Introduction: Moving from Chaotic Symptoms to a Clear Diagnosis

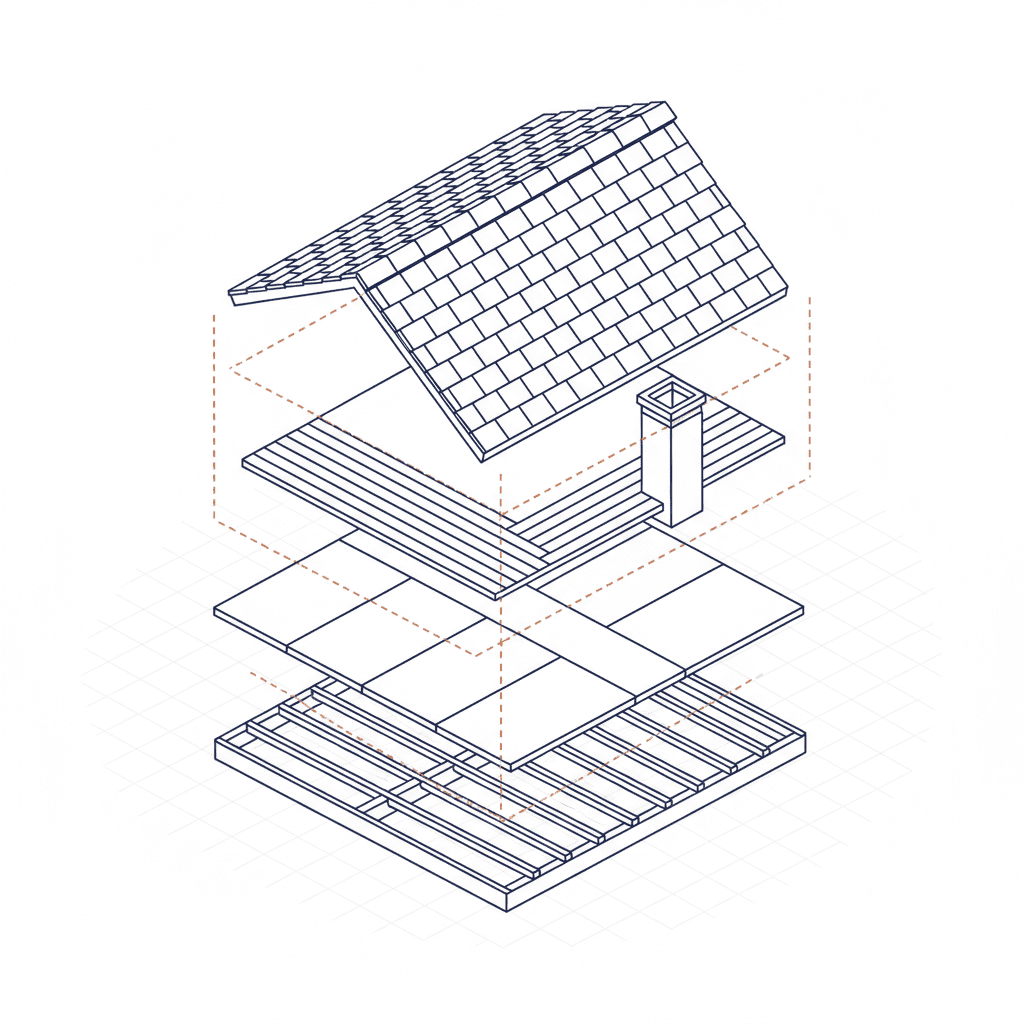

Premature roof failure is the accelerated degradation of a building’s top covering (kg:/m/06hyd) and its supporting constructions, resulting in a shortened service life due to systemic failures in installation, ventilation, or material integrity. Your roof is not merely a layer of shingles; it is a complex system engineered to provide protection against rain, snow, sunlight, and extremes of temperature. When this system fails ahead of its warrantied lifespan, the cause is rarely a mystery. It is a direct result of process failure, a symptom of chaos masquerading as construction.

For the meticulous homeowner, the anxiety surrounding a roofing project stems from this chaos: unpredictable timelines, vague pricing, and the potential for catastrophic failure years before it should be a concern. This document serves as a root cause analysis framework. It is designed to move you from observing chaotic symptoms—a leak, a loose shingle, granule loss—to a clear diagnosis of the underlying failure. Protecting your investment requires understanding how a roofing system can fail, which empowers you to hold your contractor accountable to a standard that prevents it.

Installation Errors: Diagnosing Workmanship-Related Failures

The majority of premature roof failures are not caused by defective materials but by improper installation. Workmanship is the single most critical variable in the longevity of your roof. Every component, from roofing nails and shingle alignment to flashing, must be installed according to precise manufacturer specifications and building codes. Deviations are not minor errors; they are latent defects that guarantee future problems.

