A ridge vent is an exhaust component of a balanced attic ventilation system, engineered to create a continuous point of egress for hot, moist air at the highest peak of a roof. Its function is integral to the primary purpose of a roof: to serve as the top covering of a building that provides absolute protection against rain, snow, sunlight, and the damaging effects of temperature extremes and moisture. A properly engineered ventilation system is not an option; it is a prerequisite for the structural longevity of the entire roof assembly. The alternative is a predictable sequence of material degradation and system failure.

This analysis is for homeowners who manage projects with precision. If your primary decision-making criterion is the lowest possible price, RocStout Roofing and Construction is not the right fit. Our process is built on verifiable calculations and methodical execution, designed to eliminate the chaos common in the construction industry. We deliver a predictable outcome for clients who value structural integrity as a long-term asset.

The Physics of Attic Ventilation: A System-Based Approach

Attic ventilation is a building science discipline governed by physics. It is a dynamic system designed to manage heat and moisture, the two primary catalysts for premature roof failure. Misunderstanding these principles is the root cause of most ventilation-related issues, which manifest as mold, wood rot, ice dams, and accelerated shingle decay. A roof is a complete system; its ventilation is the mechanism that allows it to breathe and endure.

Convective Flow: The Engine Driving Air Exchange

Convective flow, also known as the stack effect or thermal buoyancy, is the engine of passive attic ventilation. The process is simple and automatic. Solar radiation heats the roof deck, which in turn heats the air within the attic space. As this air warms, it becomes less dense and rises. A properly designed ventilation system provides a pathway for this hot, buoyant air to exit at the roof’s highest point while simultaneously drawing in cooler, denser replacement air from a lower point. This continuous air exchange is what prevents the buildup of destructive heat and moisture.

Intake vs. Exhaust: The Critical Balance for System Integrity

A ventilation system requires two distinct and balanced components to function: intake vents and exhaust vents. Intake vents, typically located in the soffits or eaves, provide the entry point for cool, exterior air. Exhaust vents, such as ridge vents, provide the exit point. The critical metric governing this relationship is Net Free Area (NFA), which measures the unobstructed area through which air can pass. For a system to achieve stability, the NFA for intake must be equal to or greater than the NFA for exhaust. An unbalanced system, where exhaust capacity exceeds intake, creates negative pressure, forcing the system to pull air from undesirable locations and compromising the integrity of the building envelope.

Managing Temperature & Moisture: The Primary Protective Mandate

The core mandate of a roof is to protect the structure from environmental threats. Uncontrolled attic ventilation directly undermines this mandate. In summer, an unventilated attic can reach temperatures exceeding 150°F, radiating intense heat into the living space and baking the asphalt shingles from below, drastically shortening their lifespan. In winter, warm, moist air from the living areas rises into the cold attic. When this moisture-laden air contacts the cold roof sheathing, it condenses. This condensation fosters mold and rot. It also contributes to the formation of ice dams, where melting snow refreezes at the eaves, forcing water under shingles and causing significant damage. A balanced ventilation system expels this heat and moisture, protecting the roof’s ability to shield the building from extremes of temperature and precipitation.

