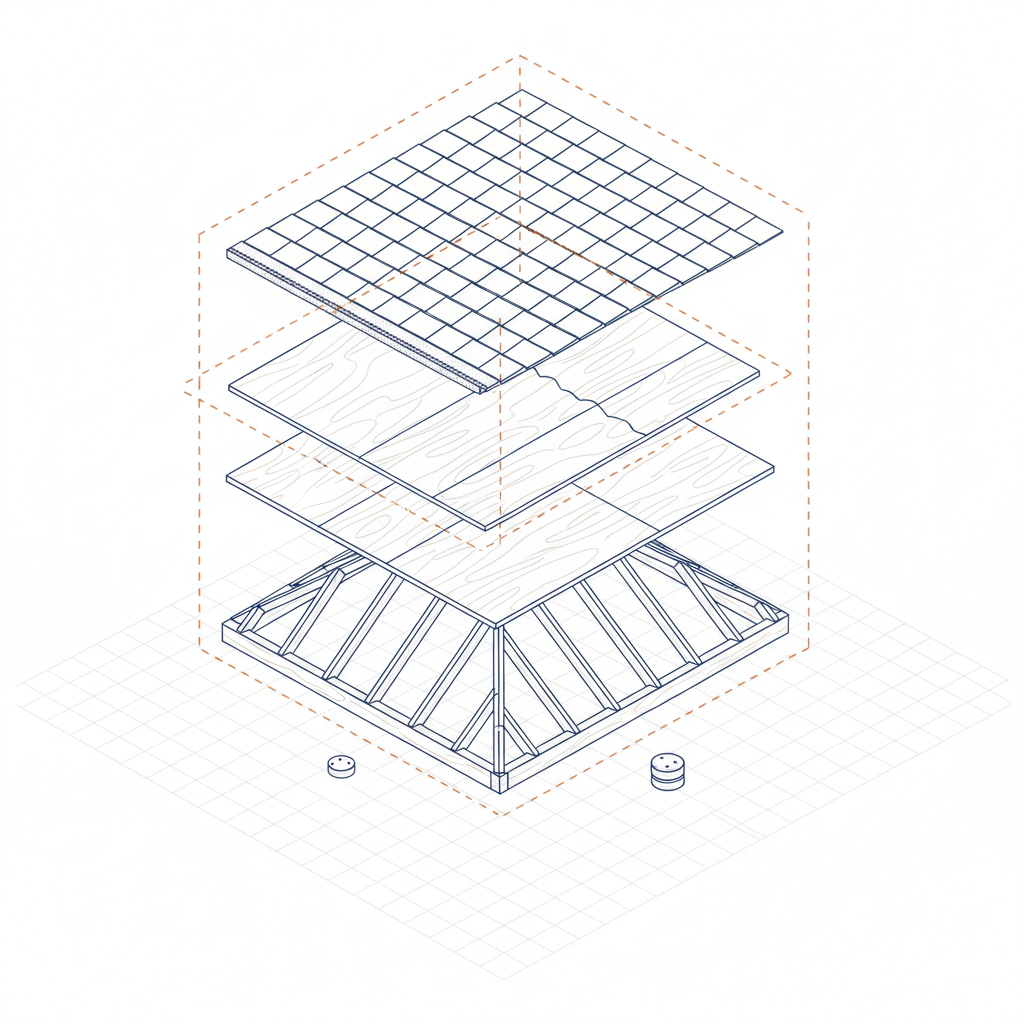

Roof deck delamination is the structural failure of the sheathing layer that forms the foundation of a complete roofing system. This condition, often called rot, represents a critical compromise to the core support structure of your home’s primary protective covering. A roof functions as an integrated system, a top covering designed with specific materials and constructions to provide absolute protection against rain, snow, sunlight, extremes of temperature, and wind. The roof deck, or sheathing, is the load-bearing surface upon which all other materials—underlayment, flashing, and shingles—depend. Its failure is not an isolated issue; it is a systemic breakdown that demands a precise, methodical response. The standard industry approach often treats symptoms, leading to chaotic project management and recurring problems. Our methodology focuses on a complete diagnosis and a predictable, systematic solution, ensuring the structural integrity of your home’s most vital asset.

Defining Roof Deck Rot: The Compromise to Your Roof’s Core Support

Roof deck rot is the decomposition of the wood sheathing—typically plywood or Oriented Strand Board (OSB)—caused by prolonged exposure to moisture. This is not a cosmetic flaw. It is a fundamental degradation of the structural support system responsible for holding the weight of the roofing materials, resisting wind uplift, and transferring loads to the building’s frame. Understanding the components and their specific failure modes is the first step in a logical diagnostic process.

