A roof ventilation system is the engineered assembly of components that regulates temperature and moisture within an attic space. Its correct design and function directly determine the longevity of a roof—the top covering of a building designed to provide protection against rain, snow, sunlight, extremes of temperature, and wind. Understanding the mechanics of exhaust ventilation, specifically the performance differences between ridge vents and box vents, is critical to ensuring your roof system achieves its maximum service life.

The Critical Role of Ventilation in Your Roof’s Structural Integrity

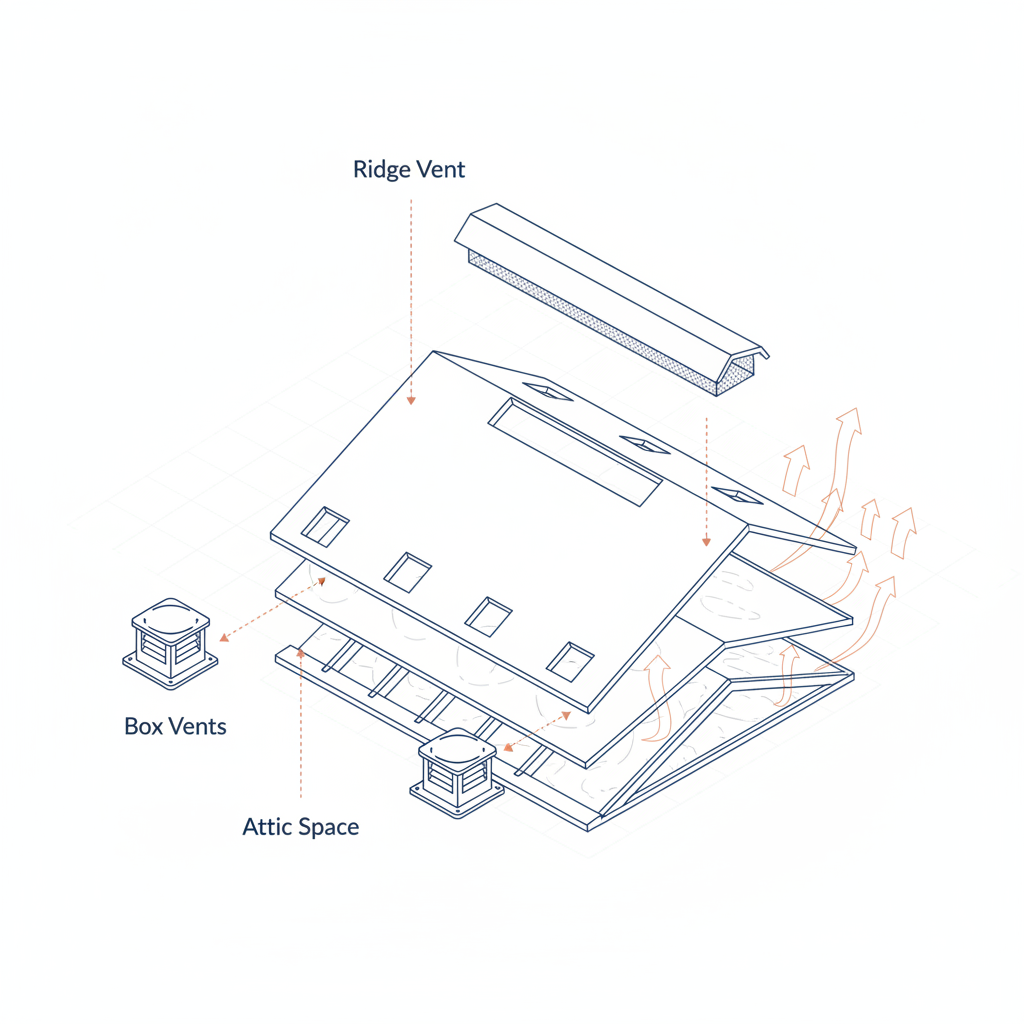

Proper attic ventilation is not an optional upgrade; it is a fundamental requirement of a high-performance roof system. It creates a continuous flow of air, moving cooler, drier air in through intake vents (typically in the soffits) and pushing hotter, moist air out through exhaust vents. This balanced exchange is the primary defense against the two forces that degrade a roof from within: extreme heat buildup and persistent moisture.

Controlling Temperature Extremes to Protect Roof Materials

An unventilated attic acts as a thermal trap. On a sunny day, the roof absorbs immense solar radiation, and attic temperatures can soar above 150°F. This superheated air directly attacks the structural components of your roof. It bakes the oils out of architectural shingles, making them brittle and shortening their life. The intense thermal regulation stress also causes the roof decking to expand and contract excessively, which can lead to warping and fastener withdrawal. A properly ventilated system continuously exhausts this trapped heat, maintaining a stable temperature that protects all roofing materials from accelerated degradation.

