Shingle curling is the physical deformation of an asphalt shingle, characterized by its edges lifting upwards, which indicates a failure in the material’s ability to protect a building from environmental elements. This condition is not a cosmetic flaw; it is a critical diagnostic indicator that the roof, as a complete system, is degrading and its primary functions are compromised. A roof is the top covering of a building, engineered to provide absolute protection against rain, snow, sunlight, extremes of temperature, and wind. Curling signals a vulnerability in this protective shield, exposing your home to moisture ingress, thermal inefficiency, and potential structural damage. Understanding its root causes is the first step in a logical, systems-based approach to remediation.

An Engineer’s Introduction to Shingle Curling

For a meticulous homeowner, any deviation from a system’s specified performance is a cause for concern. Shingle curling is precisely that: a deviation. It represents a loss of dimensional stability in the most critical component of your roof’s water-shedding surface. The shingle is no longer lying flat against the structure, which compromises the integrity of its seals and its ability to function as a unified membrane. This is a clear signal of system failure that requires methodical analysis, not a quick fix.

Distinguishing Curling from Other Forms of Roof Wear

Accurate diagnosis is the foundation of any effective solution. The term ‘curling’ is often used colloquially to describe various forms of shingle degradation. Precision is required. The following table defines the distinct forms of wear, their visual identifiers, and their most probable causes. This clarity removes ambiguity and prevents misdiagnosis by less thorough contractors.

| Degradation Type | Visual Identifier | Primary Cause |

|---|---|---|

| Curling | Shingle edges are lifted and turned upward. The center remains relatively flat. | Moisture absorption from below; severe attic heat. |

| Clawing (Cupping) | Edges and corners curl downwards or inwards, creating a cupped or claw-like shape. | Top surface shrinkage due to volatile loss and UV exposure. |

| Blistering | Bubble-like protrusions on the shingle surface. May be intact or ‘popped’. | Trapped moisture within the shingle during manufacturing, exacerbated by attic heat. |

| Granule Loss | Accumulation of sand-like particles in gutters and downspouts. Bald patches on shingles. | Natural aging, impact from hail, foot traffic, or manufacturing defects. |