The Function of Roof Decking in a Complete Protection System

The roof deck functions as the substrate for the entire roofing assembly. It is the solid plane that creates the top of the building envelope. Its first job is load-bearing; it must support the dead load of roofing materials and the live loads from snow, ice, and maintenance personnel. Its second job is to provide a uniform, stable surface for the secure attachment of the underlayment and shingles. Without a solid deck, fasteners will not hold, and the waterproofing layers will buckle and fail. The deck is the essential link that enables the outer coverings to provide protection from the elements. A compromised deck nullifies the effectiveness of every other component.

Differentiating Between Plywood and OSB Decking Failures

The two most common materials used for roof decking are plywood and Oriented Strand Board (OSB). While they serve the same function, their material science dictates how they fail under moisture stress. Acknowledging these differences is critical for accurate diagnosis. Plywood undergoes delamination, where the layers of wood veneer separate. OSB, composed of compressed wood strands and resins, tends to swell, lose its compressive strength, and disintegrate into a soft, spongy mass.

| Material | Composition | Failure Mode Under Moisture | Visual/Tactile Indicator |

|---|---|---|---|

| Plywood Sheathing | Layers of wood veneer glued together. | Delamination: The adhesive fails, and the layers separate. | Visible peeling or separation of layers, often seen from the attic. |

| Oriented Strand Board (OSB) | Wood strands and flakes compressed with adhesive resins. | Swelling and Disintegration: Absorbs water, swells (especially at edges), and loses structural integrity. | Spongy feel underfoot, swollen seams between boards. |

Diagnostic Checklist: Verifiable Signs of Roof Deck Deterioration

An accurate diagnosis is built on verifiable evidence, not guesswork. A systematic inspection protocol allows for the identification of clear symptoms of roof deck failure. These indicators can be found inside the home, on the roof’s surface, and within the attic structure. Each sign is a data point that contributes to a complete understanding of the system’s condition.

Interior Indicators: Ceiling Stains and Peeling Paint Analysis

Water stains on your ceiling or walls are the final manifestation of a multi-stage failure. For a stain to appear, water must breach the shingles, penetrate the underlayment, saturate the roof deck, and finally leak through your insulation and drywall. These stains, often yellowish or brown, are definitive proof of water intrusion. Similarly, peeling or bubbling paint on ceilings is a direct result of moisture saturating the drywall from above. These are not minor issues to be painted over; they are alerts that the entire roofing system’s integrity is compromised.

Exterior Surface Assessment: Spongy or Soft Spots Underfoot

A structurally sound roof deck provides a firm, solid surface. When walking on the roof during a professional inspection, any spongy, soft, or bouncy feedback underfoot is a primary indicator of advanced deck rot. This softness is the physical result of wood fibers that have decomposed and lost their ability to resist compression. An uneven surface or visible dips and sags in the roofline also point to deterioration in the underlying sheathing, which can no longer maintain a flat, uniform plane.

Shingle Condition Analysis: Advanced Curling, Buckling, and Dark Stains

The condition of your asphalt shingles is directly linked to the stability of the deck beneath them. When the roof deck absorbs moisture, it can cause the fasteners (nails) to loosen their grip. This allows shingles to lift, curl at the edges, or buckle along their courses. While aging can also cause these symptoms, advanced or localized curling often indicates a problem with the substrate. Dark, wet-looking stains on shingles that persist long after a rainstorm can also signal that the sheathing below is saturated and unable to dry out, trapping moisture against the shingle’s organic matting.

Attic & Rafter Inspection: Mapping Water Stains and Black Mold

The most direct and unambiguous assessment of the roof deck occurs in the attic. From this vantage point, the underside of the sheathing is visible. A systematic inspection with a powerful flashlight will reveal dark water stains on the wood, often following the path of rafters or originating from penetration points. The presence of damp wood or, in advanced cases, visible black mold, is conclusive evidence of a long-term moisture problem. These findings allow a technician to map the exact locations and extent of the damage, forming the basis for a precise scope of work.

Root Cause Analysis: How Moisture Breaches Your Roof’s Protection System

Identifying the symptoms of rot is the first phase. The second, more critical phase is determining the root cause of the moisture intrusion. A successful repair protocol does not just replace damaged materials; it corrects the systemic flaw that allowed the failure to occur. Water penetration can be traced to one of four primary causes.

Material Failure: Compromised Shingles and Underlayment

The outer covering of the roof—the shingles—is the first line of defense. As asphalt shingles age, they lose their protective granules, become brittle, and can crack or tear. This allows water to reach the underlayment. The underlayment provides a secondary layer of waterproofing, but it is not designed for permanent exposure. If this layer is also damaged or improperly installed, water will inevitably reach and saturate the wood deck.

