Systematic Metal Roof Replacement Services

A metal roof replacement is a construction process that removes a building’s failing top covering and installs a new, high-performance metal roof system. This system includes all materials and constructions necessary to support the roof, providing absolute protection against rain, snow, sunlight, extremes of temperature, and wind. The objective is to restore the building’s primary defense against the elements through a predictable, documented, and systematic methodology.

Metal Roof System Analysis: Critical Indicators for Replacement

A comprehensive analysis determines if a roof has reached the end of its functional service life. This is not a subjective assessment; it is a forensic examination of material degradation and system failure. Identifying these indicators prevents catastrophic water intrusion and structural damage.

Corrosion is the irreversible degradation of metal panels. It signals a fundamental failure of the roof’s protective coatings and, eventually, its core material. We identify specific types of corrosion, including uniform rust on steel panels and galvanic corrosion, which occurs when dissimilar metals are in contact. Panel perforation, or holes created by advanced corrosion, represents a critical system failure. Coating failure is the precursor to this process, leaving the underlying metal substrate exposed and vulnerable. This assessment directly evaluates the roof’s ability to function as a waterproof barrier and support its own weight.

A metal roof is a system of interconnected components. The failure of even the smallest parts compromises the whole. We inspect for loose or backed-out fasteners, which are a primary cause of wind damage and panel uplift. The neoprene washers on these fasteners degrade under UV exposure, becoming brittle and cracked, which creates a direct path for water intrusion. Similarly, all sealants applied at joints, flashing, and penetrations have a finite lifespan. Sealant degradation results in failed seams and leaks that are often difficult to detect until significant interior damage has occurred.

The finish on a metal roof panel is its first line of defense. High-performance coatings, such as PVDF (Kynar 500), are engineered for color stability and sunlight protection. We evaluate the condition of this finish for three key indicators of UV degradation. Fading is the visible loss of color intensity. Chalking is the formation of a white, powdery residue as the paint resin breaks down. Delamination is the physical peeling or blistering of the coating from the metal substrate. While often considered aesthetic issues, these are direct evidence that the finish warranty has expired and the panel is losing its primary protection against corrosion.

Material Specification: A Data-Driven Comparison for Your Building

Selecting the right material is a financial and operational decision based on empirical data, not preference. We analyze material options based on lifecycle cost, performance metrics, and energy efficiency to provide a clear recommendation for your specific building and environmental conditions. Our process replaces ambiguity with quantifiable data.

Lifecycle Cost vs. Initial Price: A Financial Projection

Initial price is a misleading metric for a long-term asset like a roof. The correct financial analysis is based on Total Cost of Ownership (TCO). This calculation projects costs over a 30-50 year period, including initial installation, maintenance, repairs, and eventual replacement. A standing seam metal roof, for example, has a higher initial investment than asphalt shingles but a significantly lower TCO due to its extreme longevity and minimal maintenance requirements. This approach frames the roof as a long-term investment that increases home value, not a short-term expense.

Quantifying Protection Against Wind, Rain, and Snow

A roof’s primary function is protection. This protection can be measured and specified. We analyze materials based on their certified performance ratings to ensure they meet or exceed the demands of your location.

| Performance Metric | Standing Seam Metal | Asphalt Shingles |

|---|---|---|

| Wind Resistance Rating | Typically 140+ MPH | 90-130 MPH |

| Impact Resistance | UL 2218 Class 4 (highest) | Varies; Class 4 available at higher cost |

| Fire Rating | Class A (non-combustible) | Class A |

| Expected Lifespan | 50+ Years | 15-25 Years |

We specify systems engineered to manage local snow load capacity and provide superior waterproofing against extreme weather events.

Energy Efficiency: Analyzing Solar Reflectance and Thermal Emissivity

A modern roof is an active component of your home’s energy system. A “cool roof” is a roof designed to reflect more sunlight and absorb less heat than a standard roof. This performance is measured by two values: Solar Reflectance and Thermal Emissivity, which are combined into a single Solar Reflectance Index (SRI) value. A higher SRI value translates directly to lower attic temperatures, reduced load on your HVAC system, and lower energy costs. We provide the SRI data for specified panel colors, allowing you to make an informed decision that impacts your building’s operational costs for decades.

