Premature roof failure is the accelerated degradation of a roofing system, causing it to fall short of its warranted service life due to systemic deficiencies in materials, construction, or both. This failure represents a quantifiable financial loss that extends beyond the initial installation cost to include subsequent repair costs, interior property damage, and the expense of a complete replacement years ahead of schedule. A roofing project is not a commodity purchase; it is the implementation of an integrated system designed to protect your most valuable asset. The pursuit of the lowest initial price is the leading cause of this system’s failure.

This analysis is for the meticulous homeowner who understands that value is measured by total cost of ownership, not the initial bid. If your primary objective is to secure the absolute lowest price, RocStout is not the right contractor for you. Our process is built on a foundation of predictability and risk elimination, a methodology that is incompatible with the corner-cutting required to deliver the cheapest quote. We exist to provide a controlled, transparent, and predictable roofing experience, free from the chaos that defines the standard industry process.

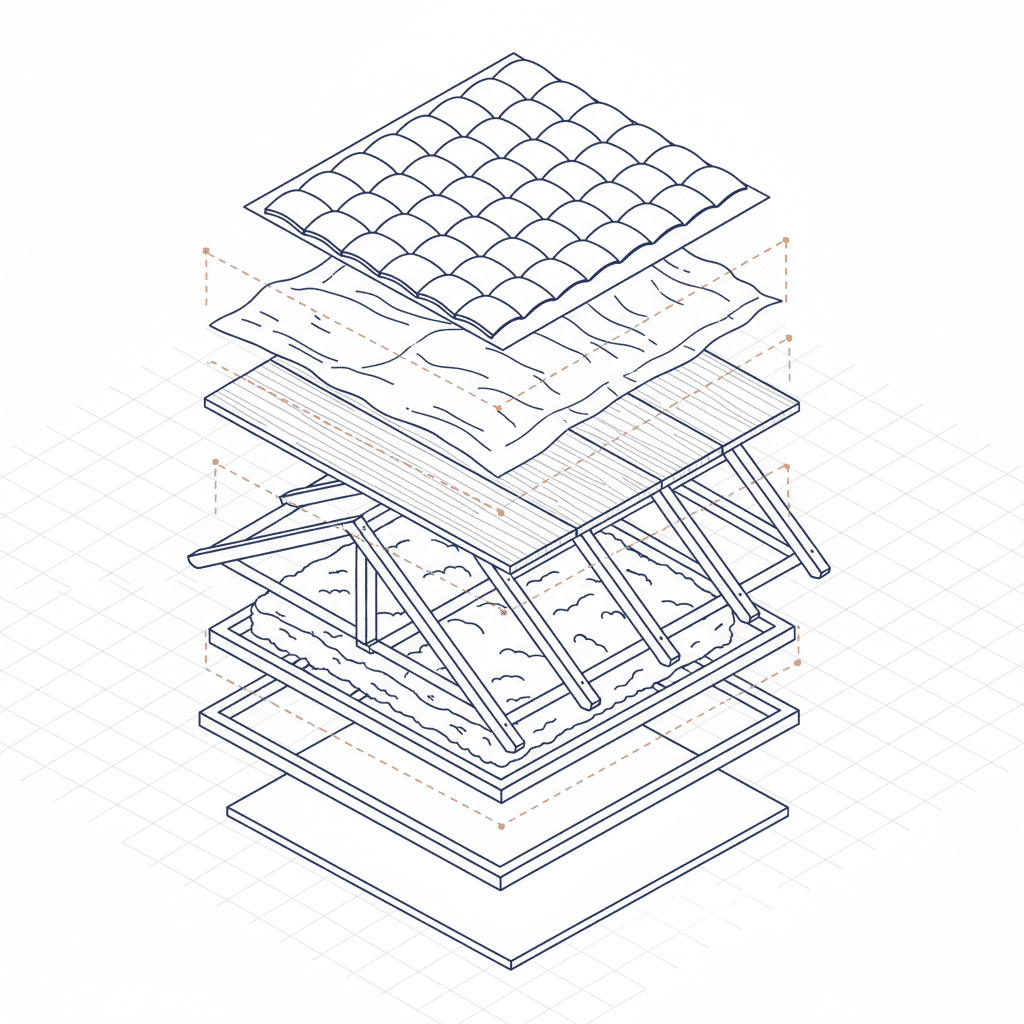

The Roof as a System: Deconstructing ‘Materials and Constructions’

A roof is defined as the top covering of a building, encompassing all materials and constructions necessary for its support and function. This is not a single product, but an assembly of interdependent components. The ‘low-bid’ roofer exploits this complexity by substituting specified components with inferior alternatives, knowing the average homeowner cannot identify the difference. This action compromises the entire system, initiating a cascade of failures that manifest over time.