Mitigating Moisture to Prevent Mold and Rot in the Roof Construction

Moisture is a constant threat to a building’s protection. Daily activities like showering and cooking introduce warm, moist air into a home, which rises and infiltrates the attic. When this air meets the cooler underside of the roof deck during colder weather, it causes condensation. This moisture damage is insidious. It saturates insulation, promotes toxic mold growth, and creates the ideal conditions for wood rot in the rafters and decking. A balanced ventilation system expels this moisture before it can condense, preserving the structural integrity of your roof construction and preventing costly secondary damage.

System Longevity: How Balanced Airflow Prevents Premature Failure

A roof system’s longevity is a direct result of its equilibrium. The balance between intake vents and exhaust vents is crucial. An imbalanced system, or one with no ventilation, is prone to catastrophic failures. In winter, inadequate ventilation allows heat to escape through the attic, melting snow on the roof. This meltwater then refreezes at the eaves, forming destructive ice dams that can tear off gutters and force water back under the shingles. Balanced ventilation keeps the roof deck uniformly cool, preventing the melt-freeze cycle that causes ice dams and ensuring the entire roof system functions as designed for decades.

Analysis of Ridge Vents: A Continuous Exhaust System

A ridge vent is a passive ventilation component installed along the entire peak, or ridge, of a roof. It functions as a continuous, linear exhaust port, allowing hot, moist attic air to escape uniformly from the highest point of the attic. This design leverages natural physics to create a highly efficient, self-regulating system that requires no moving parts or electricity.

Mechanical Principles: Leveraging Natural Airflow Along the Roof Peak

Ridge vents operate on two core principles: thermal buoyancy and the wind effect. First, as air in the attic heats up, it becomes less dense and rises, a process known as convection. The ridge vent, positioned at the absolute highest point of the roof peak, provides the natural exit path for this rising attic air. Second, as wind blows over the roof’s surface, it creates a slight negative pressure zone at the ridge. This low-pressure area acts like a vacuum, actively pulling air out of the vent and enhancing the overall airflow. The system works silently and continuously, responding dynamically to environmental conditions.

Aesthetic & Structural Integration: A Minimalist Profile

From a design perspective, the primary advantage of a ridge vent is its minimalist profile. Modern shingle-over ridge vents are designed to be almost invisible. They are installed directly on the roof peak, and then the same architectural shingles used on the rest of the roof are installed over the top covering of the vent. The result is a seamless design that does not disrupt the roofline or detract from the home’s curb appeal. Unlike the protruding profile of box vents, a ridge vent provides superior ventilation without creating visual clutter.

Performance Metrics: Calculating NFA for Maximum Efficiency

The performance of any vent is measured in Net Free Area (NFA), which quantifies the unobstructed area through which air can pass, typically measured in square inches per linear foot. Calculating the required NFA for a roof is a precise engineering task based on attic size and building codes. A key advantage of ridge vents is their ability to provide a high, continuous NFA along the entire ridge. High-quality baffled ridge vents are engineered to maximize airflow (measured in cubic feet per minute, or CFM) while preventing infiltration from wind-driven rain and snow. This precision ensures predictable, efficient performance.

Analysis of Box Vents: A Static, Position-Based Solution

Box vents, also known as louver vents or static vents, are individual, non-mechanical vents installed over holes cut into the roof plane. Unlike the continuous nature of a ridge vent, box vents create multiple, distinct points of exhaust. Each installation is a roof penetration that requires meticulous waterproofing to maintain the integrity of the roof deck.

Placement Strategy: The Engineering of Static Vent Locations

Effective ventilation with box vents depends entirely on a precise placement strategy. The vents must be positioned high on the roof plane, as close to the ridge as structurally possible, to allow rising hot air to escape. The number and spacing of the vents are determined by the total NFA requirement for the attic. The engineering must account for the roof pitch and the underlying support structure to ensure each vent contributes to an effective airflow path. Incorrect placement can create dead air spots, rendering the system inefficient and leaving parts of the attic vulnerable to heat and moisture buildup.

Installation Protocols: Ensuring Watertight Roof Penetrations

Every box vent is a potential failure point. The installation protocol is non-negotiable and demands absolute precision. A hole is cut in the roof deck, and the vent is installed with a wide flange that slides under the shingles on the upslope side and over the shingles on the downslope side. Proper integration with flashing and the application of high-grade sealant are critical to creating a permanent, watertight seal. A single error in this process guarantees a leak, compromising the very building protection the roof is meant to provide. This inherent risk is a primary reason we approach box vent installations with extreme caution.

Specific Use Cases: When Box Vents Are the Required Choice

Despite the advantages of ridge vents, certain roof architectures make them impractical or impossible to install. In these specific cases, box vents are the required choice. The most common use case is on hip roofs, which have complex geometry and a very short or non-existent horizontal ridge line. Other scenarios include roofs with numerous dormers or skylights that interrupt the ridge, or designs where the building code dictates a specific ventilation method. While effective when properly engineered and installed, they are a solution dictated by architectural constraints, not superior performance.

