Ice and water shield is a self-adhering waterproofing membrane composed of modified bitumen, engineered to seal the roof deck and protect against water intrusion from ice dams and wind-driven rain. It is a critical component of a roofing system, functioning as the final line of defense in the most vulnerable areas of a structure. Its purpose is not optional; it is a fundamental requirement for roof system integrity and longevity, ensuring the top covering of a building provides absolute protection against rain and snow. For homeowners who demand a predictable, chaos-free project, understanding this material’s function is the first step in differentiating a professionally executed roof from a future liability.

Core Function: Defining Ice & Water Shield’s Role in Roof System Integrity

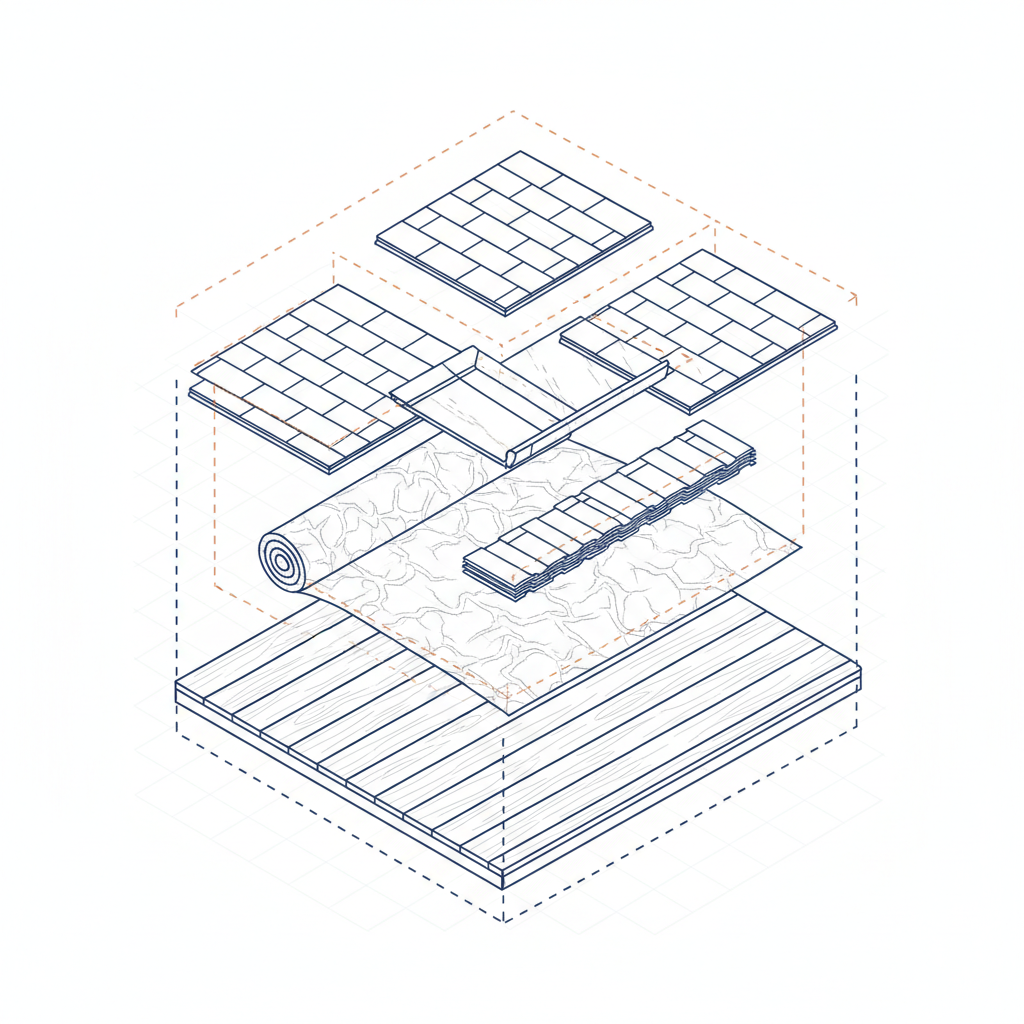

The integrity of a roof system is not determined by its shingles alone. It is a multi-layered assembly where each component has a distinct role. Ice and water shield acts as a specialized, high-performance gasket for the most critical sections of the roof deck. Unlike standard underlayment, its primary function is to create a fully adhered, waterproof barrier that actively seals around the shanks of fasteners, preventing water from migrating through penetrations. This protection is essential against two primary threats: ice dams and wind-driven rain.

