A 30-year cost-benefit breakdown of standing seam metal versus asphalt shingles is a comparative analysis of two distinct roof systems designed to function as the top covering of a building. This covering, including all materials and construction, is the primary barrier providing protection against rain, snow, sunlight, extremes of temperature, and wind. Your decision impacts not only the immediate capital expenditure but the predictable performance and long-term financial liability of your most significant asset. This analysis is designed to deliver a predictable outcome through methodical project management of information.

Defining the Objective: A Roof as a Protective System, Not a Commodity

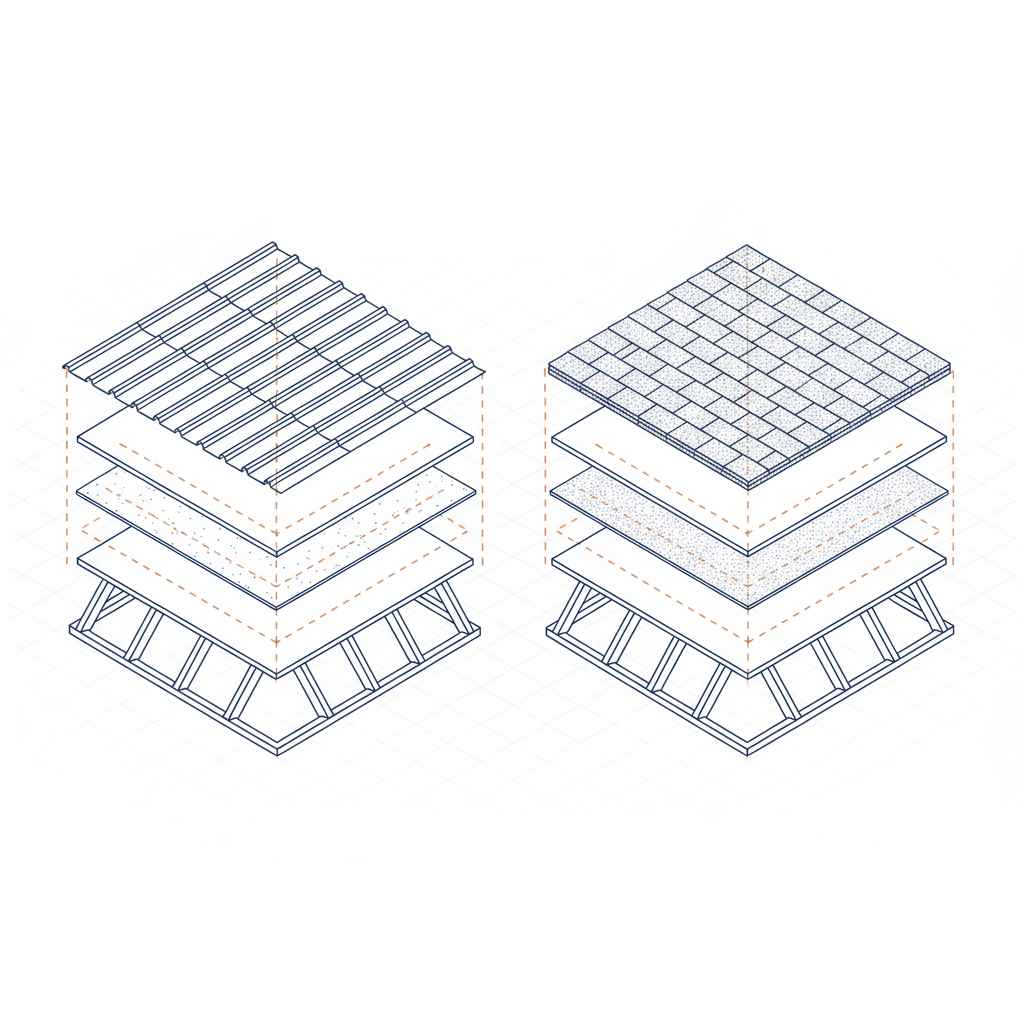

A roof is a complete system, not just a roof covering. The objective is total protection of the asset beneath it. This system is an assembly of materials and construction methodologies engineered to work in unison. The roof deck, underlayment, flashing, ventilation, and primary covering must be specified and installed as an integrated unit. Viewing any single component, such as the shingle or metal panel, as a commodity is a fundamental error that leads to system failure. The true value is in the integrity of the total assembly and the quality of its construction.

A Note on Price: If Lowest Cost is Your Primary Metric, We Are Not The Right Fit

Our process is engineered for a specific type of client: one who values precision, predictability, and peace of mind above all else. Consequently, our solutions are not the cheapest on the market. If your decision-making process is governed by finding the absolute lowest bid, we are not the right partner for your project. This is not a judgment; it is a statement of fact that ensures we serve our target clients with unparalleled focus. We engage in value engineering focused on total lifecycle cost and asset protection, not initial price reduction. This approach allows us to invest in superior craftsmanship and project management, eliminating the chaos and surprise costs that plague low-bid projects.

