Architectural shingles and 3-tab shingles are two classifications of asphalt-based roofing materials engineered to form the primary protective layer of a building’s roof system. A roof is the complete top covering of a structure, designed to provide absolute protection against environmental forces including rain, snow, sunlight, wind, and extremes of temperature. The choice between these shingle types directly impacts the roof’s ability to fulfill this primary function over its operational lifespan.

Architectural vs. 3-Tab Shingles: A Quantitative Overview

The selection of a roofing material is a critical project decision with long-term consequences for a building’s structural integrity and value. This analysis provides a quantitative comparison between architectural (dimensional) shingles and 3-tab (strip) shingles, focusing on material construction, performance metrics, and total cost of ownership. The objective is to equip property owners with the data necessary to make a sound engineering and financial decision.

Executive Summary: Key Differentiators for Project Planning

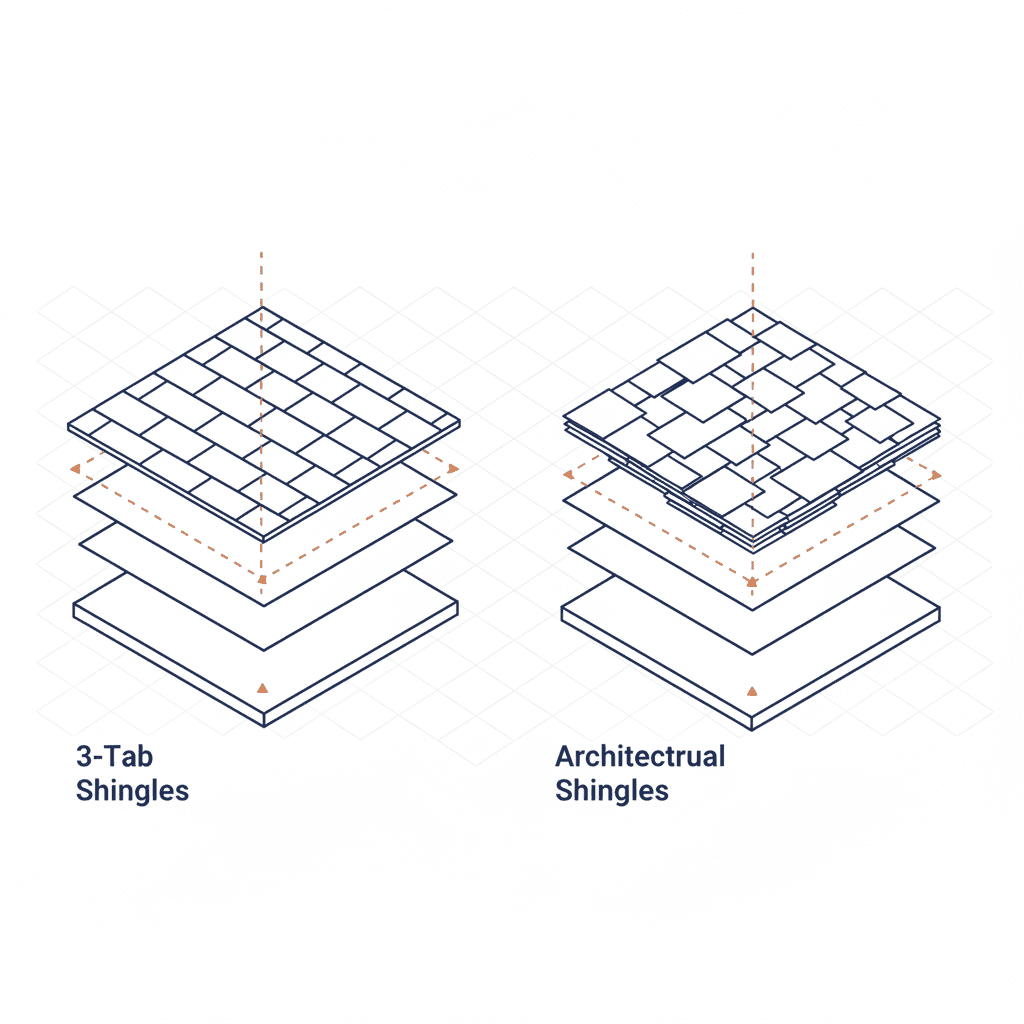

The fundamental distinction between these two components of a roof system lies in their construction. Architectural shingles possess a laminated, multi-layer design, while 3-tab shingles are a single, uniform layer. This structural difference dictates every subsequent performance metric, from wind resistance to expected service life. A cost-benefit analysis reveals that while 3-tab shingles have a lower initial material cost, their shorter lifespan and inferior protective capabilities result in a higher total cost of ownership and increased risk of premature failure. For meticulous project planning, architectural shingles offer superior predictability and long-term value.

