A roof is the top covering of a building, including all materials and constructions necessary to support it on the walls of the building or on uprights. Its function is to provide protection against rain, snow, sunlight, extremes of temperature, and wind. This is not a component; it is a complete, integrated system where the failure of one part compromises the whole. Understanding this system is the first and most critical step in protecting your home, your most significant asset. The common approach of treating a roof replacement as a simple commodity purchase is fundamentally flawed and invites the chaos, budget overruns, and premature failures that define the standard roofing experience. We reject that model. Our methodology is built on engineering principles and process control to deliver a predictable outcome, every time.

Deconstructing the Roof: Understanding It as a Complete System

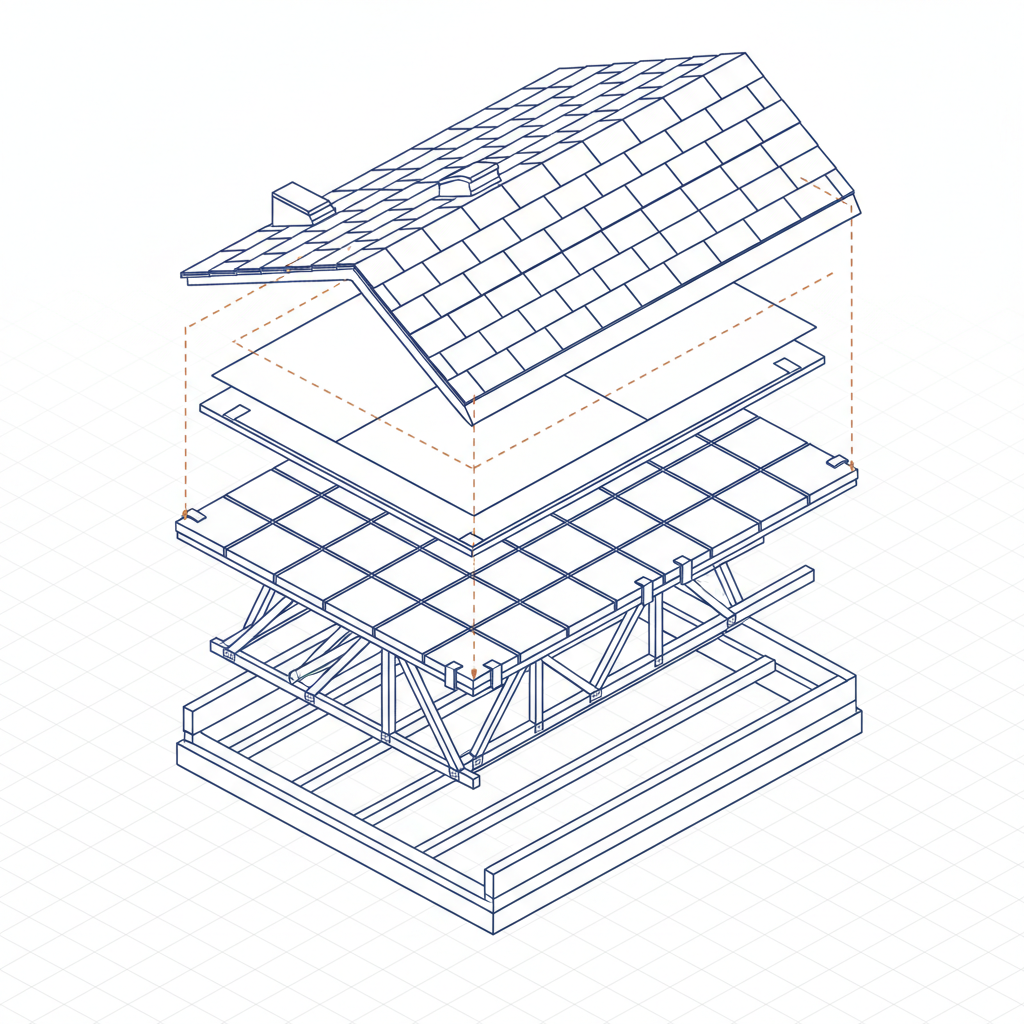

A high-performance roofing system is a series of meticulously integrated layers, each with a specific function. From the structural supports that bear its weight to the ventilation that manages its temperature, every component is codependent. A weakness in the chain, whether it’s degraded decking or improperly installed flashing, guarantees a systemic failure. The RocStout System is engineered to address the entire assembly, ensuring every layer contributes to the longevity and protective function of the whole. This holistic approach is the only way to mitigate risk and ensure long-term value.

