Roof thermal bridging is a phenomenon where heat follows a path of high thermal conductivity, bypassing the insulating layer and creating a direct connection between the interior and exterior of the building. This process compromises the primary function of a roof system, which is to serve as the top covering of a building and provide protection against extremes of temperature. For the meticulous homeowner, understanding the physics of thermal bridging is not an academic exercise; it is a critical step in risk mitigation, asset protection, and eliminating the financial and structural consequences of an inefficient building envelope. This analysis is for owners who demand precision and predictability. If your primary objective is the lowest possible price, we are not the right partner for your project. Our methodology is designed for clients who recognize that a systematic, data-driven approach is the only way to guarantee a successful outcome.

Defining Roof Thermal Bridging: An Analysis of Unseen Energy Loss

A thermal bridge is a component in a roof or wall assembly with a significantly higher thermal conductivity than the surrounding materials, creating a path of least resistance for heat transfer. This bridge effectively undermines the stated R-value of your insulation, creating localized points of energy loss across the entire building envelope. While insulation is rated in a laboratory, its real-world performance is dictated by the integrity of the entire system. Thermal bridges are the points where that system fails, compromising the roof’s ability to protect the structure from extremes of temperature.

The Physics of Heat Flow in Roof Constructions

Heat transfer in a roof assembly occurs through three distinct physical mechanisms. A failure to control any one of them results in energy inefficiency and potential structural damage.

- Conduction: This is heat transfer through direct physical contact. It is the primary mechanism of thermal bridging. Heat conducts directly through solid roof materials like wood rafters and metal fasteners, moving from the warmer side to the cooler side.

- Convection: This is heat transfer through the movement of fluids, specifically air in the case of a roof. Air leaks in the building envelope or improperly designed attic ventilation allow warm air to escape in winter and hot air to infiltrate in summer.

- Radiation: This is heat transfer via electromagnetic waves. The sun’s radiation heats the top covering of the roof, and that heat is then transferred inward. A properly designed roof system must manage this solar gain.

Heat always follows the path of least resistance. Framing members, metal connectors, and structural supports are unintentional highways for heat to bypass your insulation, rendering it less effective.

Identifying Common Thermal Bridges in Your Roof Assembly

Thermal bridges exist where the continuity of insulation is interrupted. In a standard roof construction, these interruptions are numerous and unavoidable without a specific mitigation strategy. The support structure itself is often the primary culprit.

| Component | Function | Role as a Thermal Bridge |

|---|---|---|

| Wood Rafters & Joists | Provide the primary support structure for the roof deck and top covering. | Wood has a much lower R-value than insulation (approx. R-1 per inch vs. R-3.5 to R-7 per inch for insulation). It creates a grid of conductive pathways across the entire roof plane. |

| Metal Fasteners | Nails, screws, and plates that hold the structure together. | Metal is an extremely efficient thermal conductor. Every fastener that penetrates from the interior to the exterior is a miniature thermal bridge, bleeding energy. |

| Steel Beams / Uprights | Used for long spans or heavy loads. | Steel’s conductivity is significantly higher than wood, creating major points of energy loss that can lead to severe condensation issues. |

| Roof-to-Wall Junction | The connection point between the roof’s support structure and the walls. | If not detailed with continuous insulation and air sealing, this junction becomes a massive thermal bridge along the entire perimeter of the building. |

Diagnostic Tools: Using Infrared Thermography to Visualize Inefficiency

Guesswork has no place in building science. To identify and quantify thermal bridging, we use diagnostic tools, chief among them being infrared thermography. An infrared camera translates thermal energy (heat) into a visible image called a thermogram, allowing us to visualize temperature differences across a surface. During an energy audit, a thermographer can pinpoint the exact locations of heat loss. The rafters, joists, and fasteners appear as distinct lines or spots on the thermogram, providing objective, indisputable data on the performance of your building envelope. This is not a sales tactic; it is a necessary diagnostic for any serious remediation plan.

Consequences of Unmitigated Thermal Bridging

A thermal bridge is more than just an energy issue; it is a systemic failure that introduces risk to the entire building. The roof’s core purpose is protection, and an unmitigated thermal bridge is a breach in that protection, leading to cascading financial and structural consequences.

