A predictable roof replacement is a systematic protocol that deconstructs and rebuilds a building’s top covering through a series of controlled, documented phases. The function of this system is absolute: to provide unwavering protection against rain, snow, sunlight, extreme temperatures, and wind. The conventional roofing process, however, is a study in chaos. It is characterized by vague timelines, opaque pricing, inconsistent communication, and a fundamental lack of respect for your property. This is unacceptable.

The RocStout Protocol is the antithesis of that chaos. It is a meticulously engineered methodology designed for homeowners who value order, clarity, and precision. We operate on the principle that a successful project is not an accident; it is the inevitable outcome of a superior process. This document outlines that process in detail. It is not for everyone. If your primary decision-making criterion is the absolute lowest price, we are not the right firm for you. Our process is designed to deliver a specific result—predictability—for a client who understands that value is a function of eliminating risk, not just minimizing cost.

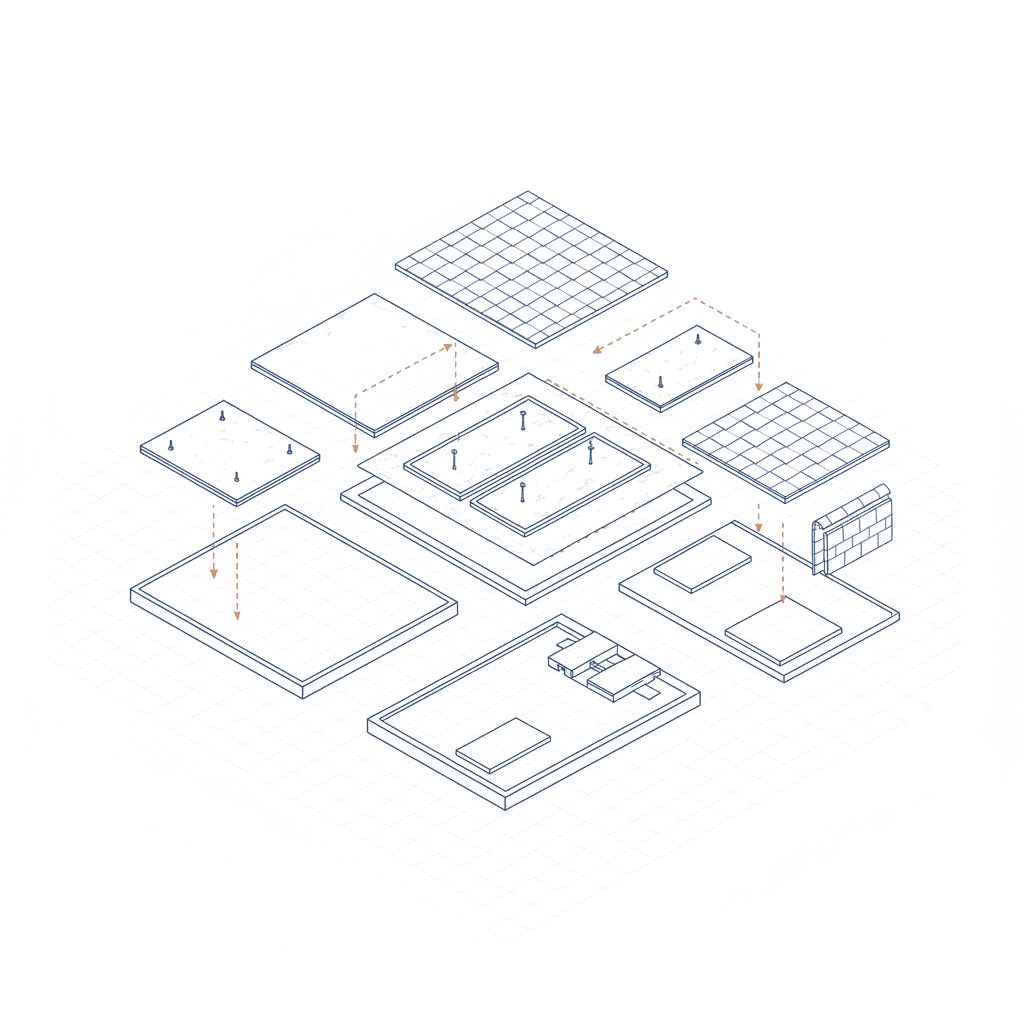

Phase 1: Pre-Construction Planning & System Design

The success of a roof replacement is determined before a single roofer steps on your property. Phase 1 is a data-driven diagnostic and engineering stage. We do not guess; we analyze, design, and specify every component of the complete roof system. This methodical approach ensures the project scope is precisely defined, building code requirements are met, and the final cost estimate is an accurate reflection of the work required.