Core Material & Construction Analysis

The fundamental difference between standing seam metal and asphalt shingles lies in their material composition and construction methodology. One is a monolithic system of interlocking metal panels designed for water shedding, while the other is a layered system of overlapping, granule-coated tabs engineered for water resistance. Understanding this distinction is critical to evaluating their long-term performance as a building covering.

Standing Seam Metal: A Monolithic, Interlocking System

A standing seam metal roof consists of vertical metal panels joined by raised, interlocking seams. The fastening system is entirely concealed, protecting it from the elements and eliminating points of water intrusion. These panels are typically manufactured from high-performance Galvalume steel, a carbon steel sheet coated with an aluminum-zinc alloy for superior corrosion resistance. The panel profile is designed to accommodate thermal expansion and contraction, allowing the entire roof to move as a single unit without stressing the fasteners. The system functions as a continuous, watertight membrane from ridge to eave.

Asphalt Shingles: A Granule-Based, Overlapping System

An asphalt shingle is a composite material. It begins with a fiberglass mat that provides structural integrity. This mat is saturated with asphalt (bitumen) for waterproofing. The top surface is then coated with a dense layer of mineral granules, which provide protection against UV degradation and add color. Laminated, or architectural, shingles consist of multiple layers fused together to create a dimensional appearance. Shingles are installed in overlapping courses, relying on a factory-applied sealant strip and mechanical fasteners to create a water-resistant, but not waterproof, field.

Performance Metrics: Protection Against Environmental Forces

A roof system’s primary function is to provide unwavering protection against environmental forces. This includes managing vast quantities of water from rain, supporting heavy snow loads, resisting wind uplift, and enduring decades of sunlight and the extremes of temperature. The performance differences between metal and asphalt in these categories are absolute.

Water & Snow Management: Shedding vs. Resisting

Standing seam metal is a hydrostatic system. Its smooth, impermeable surface and vertical seam orientation are engineered to shed water and snow with maximum efficiency. The raised seams prevent water from reaching the concealed fasteners, making it exceptionally resistant to water infiltration even on low-slope applications. This efficiency also minimizes the formation of ice damming, as snow and ice slide off before significant accumulation can occur. Asphalt shingles, by contrast, resist water. Their granular surface creates friction, slowing water runoff and retaining snow. Each shingle, nail penetration, and seam represents a potential point of failure, making them vulnerable to wind-driven rain and ice damming, which can force water uphill past the overlaps.

Wind Uplift Resistance: A Comparative Failure Analysis

Wind uplift is a critical failure point for roofing systems. A standing seam metal roof’s panels are interlocked and mechanically seamed, creating a unified structure. The concealed clips that secure the panels to the deck are engineered to withstand significant negative pressure. Wind flows over the smooth surface, creating minimal turbulence. Asphalt shingles are far more vulnerable. High winds can get underneath the edge of a shingle, breaking the sealant strip. Once a single shingle tab is lifted, it creates a cascading failure as wind peels successive courses from the roof. The exposed nailing strip on a standard shingle is its primary structural weak point.

| System | Fastening Mechanism | Typical Failure Mode | Wind Speed Rating (Typical) |

|---|---|---|---|

| Standing Seam Metal | Concealed clips & interlocking seams | Catastrophic panel detachment (rare) | 140+ MPH |

| Asphalt Shingle | Exposed nails & adhesive strip | Shingle blow-off, tab lifting | 110-130 MPH |

Solar & Thermal Performance: Managing Sunlight and Temperature Extremes

Metal roofing is a ‘cool roof’ system. Its high solar reflectance and emissivity mean it reflects a significant amount of solar radiation and efficiently releases absorbed heat. This reduces the heat load on the building, lowering cooling costs. Asphalt shingles, particularly dark ones, absorb a massive amount of solar energy, which they then conduct into the attic and building structure, increasing cooling loads. This constant exposure to high temperatures and UV radiation also accelerates the degradation of the asphalt itself, causing it to become brittle over time. Metal’s ability to handle thermal shock—rapid expansion and contraction—is engineered into the system’s floating clip design, whereas thermal shock on asphalt shingles contributes to cracking and material fatigue.

Projected Service Life: A Study in Material Degradation

The service life of a roof is dictated by its rate of material degradation. For standing seam metal, the limiting factors are the longevity of the paint finish and the corrosion resistance of the Galvalume substrate, typically warrantied for 40-50 years. Color fading is the primary aesthetic issue, but structural integrity remains for decades longer. For asphalt shingles, degradation is rapid and continuous. Granule loss begins almost immediately, exposing the underlying asphalt to UV rays. This leads to cracking, curling, and brittleness. An asphalt shingle roof in a harsh climate has a realistic service life of 15-20 years, regardless of a ’30-year’ or ‘lifetime’ marketing warranty. The system’s viability ends when it can no longer effectively resist water.

