A roof is the top covering of a building, engineered to provide protection against rain, snow, sunlight, extremes of temperature, and wind. Of these environmental forces, sunlight contains an element that causes silent, cumulative damage: ultraviolet (UV) radiation. UV degradation is a chemical process that systematically breaks down the essential components of roofing materials, primarily the bitumen in asphalt shingles, compromising their protective function and reducing the operational lifespan of the entire roofing system.

The Function of Shingles in Your Roof’s Protective System

A roofing system is an assembly of integrated components. The shingles are the primary line of defense, the system’s most visible and most exposed element. Their function is absolute: to form a durable, water-shedding barrier that protects the building’s structure and its occupants. Understanding their composition is critical to understanding their vulnerabilities.

Anatomy of an Asphalt Shingle: Granules, Bitumen, and Mat

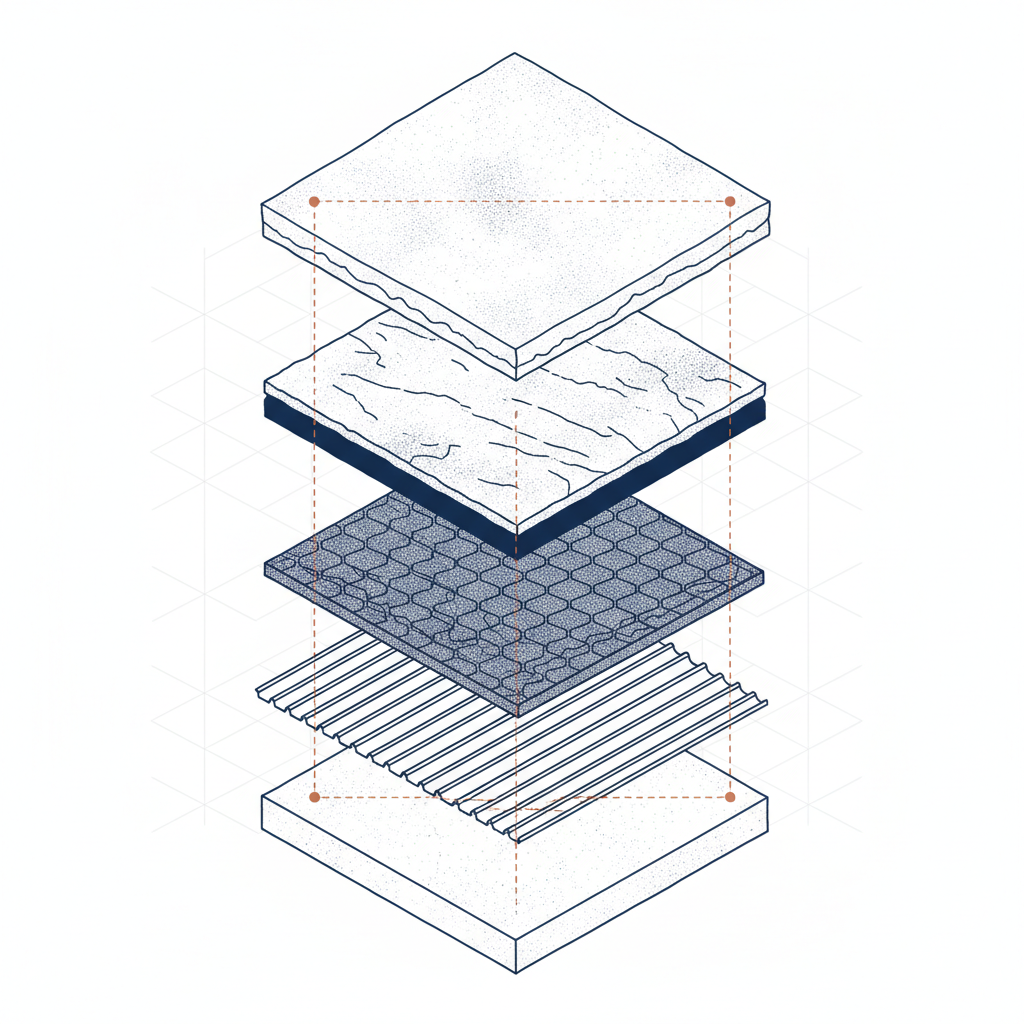

An architectural asphalt shingle is not a monolithic product. It is a composite material engineered with three distinct layers, each serving a critical function:

- Ceramic Granules: This is the outermost layer you see. These hard, dense particles are adhered to the surface of the shingle. Their primary function is to block ultraviolet radiation from reaching the underlying asphalt. They also provide color and add a degree of fire resistance. Granules are the shingle’s sacrificial shield.