Comprehensive Roof System Analysis: Beyond a Basic Inspection

A standard \”free estimate\” often involves a cursory glance from the ground. This is insufficient. Our analysis is a forensic examination of the entire roofing assembly. We begin by assessing the structural integrity of the existing system, which includes a detailed inspection of the roof decking condition from within the attic where possible. We identify any signs of water damage, delamination, or sagging that indicate underlying issues. A comprehensive ventilation assessment is performed to calculate the required intake and exhaust NFA (Net Free Area), ensuring the new system manages attic temperature and moisture correctly. This is not just an inspection; it is a risk assessment designed to identify every variable before work begins.

Material Selection: Balancing Performance, Longevity, and Environmental Factors

The materials selected for your roof are the primary defense against environmental forces like intense sunlight and temperature extremes. We guide you through a selection process based on empirical data, not salesmanship. The choice of roofing materials, from asphalt shingles to standing seam metal, is weighed against performance metrics. The synthetic underlayment, flashing materials, and fasteners are specified as an integrated system, not a collection of disparate parts. Every component is chosen to contribute to the roof’s primary function: providing robust and lasting protection.

| Material Attribute | Architectural Asphalt Shingles | Standing Seam Metal Roofing |

|---|---|---|

| Expected Lifespan | 25-30 years | 50+ years |

| Wind Resistance (Standard) | Up to 130 mph | Up to 140+ mph |

| Fire Rating | Class A | Class A (Non-combustible) |

| Initial Investment | Moderate | High |

| Maintenance Requirement | Low | Very Low |

Project Scoping & Transparent Cost Engineering

Ambiguity is the enemy of a successful project. Your roofing contract will be a detailed statement of work with a line-item estimate. Every component, from material costs to labor costs, is clearly articulated. We engineer the cost of the project with full transparency. Contingencies for potential decking replacement are defined upfront, so you understand the exact cost per sheet if required. There are no hidden fees. There are no surprise charges. The price we agree upon is the price you pay for the work we have defined. This is the only sane way to manage a significant home investment.

Phase 2: Site Preparation & Systematic Deconstruction

The physical work begins with an unwavering focus on control and order. This phase is dedicated to isolating the work area to protect your property and systematically removing the old roof to expose the foundational structure. Job site safety and meticulous debris management are not afterthoughts; they are central to the protocol.

Establishing a Controlled Job Site Environment to Mitigate Chaos

Your home is a construction zone, but it does not need to feel like a disaster area. We establish a controlled environment before any deconstruction begins. This includes deploying heavy-duty tarps to protect landscaping, siding, and windows. Driveways are shielded from dumpsters. Site logistics are planned to ensure a clear and safe path for material and waste disposal. At the end of each day, the site is organized and cleaned. This daily cleanup protocol minimizes disruption and maintains order throughout the project.

Systematic Roof Tear-Off: Exposing the Core Structural Decking

The roof tear-off is not demolition; it is a precise deconstruction. We remove the old shingles, underlayment, and fasteners in sections. This methodical process allows for a continuous and thorough decking inspection as the structure is exposed. Every square foot of the roof decking is examined for water damage, dry rot, or improper fastening to the structural supports. This is the final and most critical diagnostic step, confirming the integrity of the foundation upon which the new, complete roofing system will be built. This is non-negotiable for ensuring the longevity of your new roof.

Phase 3: Structural Fortification & Weatherproofing Installation

With the roof stripped to its foundational decking, we begin the construction of a robust, multi-layered defense against water intrusion and extreme weather. This phase is about building resilience from the structure up. It involves repairing the roof structure, installing redundant water barriers, and integrating a ventilation system that protects the building materials from premature degradation.

Decking Repair and Reinforcement: The Foundation of Your Roof

The roof deck is the structural foundation of the entire system. Any compromised plywood sheathing or OSB is removed and replaced with new, code-compliant materials. We verify the fastening schedule to ensure the decking has maximum resistance to wind uplift forces. If any underlying rafter or building uprights show signs of damage, they are repaired or reinforced. A weak foundation guarantees a failed roof; therefore, we ensure its absolute structural soundness before proceeding.

Installing the Water Barrier: Underlayment and Ice & Snow Shields

The primary weatherproofing layer is installed directly onto the prepared deck. This system acts as the last line of defense against water intrusion from rain and snow. The process is layered and systematic.

Repaired and structurally sound plywood or OSB sheathing.

A self-adhering membrane applied to eaves, valleys, and penetrations for superior snow and ice dam protection.

High-performance synthetic felt is applied to the entire remaining roof deck, providing a secondary layer of rain protection.

Metal components installed at edges and transitions to direct water away from the structure.

Critical Flashing Installation at All Penetrations and Transitions

Flashing is the single most critical component for preventing leaks. The vast majority of roof failures occur at penetrations (chimneys, vent pipes) and transitions (valleys, walls). We install new, custom-fabricated or manufacturer-specified flashing systems at every vulnerable point. This includes chimney flashing, valley flashing, step flashing along walls, and new boots for every vent pipe. This is an area where shortcuts are common in the industry. For us, precise water diversion engineering is mandatory.