Structural & Support System Requirements

A roofing system is supported by the walls of the building and the underlying roof deck. The dead load of the roofing material and its specific installation requirements directly impact these structural support components. Both systems require a solid, stable substrate, but their demands differ significantly.

Weight & Structural Load Comparison

Standing seam metal is exceptionally lightweight. It typically weighs between 1.0 to 1.5 pounds per square foot (PSF). This minimal dead load places very little stress on the building’s framing and truss system. Architectural asphalt shingles are substantially heavier, weighing from 2.5 to 4.5 PSF. This additional weight is a critical consideration, especially in older structures or regions with high snow load requirements, where the combined weight of the roof and snow can push structural limits.

Underlayment and Decking Specifications for Optimal Performance

Both systems require a properly installed, solid roof deck, typically plywood or OSB sheathing. The critical difference is the underlayment. For a standing seam metal roof, a high-temperature synthetic underlayment is mandatory. Metal panels can reach high surface temperatures, which would degrade standard asphalt-saturated felt. This specialized underlayment also acts as a crucial vapor barrier and a secondary layer of protection. Asphalt shingles are typically installed over standard felt or a basic synthetic underlayment. Proper roof deck preparation, including re-nailing and ensuring a flat plane, is critical for both, but imperfections are more visually apparent under the clean lines of a metal panel.

Long-Term Cost of Ownership: A Financial Projection

A meticulous financial analysis moves beyond the initial invoice to calculate the total lifecycle cost of an asset. This includes the initial capital expenditure, predictable maintenance, and eventual replacement cost, amortized over a defined period. When evaluating a roof, this is the only logical approach to determine value.

Initial Investment vs. Total Lifecycle Cost Analysis

The initial investment for a standing seam metal roof is significantly higher than for an asphalt shingle roof, often 2 to 3 times the cost. However, its projected service life is also 2 to 3 times longer. Over a 30-year period, a homeowner will install one standing seam metal roof. In that same period, they will likely install two complete asphalt shingle roofs. When factoring in the cost of the second replacement—including tear-off, disposal, and the inflated cost of labor and materials in 15-20 years—the long-term value proposition shifts dramatically.

| Cost Factor | Asphalt Shingles (2,500 sq. ft.) | Standing Seam Metal (2,500 sq. ft.) |

|---|---|---|

| Initial Installation (Year 0) | $15,000 | $35,000 |

| Maintenance (Years 1-15) | $750 (minor repairs) | $250 (inspections) |

| Replacement (Year 17) | $22,500 (projected) | $0 |

| Maintenance (Years 18-30) | $750 (minor repairs) | $250 (inspections) |

| Total 30-Year Cost | $39,000 | $35,500 |

| Cost Per Year of Service | $1,300 | $1,183 |

Maintenance Protocols and Repair Complexity

Predictable upkeep for a standing seam roof involves routine inspection of seams, flashing, and penetrations, typically annually. Debris should be cleared from valleys. System maintenance is minimal. Repairing a damaged panel is a specialized task that requires removing the seam and replacing the full-length panel. For asphalt shingles, maintenance involves inspecting for granule loss, cracked or lifted tabs, and compromised sealant strips. Shingle repair is simpler for isolated damage but becomes impractical for systemic failure, necessitating full replacement. The maintenance burden for shingles is consistently higher and less predictable.

The Decisive Factor: Eradicating Chaos from the Installation Process

The choice between materials is an engineering decision. The choice of a contractor is a risk management decision. The superior material can be rendered worthless by a chaotic, disorganized installation process. The true enemy of a successful roofing project is not wind or rain; it is poor communication, undefined timelines, and a lack of on-site project management. Predictability is the most valuable component we deliver.

Standard Industry Chaos vs. A Meticulous, Predictable Methodology

The standard roofing experience is defined by chaos. Vague start dates, messy job sites, unexpected charges, and inaccessible supervisors are the norm. This is unacceptable. Our methodology is the antidote. We operate with the precision of a manufacturing process applied to construction. Every step is documented, every day includes a progress update, and the scope of work is locked before the project begins. There are no surprise charges. Job site cleanliness is a system component, not an afterthought.

Vague estimates, loose timelines, poor communication, messy site, and surprise charges.

A detailed, line-item scope of work that functions as the project blueprint. The price is fixed.

You receive a single point of contact responsible for all logistics, communication, and quality control.

Your Project Manager provides a mandatory end-of-day report with photos and status updates.

The project is not complete until you and your Project Manager conduct a final inspection and approve every detail.

Your Project Manager Is the Most Critical System Component

The material choice is important, but the human system that manages the installation is paramount. Your dedicated Project Manager is your single point of contact and the guarantor of a stress-free experience. They are not a salesperson; they are a process-driven logistics expert responsible for quality assurance. They own the project timeline, the crew’s performance, and the final outcome. This is the only sane way to manage a significant construction project on your home. It replaces anxiety with certainty. It delivers a predictable, controlled, and satisfactory outcome. Every time.