Why ‘Just Shingles’ Is a Flawed and Costly Mindset

The belief that a new roof is ‘just new shingles’ is the most expensive misconception a homeowner can have. Shingles are the visible surface, the primary shield against UV radiation and physical impact. They are, however, only one component of a five-part system: Structure, Waterproofing, Covering, Ventilation, and Penetration Seals. Focusing solely on the shingle brand or color ignores the critical substructure that dictates the performance and lifespan of the entire assembly. A $20,000 shingle installation on top of soft, water-damaged decking is not a new roof; it is a new surface on a failing system. Premature aging, granule loss, and persistent leaks are the inevitable result. An integrated system approach recognizes that the shingles are only as effective as the underlayment, decking, and ventilation that support them. This is the difference between a temporary patch and a permanent asset upgrade.

The Primary Functions: A Shield Against Rain, Wind, and Extreme Temperatures

The roof’s purpose is to create a stable interior environment by neutralizing external threats. Each function is managed by a specific subsystem. Protection from rain and snow is achieved through a dual-layer strategy: the primary water-shedding surface (shingles or metal) and a secondary waterproofing barrier (underlayment and ice-and-water shield). Wind uplift is resisted by the combination of a solid substrate (decking), a precise fastening pattern, and the shingle’s own adhesive properties. Temperature regulation is not a passive quality; it is an active process managed by a balanced ventilation system. This system continuously moves air through the attic space to exhaust damaging heat and moisture. When all subsystems are specified and installed correctly, they work in concert to form an impenetrable building envelope that protects the structure from its most persistent adversaries.

The Structural Foundation: Verifying Support Integrity

The structural foundation is the load-bearing framework of the entire roof system. It consists of the rafters or trusses that create the roof’s shape and the decking that forms the solid plane over them. This foundation supports the static load of all roofing materials and the dynamic loads imposed by wind, snow, and ice. Any compromise in this layer, whether from water damage, age, or improper modification, invalidates the performance of every component installed above it. Our process begins with a rigorous structural audit because building a new system on a faulty foundation is not an option. It is a guarantee of failure.

Decking Analysis: The Non-Negotiable Role of Plywood and OSB

Roof decking, typically Plywood or Oriented Strand Board (OSB), is the solid substrate to which the entire roofing system is fastened. Its primary function is to provide a solid, continuous surface with adequate nail-holding power. When decking becomes saturated from a leak, the wood fibers separate and lose their structural integrity. This results in ‘soft spots’ that cannot securely hold a roofing nail. Fasteners driven into compromised decking will pull out under wind load, leading to shingle loss and catastrophic water intrusion. During our pre-construction analysis, we physically inspect every square foot of the roof deck. Any panel that is delaminated, swollen, or soft is identified for replacement. This step is non-negotiable. Installing new materials over degraded decking voids manufacturer warranties and constitutes a planned failure. Our fixed-price proposal includes a clear contingency for decking replacement, ensuring a solid foundation without surprise charges.

Assessing Rafter and Truss Condition for System Longevity

The roof framing—the rafters and trusses—is the skeleton of your home’s protective envelope. These components transfer the entire roof load down to the building’s load-bearing walls. Our inspection protocol includes an attic-level assessment of the framing system to identify any signs of structural distress. We look for cracked or sagging rafters, improperly cut or modified trusses, and evidence of water damage or rot at connection points. Decades of thermal cycling and moisture exposure can compromise the framing’s ability to support the roof system, especially when upgrading to heavier materials. Verifying that the roof framing meets current building codes and is free of defects is a critical step in ensuring the system’s longevity for the next 30 to 50 years. We do not proceed with a project until we have verified the structural integrity of the underlying frame.

Weatherproofing Layers: A Multi-Point Defense Against Water Intrusion

The weatherproofing assembly is an engineered, multi-layer defense designed for redundancy. Water is a relentless force that exploits the smallest weakness. A single layer of defense is insufficient. The RocStout System integrates three distinct waterproofing layers—a self-adhering membrane at critical zones, a full-coverage synthetic underlayment, and a precision-engineered flashing system—to create a barrier that is impenetrable to water in all its forms, from ice dams to wind-driven rain. This methodology ensures that even if the primary roof covering is compromised, a secondary and tertiary defense remains intact to protect the structure.

