Residential roofing building codes are a set of legal mandates that establish the minimum standards for the design, construction, and installation of a roof system. A roof is the top covering of a building, engineered to provide absolute protection against rain, snow, sunlight, extremes of temperature, and wind. These codes are not suggestions; they are the blueprint for safety, structural integrity, and asset longevity. They exist to translate engineering principles into non-negotiable construction practices, protecting your home from both the elements and substandard workmanship. For the meticulous homeowner, understanding these codes is the first step in eliminating the chaos common in the roofing industry.

The Purpose of Building Codes: Your Project’s Foundational Blueprint

Building codes serve as the foundational legal and technical framework for any construction project. They represent the minimum acceptable standard for safety and performance, ensuring your new roof can withstand predictable environmental stresses like wind and snow loads. This framework provides a baseline for quality, giving you, the homeowner, a mechanism for protection against contractors who might otherwise cut corners. The entire system of permits and inspections is built upon this codified standard of quality.

Differentiating Local Codes from the International Residential Code (IRC)

The International Residential Code (IRC) provides a comprehensive, standardized model code for single-family and duplex homes. However, it is a model, not a national law. Your local municipality, county, or state adopts a version of the IRC and frequently modifies it with local amendments based on regional climate and geological conditions. A building official in a coastal, hurricane-prone jurisdiction will enforce different wind-resistance requirements than one in a region with heavy snowfall. Your project’s compliance is measured against the locally adopted and amended code, not the generic IRC. A competent contractor works from local requirements as their primary directive.

| Code Source | Function | Applicability |

|---|---|---|

| International Residential Code (IRC) | Provides a standardized model for residential construction codes. | Serves as a baseline; not directly enforceable unless adopted. |

| State/Local Building Codes | Adopt and amend the IRC to address specific regional needs (e.g., wind speed, snow load, seismic activity). | Legally binding and enforceable by the local building official for your specific project. |

The Permitting and Inspection Process: A Non-Negotiable System of Accountability

The building permit is not a bureaucratic formality; it is the mechanism that activates regulatory oversight. Securing a permit registers your project with the local jurisdiction and triggers a series of mandatory inspections. These inspections, conducted by an impartial municipal inspector, verify that the work performed at critical stages meets the codified standard. This process creates accountability. It forces the contractor to adhere to the plan and the code, preventing the concealment of subpar work beneath layers of shingles. A project without a permit operates in a void of accountability, exposing you to immense financial and legal risk. The project timeline must account for these inspections as non-negotiable quality gates.