Substandard Top Covering: Quantifying the Lifespan Reduction

The top covering, typically asphalt shingles, is the most visible component, but its performance is dictated by unseen material specifications. A low-cost shingle achieves its price point by reducing the two most critical ingredients: asphalt and ceramic granules. Less asphalt results in a thinner, more brittle shingle that cannot withstand thermal cycling. Fewer granules expose the underlying asphalt to UV radiation, accelerating its breakdown. A 30-year architectural shingle from a reputable manufacturer has a specific weight and composition. A cheaper alternative may look similar but fail in 10-15 years, a 50% reduction in service life. This degradation voids any manufacturer warranty, as the failure is systemic, not a material defect.

| Metric | Quality Architectural Shingle | Low-Bid ‘Equivalent’ Shingle |

|---|---|---|

| Asphalt Content | High; provides flexibility and water resistance | Low; results in brittleness and premature cracking |

| Granule Density | Thick, uniform coverage for UV protection | Thin, sparse coverage, leading to rapid UV exposure |

| Warranted Lifespan | 30-50 years (with proper installation) | Fails in 10-15 years (voiding warranty) |

| True Cost | Higher initial cost, lowest long-term cost | Lowest initial cost, highest long-term cost |

Underlayment & Flashing Failures: The Primary Vector for Rain Intrusion

A roof’s primary function is protection against rain. This protection is not provided by the shingles alone, but by the water-resistant barrier beneath them. The most common cost-cutting tactic is using cheap tar-saturated felt paper as an underlayment. This material rips easily during installation and degrades quickly with heat, offering minimal secondary protection. The industry standard for a durable system is a synthetic underlayment, which provides a robust, tear-resistant secondary water barrier. Similarly, flashing—the metal work at valleys, chimneys, and walls—is a critical defense. Low-bid jobs reuse old, failing flashing or use improperly sized, unsealed pieces. A single flashing failure provides a direct path for water intrusion, leading to rot, mold, and costly interior damage. The failure is not a matter of ‘if’, but ‘when’.

Compromised Structural Support: The Unseen Costs in Decking and Fasteners

The entire roofing system relies on its structural support: the roof decking (typically plywood or OSB sheathing). A thorough roofing process includes a full inspection of this decking, with clear provisions for replacing any water-damaged or delaminated sections. A cheap roof is installed directly over compromised decking. This is a critical failure. Fasteners driven into soft, rotten wood have no holding power, making shingles susceptible to wind uplift from day one. Furthermore, the fastener schedule itself is a point of compromise. Using fewer nails per shingle, or using the wrong type of nail (e.g., electro-galvanized instead of hot-dip galvanized), saves a negligible amount on the initial bid but guarantees future problems, from shingle blow-off to rust-driven leaks.

Analyzing Protection Failures: The Long-Term Cost of Low Bids

A roofing system’s performance is measured by its ability to provide continuous protection against environmental forces: sunlight, wind, snow, and temperature extremes. A system built with substandard materials and poor workmanship lacks the resilience to manage these loads, leading to accelerated, predictable failures that impose significant long-term costs on the homeowner.

Accelerated UV Degradation: The True Cost of Sunlight Exposure

Protection from sunlight is a core function of a roof’s top covering. The ceramic granules on an asphalt shingle are not for aesthetics; they are a functional barrier against UV radiation. Low-quality shingles have a thinner, less-adherent layer of these granules. Normal weathering dislodges them over time, but on a cheap shingle, this process is dramatically accelerated. You will see this as an excessive accumulation of ‘sand’ in your gutters. Once the granules are gone, UV rays directly attack the asphalt substrate, causing it to become brittle and crack. This thermal cycling—expansion during the day and contraction at night—exacerbates these cracks, creating a network of entry points for water. The result is a roof that fails from the top down, long before its expected end-of-life.

Catastrophic Wind Uplift: The Consequence of Improper Nailing

A roof must provide robust protection against wind. Wind does not push shingles down; it creates a pressure differential that lifts them up. This ‘wind uplift’ force is counteracted by a precise nailing pattern. A low-cost installation compromises this structural requirement in several ways: incorrect nail placement (high nailing), under-driving or over-driving nails, and using fewer nails than specified by the manufacturer for the building’s wind zone. High nailing is the most common error; placing the nail above the shingle’s designated nailing strip means it holds only the top layer, not the two layers as designed. A single misplaced nail per shingle, replicated across an entire roof plane, creates a systemic vulnerability. In a moderate to high wind event, this results in catastrophic shingle blow-off, exposing the underlayment and requiring emergency repairs or a complete re-roof.

Ice Damming & Poor Ventilation: Compounding Costs from Snow & Temperature Extremes

Effective protection against snow and temperature extremes is a function of the entire roofing and attic system, not just the shingles. Ice dams are a classic symptom of a failed system. They form when heat from an improperly ventilated attic melts snow on the roof. The water runs down to the colder eave, where it refreezes, creating a dam. Water pools behind this dam, backing up under the shingles and penetrating the roof deck. A low-bid roofer never addresses the root cause: inadequate ventilation. They simply install the shingles. A properly engineered roofing project calculates the required intake and exhaust ventilation to create a cold attic, preventing snow melt and ice dam formation. The cost of ignoring this is not just a new roof, but also new insulation, drywall repair, and mold remediation inside your home.