Inadequate Ventilation: Trapped Moisture from Temperature Extremes

Moisture damage is not always from an external leak. In many cases, it originates from inside the attic. During colder months, warm, moist air from the living space rises into the attic. If the attic lacks a balanced ventilation system (equal intake at the soffits and exhaust at the ridge), this moisture-laden air becomes trapped. It then condenses on the cold surface of the roof deck, creating a persistent dampness that rots the wood from the inside out. This is a common, and often misdiagnosed, cause of widespread sheathing failure.

Systemic Weak Points: Flashing, Sealant, and Penetration Failures

A roof is not a monolithic surface. It is penetrated by chimneys, plumbing stacks, roof vents, and skylights. Each of these points requires a specialized installation of flashing—metal components designed to channel water away from the joint. The integrity of these systems relies on both the metal itself and the sealants used. Over time, sealants degrade under UV exposure and temperature cycles. A failure in the flashing system creates a direct and often significant path for water to enter and damage the deck.

Ice Dam Formation: The Impact of Snow and Freeze-Thaw Cycles

In colder climates, ice dams present a significant threat. They form when snow melts on a warmer upper portion of the roof and refreezes at the colder eaves. This ridge of ice, often in the gutters, blocks proper drainage. Water pools behind the dam, submerging the lower courses of shingles. This standing water works its way under the shingles and through the underlayment, saturating the eaves and lower sections of the roof deck. This concentrated, prolonged exposure leads to severe and localized rot.

Risk Assessment: The Structural and Financial Costs of Unaddressed Rot

Deferring the repair of a rotted roof deck is not a viable financial strategy. It is a decision that allows a manageable problem to escalate into a catastrophic structural and financial liability. A logical assessment of the risks demonstrates the clear necessity of immediate, decisive action.

Quantifying the Impact on Your Building’s Structural Integrity

A rotted roof deck loses its designed load capacity. This means its ability to support snow loads or the weight of personnel is severely diminished, creating a risk of collapse. The rot can also spread to adjacent structural members, such as rafters and trusses. Once these primary supports are compromised, the repair transitions from a sheathing replacement to a major structural rebuild, often requiring engineering oversight and violating building codes until corrected. This is a direct threat to the safety and integrity of your home.

Projecting Escalating Costs: Why Delaying Repairs is Illogical

The cost of replacing a few sheets of plywood is linear and predictable. The cost of allowing that rot to continue is exponential. Unchecked moisture leads to mold remediation, drywall and paint repair, insulation replacement, and potential damage to electrical systems. What begins as a roofing project can quickly spiral into a multi-trade restoration. A predictable, fixed-cost roof deck replacement is a sound investment. An emergency repair after a ceiling collapses is an exercise in damage control with an unpredictable budget. Delay introduces scope creep and eliminates cost control.

The Solution Protocol: A Predictable Process for Roof Deck Replacement

The enemy of a successful home construction project is chaos. Vague timelines, surprise charges, and poor communication are the hallmarks of a broken process. We have engineered a solution protocol designed to deliver a predictable, stress-free outcome. Our methodology is the only sane way to manage the complexity of a roof replacement.

Step 1: Meticulous Inspection to Eliminate Surprise Charges Our process begins not with a quick estimate, but with a thorough, multi-point inspection of the entire roofing system. We assess the exterior, analyze the attic, and map all existing and potential failure points. This data allows us to develop a precise, fixed-price scope of work. You will know exactly what needs to be done and exactly what it will cost before the project begins. We eliminate the hidden fees and surprise up-charges that define the typical contractor experience. Predictability is our primary deliverable.

Step 2: Transparent Communication vs. Industry Chaos Upon project approval, you are assigned a dedicated Project Manager who serves as your single point of contact. You will receive a detailed project schedule and regular, proactive updates. Our job sites are organized and clean. Our crews are professional. We answer the phone. This is not a revolutionary concept, but in the construction industry, it is a radical commitment to order. You will never be left wondering about the status of your project. We manage the logistics so you can continue with your life.

Step 3: Quality Control and Project Closeout A project is not complete simply because the shingles are installed. Our protocol mandates a rigorous closeout phase. We conduct a final, multi-point quality assurance walkthrough to ensure every detail meets our exacting standards. We perform a final magnetic sweep to ensure the safety of your property, process all manufacturer warranty documentation on your behalf, and provide a comprehensive project record. We do not disappear after the final check; we ensure the handover is as structured as the installation.

Our Commitment to Order: Why We Are Not a Low-Bid Contractor We must be clear. If your primary decision variable is finding the lowest possible price, we are not the right partner for your project. Our process, our materials, and our master craftsmen are not commodities. We have built our business to serve meticulous homeowners who value certainty, communication, and a predictable outcome above all else. Our clients choose us to eliminate the risk and chaos inherent in the standard roofing process. The premium for our service is not for materials; it is for a guaranteed, stress-free result and a long-term solution that protects your investment. We are not for everyone, and we are confident in the value we provide to the clients who are right for us.