Material Composition: The Science Behind Self-Sealing Protection

Ice and water shield consists of a specialized blend of modified bitumen (asphalt) and rubberized polymers, with a top surface of high-density, cross-laminated polyethylene. This composition provides its two most critical properties: adhesion and waterproofing. The modified bitumen adhesive backing creates a tenacious bond directly to the roof deck, eliminating pathways for water to travel underneath. Crucially, the rubberized polymers give the material a “flow” characteristic. When a nail or staple penetrates the membrane, the pliable bitumen flows around the fastener shank, creating a watertight seal that standard felt or synthetic underlayments cannot replicate. This self-sealing capability is the core science behind its effectiveness.

System Integration: How It Protects Against Rain, Snow, and Wind

Within the complete roof system, ice and water shield serves as the redundant layer of protection beneath the primary shingles. While shingles are designed to shed the vast majority of water, they are not a monolithic, waterproof surface. Severe wind can lift shingle edges, driving rain sideways and upwards. Snow can melt and refreeze at the eaves, creating ice dams that force water back up under the shingles. In these scenarios, the ice and water shield membrane is the component that stops water from reaching the wooden roof deck, preventing rot, mold, and interior leaks. It ensures the roof continues to perform its primary function of providing protection even when the outer layer is compromised by severe weather.

Felt vs. Synthetic vs. Self-Adhered: A Comparative Analysis for System Longevity

Choosing the correct underlayment is a critical decision that directly impacts the roof’s long-term performance. The options vary significantly in material composition, function, and cost-benefit analysis. A meticulous analysis reveals why self-adhered membranes are the only logical choice for critical areas.

| Underlayment Type | Material Composition | Primary Function | Performance Characteristic |

|---|---|---|---|

| Asphalt Felt (No. 15, No. 30) | Cellulose or fiberglass base saturated with asphalt | Water-resistant barrier | Low cost. Prone to tearing. Can wrinkle if exposed to moisture, creating channels for water. Does not seal nail penetrations. |

| Synthetic Underlayment | Woven polypropylene or similar polymer | Water-resistant barrier | High tear resistance. Lightweight. Excellent UV resistance. Offers superior water resistance over felt but does not self-seal nail penetrations. |

| Self-Adhered Membrane (Ice & Water Shield) | Modified bitumen with a polyethylene surface | Waterproofing membrane | Fully adheres to deck. Actively seals around fasteners. Provides the highest level of protection against ice dams and wind-driven rain. Non-negotiable for system longevity in critical zones. |

Code Requirements vs. Best Practices: A Non-Negotiable Baseline for Protection

Building codes represent the absolute legal minimum required for construction. They are not a manual for best practices or long-term durability. A roofer focused on meeting the bare minimum is building a system designed to pass a single inspection, not one designed to withstand a decade of harsh weather. Our process treats the building code as the starting point, not the finish line. For a structure meant to last, exceeding code is the only rational approach to asset protection.

Decoding the IRC: Minimum Mandates for Critical Roof Areas

The International Residential Code (IRC) mandates the use of a self-adhering polymer-modified bitumen membrane at the eaves in regions with a history of ice formation. The code specifies that this membrane must extend from the lowermost edge of the roof (the drip edge) up the roof to a point at least 24 inches inside the interior face of the exterior wall. This is the minimum requirement to protect against ice damming. The code also requires similar protection in valleys and around roof penetrations. While compliant, this minimum coverage often proves insufficient in severe weather events.