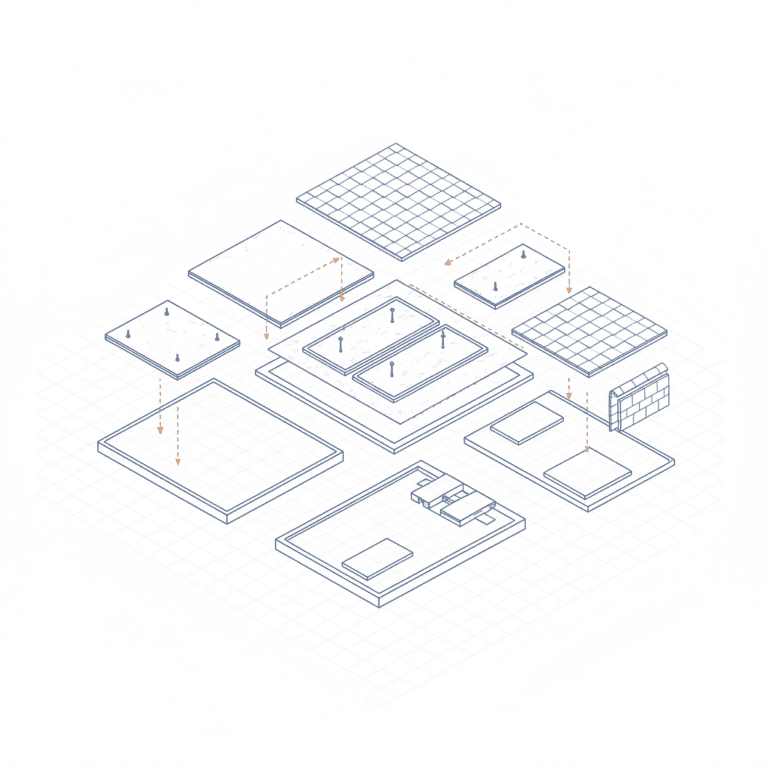

The Anatomy of a High-Performance Metal Roof: Materials and Constructions

A roof is not just the metal panels you see. It is an integrated system of layers, each performing a critical function. The longevity and waterproofing capability of the entire roof construction depend on the correct specification and installation of every component, from the structural deck to the ventilation system.

Structural Roof Deck: The Foundation for All Materials

The roof deck, or sheathing, is the structural foundation for the entire roofing system. It must be sound, clean, and dry. This layer provides the load-bearing capacity to support the weight of the roofing materials, workers, and environmental loads like snow. Any rotted, delaminated, or damaged decking is identified during our inspection and tear-off phases. It is replaced to meet or exceed building code requirements before any new materials are loaded. This is a non-negotiable step.

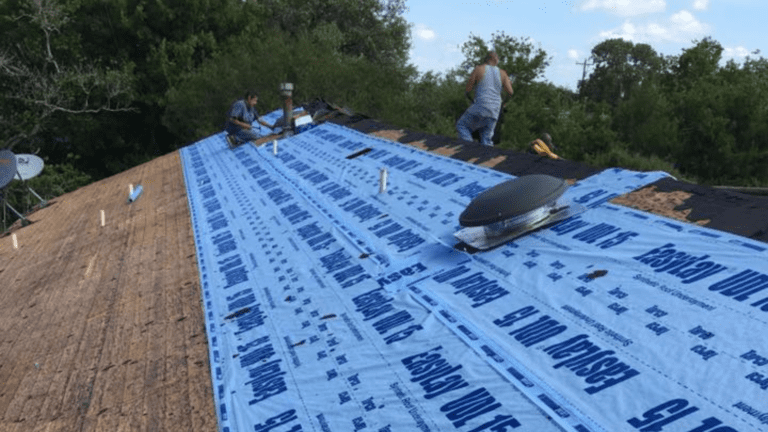

High-Temperature Underlayment: The Essential Secondary Protection

A roof is not just the metal panels you see. It is an integrated system of layers, each performing a critical function. The longevity and waterproofing capability of the entire roof construction depend on the correct specification and installation of every component, from the structural deck to the ventilation system.

