A final inspection using a 72-point quality assurance checklist is the systematic verification that a roof system conforms to all contractual, manufacturer, and building code requirements. The roof is the top covering of a building; its sole purpose is to provide absolute protection against rain, snow, sunlight, extremes of temperature, and wind. This final acceptance protocol is not a suggestion. It is a mandatory process that validates the integrity of the materials and the precision of the construction necessary to support those materials and fulfill their protective function.

The standard roofing project ends in ambiguity. You are left with a vague punch list, unanswered questions, and a lingering anxiety that something was missed. That is chaos. Our process is the antidote. This checklist is a tool of accountability, designed for the meticulous homeowner who demands clarity and a predictable outcome. It is the final, documented proof that every detail of your investment is correct.

The Pre-Inspection Framework: Establishing a Baseline for Quality

A valid final inspection does not begin on the roof. It begins with a comprehensive review of the project documentation. This framework establishes the objective criteria against which the completed work is measured. Your dedicated project manager uses this baseline to ensure every specification is met without deviation. There is no room for interpretation or on-the-fly adjustments that deviate from the agreed-upon plan.

As-Built Documentation vs. Contract Specifications

The scope of work, material list, and any approved change orders constitute the project’s legal and technical blueprint. The final inspection is a direct comparison of this blueprint against the physical, as-built reality. We verify that the specified materials are the installed materials, from the brand of asphalt shingle down to the gauge of the fasteners. Every line item in the contract specifications must have a corresponding, verifiable element on your roof. Manufacturer specifications for installation are treated as an extension of the contract; deviation from them invalidates the material warranty and is therefore unacceptable.

Essential Safety Protocols for On-Roof Assessment

A quality assessment is impossible without a safe assessment. Our team adheres to strict safety protocols before a single measurement is taken. This includes mandatory use of fall protection systems, proper harness and lanyard configurations, and adherence to ladder safety standards. The inspection is scheduled based on safe weather conditions, avoiding rain, high winds, or electrical hazards. This is not just a compliance issue; it is a mark of professionalism. A chaotic, unsafe job site is a leading indicator of a chaotic, poor-quality installation.