Comparative Matrix: Ridge Vents vs. Box Vents

Choosing the correct ventilation system is a technical decision based on objective performance metrics, not preference. The following matrix provides a direct comparison of the two primary passive exhaust systems.

| Performance Metric | Ridge Vents | Box Vents |

|---|---|---|

| Airflow Efficiency | Superior. Provides even, continuous airflow along the entire roof peak, eliminating hot spots. Leverages both convection and wind effect for maximum air exchange. | Moderate. Creates intermittent points of exhaust. Prone to creating dead air spots if not perfectly placed. Less efficient air circulation overall. |

| Weather Performance | Excellent. Modern baffled designs offer high wind resistance and are engineered to prevent infiltration from wind-driven rain and snow. | Variable. Highly dependent on installation quality. Each vent is a roof penetration and a potential leak point. Can be susceptible to snow infiltration. |

| Long-Term Cost | Higher initial installation cost. Delivers superior return on investment through better energy savings, shingle life extension, and lower risk of moisture-related roof repair. | Lower initial installation cost. Higher long-term risk of costly repairs due to leaks from failed seals or premature roof failure from inefficient ventilation. |

| Visual Impact | Minimal. Shingle-over designs create a clean, seamless roofline that is nearly invisible from the ground, preserving architectural style. | Noticeable. The static vents create multiple protrusions on the roof plane, which can disrupt the home’s aesthetic, especially on simple gable roofs. |

| Design Compatibility | Ideal for simple gable and shed roofs with long, uninterrupted ridge lines. | Required for complex rooflines, especially hip roofs, where a continuous ridge is not available. |

Airflow Efficiency: Continuous vs. Intermittent Air Exchange

The primary performance differentiator is the nature of the airflow. A ridge vent creates a uniform draft across the entire attic, preventing the formation of isolated hot spots. Box vents, by contrast, only draw air from their immediate vicinity. This can lead to uneven attic temperatures and pockets of stagnant, moist air, compromising the balance of the entire system.

Performance Under Load: Resistance to Wind, Rain, and Snow

Modern baffled ridge vents are subjected to rigorous testing for weather protection. Their internal structure is designed to deflect wind-driven rain and prevent snow infiltration while maintaining airflow. The durability of a box vent system is entirely dependent on the seals around its multiple penetrations. Over time, these seals are a point of weakness, vulnerable to material degradation and installer error.

Long-Term Cost Analysis: Initial Investment vs. System Lifespan

While the material and labor cost for a ridge vent may be higher upfront, it is a superior long-term investment. Its efficiency translates directly into energy savings and extends the life of your shingles and roof structure, providing a clear return on investment. The lower initial cost of box vents can be deceptive, often leading to higher costs down the line from premature roof repair or replacement caused by suboptimal performance.

Design Compatibility: Matching the Vent to Your Roof’s Architecture

The architecture of your roof is the ultimate deciding factor. For a standard gable roof, a ridge vent is the unequivocally superior engineering choice. For a complex hip roof, a correctly calculated and meticulously installed system of box vents is the only viable solution. The choice is not a matter of opinion but of applying the correct engineering principle to the specific architectural design.

Our Methodology: A Process-Driven Approach to Roof Ventilation

We do not guess. We do not approximate. We treat roof ventilation as the critical engineering system it is. Our methodology is designed to eliminate the chaos and uncertainty that defines the typical roofing experience. We deliver a predictable outcome through a transparent, documented process.

Our process begins with data collection. We conduct a thorough roof inspection and attic assessment, measuring attic dimensions, evaluating existing intake ventilation, and checking insulation levels. This audit provides the hard data required for accurate system design.

With the audit data, we apply the industry standard ventilation formula to determine the exact NFA your roof requires for code compliance and optimal performance. This engineered solution is documented and presented to you. There is zero guesswork in our process.

You receive a detailed project timeline with transparent pricing. A dedicated project manager serves as your single point of contact, providing frequent updates. We ensure a clean job site and conclude with a final inspection to verify that every detail of the plan was executed flawlessly.

The Antidote to Industry Chaos: Why Predictability is Non-Negotiable

The standard roofing industry experience is defined by chaos: vague estimates, missed deadlines, poor communication, and a lack of accountability. This approach is unacceptable for a project as critical as your home’s primary protective asset. We have built our company to be the direct antidote to that chaos. Our value is not in being the cheapest option; it is in delivering a predictable, stress-free, and technically perfect result.

The High Cost of ‘Good Enough’: Avoiding Ventilation System Failure

Improper ventilation installation is one of the most common forms of contractor error. It is a costly mistake that can void your shingle manufacturer’s warranty and lead to premature roof failure within years, not decades. Cutting corners on ventilation calculations or installation protocols is a gamble that a meticulous homeowner should never have to take. A ‘good enough’ approach inevitably leads to expensive, avoidable problems.

Our Commitment: We Deliver Order, Not the Lowest Bid

We must be clear about our client alignment. If your primary objective is to secure the absolute lowest price, RocStout is not the right contractor for your project. This is not a statement of arrogance; it is a commitment to quality. Our process-driven methodology, dedicated project management, and refusal to compromise on materials or technique require a commensurate investment. We deliver a premium service for clients who, like us, understand that the true value of a project lies in its predictability, durability, and the peace of mind that comes from knowing it was done right the first time.