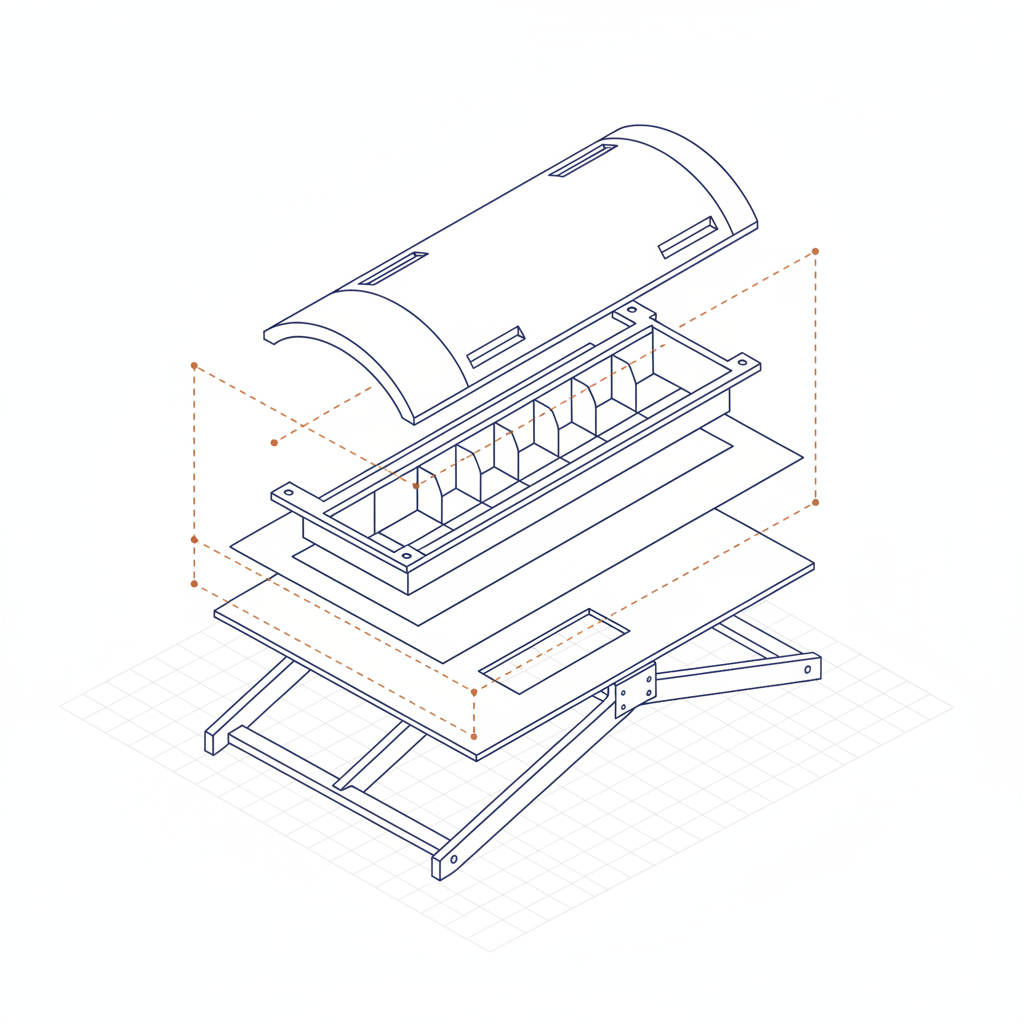

Ridge Vent Mechanics: Deconstructing the Core Components

A ridge vent is not merely a plastic cover; it is an engineered component with specific mechanical features designed for airflow and weather resistance. Its effectiveness is contingent upon its material composition, internal design, and precise integration with the surrounding roof materials. Every element must work in concert to provide exhaust without creating a vulnerability to water intrusion.

The Vent Structure: Materials and Baffle Design for Weather Protection

Modern ridge vents are typically manufactured from high-impact polypropylene, a durable copolymer resistant to cracking, warping, and UV degradation. The critical internal feature is the baffle system. A baffle is a series of partitions and vents that create a complex pathway for air. This design allows hot, moist air to escape unimpeded while simultaneously preventing wind-driven rain and snow from entering the attic. The baffle creates a Venturi effect, using external wind to help pull air out of the vent, enhancing its performance. Vents lacking a sophisticated baffle system are little more than a covered hole, offering inadequate weather protection.

The Airflow Channel: Creating a Continuous Exhaust Point at the Roof Apex

The installation of a ridge vent begins with a precise cut in the roof sheathing. A slot, typically 1.5 to 2 inches wide, is cut along the length of the ridge beam, stopping short of the gable ends. This slot creates the continuous airflow channel. The ridge vent unit is then placed over this channel, secured directly to the roof deck. This design provides uniform ventilation across the entire underside of the roof deck, preventing the formation of isolated hot spots that can occur with less effective solutions like box vents.

Integration with the Roof Covering: Ensuring a Watertight Seal

The final step is integrating the vent into the roof’s primary water-shedding layer. Ridge cap shingles are installed directly over the ridge vent, matching the rest of the roofing materials. These cap shingles are secured with long, gasketed roofing fasteners that penetrate through the cap, the vent, and into the roof decking. The type and length of these fasteners are specified by the manufacturer to ensure a secure and watertight seal. This meticulous integration ensures the vent functions as an exhaust point without compromising the roof’s fundamental duty to provide protection against rain and snow.