Code Mandates for Structural Integrity: Supporting the Entire Roof System

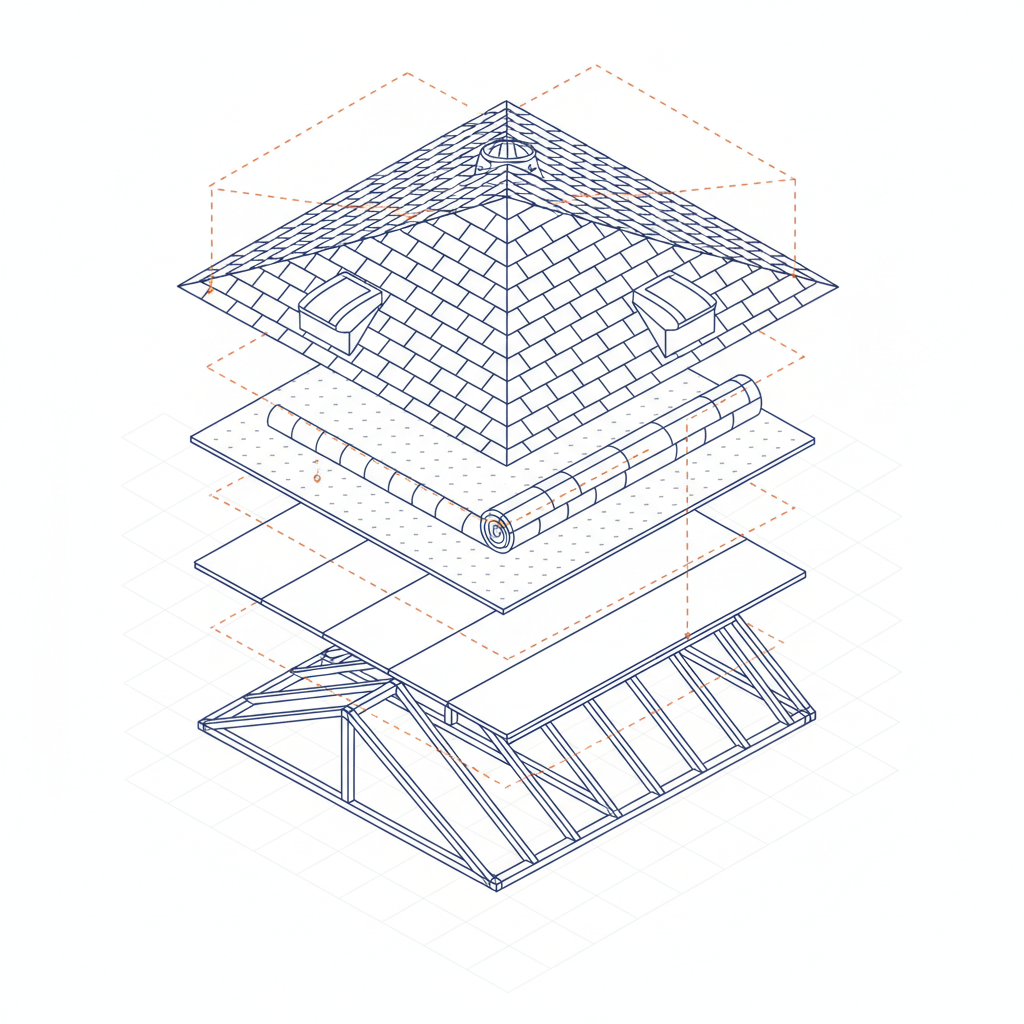

The structural integrity of a roof system begins long before the first shingle is installed. Building codes mandate specific requirements for the underlying structure—the decking, sheathing, and fasteners—because this foundation is what enables the roof to perform its primary function: resisting physical forces like wind and the weight of snow. Failure at this level is catastrophic and non-negotiable.

Decking and Sheathing Requirements: The Unseen Foundation

Roof decking, also called sheathing, is the layer of wood panels (typically plywood or Oriented Strand Board – OSB) that covers the rafters and creates the solid surface for the roofing materials. Codes dictate the minimum thickness of this sheathing, a specification that is directly dependent on the spacing of the roof rafters. Wider rafter spacing requires thicker, more rigid sheathing to prevent sagging under load. An inspector will verify that the sheathing material and thickness are appropriate for the structure, ensuring a solid, stable foundation for the entire roof assembly.

Fastener Schedules: Mandated Nailing Patterns for Wind Resistance

How shingles and sheathing are attached to the roof is not a matter of contractor preference. Building codes specify a mandatory fastener schedule, which dictates the type, size, and spacing of nails. For asphalt shingles, this typically means a minimum of four nails per shingle, placed in a specific manufacturer-designated nailing strip. In high-wind zones, the code mandates six nails per shingle, along with specific nailing patterns for the roof sheathing at the perimeter and in the field of the roof. This precise nailing pattern is a critical defense against wind uplift, the force that tears shingles from a roof during a storm. This is a direct codification of the roof’s requirement to provide protection against wind.

Code Requirements for Weather Protection: A Multi-Layered Defense

A code-compliant roof is a system of integrated layers designed to provide redundant protection against water intrusion from rain and snow. Each component has a specific function, and the building code ensures these components are installed correctly to create a seamless, waterproof barrier. The enemy is water, and the code is the battle plan.

Underlayment and Ice Dam Protection: Your Primary Water Barrier

Roofing underlayment is a water-resistant or waterproof barrier installed directly onto the roof decking. Modern codes often mandate the use of synthetic underlayment for its superior durability and water resistance. In climates prone to snow and ice, codes require a specialized, self-adhering membrane known as an ice and water shield. This shield must be installed from the roof’s edge (the eave) up the roof to a point at least 24 inches inside the building’s exterior wall line. This specific requirement prevents water from ice dams—ridges of ice that form at the eaves—from backing up under the shingles and penetrating the roof structure. This is a critical defense against snow and ice-related water intrusion.

Flashing Specifications: Sealing Critical Transition Points Against Rain

Flashing refers to thin pieces of impervious material, typically galvanized steel or aluminum, used to direct water away from the most vulnerable areas of a roof. Codes mandate specific types and installation techniques for flashing at every point where the roof plane is interrupted: where a wall intersects a roof (step flashing), where two roof planes meet in a valley (valley flashing), and around chimneys, skylights, and vents. Improper or missing flashing is a leading cause of roof leaks. The code’s strict requirements for material, overlap, and integration with the roofing material ensure these critical transition points are permanently sealed against rain.