Core Causes of Shingle Degradation: A Systems-Based Approach

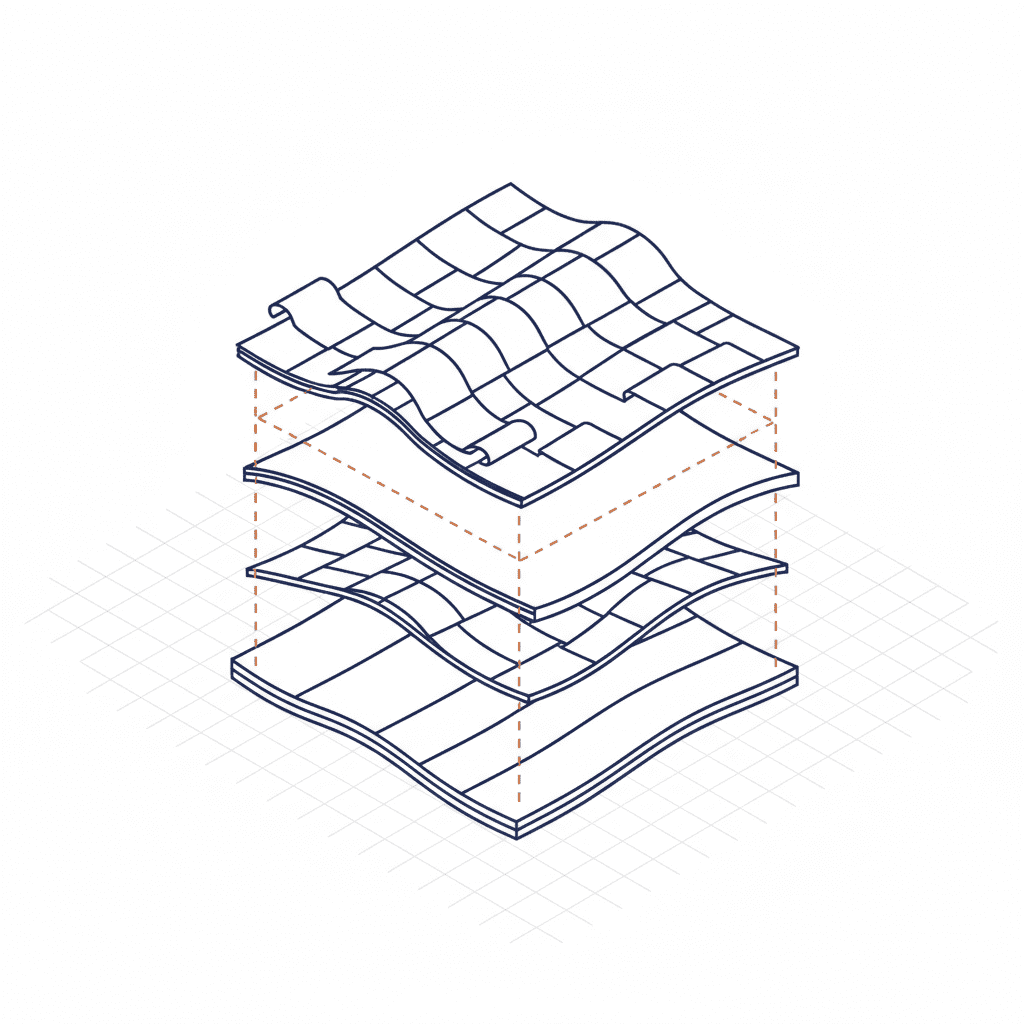

An asphalt shingle is a composite material engineered for a specific lifecycle. Its degradation is not random but a predictable outcome of material science and environmental exposure. The roofing system fails when its core components, the shingles, can no longer perform their function. This failure originates from two primary internal factors: the aging of the material itself and its reaction to thermal and moisture dynamics.

Material Aging and Volatile Compound Loss

Asphalt shingles consist of a fiberglass mat saturated with bitumen (asphalt) and coated with ceramic granules. The bitumen contains volatile organic compounds—oils that provide flexibility and waterproofing. Over the shingle’s lifecycle, exposure to solar radiation (UV rays) and heat causes these volatiles to slowly evaporate. As the shingle loses these plasticizing compounds, it becomes brittle, shrinks, and loses its ability to expand and contract without stress. This shrinkage of the top asphalt layer is the direct mechanism behind clawing, where the surface pulls inward, forcing the edges down.

Impact of Thermal Cycling and Moisture Absorption

Your roof system is subjected to constant thermal cycling—the daily expansion and contraction caused by heating from sunlight and cooling at night. This movement stresses the entire assembly. Furthermore, the fiberglass mat at the core of the shingle can, over time, begin to absorb minuscule amounts of moisture. When the underside of the shingle absorbs more moisture than the sun-baked top surface, the mat expands relative to the top layer. This differential forces the edges of the shingle to lift upward, a condition defined as curling. This process is drastically accelerated by improper attic ventilation, which traps moisture-laden air directly beneath the roof deck.

Environmental Stressors: Quantifying External Factors

While internal material degradation is inevitable, external environmental factors dictate the rate of that decay. A roof does not exist in a vacuum; it is in a constant battle with sunlight, wind, and weather. These stressors are quantifiable variables that a superior roofing process must account for to ensure the longevity of the building’s top covering.

Analysis of Solar Exposure and UV Radiation

Solar radiation is the primary catalyst for shingle aging. A roof slope with a southern or western exposure absorbs significantly more heat and UV radiation throughout the day. The ceramic granules embedded in the shingle’s surface are the first line of defense; they function as a shield, reflecting some sunlight and protecting the bitumen beneath from direct UV degradation. As these granules are lost over time, the bitumen is exposed, and the rate of volatile loss accelerates dramatically. Darker colored roofs also absorb more infrared radiation, leading to higher surface temperatures and a faster aging process. This is a critical factor in material specification.

Wind Uplift Dynamics and Sealant Strip Failure

Curled shingles present a direct threat to the roof’s ability to resist wind. A flat, properly sealed shingle offers a low profile to the wind. A curled edge, however, acts as a small airfoil. Wind flowing over the roof can get under this lifted edge, creating an upward pressure known as wind uplift. This force can break the shingle’s sealant strip, which is the tar line that bonds it to the course below. Once one seal is broken, the shingles are far more susceptible to being torn off in high winds, leading to a cascading failure across the roof field and a total loss of protection against rain.

Installation & Construction Defects: A Failure in Process

Environmental factors and material aging are expected variables. Failures in workmanship are not. The vast majority of premature roof failures, including accelerated shingle curling, are a direct result of defects in the installation process. The enemy here is chaos: the lack of a strict, repeatable protocol for construction. These are not mistakes; they are systemic flaws introduced by contractors who prioritize speed over precision.

Inadequate Attic Ventilation: The Primary Systemic Flaw

This is the single most common and destructive installation defect. A roof system is not just shingles; it includes the attic space below. Proper ventilation requires a balanced system of intake vents (at the soffits or eaves) and exhaust vents (at the ridge). This system creates a continuous flow of ambient air that removes the super-heated, moist air that builds up in the attic. Without adequate ventilation, the attic becomes a solar oven. This trapped heat bakes the shingles from below, drastically accelerating the loss of their volatile compounds and leading to premature brittleness and curling. Simultaneously, trapped moisture condenses on the underside of the roof deck, where it is absorbed by the sheathing and the shingles, causing them to curl.