Improper Fastening: The Primary Cause of Wind Uplift

A shingle’s resistance to wind is determined almost entirely by its fastening. Improper nail placement is the most common installation defect. Nails must be placed on the designated nail line, driven perpendicular to the roof deck, and set to the correct depth. An overdriven nail fractures the shingle’s fiberglass mat, creating a path for water. An underdriven nail prevents the shingle above it from sealing correctly and can puncture it from below. Both errors violate building code and void manufacturer warranties, leaving the homeowner financially exposed to wind damage.

Flashing Failures: Critical Weak Points for Water Intrusion

Flashing is the waterproofing component used where the roof plane is interrupted by a chimney, wall, vent, or another roof plane. It is the system’s most critical defense against water intrusion at its most vulnerable points. Failures in chimney flashing, valley flashing, or step flashing are not possibilities; they are eventualities when installed incorrectly. Relying on caulk or roof cement as a primary sealant instead of properly layered metal flashing is a hallmark of low-bid workmanship. This approach is a temporary patch, not a permanent solution, and it guarantees a leak.

Component Misapplication: How Skipping Steps Guarantees Failure

A roofing system is a layered assembly of components, each with a specific function. The failure to install any one of these components correctly compromises the entire system. A missing starter strip at the eave allows wind to lift the first course of shingles. Inadequate ice and water shield in valleys or at penetrations allows water from ice dams or wind-driven rain to reach the roof deck. Omitting a metal drip edge allows water to wick back onto the fascia and sheathing, causing rot. These are not ‘value engineering’ decisions; they are calculated omissions that shorten the life of the roof to lower the upfront price, transferring the long-term cost and risk directly to you.

| Failure Point | The Industry Norm (High-Risk Chaos) | The RocStout Standard (Predictable Outcome) |

|---|---|---|

| Nail Placement | Inconsistent placement, incorrect depth (over/under-driven), 4 nails per shingle in all areas. | Mandatory 6-nail pattern for maximum wind resistance, precisely on the manufacturer’s nail line, with calibrated air compressors for consistent depth. |

| Flashing | Reusing old flashing, reliance on face-caulking as a primary water seal, using inappropriate materials. | New, custom-fabricated metal flashing for all penetrations, installed in layered, code-compliant fashion. We build waterproofing into the system. |

| Underlayment | Standard, cheap felt paper that can tear easily and wrinkle, offering minimal secondary protection. | High-quality synthetic underlayment for superior water resistance and durability during and after installation. Ice and water shield at all eaves, valleys, and penetrations. |

Ventilation System Analysis: How Trapped Heat & Moisture Accelerate Failure

A roof is not just an external shield; it is part of a system that includes the attic space below it. Proper attic ventilation is a non-negotiable requirement for roof longevity. A poorly ventilated attic traps heat and moisture, creating an internal environment that actively destroys your roof deck and shingles from within, causing failure due to extremes of temperature and moisture accumulation.

Evaluating Airflow: The Impact of Unbalanced Intake and Exhaust

A functional ventilation system operates on the principle of convection. Cool, dry air enters through intake vents (soffit vents) at the lowest point of the roof, and warm, moist air exits through exhaust vents (ridge vents) at the highest point. This creates continuous airflow. A balanced system requires an equal amount of intake and exhaust ventilation. An imbalance, or blocked soffit vents, short-circuits this process, trapping hot, moist air in the attic and negating the system’s function.

Condensation Effects: The Internal Threat to Your Roof’s Structure

In colder climates or seasons, warm, moist air from the living space rises into the cold attic. When this air contacts the cold underside of the roof deck, it causes condensation. This persistent moisture leads directly to mold growth, rafter deterioration, and sheathing rot. The structural integrity of the roof’s foundation is compromised not by an external leak, but by an internal atmospheric failure. This is a silent destroyer that often goes unnoticed until significant structural damage has occurred.

Shingle Thermal Degradation: How Your Attic Can ‘Cook’ Your Roof

During the summer, an unventilated attic can reach temperatures exceeding 150°F. This superheated air ‘cooks’ the asphalt shingles from the underside. This constant thermal shock accelerates the breakdown of the asphalt, causing granule loss, shingle curling, and premature aging. The sealant strips that bond the shingles together can also melt and lose their adhesion. Your 30-year shingles can fail in as little as 10-15 years, not from sunlight or rain, but from the intense heat radiating from your own attic.

Component Integrity Assessment: Analyzing the Layers of Protection

A roof’s durability is a function of its constituent materials and their proper construction. The visible shingles are only one layer of a multi-part defense system. Assessing the integrity of each component, from the protective granules to the underlayment, provides a clear picture of the roof’s remaining service life and its vulnerability to failure from sunlight and weather.