Financial Impact: Calculating Increased Heating & Cooling Costs

The most immediate consequence of thermal bridging is increased energy consumption. These thermal leaks force your HVAC system to work harder to maintain the set interior temperature, directly increasing utility bills. In summer, heat gained through the roof structure from direct sunlight places a greater load on your air conditioning. In winter, heated air escapes through these same pathways. This constant energy waste represents a significant financial drain over the life of the building and causes premature wear on expensive mechanical systems. An investment in mitigating thermal bridging has a direct and measurable return on investment through lower operating costs.

Structural Risk: Condensation, Moisture, and Material Degradation

This is the most critical risk for the long-term integrity of your property. In colder climates, warm, humid air from inside your home comes into contact with the cold interior surface of a thermal bridge (such as a rafter or metal fastener). When the surface temperature drops below the dew point, the moisture in the air condenses into liquid water. This interstitial condensation occurs inside your roof assembly, where it is not visible. The results are catastrophic:

- Mold Growth: Trapped moisture on organic materials like wood sheathing and drywall creates ideal conditions for mold.

- Wood Rot: Persistent moisture leads to fungal growth that causes structural wood framing to decay, compromising the support for the entire roof.

- Insulation Degradation: Wet insulation loses its R-value and becomes ineffective, exacerbating the problem.

Effective moisture management is as critical as rain protection. Thermal bridging creates an internal moisture threat that can silently destroy your roof from the inside out.

System Failure: How Thermal Leaks Contribute to Ice Dam Formation

Ice dams are a classic symptom of thermal bridging in climates with significant snow load. The process is a clear failure of the roofing system to provide adequate protection against snow.

- Heat escapes through thermal bridges in the roof, warming the underside of the roof deck.

- This heat conducts through the shingles and melts the bottom layer of snow on the roof.

- Liquid water runs down the roof surface until it reaches the cold eaves (which are not heated from below).

- The water refreezes at the eave, forming a small ridge of ice.

- This process repeats, and the ridge grows into a large ice dam, trapping meltwater behind it.

This trapped water leads to severe water infiltration, gutter damage, and leaks directly into the walls of your home. An ice dam is not a gutter problem; it is a thermal management problem originating within the roof assembly itself.