Incorrect Nailing: A Critical Point of Failure

The placement and depth of fasteners are not matters of opinion; they are dictated by manufacturer specifications and building codes. A failure to adhere to this protocol is a critical point of failure. Common errors include:

- High-Nailing: Placing the nail above the designated nailing strip. This error means the nail only penetrates a single layer of shingle, dramatically reducing its wind uplift resistance.

- Overdriven Nails: Using too much pressure with a pneumatic nail gun, causing the nail head to break through the shingle’s surface. This fractures the mat and creates a direct path for water intrusion.

- Underdriven Nails: Leaving the nail head elevated. This prevents the shingle above from sealing correctly and can eventually puncture it.

- Angled Nails: Driving the nail at an angle, which causes the nail head to cut into the shingle material, weakening it.

These are not minor issues. They are fundamental errors that undermine the entire system’s structural integrity.

Layering Shingles (Re-Roofing): Introducing Unnecessary Variables

Installing a new layer of shingles over an existing one is a shortcut that introduces unacceptable variables into a roofing project. This practice is a hallmark of contractors focused on providing the lowest price, not the best outcome. It creates two significant problems:

- Heat Trapping: The extra layer of material acts as an insulator, trapping even more heat and accelerating the degradation of both the new and old shingles.

- Uneven Surface: The new shingles cannot lie perfectly flat over the uneven surface of the old ones. This creates gaps and voids that prevent proper sealing and make the roof more vulnerable to wind uplift. Furthermore, it prevents inspection of the roof deck for rot or damage—a non-negotiable step in any professional process.

Diagnostic Framework: How to Methodically Assess Your Roof

You do not need to be a roofer to perform a preliminary assessment of your roofing system. A methodical visual inspection from the ground can provide the objective data needed to determine if a professional, on-roof analysis is warranted. This is about risk mitigation through observation.

A Step-by-Step Self-Inspection Checklist (From the Ground)

Execute this process systematically. Use binoculars for a detailed view. Never get on your roof yourself. The risk of a fall is unacceptable.

From multiple points on your property, observe the overall planes of the roof. Look for any noticeable sagging, unevenness, or dark patches that may indicate moisture.

Systematically scan each roof slope. Identify areas with lifted (curling) or cupped (clawing) shingles. Note any missing shingles or visible ‘bald’ spots where granules are gone.

Examine the area around your downspouts for an accumulation of black, sand-like ceramic granules. An excessive amount indicates the roof is nearing the end of its functional life.

Using binoculars, inspect the flashing and seals around chimneys, pipes, and vents. Look for cracked sealant, rusted metal, or shingles that are lifting away from these critical areas.

Interpreting the Data: When to Engage a Professional

If your inspection reveals widespread shingle curling, significant granule loss, or any other signs of systemic wear, the next logical step is to engage a professional for a comprehensive assessment. A true professional assessment extends beyond a simple visual look. It should include an inspection of the attic space to analyze ventilation and check for signs of moisture, the use of moisture meters to detect non-visible leaks, and potentially infrared thermography to identify areas of heat loss or moisture retention. The output should be a detailed, documented report of the system’s condition, not a hastily scribbled quote.

The Antidote to Chaos: A Process-Driven Roofing Solution

The standard roofing experience is defined by chaos: vague estimates, unpredictable timelines, messy job sites, and poor communication. The root of this chaos is a lack of process. RocStout was founded on the principle that a complex construction project demands a rigorous, transparent, and predictable methodology. We treat your roof as the critical building system it is, and we manage its replacement with the precision you expect for any significant investment.

Why a Comprehensive Roof System Analysis is Non-Negotiable

We do not provide simple ‘quotes’. We produce a comprehensive roof system analysis. Before any price is discussed, we conduct a holistic assessment of your entire roofing assembly. This includes:

- A full inspection of the roof surface, deck, and flashing systems.

- A detailed calculation of your attic’s ventilation requirements to ensure the new system meets or exceeds building code.

- A core sample analysis if necessary to understand existing layers.

- A clear specification of all materials, from underlayment to fasteners to shingles.

The result is a written proposal that functions as a project blueprint. It eliminates ambiguity, defines every step of the installation protocol, and establishes a fixed project scope. There are no surprises.

Predictability Over Price: Our Commitment to Meticulous Clients

Our process is meticulous, documented, and transparent. It is engineered to produce a predictable, stress-free outcome and ensure the long-term protection of your home. This approach is not designed to generate the lowest possible price. It is designed to deliver the highest possible value and eliminate the risks associated with shortcuts and poor workmanship.

If your primary decision variable is securing the cheapest bid, we are not the right partner for your project.

Our clients are organized, intelligent homeowners who understand the lifecycle cost of their assets. They choose us because they value order over ambiguity. They receive a dedicated project manager, a clear project timeline, proactive communication, and an unwavering commitment to quality control. We do not just replace shingles; we execute a predictable process that delivers a superior roofing system and protects your peace of mind.