Failure Analysis: Common Misconceptions and Installation Errors

A ridge vent system fails not because of the concept, but because of flawed calculations and chaotic installation practices. The roofing industry is rife with contractors who treat ventilation as an afterthought, leading to systemic failures that void warranties and cause thousands in damage. These errors are entirely preventable with a process-driven methodology.

Unbalanced Systems: The Consequences of Improper Intake Calculation

The most common failure is an unbalanced system. When a contractor installs a high-capacity ridge vent without verifying or installing adequate soffit intake, they create negative pressure. The powerful exhaust vent will pull air from the path of least resistance. This is often not the soffits, but rather gable vents, can lights, or other roof penetrations. This short-circuits the system, leaving large sections of the roof deck unventilated. Worse, it can pull moist, conditioned air from the living space into the attic, adding to the moisture load and defeating the entire purpose of ventilation.

Installation Deviations: How Bypassing Manufacturer Specs Creates Systemic Risk

Every ridge vent manufacturer provides detailed installation specifications. Deviating from these specifications is not a shortcut; it is a decision to introduce risk. Common errors include:

- Improper Nailing Pattern: Using the wrong type, length, or number of fasteners can allow the vent to lift under wind load, breaking the watertight seal.

- Incorrect Sheathing Cut: Cutting the slot too wide compromises structural support for the vent; cutting it too narrow restricts airflow and reduces the NFA.

- Omitting End Caps: Failing to properly seal the ends of the vent run creates a large opening for insects, bats, and wind-driven rain to enter the attic.

These are the direct results of a chaotic, low-bid installation process. A methodical approach makes these errors impossible.

The Myth of \”One Size Fits All\”: Rejecting Inadequate Venting Solutions

Box vents and turbine vents are often presented as equivalent alternatives. They are not. These are point-based solutions that only ventilate small, isolated sections of the attic. This creates an uneven temperature profile across the roof deck, leading to hotspots and condensation zones. While they may be acceptable for certain complex roof designs, a continuous ridge vent is the superior engineering solution for standard gable and hip roofs. It provides consistent, balanced airflow along the entire apex. Choosing a ventilation solution should be a deliberate decision based on roof design and building science, not contractor convenience or minimal material cost.

System Verification: Our Protocol for Predictable Performance

Predictable results are the product of a defined, verifiable process. We treat roof ventilation not as a task to be completed, but as a system to be engineered and commissioned. This begins with calculation, proceeds with methodical installation, and is built upon a foundation of superior materials. This is the only way to eliminate chaos and guarantee long-term performance.

Calculating Net Free Area: A Non-Negotiable Prerequisite

Before any work begins, we perform a complete ventilation calculation. The standard building science guideline is the 1/300 rule: 1 square foot of total Net Free Area for every 300 square feet of attic floor space, balanced evenly between intake and exhaust. We measure the attic, calculate the required NFA, and audit the existing soffit vents to determine the current intake capacity. If intake is insufficient, we present a clear plan to correct it. This calculation is a non-negotiable prerequisite to our work. We do not guess or assume; we verify.

The RocStout Roofing and Construction Installation Protocol: Eliminating Chaos from the Apex

Our installation process is a defined, step-by-step protocol designed to ensure every detail is executed according to manufacturer specifications and building science principles. This is how we convert a chaotic construction project into a predictable manufacturing process.

Confirm total NFA requirements based on attic square footage and verify existing intake meets or exceeds exhaust specifications.

Execute a precise, straight cut along the ridge, adhering strictly to the manufacturer’s specified width and end-point clearance.

Align and fasten the ridge vent sections using the specified fasteners at the prescribed interval to guarantee wind resistance.

Install ridge cap shingles over the vent, ensuring a proper overlap and using gasketed fasteners of the correct length for a permanent, watertight seal.

A project manager conducts a final inspection to verify every checkpoint in the protocol has been met before project sign-off.

Why We Reject Low-Bid Materials: A Commitment to Long-Term Structural Integrity

We exclusively use high-performance ventilation products from reputable manufacturers. Low-bid alternatives, often found at retail big-box stores, are manufactured from inferior resins that become brittle and crack under UV exposure and temperature cycling. Their internal baffles are often simplified to reduce cost, rendering them ineffective against wind-driven rain. The marginal savings on these materials are insignificant compared to the cost of attic remediation and structural repairs resulting from their inevitable failure. Your roof is a significant investment. Protecting that investment with subpar components is illogical. We select materials based on documented long-term performance and durability, not on initial cost.