Algae-resistant shingles are a specialized roofing material engineered with copper-infused granules to inhibit the growth of Gloeocapsa magma. This cyanobacterium causes the black streaks that degrade the aesthetic and protective qualities of a building’s top covering. The integrity of your roof—its fundamental duty to provide protection against rain, snow, sunlight, and extremes of temperature—depends on the material science of its components. Understanding this science is the first step in eliminating the chaos associated with premature roof degradation.

Root Cause Analysis: Why Algae Colonizes Your Roofing Materials

The appearance of dark stains on asphalt shingles is not a sign of dirt or decay; it is a biological colonization. Standard asphalt shingles contain limestone filler, a calcium carbonate compound that serves as a nutrient source for specific microorganisms. When this food source combines with environmental moisture, the conditions for colonization are met, directly compromising the roof’s function as a protective barrier.

Identifying Gloeocapsa Magma: The Organism Behind Roof Stains

Gloeocapsa magma is the specific cyanobacterium responsible for the prevalent black streaks seen on roofs. While not structurally damaging in its early stages, its growth leads to significant aesthetic degradation. These streaks diminish a property’s curb appeal, which is a direct reflection of its asset value. The discoloration is a clear visual indicator that the roofing materials are supporting biological life, a condition that a properly engineered system should prevent. The dark pigment of the bacteria also absorbs more heat, which can slightly increase attic temperatures over time.

Critical Environmental Factors: Moisture, Sunlight, and Temperature

The proliferation of Gloeocapsa magma is governed by a precise set of environmental variables. A roof system must manage these variables to maintain its integrity.

- Moisture: Rain, dew, and high humidity provide the necessary water for the cyanobacteria to thrive. Roof planes with slower water runoff or those shaded by trees remain damp longer, accelerating growth.

- Sunlight: While direct, intense sunlight can inhibit growth through UV exposure and rapid drying, the shaded portions of a roof (typically north-facing slopes) create an ideal, less extreme environment.

- Filler Material: The limestone in traditional asphalt shingles is the primary nutrient. The bacteria metabolize the calcium carbonate, etching the shingle surface on a microscopic level.

The combination of these factors dictates the speed and severity of colonization. Your building’s location and specific roof orientation are critical inputs in determining the risk profile for this type of aesthetic and material failure.

Engineering Algae Resistance: An Analysis of Shingle Construction

Modern roofing materials are not passive coverings; they are engineered systems designed to counteract specific environmental threats. Algae-resistant shingles directly address the biological threat of Gloeocapsa magma through advancements in material science. The construction integrates a biocide directly into the shingle’s structure, providing continuous protection.

The Role of Copper-Infused Granules in Algae Inhibition

The core of modern algae resistance is the integration of copper granules among the standard ceramic-coated mineral granules. The mechanism is straightforward and effective. When it rains, water flows over the copper granules, releasing a minute and controlled quantity of copper ions. These ions are a potent algaecide and biocide, traveling down the roof slope and rendering the surface uninhabitable for Gloeocapsa magma. This time-release technology provides long-term effectiveness, ensuring the roof maintains its intended appearance and function for the duration of its warranted life.

