Hip and ridge cap shingles are specialized, pre-formed roofing components engineered to cover the apexes of a roof—the hips and ridges—providing a critical seal against water ingress and mechanical damage. These components are not aesthetic afterthoughts; they are integral to the roofing system’s ability to perform its primary function: to provide robust protection against rain, snow, sunlight, extremes of temperature, and wind. Their correct specification and installation are non-negotiable for the long-term structural integrity of the building.

Many homeowners, even meticulous ones, focus on the main field shingles, underlayment, and ventilation. This is logical. However, a roofing system fails at its weakest point. Frequently, that point is the ridge line, where improperly specified materials create an immediate vulnerability. This article provides a technical breakdown of hip and ridge cap shingles, contrasting correct, system-based installation with the common, failure-prone shortcuts that define the chaotic standard in the roofing industry.

The Systemic Role of Hip & Ridge Caps in Total Roof Integrity

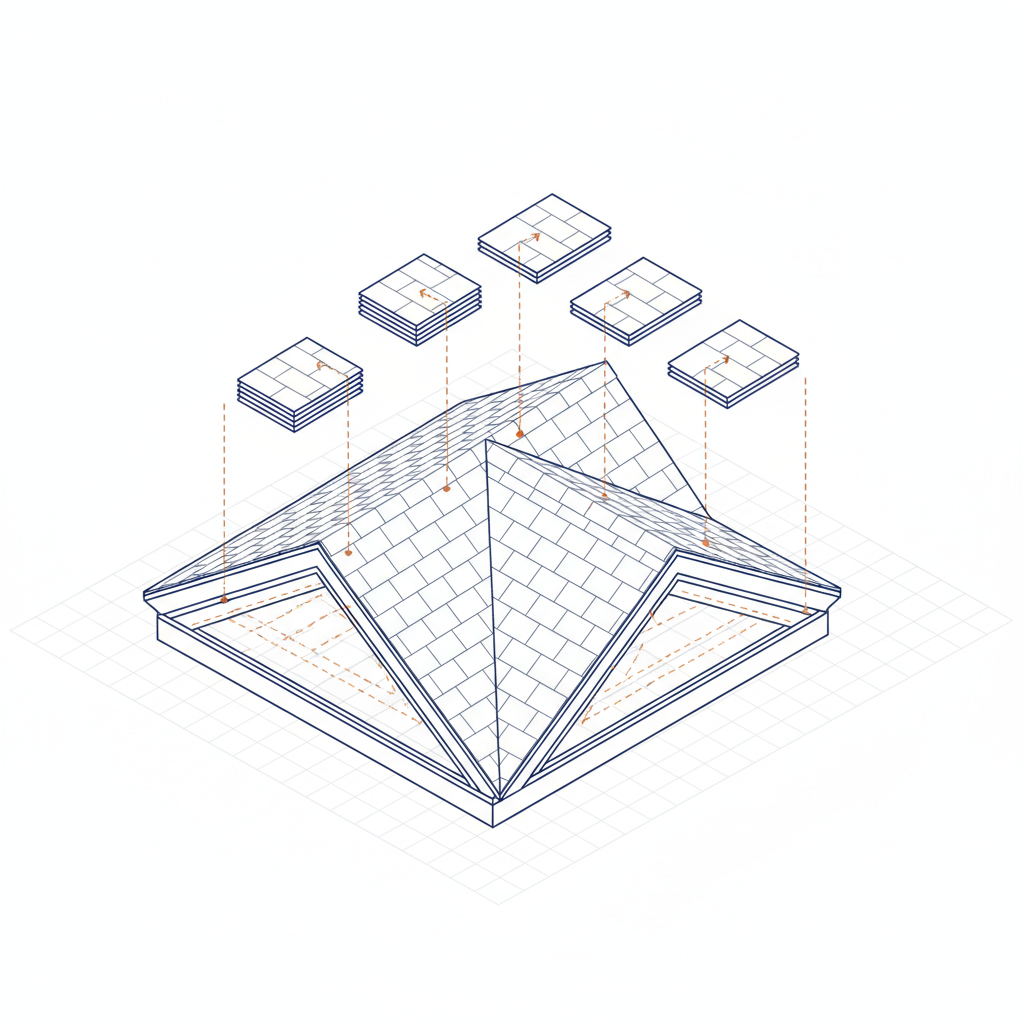

A roof is a complete system, not just a collection of parts. Hip and ridge cap shingles function as the final, critical seal that unifies the different planes of the roof into a single, monolithic barrier against the elements. Their role is both structural and aesthetic, and compromising on their quality introduces unacceptable risk into the entire building envelope.