Climate Zone Impact: Why Local Requirements Demand Stricter Application

Local climate dictates roofing system requirements. A roof in a region with heavy snow loads and frequent freeze-thaw cycles faces entirely different stresses than one in a mild climate. The IRC’s 24-inch rule may be adequate for moderate conditions, but in areas with significant snowfall, ice dams can and do form higher up the roof slope. Best practice, therefore, is to extend the membrane coverage well beyond the code minimum, often requiring two full courses (approximately 72 inches) to provide a robust defense against water intrusion caused by extremes of temperature and heavy snow accumulation.

Beyond the Code: High-Wind and Severe Weather Installation Protocols

In regions prone to high winds, such as coastal areas or storm-prone plains, the entire roof deck must be treated as a critical area. Wind-driven rain does not respect code minimums. A standard roofing installation can fail catastrophically during a hurricane or severe thunderstorm if the underlayment is not robust. The ultimate protection in these zones is a fully sealed roof deck, where every square inch is covered with a self-adhered membrane. This creates a completely waterproof monolithic surface beneath the shingles, ensuring that even if the primary roof covering is damaged or blown off, the structure’s interior remains protected from water. This is the definition of a resilient, storm-ready roof.

Critical Application Zones: A Systems-Based Map of Your Roof’s Vulnerabilities

A roof is a system of interconnected planes and junctures. Water intrusion almost never occurs in the open field of the roof; it happens where geometries change, materials meet, or objects penetrate the roof plane. A systematic approach requires identifying and reinforcing these vulnerabilities with ice and water shield as a non-negotiable step.

Eaves and Overhangs: The Primary Defense Against Ice Damming

The eaves are the leading edge of the roof and its first point of failure from ice dams. An ice dam forms when heat escaping from the attic melts snow on the upper portion of the roof. This water runs down to the colder eaves, where it refreezes, forming a ridge of ice. This ridge traps subsequent meltwater, creating a pool that backs up under the shingles. Ice and water shield applied from the gutter line well past the wall line creates an impermeable barrier that prevents this captured water from reaching the sheathing, soffit, and interior walls.

Valleys: Managing High-Volume Water Flow Without Intrusion

Valleys are created where two roof planes intersect, forming a channel that collects and directs a high volume of water. This concentration of water flow makes valleys exceptionally vulnerable to leaks. Whether constructed as an open or closed valley system, a full, unbroken layer of ice and water shield must be installed down the centerline before any metal flashing or shingles are applied. This provides a critical secondary layer of defense, ensuring that any water that might penetrate the primary valley construction is safely captured and routed off the roof.

Roof-to-Wall Transitions: Sealing the Juncture Between Dissimilar Materials

Anywhere the roof plane abuts a vertical wall is a high-risk transition point. These areas are protected by layers of step flashing and apron flashing integrated with the siding. However, a properly installed flashing system relies on a waterproofed substrate. Applying ice and water shield up the vertical wall surface and onto the roof deck before the flashing is installed creates a continuous, sealed corner. This prevents wind-driven rain from being forced behind the flashing and into the building envelope, a common failure point in chaotic, low-bid installations.

Penetrations: A Zero-Tolerance Approach to Vents, Pipes, and Skylights

Every pipe, vent, chimney, or skylight that penetrates the roof deck is a potential leak. While each uses a specific flashing kit (e.g., pipe boot, vent flashing), these kits are the primary seal. Ice and water shield provides the essential secondary seal. A collar of the membrane should be cut to fit tightly around the penetration and adhered directly to the deck before the flashing is installed. This ensures that even if the primary flashing seal degrades over time, a watertight barrier remains in place, preventing a slow, destructive roof leak.

Common Points of Failure: How Substandard Installation Creates Chaos

The highest quality materials are rendered useless by improper installation. The chaos of a typical roofing project—rushed work, lack of surface preparation, and disregard for manufacturer specifications—is the direct cause of premature roof failure. These are not mistakes; they are the predictable result of a process that prioritizes speed over precision.

