The selection of a roofing material is a technical decision about the performance of a building’s primary protective covering. A roof is the system of materials and constructions that shields the structure from environmental loads, including precipitation, snow, sunlight, wind, and extremes of temperature. This analysis compares the empirical performance and lifecycle cost of Class 4 impact-resistant shingles against standard architectural shingles to define a framework for your investment.

UL 2218 Testing Protocol: Defining Class 4 Impact Resistance

The Underwriters Laboratories (UL) 2218 classification is the standardized test protocol for measuring the impact resistance of roofing materials. This test is not a subjective assessment; it is a repeatable, physics-based experiment. The procedure involves repeatedly dropping a 2-inch diameter steel ball from a height of 20 feet onto the shingle surface. The material’s response to this kinetic energy transfer determines its classification.

Standard Shingle Performance Under Test Conditions

A standard architectural shingle subjected to the UL 2218 test protocol will fracture. The oxidized asphalt and fiberglass mat, while providing adequate waterproofing under normal conditions, are too brittle to withstand the concentrated force of the steel ball impact. This material failure manifests as visible cracking, tearing, or rupturing of the shingle’s surface and substrate. This baseline performance demonstrates a vulnerability to focused impacts, such as those from significant hail or falling debris.

Class 4 Shingle Performance: The Engineering Difference

A Class 4 rated shingle, by definition, must withstand the same UL 2218 test without exhibiting any evidence of cracks or ruptures. The engineering difference is its core composition: polymer-modified asphalt. By integrating Styrene-Butadiene-Styrene (SBS), a synthetic rubber, into the asphalt, the material gains significant elasticity. This allows the shingle to absorb and dissipate the impact energy across its surface, functioning more like a membrane and less like a rigid plate. The result is no visible damage and a preserved water-shedding barrier.

Comparative Analysis: Protection Against Environmental Threats

The primary function of a roof is to maintain the integrity of the building envelope against all environmental threats. A material’s rating directly correlates to its ability to perform this function over time. The selection of a Class 4 shingle is an act of risk mitigation against predictable environmental loads.

Hail & Debris Impact (Snow & Ice Load)

Hail damage is the most direct threat addressed by a Class 4 rating. The puncture resistance demonstrated in the UL 2218 test translates directly to preventing granular loss, mat fracturing, and water penetration during a hailstorm. Standard shingles can be compromised by a single severe event, creating immediate and often hidden leaks. While not directly an impact, heavy snow and ice loads create stress on the roof system. The superior flexibility of Class 4 shingles allows them to better withstand the stresses of thermal expansion and contraction associated with ice damming, reducing the risk of cracking under load.

Wind Uplift Resistance (Wind Loads)

Wind load performance is critical for roof system longevity. While primarily governed by installation method and sealant adhesion, the shingle’s material composition plays a significant role. Class 4 shingles often meet the requirements for ASTM D3161, Class F, the 110 mph wind resistance test. The SBS-modified asphalt provides a more aggressive and pliable sealant strip, creating a stronger bond between shingle courses. This enhanced adhesion, combined with the material’s greater tear resistance, dramatically reduces the likelihood of shingle blow-off during high wind events.

UV Degradation & Thermal Shock (Sunlight & Temperature)

A roof is subject to constant thermal cycling—the expansion and contraction caused by daily and seasonal extremes of temperature. Standard shingles, with their brittle oxidized asphalt, can become more susceptible to cracking over years of this stress. The rubberizing properties of SBS in Class 4 shingles allow them to remain flexible, accommodating thermal shock without failing. Furthermore, the enhanced adhesion of the SBS bitumen helps lock the ceramic-coated granules in place, providing superior, long-term protection against UV radiation, which is the primary driver of asphalt degradation.