Ice & Water Shield: Critical Protection for Eaves and Valleys

An ice and water shield is a specialized, self-adhering membrane composed of polymer-modified bitumen. Its purpose is to seal the most vulnerable areas of the roof against water intrusion from ice damming and severe, wind-driven rain. We install this membrane at all roof eaves, in all valleys, and around all penetrations. At the eaves, it prevents water that backs up from frozen gutters (ice dams) from migrating under the shingles and into the attic. In valleys, where massive volumes of water are channeled, it creates a seamless, waterproof trough beneath the shingles. Unlike standard underlayment, an ice and water shield self-seals around the shank of every nail driven through it, eliminating thousands of potential leak points. This component is a mandatory requirement for any roof in a climate with freezing temperatures.

Underlayment Specification: Synthetic vs. Felt Performance

The underlayment is the secondary water-resistant barrier that covers the entire roof deck. It provides protection during installation and acts as a backup defense against any water that might bypass the primary shingles. Historically, asphalt-saturated felt paper was the standard. This material is now obsolete for high-performance systems. We exclusively specify high-tensile-strength synthetic underlayment for its superior performance characteristics.

| Attribute | Synthetic Underlayment | Asphalt Felt (#30) |

|---|---|---|

| Tear Resistance | Extremely high. Resists tearing from fasteners and foot traffic. | Low. Easily tears during installation, creating vulnerabilities. |

| Water Resistance | Impermeable. Does not absorb water. | Absorbs water, can wrinkle when wet and telegraph through shingles. |

| UV Exposure Limit | 6-12 months. Protects the deck if installation is delayed. | A few days. Degrades rapidly in sunlight. |

| Traction | Engineered non-slip surface for improved installer safety. | Slippery when wet or dusty. |

Synthetic underlayment provides a more durable, reliable, and safer secondary barrier. Its dimensional stability and water repellency ensure that the roof deck remains protected and the final shingle installation lays flat and uniform. It is a critical component for system longevity.

Flashing Systems: Sealing Vulnerable Penetrations with Precision

The majority of roof leaks do not occur in the open field of the roof. They occur at penetrations: the points where the roof plane is interrupted by a chimney, a vent pipe, a skylight, or a vertical wall. These intersections require a flashing system, a set of carefully integrated metal components designed to divert water away from the joint. Flashing is not a single piece of material; it is a system. For a chimney, this includes front apron flashing, step flashing woven into the shingle courses, and counter-flashing set into the masonry. For a wall, it requires step flashing and a rigid cap flashing. Each penetration has a specific, code-mandated flashing detail. There is no room for shortcuts or sealants as a primary defense. Our crews are trained in sheet metal fabrication and installation to ensure every flashing detail is executed with precision. This meticulous attention to sealing vulnerable points is what separates a 30-year roof from a 10-year roof that leaks.

The Primary Covering: Your Shield Against Sunlight and Wind

The primary roof covering is the component most exposed to the elements. It serves as the first and most robust line of defense against solar radiation, wind, rain, and impact from hail. While aesthetics are a consideration, the material’s primary value is its performance under these constant stresses. An architectural asphalt shingle is a composite material, engineered with distinct layers that work together to provide protection. Its effectiveness and longevity are determined not only by its composition but also by the precise methodology used to fasten it to the underlying structure. The fastening pattern is an engineering specification, not a guideline.

Asphalt Shingle Composition: Granules, Bitumen, and Matting

A modern architectural asphalt shingle is a multi-layered composite, engineered for durability and performance. It consists of three primary components. First is the fiberglass mat, which provides the shingle’s core strength, dimensional stability, and fire resistance. Second is the asphalt (bitumen), a waterproofing agent that makes the shingle impervious to water. This asphalt layer is modified with polymers to enhance its flexibility and adhesion in a wide range of temperatures. Third, and most visibly, are the ceramic-coated mineral granules. These granules serve a critical function: they shield the asphalt layer from damaging ultraviolet (UV) radiation, which would otherwise cause it to become brittle and crack. The granules also provide the shingle’s color and can be enhanced with additives to resist algae growth. Understanding this composition reveals that a ‘balding’ shingle losing its granules is not just a cosmetic issue; it is a sign that the shingle’s waterproofing core is now exposed to rapid degradation.

