surface clear of debris and ensuring gutters are functional to prevent water backup. Regular inspections are necessary to identify and address minor issues like lifted shingles or compromised sealant around flashings before they lead to systemic failure.

Material Analysis: Standing Seam Metal Roofing

Standing seam metal roofing is a premium system defined by its interlocking panels and concealed fasteners. The panels run vertically from the eave to the ridge of the roof, with the seams between panels raised above the roof’s surface. This design creates a robust, monolithic barrier that is fundamentally superior at shedding water and resisting wind uplift compared to shingled roofs. The primary materials used are steel (typically Galvalume-coated) and aluminum, selected for their strength, corrosion resistance, and longevity.

Material Gauges and Coating System Specifications

The performance of a metal roof is dictated by its material specifications. For steel, the thickness, or gauge, is a critical factor; a lower gauge number indicates thicker, more durable steel (24-gauge is a common high-quality standard for residential use). The protective coating is equally important. Most high-quality steel panels use a Galvalume coating, which is an alloy of zinc and aluminum that provides exceptional corrosion resistance. The final layer is the paint system, which provides color and an additional barrier against the elements. The industry standard for high-performance coatings is Kynar 500 or Hylar 5000, brand names for a PVDF (polyvinylidene fluoride) resin. These coatings offer superior resistance to color fading, chalking, and chemical degradation. A manufacturer’s paint warranty, often 30 to 40 years, is a direct indicator of the coating system’s quality.

Performance Profile: Unmatched Wind, Snow, and Fire Resistance

A properly installed standing seam metal system offers an unparalleled performance profile. Its interlocking panels, secured with concealed fasteners that do not penetrate the panel’s surface, create a unified structure with extreme wind uplift resistance, often rated for wind speeds exceeding 140 mph. The smooth, low-friction surface is excellent at snow shedding, reducing the risk of dangerous snow load accumulation on the structure. Metal is a non-combustible material, giving it a natural Class A fire rating without any chemical treatment. This combination of attributes makes it a superior choice for regions subject to extreme weather events, from hurricanes to heavy snowfall. The system’s primary failure point is improper installation, particularly concerning the management of thermal expansion and contraction.

Lifecycle Cost and Energy Efficiency ROI

While the initial installation complexity and cost of a standing seam metal roof are significantly higher than asphalt shingles, its lifecycle cost is often lower. With a service life of 50 years or more, it may last two to three times as long as an asphalt roof. The return on investment (ROI) is further enhanced by its energy efficiency. Many metal roofing products are classified as ‘cool roofing’ materials, with high Solar Reflectance Index (SRI) values. By reflecting a high percentage of solar radiation, a metal roof can reduce cooling energy costs by 10-25%. This long-term value, combined with minimal maintenance requirements and increased home resale value, makes standing seam metal a strategic, long-term investment in asset protection and energy savings. The primary technical challenge during installation is accommodating the material’s natural thermal expansion and contraction by using floating clips and proper detailing.

Material Analysis: Slate and Composite Alternatives

Slate roofing represents the pinnacle of durability and aesthetics, a permanent roofing solution with a service life measured in centuries. Composite alternatives seek to replicate the appearance of natural slate while mitigating its primary drawbacks: extreme weight and high cost. Both options cater to a segment of the market where architectural authenticity and extreme longevity are the primary decision drivers. The choice between them is a trade-off between natural material authenticity and modern material science.

Natural Slate: Heritage, Weight, and Structural Demands

Natural slate is a metamorphic rock, quarried from the earth and split into thin tiles. Its dense, layered structure makes it virtually impervious to water, fireproof, and resistant to freeze-thaw cycles. A properly installed slate roof can easily last over 100 years, making it a true ‘100-year roof’. This permanence, however, comes with significant engineering challenges. Slate is exceptionally heavy, weighing anywhere from 800 to 1,500 pounds per square. This immense weight per square requires the building’s roof structure to be specifically engineered or reinforced to support the load. Installation is not a craft; it is an art form. It demands highly specialized labor with extensive experience in slate-specific techniques, such as proper headlap and nailing, to prevent tile breakage and ensure water tightness. The initial investment is the highest of any common roofing material.

Synthetic Composites: Replicating Aesthetics, Reducing Weight

Synthetic slate and other composite roofing materials are engineered products designed to mimic the look of natural slate or wood shake. These products are typically manufactured from a combination of recycled materials, polymers, and elastomers. The primary engineering advantage is a massive reduction in weight, often weighing 70-80% less than natural slate. This allows them to be installed on standard roof structures without the need for costly structural reinforcement. High-quality synthetic slates also offer a Class 4 impact resistance rating, making them far more durable against hail than natural slate, which can be brittle. The primary long-term performance concerns are color fading from UV exposure and long-term material stability. A warranty comparison is critical, as coverage for color retention and material integrity varies significantly between manufacturers.

Lifecycle Cost and Specialized Maintenance Protocols

The lifecycle cost for both natural slate and high-end composites is defined by a very high upfront investment offset by extremely low maintenance and an extended lifespan. For natural slate, the initial cost, driven by material price and specialized labor, is substantial. However, with a lifespan that can exceed the building itself, its long-term ROI is unmatched for heritage properties. Maintenance involves periodic inspection for broken or slipped slates, which must be repaired by a slate specialist. For synthetic composites, the upfront cost is lower than natural slate but still significantly higher than asphalt or metal. The long-term value proposition depends heavily on the product’s proven performance and warranty. Both systems enhance curb appeal and resale value significantly, but they cater to a buyer who prioritizes permanent solutions over short-term cost savings.

