Proper roof deck preparation is the systematic process of inspecting, repairing, and conditioning the structural sheathing of a building’s top covering to create a uniform, code-compliant, and secure substrate for a new roofing system. This foundational stage is not an option; it is a prerequisite for the performance and longevity of the entire roof assembly. The integrity of the deck directly dictates the roof’s ability to provide protection against rain, snow, and wind.

The standard roofing industry often treats this phase as an inconvenient delay. The goal is to cover the deck as quickly as possible, hiding deficiencies that will inevitably lead to failure. This approach introduces chaos, uncertainty, and future expense. Our methodology is the direct antithesis of this practice. We operate on the principle that what you cannot see is more important than what you can. A meticulously prepared roof deck is the ultimate expression of this principle. It is the only sane way to manage a significant asset protection project.

A note on priorities: If your primary decision-making metric is finding the lowest possible bid, RocStout Roofing and Construction is not the right partner for your project. Our process is intentionally thorough, designed to eliminate variables and deliver a predictable outcome. This commitment to quality is incompatible with a low-cost, high-speed approach. We serve meticulous homeowners who value order, transparency, and certainty above all else.

Structural Integrity Assessment: The Foundation of a Weatherproof Roof

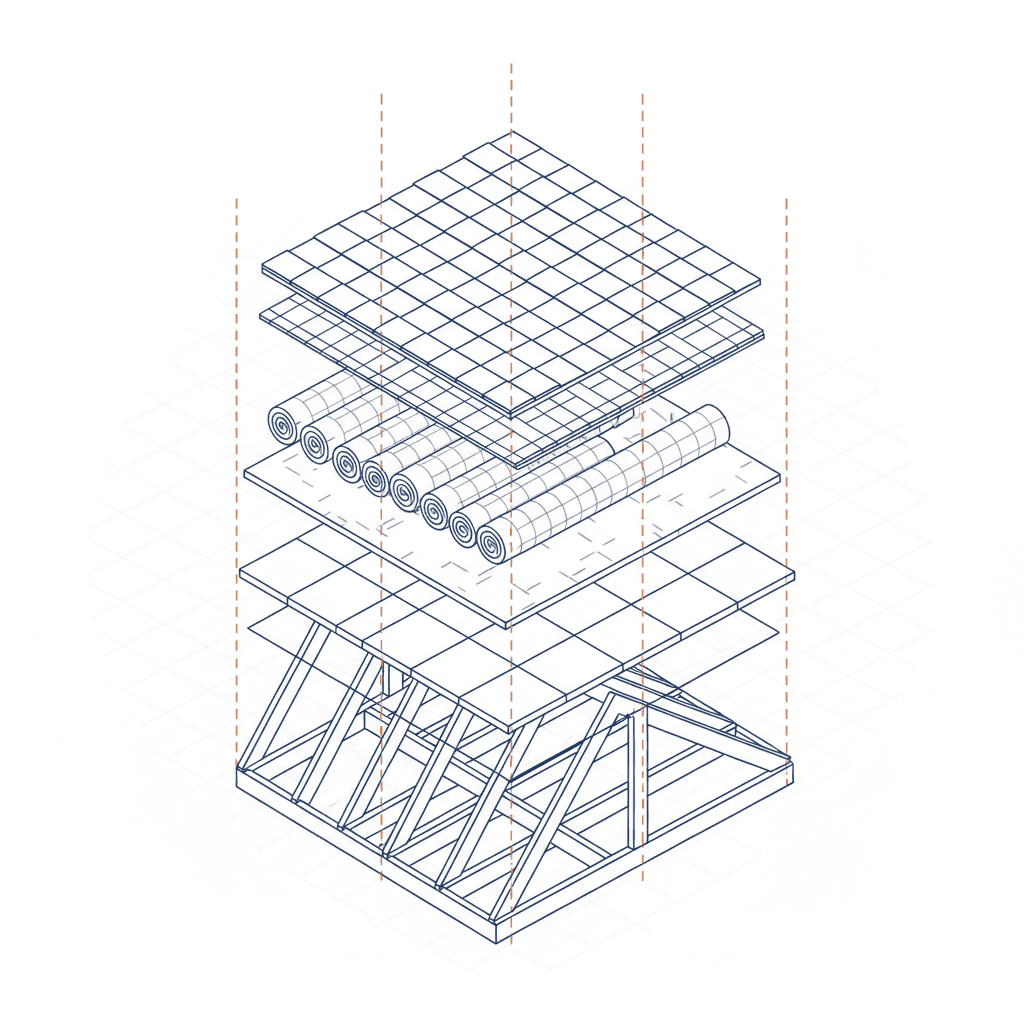

A roof is a complete system, and the roof deck, or sheathing, is its structural foundation. Before any new roofing materials are installed, this foundation must be verified as sound. A superficial inspection is insufficient. We conduct a detailed structural assessment to confirm the deck can support the new system and withstand environmental forces. This is the first line of defense in risk mitigation for your home.