Core Shingle Composition: The Foundation of Structural Support

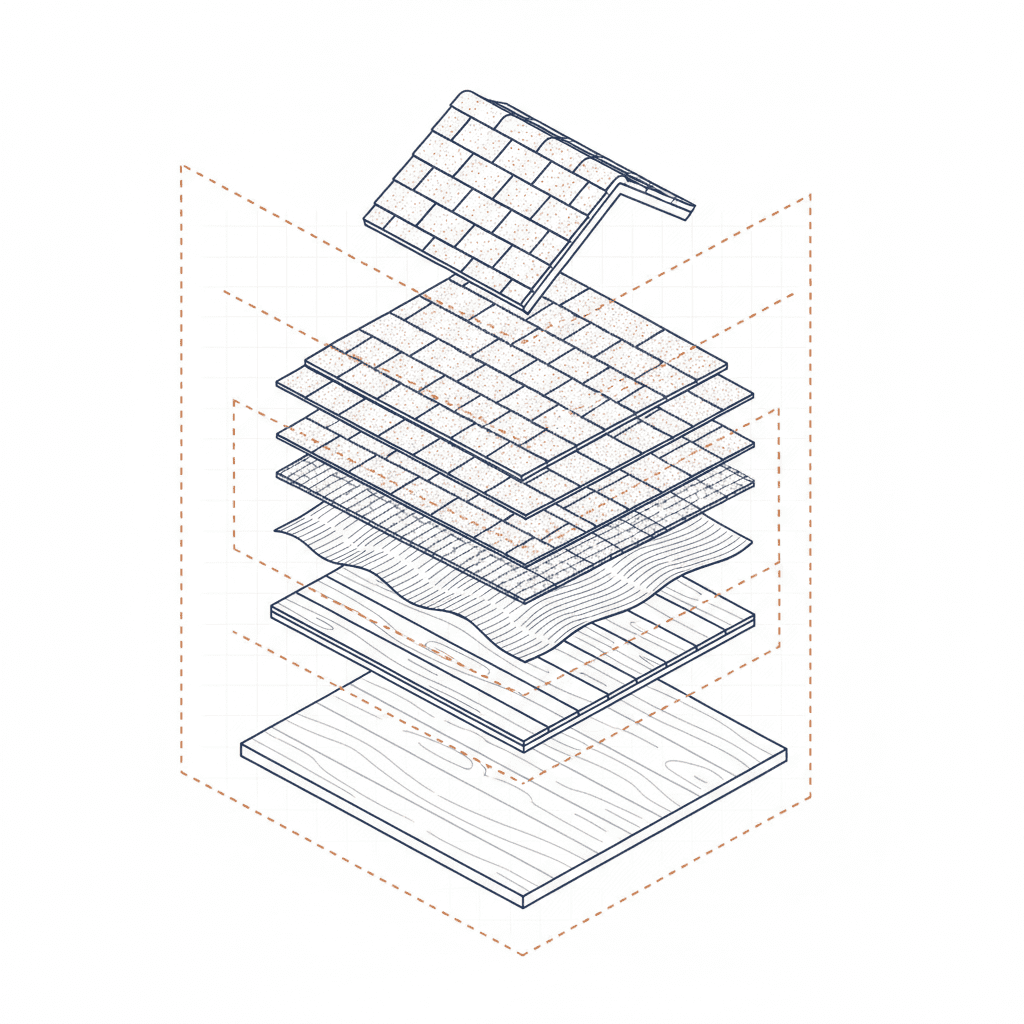

Algae resistance is a feature built upon a foundation of proven structural components. A high-performance asphalt shingle consists of several layers, each with a specific function:

- Fiberglass Mat: This is the shingle’s skeleton. It provides dimensional stability, structural support, and a base for the other materials. Its strength is critical for impact resistance and protection against wind.

- Asphalt (Bitumen): This layer saturates the fiberglass mat, providing the primary waterproofing characteristic of the shingle. It is the core barrier against rain and snow.

- Mineral Granules: These ceramic-coated particles are pressed into the top asphalt layer. They serve two primary functions: shielding the asphalt from damaging UV radiation and providing the shingle’s color and aesthetic. In algae-resistant shingles, copper granules are mixed into this layer.

The integrity of the complete shingle relies on the quality and synergy of these components.

Comparing Technologies: Legacy Zinc vs. Modern Copper Systems

Early attempts at algae resistance relied on zinc strips installed at the roof’s ridge. While functional to a degree, this legacy system is inferior to modern, integrated copper technology. The following table outlines the critical differences:

| Attribute | Legacy Zinc Strips | Modern Copper-Infused Granules |

|---|---|---|

| Mechanism | Relies on rainwater washing zinc particles from a single strip at the roof’s peak. | Copper ions are released evenly from granules distributed across the entire shingle surface. |

| Effectiveness | Effectiveness diminishes significantly further down the roof slope. Prone to inconsistent protection. | Provides uniform, consistent stain protection across the entire roof surface. |

| Longevity | Zinc strips can corrode, detach, or become less effective over time. | Engineered for time-release, with longevity warrantied to match the shingle’s lifespan. |

| Aesthetics | Visible metal strip at the roof ridge, which can be aesthetically displeasing. | Copper granules are blended with colored granules, making them invisible. |

| Warranty | Typically not covered by shingle manufacturer’s stain warranty. | Integrated into the manufacturer’s stain-free guarantee, often for 10 to 25 years. |

Modern copper systems offer superior performance, longevity, and aesthetic integration, making them the only logical choice for a new roofing system.

Evaluating Algae-Resistant Systems: A Framework for Decision-Making

Choosing a material is only the first step. You must have a clear framework for evaluating the long-term performance and guarantees associated with that material. A roof is a significant capital investment; its warranty and certifications are non-negotiable proof of its engineering.