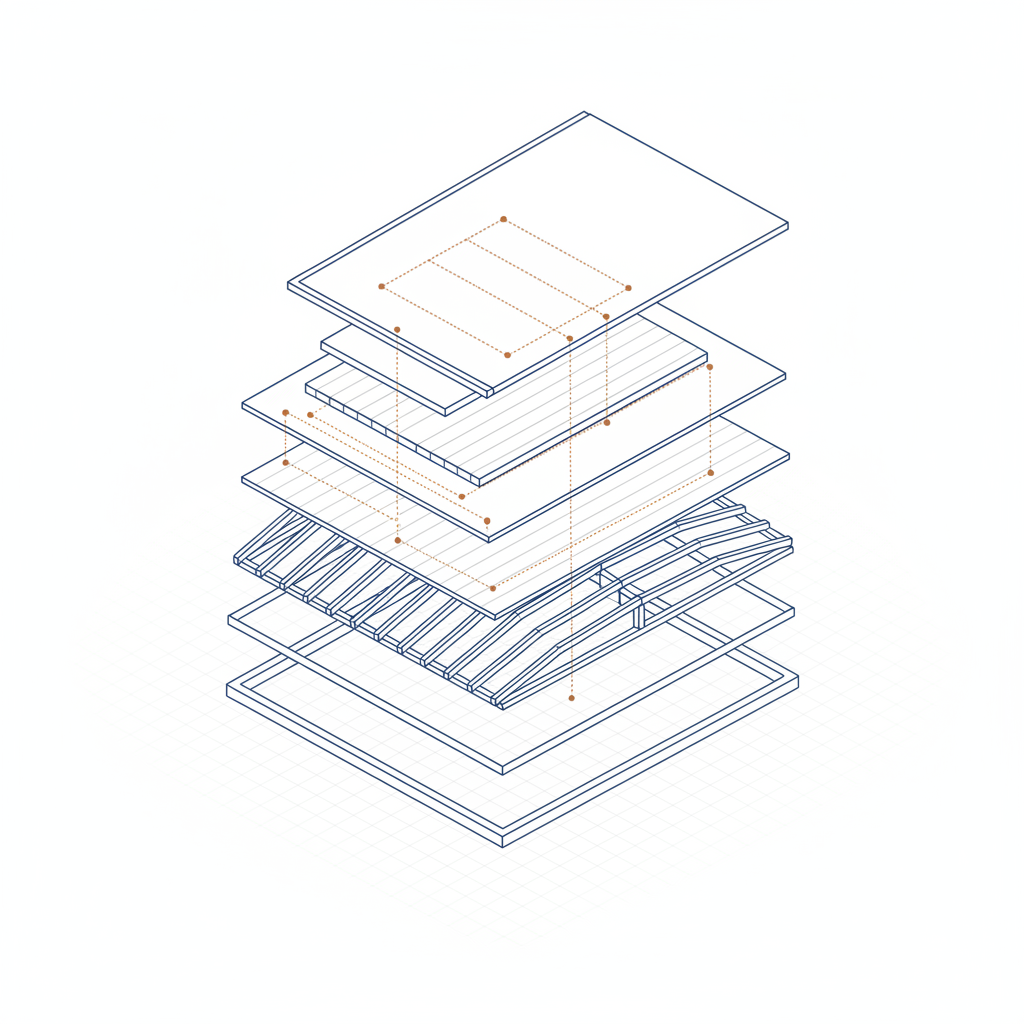

Structural and Material Assessment: Verifying the ‘Top Covering’

The core of the inspection evaluates the primary components of the roof construction. This is a forensic examination of the materials that form the top covering of the building and the structural support system that holds them in place. Each layer is scrutinized for compliance with best practices and manufacturer mandates.

Decking and Support Integrity: The Foundation of Your Roof System

The roof deck, or sheathing, is the foundation upon which the entire weatherproofing system rests. Before any materials are installed, we identify and replace any compromised decking. The final inspection verifies the integrity of this foundation. We check that all sheathing is properly secured to the rafters with the correct fasteners at the specified intervals. A compromised roof deck cannot adequately support the roofing materials or provide the required wind uplift resistance. It is an immediate point of failure.

Shingle Course Alignment, Exposure, and Fastening Analysis

The installation of an asphalt shingle system is a geometric science. Every course must be perfectly straight, with a consistent shingle exposure as specified by the manufacturer. We measure these exposures across multiple sections of the roof to ensure uniformity. The nailing pattern is the most critical element. We confirm the correct number of fasteners per shingle, their precise placement within the manufacturer’s designated nailing zone, and that they are driven flush—not overdriven or underdriven. Improper fastening is the primary cause of shingle blow-off in high winds. Our inspection guarantees this will not happen.

Granule Coverage Analysis: Your Roof’s Primary Shield Against Sunlight

The stone granules on an asphalt shingle serve one primary purpose: to shield the underlying bitumen from UV degradation caused by sunlight. During installation, careless foot traffic or improper material handling can scuff these granules off, creating premature bald spots. Our inspection includes a close visual analysis of granule coverage across the entire roof surface. We identify any areas of significant granule loss, which compromises the shingle’s ability to protect your home from extremes of temperature and shortens its functional lifespan.

Weatherproofing System Audit: Defense Against Rain, Wind, and Snow

A roof’s primary function is water and wind management. Every component must work in concert to provide total protection against water intrusion from rain and snow, and to resist wind uplift forces. This audit is a systematic check of every seal, seam, and transition point where the roof is most vulnerable.

Flashing Systems Verification: Sealing All Penetrations and Transitions

Anywhere the roof plane is penetrated or meets a vertical wall is a potential entry point for water. Flashing is the non-negotiable metal or membrane system that seals these transitions. Our checklist mandates a point-by-point verification of every flashing component: chimney flashing, step flashing along walls, vent pipe flashing, and valley flashing. We ensure the correct materials were used, installed in the proper sequence (shingle-fashion), and sealed correctly. There is zero tolerance for error in the flashing system.

Underlayment and Water Barrier Review at Eaves and Valleys

The most critical lines of defense after the shingles are the underlayment and specialized ice and water shield. At vulnerable areas like roof eaves and valleys, code and best practices require a self-adhering membrane that seals around fasteners to prevent water intrusion from ice dams or wind-driven rain. Our inspection verifies that this barrier was installed correctly, extends the proper distance up from the eave, and is properly integrated with the drip edge. This system is your roof’s hidden, but essential, protection against water.