Defining Their Purpose: Sealing the Most Vulnerable Seams of a Building

The hip and ridge lines of a roof are the areas of highest exposure. These seams are the convergence points for large roof planes, concentrating water flow and bearing the full force of wind uplift. The primary purpose of a hip and ridge cap shingle is to cover this vulnerable joint, preventing wind-driven rain and water from bypassing the main shingles and penetrating the roof deck. This function is essential for weatherproofing. Without a properly sealed cap, water ingress is not a possibility; it is an inevitability. The integrity of this seam directly impacts the longevity of the sheathing, rafters, and everything below.

Aesthetic Completion vs. Structural Necessity: Why Both Matter

While hip and ridge caps provide a clean, finished look to the roofline, their aesthetic function is secondary to their structural necessity. A well-defined ridge line enhances curb appeal and complements the texture of architectural or dimensional shingles. However, this finished look is a direct result of proper engineering. The thickness and dimension that create a visually appealing, high-profile ridge are the same properties that provide superior resistance to weather. One cannot exist without the other. Viewing these components as merely cosmetic is a fundamental misunderstanding of roofing system dynamics and a precursor to costly failure.

The Critical Failure of ‘Field-Cut’ Shingles: A Common Contractor Shortcut

The most common substandard practice in the roofing industry is the creation of ‘field-cut’ ridge caps. This involves a contractor taking a standard 3-tab shingle and cutting it into three pieces to fashion a makeshift cap. This is not a cost-saving measure; it is a defect. Standard shingles are not designed to be bent over a sharp apex. This action damages the shingle’s internal fiberglass mat, creating micro-fractures that accelerate material degradation and brittleness. Furthermore, the sealant lines are improperly located, and the nail zone is compromised. This shortcut invariably leads to premature failure, cracking, and blow-offs. It also voids the manufacturer’s system warranty. RocStout Roofing considers this practice unacceptable. If a prospective contractor’s proposal includes cutting corners on critical system components to reach the lowest possible price, they are not the right partner for a homeowner who values asset protection and predictable outcomes.

Material Analysis: Protection Against Environmental Forces

A roof’s function is to protect a building from environmental forces. The materials specified for its most exposed areas must be engineered to withstand constant assault from sunlight, wind, rain, and temperature fluctuations. Dedicated hip and ridge cap shingles are manufactured with specific formulations to meet these demands.

Composition: Polymer-Modified Asphalt for Thermal Flexibility

Dedicated hip and ridge caps consist of a fiberglass mat saturated with polymer-modified asphalt, also known as bitumen. The addition of specific polymers, such as Styrene-Butadiene-Styrene (SBS), gives the asphalt a rubber-like quality. This modification is critical for thermal flexibility. A roof expands and contracts with daily and seasonal temperature changes. Standard shingles have a limited tolerance for this movement. The polymer-modified asphalt in dedicated caps allows them to flex without cracking, maintaining their seal integrity across a wide range of temperatures. This prevents the material fatigue that causes field-cut shingles to fail.

Granule Adhesion: Quantifying Protection Against UV Degradation (Sunlight)

The ceramic-coated granules on a shingle’s surface serve two purposes: they provide color and, more importantly, they block damaging ultraviolet (UV) radiation from the sun. UV rays break down the asphalt in shingles, leading to brittleness and eventual failure. Because hip and ridge lines receive the most direct sunlight, the quality and adhesion of these granules are paramount. Premium ridge cap products feature superior granule adhesion technology and may incorporate reflective granules to improve solar reflectance, reducing heat absorption and contributing to the longevity of the entire roofing system.

Wind Resistance: Uplift Ratings and Their Impact on Roof Longevity

Wind places significant uplift pressure on a roof, particularly at the ridges and edges. Hip and ridge cap shingles are tested and rated for their ability to resist this force. The primary industry standard is ASTM D3161, which tests resistance at sustained wind speeds. Products are rated as Class A (60 mph), Class D (90 mph), or Class F (110 mph). High-quality ridge caps, combined with the correct number and placement of fasteners, achieve high wind ratings. A field-cut shingle has no such rating and is the first component to detach in a high-wind event, creating a cascading failure across the entire roof. For any homeowner concerned with longevity, specifying a ridge cap with a wind rating that matches or exceeds the field shingles is a baseline requirement.

Technical Comparison: Dedicated Ridge Caps vs. Standard Shingles

A data-based comparison between purpose-built components and a contractor shortcut reveals a clear disparity in performance, longevity, and risk. The choice is not a matter of opinion; it is a matter of adhering to or ignoring engineering specifications.