Identifying Deficiencies: Protecting Against Water Intrusion & Wind Damage

The most significant threats to your home are water intrusion and wind uplift. A compromised roof deck is an open invitation for both. Our inspection process is forensic, designed to identify specific points of failure before they are concealed by underlayment and shingles.

-

Rot Detection: We physically probe for soft spots in the wood sheathing, which indicate moisture has penetrated the old roof and initiated decay. Rotted wood has zero structural value and cannot hold a fastener.

-

Water Stains and Delamination: Dark staining or peeling layers in plywood (delamination) are clear evidence of past or present leaks. These compromised areas must be removed and replaced to prevent future water intrusion from reaching your home’s interior.

-

Sagging and Support Issues: A visibly sagging roof line points to underlying structural problems, such as inadequate truss support or decking that is too thin for the rafter span. Ignoring this is a catastrophic error. We verify that the entire support structure is sound.

Ensuring a Uniform Nailing Surface: The Prerequisite for Shingle Adhesion

Asphalt shingles are not merely laid on a roof; they are fastened to it according to a precise nailing pattern specified by the manufacturer. The condition of the deck’s surface determines the effectiveness of every single fastener. An uneven or damaged surface guarantees premature failure.

A uniform plane is non-negotiable. Any variations, gaps between sheathing panels, or popped nails from the previous installation will prevent the new shingles from laying flat. This compromises the thermal sealing process, creating pathways for wind-driven rain. It also leads to fastener pull-through, where wind forces can rip the shingle head through the sheathing. A perfectly flat, secure nailing surface ensures every shingle bonds correctly, forming a monolithic, weatherproof shield.

Verifying Code Compliance: The Non-Negotiable Parameters for Safety & Warranty

Building codes and manufacturer warranties are not suggestions; they are minimum standards for safety and performance. Adherence is mandatory. Most roofing warranties are voided on day one by contractors who fail to prepare the deck according to these explicit requirements. We verify and document several key parameters:

-

Sheathing Thickness and Span Rating: The decking material (e.g., plywood, OSB) must have the correct thickness and span rating for the distance between your roof trusses or rafters. Using undersized sheathing leads to sagging and compromises the roof’s load capacity.

-

Proper Gapping: Wood sheathing panels require a specific gap (typically 1/8 inch) between them to allow for thermal expansion and contraction. Improperly butted panels will buckle, creating an uneven surface and stressing the shingles above.

-

Fastener Schedule: The building code dictates the type, size, and spacing of fasteners used to secure the sheathing to the trusses. We ensure this schedule is met or exceeded to guarantee resistance to wind uplift forces.

The Systematic Process for Roof Deck Preparation

Chaos is the result of an undefined process. Our approach to roof construction is built on a clear, sequential, and verifiable methodology. Each step is a prerequisite for the next, ensuring nothing is overlooked. This is how we transform the typically disorganized roofing project into a predictable and controlled experience.

- Step 1: Complete Tear-Off and Meticulous Debris Management

The project begins with a full removal of all existing roofing materials down to the bare wood deck. Property protection is paramount, with strategic tarping and controlled dumpster placement. This step is not complete until a magnetic sweep of the grounds is performed.

↓

- Step 2: Deck Inspection and Sheathing Repair or Replacement

With the deck exposed, we conduct the full structural inspection. Any sheathing that exhibits soft spots, delamination, or water damage is marked, cut out, and replaced with new, code-compliant material. There is no compromise on this step.

↓

- Step 3: Fastener Verification and Correction for All Decking

We inspect the entire roof deck for popped or loose nails. Every sheathing panel is checked to ensure it meets the required fastener schedule. We add new ring-shank nails as necessary to secure the entire surface and install H-clips between panels if needed for support.

↓

- Step 4: Final Surface Cleaning for Optimal Underlayment Adhesion

The final preparation step is to achieve a ‘broom-clean’ standard. The entire deck surface is cleared of all dust, debris, and stray fasteners. This creates a pristine substrate, ensuring the synthetic underlayment can be laid flat and achieve maximum adhesion where required.

Installing Protective Barriers: Your System’s Defense Against Rain, Snow, & Ice

With a verified and prepared structural deck, the next phase involves installing the primary water and weather-shedding layers. These components work in concert to form a multi-layered defense system. The selection and installation of these barriers are just as critical as the deck preparation itself, as they are the last line of defense before the sheathing.