| Attribute | Architectural (Dimensional) Shingles | 3-Tab (Strip) Shingles |

|---|---|---|

| Construction | Laminated, multi-layer fiberglass mat | Single-layer fiberglass mat |

| Weight | ~280-450 lbs per square | ~180-210 lbs per square |

| Wind Resistance Rating | 110-130 MPH (Standard) | 60 MPH (Standard) |

| Expected Lifespan | 25-50 years | 10-15 years |

| Warranty | Limited Lifetime (often non-prorated for the first 10-20 years) | 20-25 years (heavily prorated) |

| Aesthetic | Dimensional, textured look mimicking wood shake or slate | Flat, uniform, repetitive pattern |

Who This Analysis Is For (And Who It Is Not For)

This analysis is engineered for the meticulous homeowner, the project manager, or the engineer. It is for the individual who values data, understands that quality is a function of material and process, and seeks a predictable outcome. Our clients view their roof not as a commodity, but as a critical system protecting their most significant asset.

This analysis is not for the property owner whose primary objective is the lowest possible upfront cost. If your decision-making process is driven by finding the cheapest bid, RocStout is not the right partner for your project. We have engineered our entire process to eliminate the chaos, risk, and poor quality that are inherent in low-cost roofing. This focus on a predictable, stress-free experience is fundamentally incompatible with a lowest-price model.

Core Construction and Material Integrity Analysis

The performance of any shingle is a direct result of its composition. Both shingle types are fundamentally composed of a fiberglass mat, weathering-grade asphalt, and ceramic-coated mineral granules. However, the configuration and quality of these materials differ significantly, leading to disparate outcomes in durability and longevity.

Architectural Shingles: Laminated, Multi-Layer Construction

Architectural shingles consist of two or more layers of fiberglass mat and asphalt laminated together. This multi-layer construction serves several critical functions. It creates a thicker, heavier product that is substantially more resistant to wind uplift and physical damage from hail or debris. The lamination process allows for varied shapes and sizes in the top layer, creating a dimensional appearance that adds depth and aesthetic value. The fiberglass core provides structural stability, while the layers of weathering-grade asphalt serve as the primary waterproofing agent. The entire system is engineered for resilience.

3-Tab Shingles: Uniform, Single-Layer Construction

3-tab shingles are manufactured from a single, continuous layer of asphalt-coated fiberglass. Cutouts are made along the bottom edge of the shingle to create the appearance of three separate tabs, hence the name. This single-layer design results in a flat, uniform pattern. While functional for basic water-shedding, this basic construction lacks the structural redundancy and weight of its architectural counterpart. It is more susceptible to damage from wind, thermal cycling, and physical impacts, making it an obsolete choice for any property owner concerned with long-term asset protection.

Performance Metrics: Protection Against Environmental Forces

A roof’s primary mandate is to protect the building envelope from environmental forces. A shingle’s performance is measured by its ability to resist wind, shed water, and withstand solar radiation over decades. In these categories, the performance gap between architectural and 3-tab shingles is not incremental; it is absolute.

Wind Resistance & Uplift Dynamics

Wind uplift is a critical failure point for any roof system. It occurs when wind creates negative pressure on the roof surface, attempting to lift the shingles. Architectural shingles are rated to withstand winds of 110-130 MPH, meeting the stringent ASTM D7158 (Class H) standard. Their weight and robust, continuous sealant strips create a formidable defense against delamination. In contrast, standard 3-tab shingles are typically rated for only 60 MPH winds. Their lighter weight and smaller, intermittent sealant points present a significant vulnerability, making them unsuitable for most modern building codes and climates where high winds are a possibility.