Improper Surface Preparation: Negating Material Efficacy Before It Begins

Ice and water shield requires a clean, dry, and sound substrate for proper adhesion. A roof deck littered with debris, dust, or protruding fasteners will compromise the bond. Any moisture present on the deck will be trapped, preventing the adhesive from curing and potentially leading to deck rot. A systematic process mandates that the roof deck is thoroughly swept, all fasteners are set flush, and the surface is confirmed to be completely dry before membrane application begins. Skipping this step is a guarantee of future failure.

Ignoring Temperature Constraints: The Physics of Failed Adhesion

The modified bitumen adhesive on ice and water shield has a specific temperature range for effective application, typically 40°F (4°C) and rising. Attempting to install the product in cold weather without proper material handling results in poor adhesion. The membrane will not bond correctly to the cold deck or to itself at the seams. This creates a false sense of security; the membrane is in place but is not functioning as a monolithic waterproof barrier. Professional protocol demands adherence to manufacturer temperature guidelines or the use of specific primers designed for low-temperature application.

Incorrect Overlap and Shingling: Creating Pathways for Water Intrusion

Water flows downhill. All roofing materials must be installed in a shingled fashion to accommodate this fact. Ice and water shield must be applied starting at the lowest point of the roof (the eaves) and working upwards, with each subsequent course overlapping the lower one. Lap seams must be oriented correctly to shed water, not catch it. A backwater lap, where the upper course is tucked under the lower one, is a fundamental error that channels water directly onto the roof deck. This level of incompetence is a hallmark of contractors who lack a fundamental understanding of roofing physics.

The RocStout Roofing Protocol: Mandating Predictability in Roof Protection

We do not manage projects based on hope or circumstance. We operate on a verifiable, systematic process designed to eliminate chaos and produce a predictable, superior outcome. This is not the cheapest way to install a roof. If your primary decision criterion is the lowest possible price, we are not the right company for you. Our process is for homeowners who understand that the total cost of ownership includes the price of correcting failures born from a low-bid mentality.

Our Specification Standard: Exceeding Code is the Only Acceptable Baseline

Our scope of work is not based on minimum code compliance. It is engineered for maximum resilience and longevity. This means our standard specification for ice and water shield application often doubles the coverage required by the IRC. We specify its use in all valleys, around all penetrations, at all roof-to-wall transitions, and at a minimum of two courses on all eaves. This is not an upgrade; it is our baseline for a properly constructed roofing system.

Verifiable Checklists: Photo-Documenting Every Layer of Protection

Trust is not enough; we provide verification. Our project managers use detailed, multi-point checklists at every stage of the project. The installation of every piece of ice and water shield is photo-documented and uploaded to your client portal. You will see the clean deck, the proper overlaps, and the meticulous sealing around penetrations. This transparency provides absolute accountability and eliminates any anxiety about what lies beneath your shingles.

Deck is confirmed to be clean, dry, and structurally sound. All fasteners are set flush. Documented with photos.

Ice & water shield is applied according to our ‘beyond code’ standard. Overlaps are checked for proper shingling. Documented with photos.

All critical zones (valleys, walls, pipes, vents) are meticulously detailed and sealed. Documented with photos.

Project Manager signs off on the completed underlayment system before any shingles are installed.

Why We Actively Reject the Low-Bid Mentality

The decision to omit or minimize the application of ice and water shield is a classic example of flawed ‘value engineering’ by bargain-hunter contractors. They reduce the upfront cost by a negligible amount while catastrophically increasing the long-term risk of failure. This is a trade-off we will never make. Our clients invest in the certainty that their roof will perform its function without fail. This certainty is achieved through a combination of superior materials and a rigid, verifiable installation process. This approach is fundamentally incompatible with the low-bid model, and we confidently serve the clients who understand the difference.