- Asphalt Bitumen: This is the waterproofing agent and the core functional component. It is a petroleum-based substance that makes the shingle impervious to water. Its flexibility allows the shingle to conform to the roof deck and withstand minor impacts and thermal-induced movement.

- Fiberglass Mat: This is the shingle’s structural core or skeleton. The fiberglass mat provides dimensional stability, tear resistance, and strength. The asphalt bitumen is saturated into this mat to create the final, cohesive product.

Defining the Protective Barrier Against Rain, Snow, and Wind

The synergy of these layers creates a formidable barrier. The shingle’s shape and overlapping installation pattern use gravity to shed rain and snow effectively. The asphalt content ensures water cannot penetrate the material itself. Factory-applied sealant strips on each shingle are thermally activated by the sun after installation, bonding the shingles together to create a monolithic, wind-resistant surface. When this system is intact, it performs its function with high reliability. UV degradation is the primary process that dismantles this system over time.

The Mechanics of UV Degradation on Roofing Materials

The relentless exposure to sunlight initiates a destructive chemical process within the shingle’s most critical layer: the asphalt bitumen. This process, known as photodegradation, is accelerated by daily temperature fluctuations, creating a compounding cycle of material failure.

Photodegradation: How UV Rays Break Down Asphalt Bitumen

Photodegradation is the breakdown of chemical bonds by photons, specifically the high-energy photons found in ultraviolet light. When UV radiation strikes the asphalt, it transfers energy to the hydrocarbon molecules within the bitumen. This energy breaks the chemical bonds that give the asphalt its flexibility and adhesive properties. The process has several observable effects:

- Volatilization: The lighter oils and resins within the bitumen, which act as plasticizers, are cooked off. This process is analogous to evaporation.

- Oxidation: The loss of these oils allows oxygen to penetrate and react with the remaining asphalt, making it harder and more rigid.

- Brittleness: The combined result of volatilization and oxidation is a shingle that has lost its flexibility. It becomes brittle, similar to how an old rubber band loses its elasticity and cracks when stretched.

A brittle shingle can no longer effectively expand and contract, nor can it resist physical impacts from hail or debris. It has fundamentally failed as a protective material.

Thermal Cycling: The Impact of Temperature Extremes

Thermal cycling refers to the expansion and contraction of roofing materials due to daily and seasonal temperature changes. A new, healthy shingle has the flexibility to accommodate this movement without issue. However, when photodegradation has made the shingle brittle, thermal cycling becomes a destructive force. The constant stress of expansion in the heat of the day and contraction in the cool of the night induces micro-cracks in the shingle’s surface. This process is known as thermal shock. Over thousands of cycles, these micro-cracks propagate and deepen, creating pathways for water intrusion and accelerating the overall deterioration of the roofing system.

Observable Indicators of Advanced UV Damage

A systematic roof inspection is not guesswork. It is a process of failure analysis, identifying clear, quantifiable indicators of material degradation. For a meticulous homeowner, understanding these indicators allows you to assess the condition of your primary asset and plan accordingly, avoiding the chaos of an emergency replacement.

Granule Loss Analysis: Quantifying Reduced UV Protection

Granule loss is the first and most obvious sign of aging. As the underlying asphalt bitumen loses its oils, its ability to securely hold the protective granules weakens. Rain and wind then easily dislodge them.

- Assessment Point 1: Examine the contents of your gutters and the area around your downspouts. A significant accumulation of black or colored sand-like particles indicates accelerated granule loss.

- Assessment Point 2: Visually inspect the roof surface for \”bald spots.\” These are areas where the black asphalt underlayer is exposed due to granule loss. Each bald spot is a point of direct UV exposure, creating a feedback loop of accelerated aging for that shingle and those around it.

Identifying Stress Cracks and Brittleness in Shingles

As volatilization and oxidation progress, the shingle surface begins to exhibit visible stress cracks. This is not mechanical damage from an impact; it is evidence of internal material failure. These fine, random cracks, often called crazing, indicate the shingle has lost its tensile strength and flexibility. A shingle in this state is highly vulnerable to hail, which can shatter it, or wind, which can easily snap a curled edge.