Material Science: A Structural Breakdown of Shingle Composition

The performance differential between standard and Class 4 shingles is rooted in their fundamental material science. While both are laminate shingles built on a fiberglass mat, the composition of the asphalt bitumen binder is the critical variable.

| Feature | Standard Shingle (Oxidized Asphalt) | Class 4 Shingle (SBS Modified Asphalt) |

|---|---|---|

| Core Binder | Oxidized Asphalt | Styrene-Butadiene-Styrene (SBS) Polymer |

| Performance Under Impact | Brittle; prone to fracturing | Flexible; absorbs and dissipates energy |

| Flexibility | Low, especially in cold temperatures | High; remains pliable in a wide temperature range |

| Granule Adhesion | Standard; degrades with UV/thermal cycling | Enhanced; SBS polymer creates a stronger bond |

| Expected Failure Mode | Cracking, granule loss, wind uplift | Gradual weathering over an extended lifespan |

Standard Shingles: Oxidized Asphalt and Filler

Standard architectural shingles use oxidized asphalt as the binder. This process involves blowing air through hot asphalt to raise its viscosity and weathering resistance. However, it results in a fundamentally brittle material. To add weight and bulk, manufacturers mix in a mineral filler, typically calcium carbonate. This filler does not enhance performance; it is an economic choice that contributes to the shingle’s rigidity and eventual failure through cracking.

Class 4 Shingles: Styrene-Butadiene-Styrene (SBS) Formulation

Class 4 shingles utilize a superior formulation of SBS modified asphalt. SBS is a thermoplastic elastomer that imparts rubber-like characteristics to the bitumen. This creates a cohesive, flexible, and tough material with significantly higher tensile strength. The rubberizing polymers form a network within the asphalt, allowing it to bend and stretch upon impact before returning to its original shape. This formulation is the source of its impact resistance, enhanced adhesion, and superior durability.

Total Cost of Ownership: A Financial Framework for Your Roof

A meticulous homeowner analyzes an investment based on its total lifecycle cost, not just its initial price tag. Your roof is a long-term asset, and its cost should be calculated across its entire service life. The financial framework for a roofing decision must include initial investment, insurance costs, repair frequency, and expected replacement cycles.

Calculating the Initial Investment Differential

The upfront cost for a Class 4 impact-resistant roof system is higher than a standard shingle installation. This is a fact. The premium is driven by the higher material price of the SBS-modified shingle, which typically costs 10-25% more per square. Installation labor may be marginally higher due to the increased weight and stiffness of the material, requiring methodical handling. This initial differential is the capital investment required to achieve long-term savings and predictability.

Quantifying Long-Term Savings: Insurance, Repairs, and Replacement

The return on investment (ROI) for a Class 4 roof is realized through three primary channels. First, many insurance carriers offer significant premium discounts—often ranging from 5% to 30%—for homes with a certified Class 4 roof, as it dramatically reduces the insurer’s risk of a hail claim. Second, the cost of post-storm repairs is reduced to near zero. You avoid the chaotic cycle of filing claims, sourcing emergency repairs, and managing unpredictable expenses. Third, and most critically, a Class 4 system avoids premature failure. You are investing in a roof that is engineered to reach its full warrantied lifespan, eliminating the catastrophic expense of a full replacement after only 10 or 15 years due to storm damage.