Mitigation Blueprints: Engineering a Thermally-Resistant Roof System

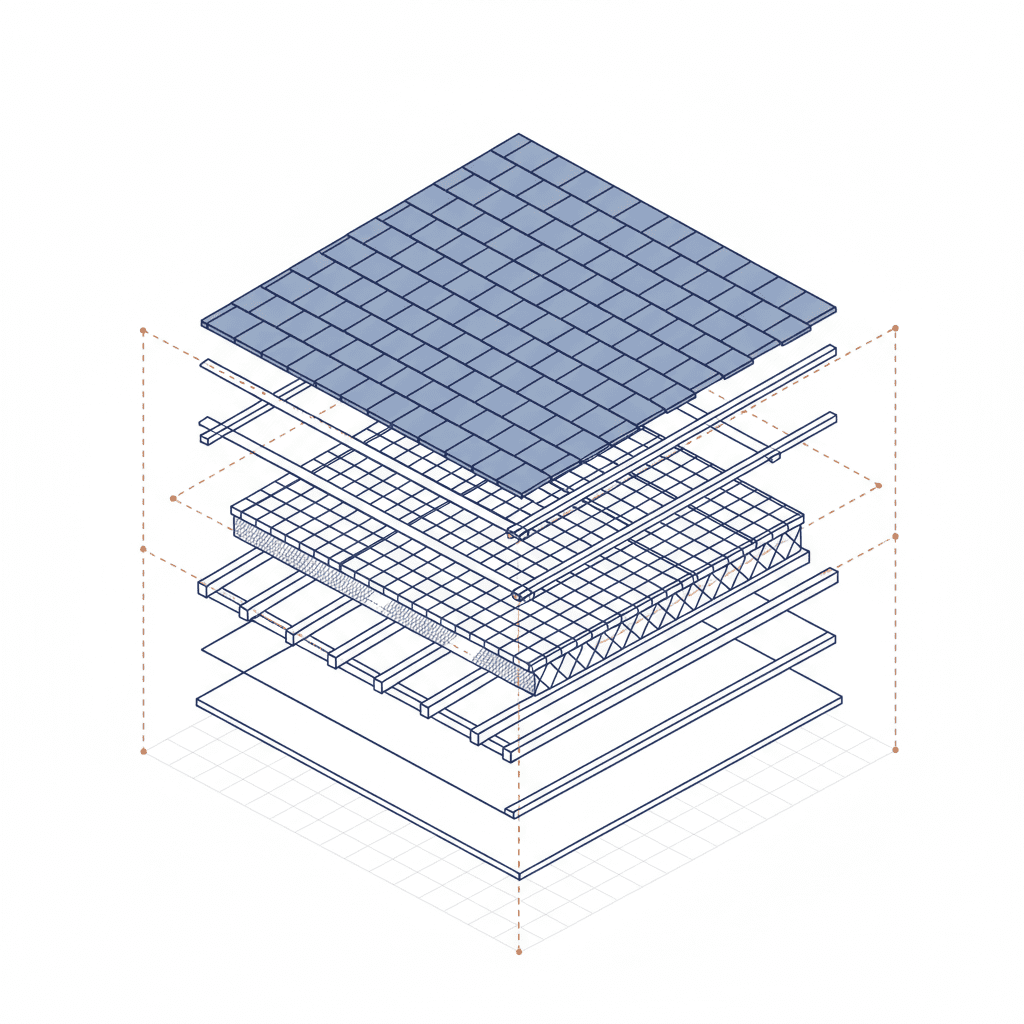

Addressing thermal bridging requires a strategic, engineered approach. The solution is not more insulation between the rafters; the solution is a design that creates a continuous, unbroken thermal barrier. These are not upgrades; they are fundamental components of a correctly designed roof system.

Exterior Continuous Insulation: The Definitive Thermal Break Solution

The most effective method to eliminate thermal bridging is to install a layer of continuous insulation over the exterior of the roof deck. This strategy, sometimes called ‘outsulation’, involves covering the entire support structure with rigid foam boards before the final top covering is installed. This creates a thermal break. The insulation physically separates the conductive framing members from the exterior temperature, neutralizing them as pathways for heat transfer. Common materials like polyisocyanurate (Polyiso) or extruded polystyrene (XPS foam) provide a high R-value in a thin profile, making them ideal for this application.

Advanced Framing Techniques to Minimize Conductive Pathways

A superior roof system begins at the design phase. Advanced framing techniques reduce the amount of thermally-inefficient material (wood) and maximize the space for insulation. This is fundamental to designing robust constructions to support the roof on the building’s walls. Techniques include:

- Raised Heel Trusses: These trusses are designed with a raised top chord at the building’s perimeter, allowing for full-depth insulation over the exterior walls, a common point of thermal bridging and ice dam formation.

- Structural Insulated Panels (SIPs): SIPs are composite panels made of an insulating foam core sandwiched between two structural facings. They create a strong, airtight, and highly insulated structure with minimal thermal bridging.

- Optimized Framing: Using 24-inch on-center framing instead of the traditional 16-inch reduces the amount of wood in the assembly by about 30%, which is then replaced by insulation.

Detailing Critical Junctions: Roof-to-Wall and Penetration Seals

A thermal envelope is only as good as its connections. The roof-to-wall junction is a critical point that must be meticulously detailed to ensure continuity of the thermal control layers. Proper air sealing with high-performance tapes and membranes prevents convective heat loss. A continuous vapor barrier protects the assembly from internal moisture drive. Every penetration through the roof—vents, pipes, skylights—must be treated as a potential thermal bridge and sealed with appropriate flashing and high-quality sealants to maintain the integrity of the building connections.

Our Methodology: A Process-Driven Approach to Thermal Control

The roofing industry is plagued by chaos, vague estimates, and a focus on speed over precision. This approach is incompatible with complex projects that require a deep understanding of building science. We have engineered a process that eliminates guesswork and delivers predictable outcomes. Our service is not for everyone. It is for the homeowner who values order, clarity, and a project executed correctly the first time.

We begin every project with a data-driven forensic analysis. This includes a full structural inspection and thermographic imaging to identify all points of thermal inefficiency. There is no guesswork. Our recommendations are based on verifiable data.

Using the diagnostic data, we engineer a complete roofing system tailored to your building. You receive a detailed, fixed-price proposal that specifies all materials, construction details, and project logistics. There are no hidden fees or vague allowances. This is a blueprint for success.

Your project is managed by a dedicated project manager who is your single point of contact. You receive daily updates, the job site is kept meticulously clean, and the project unfolds according to the plan. This orderly process eliminates surprises and delivers a superior result.

Thermal bridging is a complex technical problem that requires a systematic solution. It cannot be solved with a low-bid patch job. Protecting the long-term value and structural integrity of your home requires an investment in a process that prioritizes diagnostic precision and methodical execution. We provide predictability in an industry defined by chaos. If your priority is a project executed with absolute certainty, we are your roofing partner.