Ventilation System Integration: Managing Temperature and Moisture

A roof is not just a shield; it is a breathing system. A balanced ventilation system—combining soffit vents for intake and a ridge vent for exhaust—is essential for managing attic temperature and controlling moisture. This protects the structural integrity of the roof deck from rot and mold, prevents the formation of ice dams in winter, and improves the overall energy efficiency of your home. The system is designed to extend the life of all building materials, from the shingles to the insulation.

Phase 4: Final Covering Installation & System Completion

This phase involves the precise application of the final roof covering. It is a systematic process governed by manufacturer specifications and engineering best practices to ensure maximum wind resistance and a complete, watertight seal. Every detail, from the nailing pattern to the sealant application, is executed with technical precision.

Shingle Installation: A Grid-Based, Systematic Application

We install shingles according to a precise, grid-based layout. A starter strip is applied at all eaves and rakes to provide a secure base and prevent wind uplift. Each shingle is installed with the correct exposure and fastened with the manufacturer-specified number of nails in the designated nailing zone. This exact nailing pattern is critical for validating the material warranty and ensuring the system’s rated wind resistance. The process is uniform and repeatable, resulting in a functionally superior and aesthetically flawless finish.

Ridge Cap and Hip Shingle Installation for Maximum Protection

The roof’s peaks (ridges) and angled transitions (hips) are high-exposure areas that bear the brunt of wind and weather. We install specialized ridge cap and hip shingles designed to provide enhanced protection at these critical points. They create a secure, overlapping seal that completes the system’s integrity and prevents weather from penetrating the most vulnerable lines of the roof.

Final Sealant Application and Component Integration

The last step in creating a watertight seal is the application of high-grade roofing sealant. This is used to seal all pipe boots, flashing terminations, and any exposed fasteners. This final detailing ensures every potential point of entry for water is permanently closed, rendering the entire roof covering a monolithic, impenetrable barrier.

Phase 5: Quality Assurance & Meticulous Project Close-Out

A project is not complete until it has been verified and the site has been returned to its original condition. This final phase is a formal process of quality control, site decontamination, and documentation handover. It is our final proof of a job executed to the highest standard.

The Multi-Point Final Inspection Checklist for Flawless Execution

Upon completion of the installation, a project manager conducts a multi-point final inspection. This is not a casual walkthrough. It is a rigorous quality control audit against a detailed checklist. We verify workmanship quality, confirm adherence to installation standards and code compliance, inspect all flashing and sealant points for leak prevention, and perform a final aesthetic review. Nothing is left to chance.

Meticulous Site Decontamination and Final Cleanup

Our commitment to order extends through the final moments of the project. A complete site cleanup is performed. This includes a magnetic sweep of the entire property perimeter to collect errant nails and fasteners. Gutters are cleared of any debris generated during the project. We do not leave until your property is restored to its pre-project condition, or better.

Warranty Activation and Project Documentation Handover

As part of the project close-out, we formally activate your manufacturer warranty and provide our own workmanship warranty. You will receive a complete project portfolio containing all relevant documentation, including the contract, material specifications, and warranty certificates. We also provide a simple maintenance guide to ensure the long-term performance of your new roof. Final payment is requested only after you have signed off on the project’s completion, confirming your total satisfaction.

The RocStout Methodology: Executing a Predictable, Orderly Process

The five phases above are the mechanics of a roof replacement. How they are managed, communicated, and executed is what separates a predictable, stress-free experience from a chaotic, anxiety-inducing ordeal. The RocStout Methodology is our operational commitment to order and transparency.

An Important Distinction: The Low-Bid Contractor vs. The Process-Driven Firm

Let us be clear. If you are seeking the cheapest roofer, you will find one. That low-bid contractor makes their profit by creating chaos. Their business model relies on vague contracts, surprise change orders, the use of substandard materials, and cutting corners on critical but unseen details like flashing and underlayment. They gamble with your home to protect their thin margin.

We are a process-driven firm. Our price reflects the cost of eliminating that gamble. It includes superior materials, meticulous site protection, rigorous quality control, and dedicated project management. We do not compete on price; we compete on process. The result is a higher initial investment but a dramatically lower total cost of ownership and zero stress.

Your Dedicated Project Manager: A Single Point of Contact, Not a Void

The most common complaint in the construction industry is a lack of communication. Once the contract is signed, the salesperson disappears, and you are left to deal with a crew with whom you may not even share a language. This is the void we have eliminated. From day one, you are assigned a dedicated Project Manager. This individual is your single point of contact for the duration of the project. They are responsible for providing you with regular project updates, answering your questions, and ensuring the entire process adheres to the documented plan. This structure creates absolute accountability.

Our Commitment: A Predictable Schedule, A Transparent Price, and Absolute Order

Our entire protocol is engineered to deliver three core outcomes. First, a predictable project timeline that we communicate clearly and adhere to rigorously. Second, a fixed, transparent price that protects you from the hidden costs and financial surprises that define the industry standard. And third, a level of job site order that demonstrates our respect for your property. This is our promise. It is the only way we work.