Granule Loss Analysis: Estimating Remaining UV Protection and Roof Life

The colored asphalt granules on a shingle are not cosmetic. They are a critical barrier that shields the underlying asphalt (bitumen) from UV degradation. Sunlight breaks down asphalt, making it brittle. Significant granule loss, evidenced by ‘bald spots’ on shingles or an accumulation of granules in your gutters, indicates that the roof’s primary UV protection is failing. This exposes the bitumen to direct sunlight, dramatically accelerating the aging process and leading to cracks and leaks.

Sealant Failure: The Breakdown of Your Roof’s First Line of Defense

Each shingle has a factory-applied sealant strip. Once heated by the sun after installation, this strip bonds the shingle to the one below it, creating a continuous, water-resistant surface. This shingle adhesion is the roof’s first line of defense against wind uplift and wind-driven rain. If this seal fails due to improper installation, thermal degradation from a hot attic, or material age, shingles can be lifted and torn off by moderate winds, creating an immediate and catastrophic failure point for water infiltration.

Underlayment Evaluation: Assessing the Secondary Water Barrier

The underlayment, either traditional roofing felt or modern synthetic material, is the secondary water barrier. Its function is to protect the roof deck from any water that gets past the shingles. While a properly installed shingle roof should not leak, the underlayment is critical protection during installation and in the event of shingle damage. A low-quality, torn, or improperly installed underlayment offers no secondary protection. When a shingle is lost or damaged, a compromised underlayment means water immediately reaches the wooden sheathing, leading to rot and interior damage.

Structural Support Evaluation: Assessing the Roof’s Foundation

The entire roofing system relies on the integrity of its foundation: the structural supports and the roof deck. The walls and uprights must be sound, but the sheathing that makes up the deck is the direct substrate to which all roofing materials are attached. A failure at this level compromises everything above it.

Decking Deterioration: Identifying Spongy or Sagging Sheathing

The roof deck is typically made of plywood or Oriented Strand Board (OSB) sheathing. It must be solid and stable to provide adequate nail-holding power. Water damage from a long-term leak or attic condensation will cause this wood to delaminate, rot, and lose its structural integrity. Walking on the roof may reveal spongy spots. From the ground, a sagging roofline is a clear indicator of decking deterioration or even failed rafters. Installing a new roof over a compromised deck is a guaranteed failure. The new shingles will not hold, and the underlying problem remains unaddressed.

Inadequate Slope: How Low Pitch Roofs Present Unique Failure Risks

Roof pitch, or slope, dictates how effectively a roof sheds water. Standard asphalt shingles are designed for roofs with a certain minimum pitch. On low-slope roofs, water and snow do not drain quickly, increasing the risk of water pooling and infiltration. Installing standard shingles on a roof with inadequate slope is a direct violation of installation codes and guarantees failure. These applications require specialized materials and techniques to prevent leaks caused by poor drainage and snow accumulation.

The Antidote to Chaos: A Process-Driven Roofing Methodology

The variables that lead to premature roof failure all stem from a single root cause: a lack of process and accountability. The standard roofing industry experience is built on ambiguity and shortcuts. The antidote is a transparent, process-driven methodology that ensures predictability and eliminates the potential for chaos. This is not an idealistic goal; it is a strict operational requirement for a successful project.

Our Non-Negotiable Installation Standards vs. The Industry Norm

We operate from a zero-defect installation checklist derived directly from manufacturer certification programs and stringent building codes. Our approach is systematic and verifiable, not dependent on the whims of a particular crew on a particular day. Every step, from deck preparation to final cleanup, is executed according to a quality assurance protocol. This systematic approach is the only way to ensure every roof we install has the structural integrity to last its full warrantied life.

Transparent Project Management: Eliminating Surprises and Ambiguity

Your project is managed with the precision you expect in your own professional life. You will have a dedicated, accessible project manager and a detailed scope of work that clearly defines every material, every procedure, and the total cost. Our contracts are fixed-price. There are no hidden fees or surprise charges. Communication is proactive and scheduled. This is how we eliminate the anxiety of the unknown and replace it with the confidence of a well-managed project.

Why We Reject Low-Bid Work: A Commitment to Predictable Outcomes

We must be direct. If your primary decision-making criterion is securing the absolute lowest price, RocStout is not the right contractor for your project. We are not for the bargain hunter. The low-bid model is fundamentally incompatible with a predictable, stress-free outcome. It necessitates the very compromises—cheap materials, unskilled labor, skipped steps—that lead to the premature failures detailed in this analysis.

Our clients are engineers, project managers, lawyers, and meticulous homeowners who understand that long-term value is more important than short-term savings. They hire us because they are purchasing a predictable process and a guaranteed outcome. Our pricing reflects the cost of doing the job correctly, without compromise, the first time. This focus allows us to provide a level of project management, communication, and quality control that the low-bid model simply cannot support.