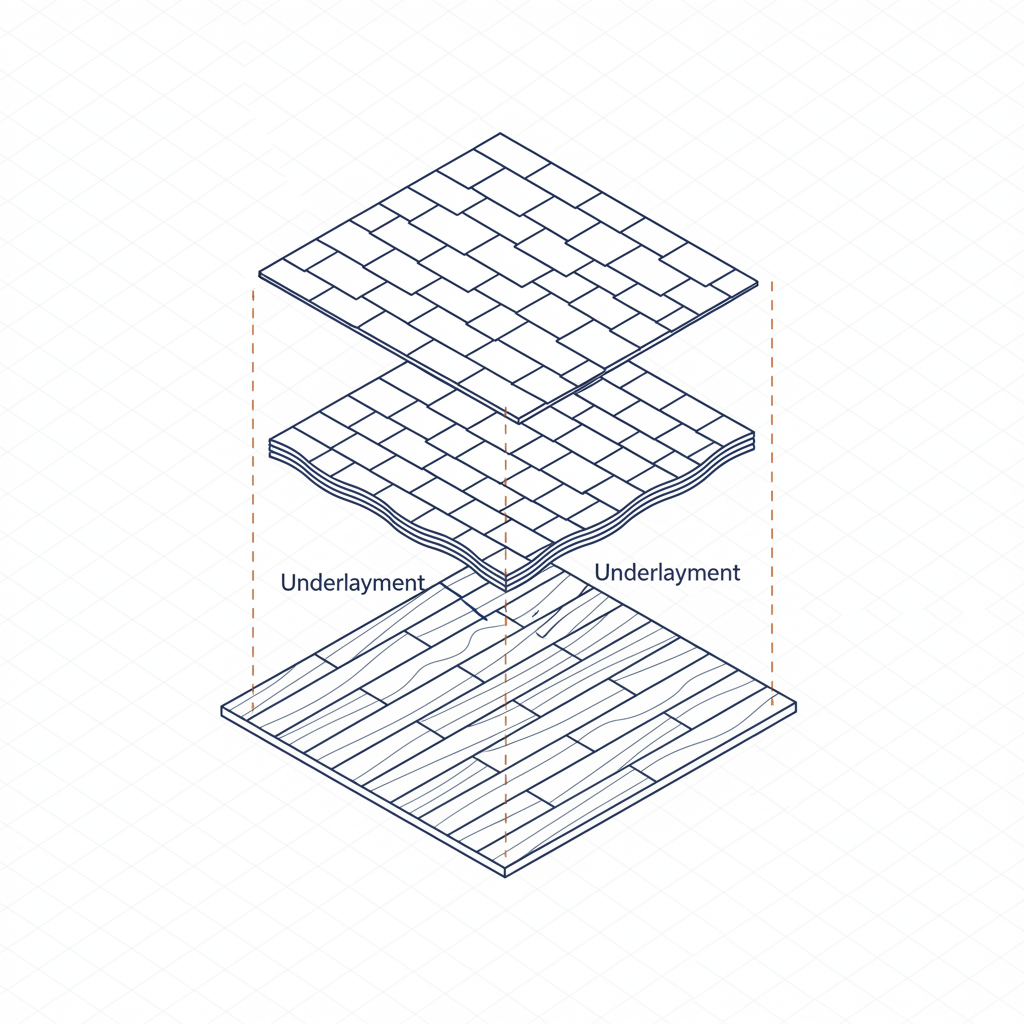

Our Methodology: A Predictable Framework for Roof Installation

The material you choose is only one component of a successful project. The second, and equally critical, component is the installation process. The enemy of any major home project is chaos. Our entire methodology is engineered to eliminate it. We deliver a predictable, stress-free experience through a transparent, step-by-step process.

Eliminating Chaos: The Fallacy of the Lowest Bid

Let us be direct. If your primary decision driver is the lowest possible price, we are not the right partner for your project. The lowest bid in the roofing industry is a red flag for chaos. It is the entry point for vague timelines, surprise change orders, subpar materials swapped in at the last minute, poor communication, and disorganized job sites. This approach does not save money; it merely defers costs and externalizes stress onto you, the homeowner. We have built our company to serve clients who understand the fallacy of this approach.

The Process-Driven Approach for Meticulous Homeowners

A superior roof requires a superior process. We replace the standard industry chaos with a framework built on communication, accountability, and meticulous execution. Your project will follow a strict, predictable protocol designed for your peace of mind.

We deliver a comprehensive scope of work detailing every material, every procedure, and a final, fixed price. There are no hidden fees or surprise charges.

You are assigned a single point of contact who is responsible for all logistics and communication. You have one number to call for any question, at any time.

Your project manager provides a proactive, detailed update at the end of each workday. You will always know what was accomplished and what to expect the next day.

We conduct a comprehensive final inspection against a detailed checklist. The project is not complete until every line item is verified and you sign off on the result.

This is the only sane way to manage a significant investment in your home. The choice between a Class 4 shingle and a standard one is a technical decision based on risk and lifecycle cost. The choice of your contractor is a procedural decision based on a commitment to order and predictability. We believe both choices should align to protect the value of your asset and eliminate stress.