Dimensionality and Thickness: A Data-Based Rationale for Pre-Formed Caps

Dedicated ridge caps are manufactured to be thicker and more durable than field shingles. Many are multi-layer, laminated products pre-formed or pre-scored to bend perfectly at the apex without stress. This dimensional stability is a key performance indicator.

| Attribute | Dedicated Hip & Ridge Cap | Field-Cut 3-Tab Shingle |

|---|---|---|

| Composition | Polymer-Modified (Flexible) Asphalt | Standard Oxidized Asphalt |

| Construction | Multi-layer, laminated; pre-scored | Single layer, not designed for bending |

| Thickness | Significantly thicker for durability | Thin, prone to cracking when folded |

| Warranty Compliance | Required for system warranty | Immediately voids system warranty |

| Wind Rating | Independently tested and rated | No rating when used as a cap |

Warranty Adherence: How Using Non-Specified Materials Creates Risk

Leading roofing manufacturers like GAF, Owens Corning, and CertainTeed offer enhanced system warranties. These warranties provide comprehensive, long-term coverage, but they are contingent on the installation of a complete system of compatible components. This explicitly includes the starter shingles, underlayment, field shingles, and the hip and ridge cap shingles from the same manufacturer. Using a non-specified material, such as a field-cut shingle from another brand or line, breaks the system and voids the warranty. This transfers the full liability for any future failure from the manufacturer directly to the homeowner. It is a risk with no corresponding reward.

Color and Texture Matching for a Cohesive Roof System

Beyond the critical performance metrics, dedicated hip and ridge caps are designed within a specific product line to ensure perfect aesthetic consistency. Manufacturers produce caps that precisely match the color and granule blend of their architectural shingles. This includes algae-resistant formulations that prevent black streaks, ensuring the entire roof weathers uniformly over time. Attempting to match colors with a disparate 3-tab shingle often results in a visually jarring roofline that detracts from the property’s value.

Installation Protocol: A Zero-Deviation Process for Execution

The highest quality materials will fail if not installed correctly. Execution is everything. A process-driven installation protocol eliminates the variables and errors that lead to roof failure. At RocStout, our installation standards are absolute and non-negotiable, ensuring every component performs as designed.

Substrate and Underlayment Verification Before Cap Installation

Installation of the ridge cap is one of the final steps, but its success depends on the preceding work. Before any cap is installed, our protocol requires a full verification of the substrate. This means ensuring the roof deck sheathing is sound, the underlayment is installed correctly up to the ridge, and any ridge vent system is properly seated. We do not cover up problems. We verify a correct foundation before proceeding.

Fastener Specifications to Mitigate Wind and Rain Penetration

Fastener type and placement are critical. Building code and manufacturer specifications dictate the use of corrosion-resistant roofing nails of a specific length to ensure proper penetration into the roof deck. Nails must be placed correctly, outside of the shingle’s sealant strip, and driven perpendicular to the deck, never over- or under-driven. Each nail creates a penetration point; correct placement and sealing are essential to prevent water intrusion. There is no room for deviation in this process.

Exposure and Overlap Standards for Guaranteed Water Shedding

Each piece of a ridge cap must overlap the previous one by a precise amount, known as the exposure. A 5-inch exposure is common, but this is dictated by the manufacturer’s instructions. This specific overlap, combined with the factory-applied sealant, creates a continuous, layered barrier that efficiently sheds water and resists wind uplift. If the final course of shingles is intended to cover a ridge vent, the process must guarantee that the vent’s airway remains unobstructed while ensuring a complete seal. This precision is not optional; it is the core of a predictable, watertight installation.

Our Methodology: A Predictable Framework for Your Roofing Project

Your home is a significant asset. Managing a major project like a roof replacement should not be a source of stress and chaos. The standard industry experience—characterized by vague quotes, material substitutions, and poor communication—is unacceptable. We have built our entire business around a predictable, transparent process that gives meticulous homeowners the control and clarity they deserve.

Material Vetting: We Only Specify System-Compatible Components

Our process begins with correct material specification. We do not entertain shortcuts like field-cut shingles. We select and specify only system-compatible, manufacturer-approved hip and ridge caps that are engineered for your specific roofing shingles. This ensures warranty compliance and predictable long-term performance from day one. Your project’s success is determined by these initial decisions, and we make them correctly.

Line-Item Proposals: Eradicating Ambiguity and Surprise Charges

You have a right to know exactly what you are paying for. Our proposals are not estimates; they are detailed, line-item scopes of work. You will see every component listed, from the specific underlayment to the exact model of hip and ridge cap shingle. This financial clarity eradicates the possibility of surprise charges or last-minute material downgrades. It transforms the project from an unknown variable into a defined, manageable process.

The Alternative to Industry Chaos: A Process You Can Trust

A roofing project should not feel like a gamble. It should be a controlled, predictable process with a guaranteed outcome. That is the framework we provide. It is the only sane way to manage a critical home investment.

We engineer a complete, warranty-compliant roofing system using only manufacturer-matched components, including dedicated hip and ridge caps.

You receive a fixed-price proposal with zero ambiguity. Every material, labor step, and contingency is documented for your review.

Our certified installers execute the plan according to a strict protocol. A dedicated project manager provides you with daily updates.

We conduct a multi-point inspection, ensure the site is immaculate, and formally register your manufacturer’s system warranty.