Quantitative Comparison Matrix: Selecting the Optimal System

The selection of a roofing system is a data-driven process. By isolating key performance indicators and financial metrics, a homeowner can make an objective decision aligned with their specific performance mandate and budget horizon. The following tables provide a normalized comparison of the primary materials discussed. These are typical industry figures and can vary based on manufacturer, location, and project complexity.

Side-by-Side Lifespan and Warranty Evaluation

A warranty is a statement of a manufacturer’s confidence in its material science. It is critical to differentiate between the manufacturer’s material warranty and the installer’s workmanship warranty. The former covers material failure, while the latter covers installation errors. Prorated coverage reduces the payout value over time, making the initial non-prorated period the most valuable part of the warranty.

| Material | Expected Service Life | Typical Manufacturer Warranty |

|---|---|---|

| Architectural Asphalt | 20-30 Years | Limited Lifetime (Prorated after 10-20 years) |

| Standing Seam Metal | 50+ Years | 30-40 Year Finish Warranty (Non-Prorated) |

| Synthetic Composite | 40-50 Years | 50 Year or Limited Lifetime (Varies) |

| Natural Slate | 100+ Years | 75-100 Year Material Warranty |

Total Cost of Ownership (TCO) Analysis Over 30 Years

Total Cost of Ownership (TCO) provides a more accurate financial picture than initial cost alone. It factors in the upfront investment, projected maintenance costs, potential repair expenses, and energy savings over a fixed period. This analysis reveals that materials with a higher initial cost can be more economical over the long term. For this 30-year projection, an asphalt roof may require one full replacement, significantly impacting its TCO.

| Material | Initial Cost (Index) | Maintenance Cost | 30-Year TCO (Index) |

|---|---|---|---|

| Architectural Asphalt | 1.0x (Baseline) | Low-Moderate | High (Assumes 1 Replacement) |

| Standing Seam Metal | 2.5x – 4.0x | Very Low | Moderate (High initial cost offset by longevity & energy savings) |

| Synthetic Composite | 3.0x – 5.0x | Very Low | Moderate-High |

| Natural Slate | 6.0x – 10.0x | Low (but specialized) | Very High (Initial cost dominates 30-yr window) |

Performance Ratings Scorecard (Wind, Fire, Impact)

This scorecard aggregates the objective performance metrics for each material type. These ratings provide a clear, data-driven basis for matching a material to your home’s specific performance mandate. A higher rating indicates superior resistance to the specified force.

| Material | Max Wind Resistance | Fire Rating | Impact Rating (UL 2218) |

|---|---|---|---|

| Architectural Asphalt | 110-130 mph (Up to 150 mph for specialty products) | Class A | Class 1-4 (Class 4 is premium) |

| Standing Seam Metal | 140+ mph | Class A (Non-combustible) | Class 4 (May dent but won’t fracture) |

| Synthetic Composite | 110+ mph | Class A | Class 4 |

| Natural Slate | 100+ mph (Heavy weight provides resistance) | Class A (Non-combustible) | Not Rated (Brittle, can shatter) |

The Decisive Factor: Executing with a Process-Driven Methodology

The preceding analysis is an exercise in applied physics and financial modeling. However, the data is rendered meaningless if the execution is flawed. The best materials in the world will fail if installed incorrectly. The decisive factor in any roofing project is not the material you choose, but the methodology of the installer you entrust with your home. The enemy is chaos. The solution is process.

Why a Meticulous Material Choice Demands a Meticulous Installer

Every roofing material is manufactured to a precise set of specifications. These specifications dictate everything: the required deck condition, the type and placement of every fastener, the correct underlayment, the precise overlap of components, and the specific flashing details. Any deviation from these manufacturer specifications—a common shortcut for low-bid contractors—can result in catastrophic failure and will immediately void the manufacturer’s warranty. You are left with a compromised asset and no recourse.

A superior material choice does not just suggest a meticulous installer; it demands one. The tolerances are tighter. The skills are more specialized. The attention to detail is non-negotiable. Investing in a premium material like standing seam metal or slate and then entrusting it to a crew that lacks a rigorous quality control process is a guaranteed waste of capital. Your investment is not in the material alone; it is in the correct and verifiable assembly of that material into a functioning system.

Our Commitment: A Predictable, Transparent Roofing Experience

We have built our entire business around one principle: the elimination of chaos from the roofing process. The standard industry experience—vague timelines, surprise charges, poor communication, messy job sites—is unacceptable. Our clients are engineers, lawyers, and project managers. They value clarity, precision, and predictability. Our process delivers it.

This is our commitment. You will receive a detailed project timeline and adhere to it. You will receive transparent, line-item pricing with no surprise charges. You will be assigned a dedicated project manager who is your single point of contact and is always reachable. You will receive daily progress updates through our client portal. We do not just build roofs; we manage projects with the discipline your investment deserves. This is not an add-on service. It is the only way we operate.

Rejecting Chaos: The Only Sane Approach to Your Project

A roof replacement is a complex logistical operation on your most valuable asset. Treating it like a simple commodity purchase invites disorder and risk. The sane approach is to engage a partner who has a system designed to control every variable and deliver a predictable outcome. From our initial 30-point inspection to our final quality assurance checklist and job site cleanup protocol, every action is part of a deliberate, repeatable process.

This methodology ensures a stress-free experience for you and a flawless installation for your home. It ensures that the material science you invested in can deliver on its performance promise. If you are a meticulous homeowner who believes that a major construction project demands rigorous project management, we are the right firm for you. We provide order in an industry defined by chaos. We deliver certainty. Period.”