Diagnosing Curling and Cupping as Symptoms of System Failure

Curling and cupping are terminal signs of shingle failure caused by UV degradation. As the asphalt shrinks from the loss of its volatile oils, it creates tension with the stable fiberglass mat. This tension forces the shingle to deform.

- Curling: The edges of the shingle tab lift upwards, breaking the sealant bond with the shingle below.

- Cupping: The center of the shingle tab dips or buckles while the edges remain flat.

Both conditions create entry points for wind-driven rain and significantly increase the roof’s vulnerability to wind uplift. A roof exhibiting widespread curling or cupping has ceased to function as a unified, sealed system.

Systemic Factors That Accelerate Sunlight Degradation

The rate of UV degradation is not uniform. It is influenced by the entire roofing system’s design and orientation. A professional assessment considers these systemic factors, while a typical contractor often ignores them, leading to premature failure even with new materials.

The Role of Roof Orientation and Angle in UV Exposure

The orientation of your home dictates which roof slopes receive the most intense solar radiation. In the Northern Hemisphere, south-facing slopes receive the most direct sunlight throughout the day, while west-facing slopes receive the most intense heat and UV exposure in the afternoon. Consequently, these slopes will almost always show signs of degradation years before north-facing slopes. Roof pitch also plays a role; a lower-pitched roof receives more perpendicular sunlight, concentrating UV exposure, while a steeper pitch may have more varied exposure patterns.

How Improper Ventilation Traps Heat and Destroys Shingles

This is the most critical and most frequently overlooked factor in roof longevity. An attic space without a balanced intake and exhaust ventilation system becomes a superheated oven in the summer. This trapped heat radiates upward, baking the shingles from the underside. This constant, extreme heat drastically accelerates the volatilization of the oils in the asphalt, effectively doubling the destructive force of the UV radiation striking the top surface. A poorly ventilated roof will always fail prematurely. It is a systemic defect that no quality of shingle can overcome.

A Methodical Approach to Roof Longevity and Replacement

The roofing industry is rife with chaos, vague promises, and unpredictable outcomes. This is unacceptable for a significant capital investment like a roof replacement. Our entire philosophy is built on eliminating chaos through a transparent, predictable, and data-driven process. We are not the right fit for homeowners whose primary decision-making factor is the lowest possible price. We are the right fit for clients who value order, clarity, and the long-term integrity of their home.

Our Diagnostic Process vs. The Typical Contractor’s Guess

The typical roofing estimate is based on a quick ground-level observation or a brief walk on the roof, resulting in a vague, one-page quote. This is a guess, not an analysis. Our process is fundamentally different. We conduct a systematic, multi-point inspection of the entire roofing system, from the decking and ventilation to the flashing and shingle condition. We document our findings with photographic evidence and provide you with a detailed report that explains not just *what* is wrong, but *why* it is wrong. This data-driven approach removes all guesswork and forms the basis for a precise, accurate project plan.

Material Selection Based on Performance, Not Just Price

Bargain-priced shingles are a false economy. They often use lower-grade bitumen and fewer performance-enhancing polymers, making them more susceptible to UV degradation from day one. Our material selection process prioritizes long-term performance and value. We recommend products from reputable manufacturers with proven track records for durability and strict quality control. We will guide you through options like shingles with enhanced UV-reflective granules or cool roof technologies that lower surface temperatures, directly mitigating the factors discussed in this analysis. We specify materials that solve problems, not just cover them.

Executing a Predictable Project Plan to Eliminate Chaos

A roof replacement project should not introduce stress and disorder into your life. Our commitment is to a completely predictable experience, managed with the precision of an engineering project. This is our non-negotiable standard of care.

Comprehensive data collection on the entire roof system. We provide documented findings and a precise scope of work.

A detailed, fixed-price proposal with no hidden fees. A project plan and timeline are established and agreed upon.

All materials are ordered, verified for quality, and staged. Logistics are planned to minimize site disruption.

A dedicated Project Manager serves as your single point of contact, providing frequent updates. You are never in the dark.

A multi-point quality control checklist is executed. The job site is meticulously cleaned and demobilized.

We conduct a final walkthrough with you to ensure absolute satisfaction and deliver all project and warranty documentation.