Panel and Seam Engineering: Standing Seam vs. Exposed Fastener

The method of fastening and seaming panels defines the roof’s performance. Exposed fastener systems are less expensive initially but introduce thousands of potential failure points, as every fastener penetrates the panel. Standing seam systems are the superior engineering solution. Fasteners are concealed and protected from the elements, eliminating common leak points. The seams—either snap-lock or mechanical lock—are raised above the panel’s water-shedding surface. This design allows for the natural thermal expansion and contraction of the metal panels without stressing the fasteners, ensuring a weathertight seal for decades.

Ventilation Systems: Managing Heat and Moisture Within the Construction

A roof assembly must breathe. Proper ventilation is a balanced system of intake (soffit vents) and exhaust (ridge vents) that facilitates constant air circulation through the attic space. This system manages attic temperature extremes and removes damaging moisture that rises from the living space. An effective ventilation system prevents ice dam formation in the winter, reduces cooling costs in the summer, and extends the life of the entire roof construction by keeping the structural decking dry and stable.

The Replacement Process: A Step-by-Step Execution Plan

Construction Logistics and Material Staging

We finalize the project timeline, confirm material procurement, and develop a site-specific safety and property protection plan. Materials are delivered and staged in a designated, low-impact area.

Systematic Removal and Disposal of Old Roofing Materials

Grounds and sensitive landscaping are protected. The old roofing is torn off in manageable sections to limit roof deck exposure. All debris is managed and placed directly into the designated dumpster.

Substrate Inspection and Structural Preparation

With the substrate exposed, a detailed structural inspection is conducted. Any necessary deck repair is completed. The substrate is cleaned, and all wall flashing transitions are prepared for the new system.

Precision Installation of the Complete Roof System

The underlayment, trim, panels, and flashing details are installed according to a precise panel layout and manufacturer specifications. All penetrations are sealed using engineered, warrantied methods.

Contractor Selection: A Framework for Avoiding Project Chaos

The contractor you choose is the single most important variable in your project’s success. The vetting process should focus on a contractor’s systems and communication protocols, not just their price. The goal is to hire a project management partner, not simply a crew of installers.

Why Vague Quotes and Low-Ball Bids Are Unacceptable

We must be direct. If your primary decision criterion is finding the absolute lowest price, RocStout is not the right contractor for you. Low-ball bids are a function of incomplete scopes of work. They omit critical line items for materials, property protection, and substrate repair. This ambiguity is a deliberate strategy that leads directly to the chaos of surprise change orders, schedule delays, and conflict. A detailed, line-item estimate is the minimum standard for a professional engagement. Anything less is unacceptable and a clear indicator of a disorganized, unpredictable process.

The Non-Negotiable Requirement for a Dedicated Project Manager

A roofing project requires constant oversight and communication. Without a single point of contact who is accountable for the schedule, quality, and budget, your project will devolve into chaos. A dedicated Project Manager is the antidote. They are responsible for executing the project plan, providing you with proactive project updates, and resolving any issues that arise. This role is not an optional luxury; it is the central component of a professionally managed construction project.

Client Feedback on Our Process-Driven Approach

Our success is measured by the stress-free experience we provide our clients.

"...fast but excellent work, came as scheduled, and outstanding clean up."

-Sharon B.

"10/10 highly recommend. Wish I could give more stars but 5 is the max."

-Mika S.

"He and his crew are always very professional and communication is top notch."

-Richard P.

Our Method: The Only Process for a Predictable Roof Replacement

We have engineered a process that removes the variables that cause stress and failure in roofing projects. Our methodology is built on transparency, communication, and a fanatical commitment to order. This is how we deliver a predictable outcome, every time.