Fastening Methodologies: Nailing Patterns for Maximum Wind Resistance

A shingle’s wind uplift rating is not inherent to the material alone; it is a system rating that is only valid when the shingle is fastened according to the manufacturer’s exact specifications. Chaos in the roofing industry often stems from crews who ignore these critical instructions. The specification dictates the type of nail (3/8-inch head, 12-gauge shank, corrosion-resistant), the number of nails per shingle (typically 4, increased to 6 in high-wind zones), and their precise placement. Every architectural shingle has a reinforced ‘nailing strip’ or ‘common bond’ area. Placing the nail above or below this strip dramatically reduces the shingle’s resistance to wind uplift. Nail depth is also critical; nails must fully penetrate the roof decking without being overdriven, which can fracture the shingle mat. Our installation protocol mandates strict adherence to the manufacturer’s fastening schedule. Each installer is trained on these specifications, and our project managers perform quality control checks to verify compliance. This process-driven approach ensures the finished roof system will perform as engineered and that the manufacturer’s warranty remains in full effect.

Climate Control System: Managing Attic Temperature and Moisture

A roof system’s responsibility extends beyond deflecting external weather; it must also manage the internal climate of the attic space beneath it. Uncontrolled heat and moisture originating from inside the home are two of the most destructive forces acting on a roof system. An attic ventilation system is not an optional accessory; it is an essential climate control system. Its function is to create continuous, balanced airflow that exhausts hot, moisture-laden air and replaces it with cool, dry ambient air. This process protects the roof structure from rot and mold, extends the life of the shingles by preventing heat damage, and reduces the home’s cooling load, thereby improving energy efficiency. A roof without a properly engineered ventilation system is an incomplete, dysfunctional assembly destined for premature failure.

Intake and Exhaust: Engineering a Balanced Airflow System

An effective ventilation system operates on the simple principle of convection: hot air rises. The system is comprised of two parts: intake vents and exhaust vents. Intake vents, typically located in the soffits or eaves (the bottom edge of the roof), allow cool, dry air to enter the attic. Exhaust vents, located at or near the roof’s peak (such as a ridge vent), allow hot, moist air to escape. For this system to function, it must be balanced. The total net-free vent area (NFVA) of the intake vents must be equal to or greater than the NFVA of the exhaust vents. An imbalanced system, such as a ridge vent with no corresponding soffit vents, will not create the necessary airflow. The system becomes static, trapping heat and moisture. Our system design process includes calculating the required ventilation for your specific attic square footage and roof design to ensure a balanced, continuous flow of air. We engineer a system that actively protects your home from the inside out.

Engineered Airflow Path

Full Lifecycle Financial Planning

Develop a long-term capital expenditure forecast. Transform the eventual roof replacement from a financial crisis into a planned, budgeted expense.

Consequences of Imbalance: Mold, Heat Damage, and Ice Dams

The failure to properly ventilate an attic has severe and costly consequences. In the summer, a poorly ventilated attic can reach temperatures exceeding 150°F (65°C). This extreme heat radiates downward, increasing cooling costs, and bakes the asphalt shingles from below, drastically accelerating their degradation and shortening their lifespan. Throughout the year, moisture from household activities (showers, cooking) rises into the attic. Without adequate airflow to exhaust it, this moisture condenses on the cool underside of the roof deck, promoting the growth of mold and mildew and causing the wood sheathing to rot. In winter, this trapped heat melts snow on the roof. The meltwater runs down to the cold eaves, where it refreezes, forming destructive ice dams that force water under the shingles. These issues are not hypothetical risks; they are the predictable outcomes of an improperly engineered roofing system. Proper ventilation is the only defense.

Executing the System: A Methodology for Predictable Installation

A superior roofing system design is worthless without a precise and predictable installation methodology. The greatest source of anxiety for a homeowner is the chaos of the construction process itself: vague timelines, unexpected costs, poor communication, and a disregard for their property. The RocStout System extends beyond materials and specifications; it is a complete project management framework designed to eliminate chaos and deliver a stress-free experience. We believe the process of installing the roof is as important as the roof itself. Our methodology weaponizes predictability, transparency, and communication to ensure the project is completed on time, on budget, and to the highest standard of quality.