Sealant and Adhesion Integrity for Wind Uplift Resistance

Each shingle has a factory-applied sealant strip designed to bond with the course above it, creating a monolithic, wind-resistant surface. This adhesion is critical for wind uplift resistance, especially in high wind areas. We test this bond in multiple locations to ensure it has properly activated. The system must meet or exceed standards like ASTM D3161 for wind resistance. A failure of this adhesive seal exposes the entire roof system to catastrophic failure during a storm.

Climate Control System Review: Managing Temperature Extremes

A modern roof system does more than just block rain; it functions as a critical component of your home’s climate control system. It must manage airflow and water evacuation to protect the building structure from moisture buildup and mitigate extremes of temperature within the attic space.

Ridge and Soffit Vent Analysis for Balanced Airflow

Proper attic ventilation is a balanced system of intake and exhaust. It requires a continuous, unobstructed flow of air. Soffit vents provide the intake, and a ridge vent provides the exhaust. Our inspection verifies that both components are present and correctly installed. We calculate the net free area to ensure the ventilation is balanced, preventing heat and moisture buildup that can destroy sheathing, ruin insulation, and increase your energy costs. An imbalanced system is an ineffective system.

Gutter and Downspout Integration for Controlled Water Evacuation

The gutter system is not an accessory; it is the final step in the roof’s water management process. It must collect all water evacuated from the roof surface and direct it away from the building’s foundation. We inspect the gutters for proper slope, secure attachment to the fascia board, and seamless integration with the downspouts. The entire drainage system must be clear of debris and function as designed. Mismanaged water evacuation leads to foundation damage, siding rot, and landscape erosion.

Project Closeout: The Final Mandate Against Chaos

The completion of the roof installation is not the end of the project. The project closeout phase is where our commitment to a predictable, organized process is most visible. This is our final mandate against the chaos, mess, and ambiguity that define the typical contractor experience.

Systematic Debris and Material Cleanup Verification

A clean job site is a sign of respect for your property. Our closeout checklist includes a multi-point cleanup verification. This is not a quick pass with a leaf blower. It is a systematic process that includes a magnetic sweep of your lawn, landscaping, and driveway for nail removal. We ensure all property protection measures are removed, all debris is loaded into the dumpster, and your property is left in the same condition we found it, if not better. This level of cleanliness is a non-negotiable standard.

Final Documentation and Warranty Handover Protocol

The project concludes with a formal handover of all critical documentation. This is not an email with attachments; it is a structured meeting with your project manager. You will receive a complete packet containing the manufacturer warranty for your specific materials, our comprehensive workmanship warranty, the final paid invoice, and a signed lien waiver. We also provide a clear, concise maintenance plan to ensure the longevity of your investment. This transparent protocol provides you with the legal and financial peace of mind that the project is truly complete.

The Alternative to Uncertainty: A Process-Driven Closeout

Most roofing projects end with a homeowner cautiously walking their yard, hoping everything is okay. This is an unacceptable level of uncertainty for a major financial investment. We replace hope with verification. We substitute the vague ‘punch list’ with a systematized final acceptance checklist. This is the difference between chaos and control.

Contrast: The Vague ‘Punchlist’ vs. Our Systematized Final Acceptance

Our methodology is built on accountability and quality assurance. The industry-standard punch list is a reactive, disorganized approach to fixing obvious mistakes. Our 72-point checklist is a proactive, systematic procedure for verifying excellence.

An informal, inconsistent walkthrough to spot obvious, visible errors after the crew has mentally moved on.

No formal criteria for acceptance. Project is ‘done’ when the contractor says it is. Warranty papers are mailed later, if at all.

The homeowner is left with uncertainty, responsible for discovering hidden issues months or years later.

A project manager uses a 72-point checklist to verify every aspect of the installation against objective standards.

The project is complete only when the checklist is satisfied. A formal meeting transfers all warranties and legal documents.

The homeowner has documented, verifiable proof of a high-quality installation and total peace of mind.

Our Commitment is Not Price, It Is a Predictable Outcome

We state this directly: if your primary concern is securing the absolute lowest price, we are not the right company for you. Our process is intentionally meticulous. It requires a dedicated project manager, adherence to strict quality control checkpoints, and an unwavering commitment to communication. These elements are incompatible with a bargain-hunter business model. Our clients are engineers, lawyers, project managers, and other meticulous homeowners who understand that the true cost of a project includes the stress and risk of a chaotic process. Your investment is not just in high-quality materials; it is an investment in a predictable, transparent, and stress-free result.