Underlayment Selection: A Material Science Comparison for Durability

Roofing underlayment is a water-resistant barrier installed directly onto the roof deck. The traditional material, asphalt-saturated felt, is technologically obsolete. We exclusively use high-performance synthetic underlayment, which provides superior tear resistance, water repellency, and long-term stability.

| Attribute | Synthetic Underlayment | Asphalt Felt (#15 or #30) |

| Material Composition | Woven polypropylene or polyethylene | Cellulose or fiberglass mat saturated in asphalt |

| Tear Resistance | Extremely High. Resists tearing from fasteners and foot traffic. | Low. Easily torn during installation, creating vulnerabilities. |

| Water Resistance | Hydrophobic. Does not absorb water. | Water-resistant but can absorb moisture, wrinkle, and degrade. |

| UV Stability | Can be left exposed for 30-180 days, depending on the product. | Degrades rapidly under UV exposure. Must be covered immediately. |

| Weight per Square | Lightweight (2-4 lbs). Safer and faster to install. | Heavy (15-30 lbs). More difficult to handle. |

Ice & Water Shield Application: Critical Protection for Eaves and Valleys

In climates with freezing temperatures, an ice and water shield is a mandatory component for asset protection. This is a specialized, self-adhering membrane applied directly to the decking in the most vulnerable areas. Its function is to prevent water damage from ice damming, which occurs when melting snow refreezes at the roof’s edge, creating a ‘dam’ that forces water up and under the shingles.

We apply this membrane at all eaves, in all valleys, around all roof penetrations (pipes, vents, skylights), and at any wall-to-roof intersections. The self-adhering nature of the product seals around fastener penetrations, creating a completely waterproof barrier that is impervious to the forces of ice and wind-driven rain.

Drip Edge & Flashing Integration: Systematically Directing Water Flow

The final step before shingle installation is the integration of metal components designed to direct water flow. Water is a relentless force; it must be managed with precision. Metal drip edge and flashing are the tools for this task.

-

Drip Edge: This L-shaped metal flashing is installed along all roof edges (eaves and rakes). It directs water away from the fascia and prevents it from wicking back up under the roofing materials, which would rot the deck edge and fascia board over time.

-

Flashing: Flashing is used wherever the roof plane is interrupted—at chimneys, skylights, dormers, and walls. We install new, system-integrated flashing packages in these areas to create a seamless, waterproof transition. Relying on old, caulked flashing is a common point of failure for low-bid contractors.

The RocStout Roofing and Construction Method: Executing Deck Preparation with Predictability

Our commitment is not just to a superior final product, but to a superior process. A roof replacement is a complex logistical exercise that, if mismanaged, creates significant anxiety and disruption for a homeowner. We have engineered a process that eliminates chaos and replaces it with predictability, transparency, and clear communication.

Why We Reject ‘Shingle-Over’ Projects: A Commitment to Structural Certainty

Some contractors will propose installing new shingles directly over an old layer. This is known as a ‘shingle-over’ or ‘overlay’ project. We refuse to perform this work. It is a fundamentally flawed practice that violates every principle of quality construction.

An overlay makes it impossible to inspect the roof deck for rot, delamination, or improper fastening. It traps moisture between layers, accelerating decay. It adds significant weight that the structure may not be designed to support, and it almost always voids the manufacturer’s warranty for the new shingles. A complete tear-off is the only method that provides the certainty required to build a long-lasting roofing system.

Transparent Deck Repair Pricing: No Surprise Charges, Guaranteed

The most common source of homeowner anxiety is the surprise charge. Many roofers provide a low initial quote, knowing they will find ‘unexpected’ deck damage that requires expensive change orders. This is a deceptive business practice.

Our approach is built on transparency. During your initial consultation, we will clearly define the per-sheet cost for replacing any damaged plywood or OSB sheathing. This cost is included as a line item in your proposal. When we tear off the roof, we will document any necessary repairs with photographs, which will be communicated to you by your Project Manager. The final invoice will reflect the pre-agreed-upon unit price. You will have total cost certainty from the beginning. No surprises. No hidden fees.

Your Dedicated Project Manager: A Single Point of Contact, Not Chaos

The typical roofing experience involves a salesperson you never see again and a crew with whom you may not share a language. It is a recipe for miscommunication and error. This is unacceptable.

Every RocStout project is assigned a dedicated Project Manager. This individual is your single point of contact from project start to final inspection. They are responsible for the project timeline, managing the crew, providing you with daily progress updates, and answering any questions you have. You will have their direct cell phone number. This structure provides absolute accountability and ensures the entire process is managed with the precision and organization you demand.

Ultimately, a roof is a system designed to protect the significant financial and emotional investment you have in your home. The preparation of the roof deck is the most critical input that determines the output. A rushed, incomplete, or ignored preparation phase does not just lead to a poor roof; it leads to a failed system. Our methodical, transparent, and rigorous process is the only logical way to ensure that system performs as intended for decades to come.