Our Pre-Construction Blueprint: A Fixed-Price, Zero-Surprise Guarantee

Our process begins with a detailed, exhaustive assessment of your existing roof system. This is not a quick estimate. It is a forensic analysis that informs a comprehensive Pre-Construction Blueprint. This document serves as our contract and your guarantee. It includes a detailed scope of work that specifies every component to be used, from the type of underlayment to the length of the fasteners. It outlines the step-by-step installation process we will follow. It establishes a clear project timeline from start to finish. Most importantly, it provides a fixed price for the entire project. This price will not change. If we discover additional decking that needs replacement, that cost is defined upfront in the blueprint’s contingency plan. There are no hidden fees, no surprise charges, and no vague allowances. This document eliminates uncertainty and provides you with complete control and clarity before any work begins.

The On-Site Protocol: Dedicated Management and Daily Progress Reports

Once the project starts, the enemy is operational chaos. Our On-Site Protocol is designed to maintain order and communication. A dedicated Project Manager is assigned to your project. This individual is your single point of contact, always reachable, and responsible for every aspect of the job. They are not an absentee salesperson; they are an on-site manager who oversees the crew, verifies quality control at each stage, and ensures the safety and cleanliness of the work area. Your property is protected with tarps and plywood shields. At the end of each day, the site is cleaned, and all debris is removed. You will receive a daily progress report from your Project Manager, detailing the work completed and the plan for the following day. This proactive communication ensures you are always informed and that any questions are answered immediately. You will never be left wondering about the status of your project.

Final System Verification: A Multi-Point Quality Assurance Checklist

A project is not complete when the last shingle is installed. It is complete when it has passed our Final System Verification process. This is a rigorous, multi-point quality assurance inspection conducted by the Project Manager. The checklist covers every aspect of the installation, from verifying the shingle fastening pattern and flashing details to ensuring proper attic ventilation and complete site cleanup. We use a photographic documentation system to record that all critical, soon-to-be-covered components like the ice and water shield and step flashing were installed correctly. Only after every item on this checklist is verified and signed off do we consider the project finished. This final step guarantees that the system we designed in the blueprint is the system that was installed on your home. It is your assurance that every detail has been executed to our exacting standards, and it allows us to confidently issue our workmanship guarantee and register your manufacturer system warranty.

Conclusion: Choosing Order Over Industry Chaos

A roof replacement is a significant investment in the protection and value of your home. It is an engineering project, not a simple purchase. The standard industry approach, however, often treats it as a chaotic, unpredictable transaction fraught with risk. The vague quotes, poor communication, and lack of process control are not necessary evils; they are symptoms of a broken model. RocStout was founded on a simple premise: a process-driven methodology is the only sane way to manage a complex construction project. We have replaced industry chaos with a system of predictable steps, transparent communication, and absolute accountability. This is not just a different way of working; it is a fundamentally different philosophy focused on delivering peace of mind as much as a new roof.

Is a Process-Driven Roofer Right for You?

We are not the right contractor for every homeowner. We state this with confidence. If your primary decision criterion is finding the absolute lowest price, we will not be a good fit for your project. Our meticulous process, premium materials, dedicated project management, and comprehensive warranties require an investment that is greater than that of a standard, high-volume roofer. Our clients are meticulous homeowners—engineers, project managers, lawyers, and professionals—who understand the long-term cost of a cheap, improperly installed roof. They choose us because they value predictability, clarity, and the assurance that their project will be managed with the same level of precision they apply to their own professional lives. They are investing in a guaranteed outcome, not just a commodity.

Schedule Your Complete Roofing System Analysis

If you believe that a complex project demands a structured, transparent process, then we invite you to take the next step. Contact us to schedule your Complete Roofing System Analysis. We will conduct a thorough on-site inspection, listen to your concerns, and develop a detailed Pre-Construction Blueprint for your project. This is not a sales pitch. It is a technical consultation designed to provide you with the data and clarity you need to make an informed decision about protecting your home. It is the first step in replacing chaos with predictability.