Drip Edge Requirements: Directing Water Flow with Precision

A drip edge is a metal flashing installed at the edges of the roof—both eaves and rakes—to direct water away from the fascia and into the gutters. Most residential building codes now mandate the installation of a drip edge. The code specifies that the underlayment must be laid over the drip edge at the rakes and under the drip edge at the eaves. This precise layering is not arbitrary; it creates a correct path for water to follow, preventing it from wicking back onto the wooden fascia board and roof deck, which would lead to rot and degradation. This is a simple but non-negotiable element of systematic water management.

Ventilation and Temperature Control: Managing Attic Extremes

A roof’s function extends to protecting the building from extremes of temperature and sunlight. A poorly ventilated attic can reach temperatures exceeding 150°F in the summer, radiating heat into your living space and prematurely aging the shingles. In the winter, warm, moist air from the house can condense on the cold underside of the roof deck, leading to mold and rot. Building codes mandate attic ventilation to manage these temperature and moisture extremes, preserving the roof system and improving energy efficiency.

Calculating Net Free Vent Area (NFVA): The Code-Required Ratio

Building codes do not just require ventilation; they quantify it. The requirement is expressed as a ratio of Net Free Vent Area (NFVA) to the total area of the attic floor. NFVA refers to the total unobstructed area through which air can pass in a vent. The standard code-required ratio is 1:150, meaning one square foot of NFVA is required for every 150 square feet of attic floor space. This ratio can often be adjusted to 1:300 if a balanced system of intake and exhaust vents is used, with at least 40% of the ventilation at the lower portion of the roof (intake).

Code-Compliant Intake and Exhaust Venting Systems

A code-compliant ventilation system must be balanced. This means it must have an equal amount of intake ventilation (typically soffit vents) and exhaust ventilation (typically ridge vents or other high-point vents). This balance creates a continuous, passive airflow. Cool, dry air enters through the soffit vents, flows up the underside of the roof deck, collects heat and moisture, and exits through the ridge vent. This constant airflow keeps the attic temperature and humidity in check. The code ensures this system is designed for performance, not just appearance, preventing the chaotic temperature and moisture swings that destroy a roof from within.

The RocStout Roofing and Construction Method: Exceeding Code as Standard Procedure

For many contractors, the building code is a finish line to be crossed. For us, it is the starting point. Our entire methodology is designed to eliminate the chaos, uncertainty, and corner-cutting that plague the roofing industry. We do not build to code; we build to a higher standard of predictability and performance. This approach is not for everyone. If your primary decision-making factor is finding the absolute lowest price, we are not the right fit. Our process is for meticulous homeowners who value order, transparency, and the certainty that their investment is protected by a process-driven system.

Our Pre-Construction Code Compliance Audit

Before a single tool arrives on site, we conduct a comprehensive Pre-Construction Code Compliance Audit. This is not a simple estimate. We analyze your home’s structure, existing ventilation, and local municipal amendments to the IRC. We design a complete roof system—from sheathing and fastener schedules to ventilation calculations and flashing details—that is guaranteed to meet or exceed every line item of the locally enforced code. This plan becomes the blueprint for your project, removing all guesswork and ensuring every detail is accounted for before work begins.

Why the ‘Lowest Bid’ Puts Your Project’s Compliance at Risk

The lowest bid almost always comes at a cost. That cost is compliance. To achieve an artificially low price, contractors must cut corners. They use fewer fasteners, skip the ice and water shield, install inadequate flashing, or ignore ventilation requirements. These omissions are often invisible until the roof fails during the first major storm. This places the liability squarely on you, the homeowner. A non-compliant roof can void your homeowner’s insurance, create inspection failures during a future home sale, and lead to catastrophic damage. Our transparent, line-item pricing reflects the actual cost of doing the job correctly, using the right materials, and adhering to a process that guarantees compliance. It is an investment in certainty, not a bid in a race to the bottom.

A Predictable Process for Permitting and Inspections

We manage the entire permitting and inspection process as an integral part of our project management system. You are assigned a dedicated Project Manager who handles all paperwork, scheduling, and communication with the building department. This system transforms a potentially chaotic and stressful process into a series of predictable, transparent steps.

This process-driven approach is the only sane way to manage a complex roofing project. It ensures every requirement is met, every inspection is passed, and your project concludes without stress or surprise.