Decoding Manufacturer Warranties: What ‘Lifetime Protection’ Truly Means

Manufacturer warranties are legal documents that define the scope and limits of liability. Vague terms like ‘lifetime’ are meaningless without a precise definition of their terms. A meticulous review must focus on:

- Prorated vs. Non-Prorated Coverage: A non-prorated period provides full replacement value for a set number of years. Afterward, the coverage becomes prorated, decreasing in value over time. Understanding this timeline is critical.

- Stain-Free Guarantee: This is a separate clause from the primary shingle warranty. Scrutinize its duration (e.g., 10, 15, or 25 years) and its definition of ‘staining’.

- Transferability: A transferable warranty can be passed to a new homeowner, which is a significant factor in property resale value. Verify the process and any associated fees.

- Exclusions: All warranties have exclusions. Common exclusions include improper installation, inadequate ventilation, or damage from pressure washing. This reinforces the fact that material performance is inseparable from installation quality.

Verifying Performance: Third-Party Certifications and ASTM Standards

Third-party certifications provide objective, standardized validation of a manufacturer’s claims. They are the external verification that the product performs as specified under controlled testing conditions.

- ASTM International: Look for compliance with standards such as ASTM D3462 for asphalt shingle strength and durability, and ASTM D7158 for wind resistance. These are baseline indicators of quality.

- UL Certification: Underwriters Laboratories provides testing for fire resistance (UL 790) and wind resistance (UL 2218). A Class A fire rating is the highest available for residential roofing.

- Impact Resistance: A UL 2218 Class 4 rating indicates the highest level of resistance to impact from hail. This can result in significant insurance premium discounts and is essential for asset protection in hail-prone regions.

These standards are the language of performance. They transform marketing claims into verifiable data points, enabling a clear, logical decision.

The Installation Protocol: Why Superior Materials Demand a Superior Process

The performance of a technologically advanced shingle is entirely contingent upon the quality of its installation. The most precisely engineered materials will fail if they are not integrated into the building as part of a systematic, controlled process. The enemy of a successful roofing project is chaos: ambiguous timelines, poor communication, and a disregard for procedure. We have built our entire methodology to eliminate it.

A Systemic Approach: Integrating Shingles with Total Roof Construction

A roof is more than its top covering. It is a complete system where every component works in concert to provide protection. Our protocol ensures every element is installed to function as part of this cohesive whole:

- Roof Deck Preparation: We inspect and replace any damaged sheathing to provide a solid, non-negotiable foundation.

- Underlayment: A high-quality synthetic underlayment provides a critical secondary water barrier.

- Flashing and Drip Edge: These metal components are meticulously installed at all penetrations, valleys, and eaves to direct water away from the most vulnerable areas.

- Ventilation: We calculate and install a balanced ventilation system (soffit and ridge vents) to manage attic temperature and moisture, which is essential for shingle longevity and warranty compliance.

A failure in any one of these subsystems constitutes a failure of the entire roof. There are no shortcuts.

Our Zero-Chaos Methodology vs. The Industry Standard of Disorder

Our defining value is predictability. You have a complex life and cannot afford the disorganization that defines the typical construction experience. We offer a clear alternative.

An Investment in Order: The Financial Logic of a Process-Driven Roof

A roofing project is a significant financial outlay. The decision-making process must be grounded in logic, not just initial cost. The true metric is the total cost of ownership, which includes not only the initial price but also the cost of future problems, premature failures, and the unquantifiable cost of stress caused by a chaotic process.

Why We Are Not the Cheapest Bid (And How That Protects You)

We state this directly: if your project’s primary driver is securing the lowest possible price, we are not the appropriate contractor for your needs. This is a deliberate business decision that protects you and ensures we can deliver on our promises.

Our pricing is a direct reflection of our process. It accounts for:

- Skilled, Vetted Labor: We invest in highly trained, experienced crews who adhere to our strict installation protocols.

- Superior Project Management: You have a single point of contact who is dedicated to the predictable execution of your project.

- No Hidden Fees: Our proposals are exhaustive and transparent. The price you are quoted is the price you will pay.

- Uncompromising Quality Control: We do not cut corners on materials or process. Every step is executed to manufacturer specifications and beyond.

Our clients choose us because they understand that the cost of chaos—rework, property damage, and project delays—is always higher than the price of order.

Request a Consultation: The First Step in a Predictable Project

Your project deserves a clear, logical, and transparent plan. A consultation with our team is the first step in that process. We do not provide vague estimates. We deliver a comprehensive project proposal that includes a detailed scope of work, a breakdown of materials, a firm timeline, and a written guarantee. This is the foundation of a predictable, stress-free project. Contact us to begin the process of protecting your asset with precision and order.