Operational Chaos: The Hidden Labor and Liability Costs in a Low Price

The price of a roofing project is not just materials; it is labor, project management, and insurance. The chaos, risk, and disorganization inherent in a low-bid operation are direct costs transferred to you, the homeowner. These are not line items on an estimate, but they are paid for in liability exposure, project delays, and property damage.

Uninsured Labor: A Direct Transfer of Financial Risk to You

A primary way contractors achieve a low price is by not carrying adequate insurance—specifically, General Liability and Workers’ Compensation. This is not a cost-saving measure for them; it is a direct transfer of financial risk to you. If an uninsured worker is injured on your property, you can be held liable for their medical expenses. If their operation causes damage to your neighbor’s property, you are exposed to that liability. Demanding proof of insurance is a basic step, but it is not enough. Proper coverage is expensive and is a significant part of a legitimate contractor’s bid. Its absence in a low bid is a red flag indicating that you are assuming the role of primary insurer for the project.

The Inefficiency Tax: Calculating the Cost of Vague Timelines and Poor Communication

Chaos has a cost. We call it the Inefficiency Tax. It is paid through vague timelines that disrupt your life, poor communication that leads to mistakes, and the inevitable surprise charges that arise from an incomplete scope of work. The typical low-bid process is reactive. Problems are dealt with as they arise, often with a change order and an additional fee. This is the opposite of a managed process. A professional, process-driven operation invests heavily in pre-production planning. It establishes a detailed schedule, a clear communication protocol, and a comprehensive scope of work that anticipates potential issues. This eliminates surprises and delivers a predictable outcome. The absence of a dedicated project manager is the clearest indicator you will be paying the Inefficiency Tax.

Inadequate Site Protocols: The Tangible Cost of a Messy Job Site

A contractor’s respect for your property is a direct reflection of their operational discipline. A disorganized job site is more than an eyesore; it is a financial liability. Roofing debris can damage expensive landscaping, block access, and cause flat tires from stray fasteners. The cleanup process for a cheap roofer is often a quick pass at the end of the job, leaving behind nails and scrap. A systematic approach involves disciplined daily site management. This includes designated pathways, protection for sensitive areas like gardens and HVAC units, and a daily ‘magnetic sweep’ to collect fasteners. The final inspection is not just of the roof, but of the entire property, ensuring it is returned to its original condition. This protocol is a non-negotiable part of a professional project plan.

A Predictable Framework for Calculating True Roofing ROI

The antidote to chaos is a predictable system. True return on investment for a roofing project is calculated not by the initial price, but by the decades of reliable performance and the absence of stress during installation. This is achieved through a transparent, meticulously managed process that prioritizes clarity and eliminates variables.

Our Line-Item Proposal vs. The Vague ‘Lump Sum’ Estimate

A vague, one-page ‘lump sum’ estimate is a tool of obfuscation. It is designed to hide where corners are being cut. Our proposal is a detailed, line-item scope of work. It specifies the exact type and manufacturer of every component, from the starter strips to the ridge cap shingles. It defines the installation methodology, the fastener schedule, and the protocols for decking replacement. This transparency is not optional; it is the foundation of a predictable project. It allows you to see exactly what you are paying for and holds us accountable for delivering it.

A single price that hides component quality, lacks detailed scope, and invites surprise charges.

A transparent, multi-page document specifying every material, process, and cost for total clarity and accountability.

The Role of a Dedicated Project Manager in Eliminating Surprises

The most critical component we install is not on your roof; it is on your project. Every RocStout installation is managed by a dedicated Project Manager. This individual is your single point of contact from start to finish. They are responsible for the project schedule, coordinating material deliveries, managing the crew, and providing you with proactive daily updates. They are not a salesperson; they are an operations professional whose sole function is to execute the plan and ensure a predictable, stress-free experience for you. This eliminates the communication breakdowns and blame-shifting that plague the standard roofing process.

Investing in a Predictable System, Not Just a Low Price Point

Ultimately, a roof replacement is an investment in asset protection. The choice is not between a ‘cheap’ roof and an ‘expensive’ roof. The choice is between a chaotic, unpredictable process with a high probability of failure, and a managed, transparent system that guarantees a specific outcome. We have engineered a process to eliminate the variables that cause stress and failure. Our clients are partners in this process; they are meticulous homeowners who value order, clarity, and peace of mind. They understand that paying to mitigate risk upfront is smarter than paying to fix a disaster later. If you measure value in terms of long-term performance and the complete absence of operational chaos, we are the right choice for your project.