Water Shedding Efficacy (Protection Against Rain & Snow)

Both shingle types are designed to shed water. However, the multi-layer construction of architectural shingles creates a more complex path for wind-driven rain, reducing the probability of water intrusion. Their thickness also provides a greater barrier against ice damming in colder climates. Many architectural shingles now include copper or zinc-infused granules that provide active algae resistance, preventing the black streaks that diminish a roof’s appearance and can compromise granule adhesion over time. 3-tab shingles offer only a basic, single layer of defense, which degrades more rapidly.

Thermal Stability & UV Degradation (Protection Against Sunlight)

Constant exposure to sunlight subjects a roof to two primary threats: thermal cycling and UV degradation. Thermal cycling, the expansion and contraction from daily temperature changes, causes stress on the shingle. The thicker cross-section of an architectural shingle better dissipates this stress. UV radiation breaks down the asphalt itself, causing it to become brittle. The protective layer of ceramic granules is the primary defense against this. Architectural shingles feature a heavier and more densely packed layer of granules, leading to significantly less granule loss over time and superior protection of the underlying asphalt, ensuring material longevity.

Lifespan & Warranty: A Predictability Assessment

The upfront price of a roofing material is only one component of its total cost. A more accurate measure is the total cost of ownership, which accounts for service life, warranty coverage, and replacement cycles. This assessment reveals the superior long-term value of architectural shingles.

Comparing Manufacturer Warranty Structures

Manufacturer warranties are a key indicator of expected performance. 3-tab shingles typically come with a 20- to 25-year prorated warranty. Proration means the warranty’s value decreases significantly each year, offering minimal protection in the later half of the shingle’s life. Architectural shingles, conversely, are backed by limited lifetime warranties. Crucially, these warranties often feature a non-prorated period, typically the first 10 to 20 years, where the manufacturer covers 100% of material defects. This structure provides a far more predictable and secure investment.

Calculating Total Cost of Ownership vs. Upfront Price

An architectural shingle roof may have a 15-25% higher upfront cost than a 3-tab roof. However, its expected service life is typically double or triple that of a 3-tab system. A 3-tab roof may require two or even three full replacements in the time an architectural roof provides continuous protection. When factoring in the repeated labor costs, disposal fees, and the sheer disruption of multiple replacement cycles, the architectural shingle is unequivocally the more financially sound choice. It delivers a lower cost per year of service and enhances property value through superior curb appeal and documented durability.

The Decisive Factor: A Process-Driven Installation

The quality of a roofing material is irrelevant if the installation protocol is flawed. The greatest threat to your investment is not a defective shingle, but a chaotic, disorganized, and unaccountable installation process. This is the variable that determines success or failure.

Why Your Shingle Choice Is Secondary to Installation Protocol

A high-performance architectural shingle installed improperly will fail faster than a basic 3-tab shingle installed to precise manufacturer specifications. Common installation errors—improper nailing, incorrect starter strip application, poor flashing detail—void manufacturer warranties and create immediate vulnerabilities in the building envelope. The integrity of the system is entirely dependent on the discipline of the installer. Vague timelines and poor project management are hallmarks of a contractor who does not control their process, which inevitably leads to compromised technical execution.

Our Methodology: The Antidote to Industry Chaos

At RocStout, we have replaced industry chaos with a predictable, step-by-step methodology. Your choice to invest in a superior architectural shingle is protected by an equally superior process. This is our commitment.

We conduct a thorough inspection of your entire roofing system. You receive a detailed, transparent proposal with a fixed price. No surprise charges. Ever.

You are assigned a single point of contact—a dedicated Project Manager—who is responsible for all communication, scheduling, and quality control from start to finish.

We protect your landscaping, siding, and driveways before any work begins. A clean, organized job site is a non-negotiable standard.

Our certified crews install your roofing system according to precise manufacturer specifications and local building codes. Key stages are documented.

Your Project Manager conducts a multi-point final inspection to ensure every detail is correct. The project is not complete until you are satisfied and sign off.

The data is clear. 3-tab shingles are an obsolete technology with inferior performance and a higher total cost of ownership. The correct technical choice for any homeowner focused on asset protection and predictable outcomes is a high-quality architectural shingle. The correct partner is one who can guarantee a stress-free experience through a disciplined, transparent, and proven installation methodology.