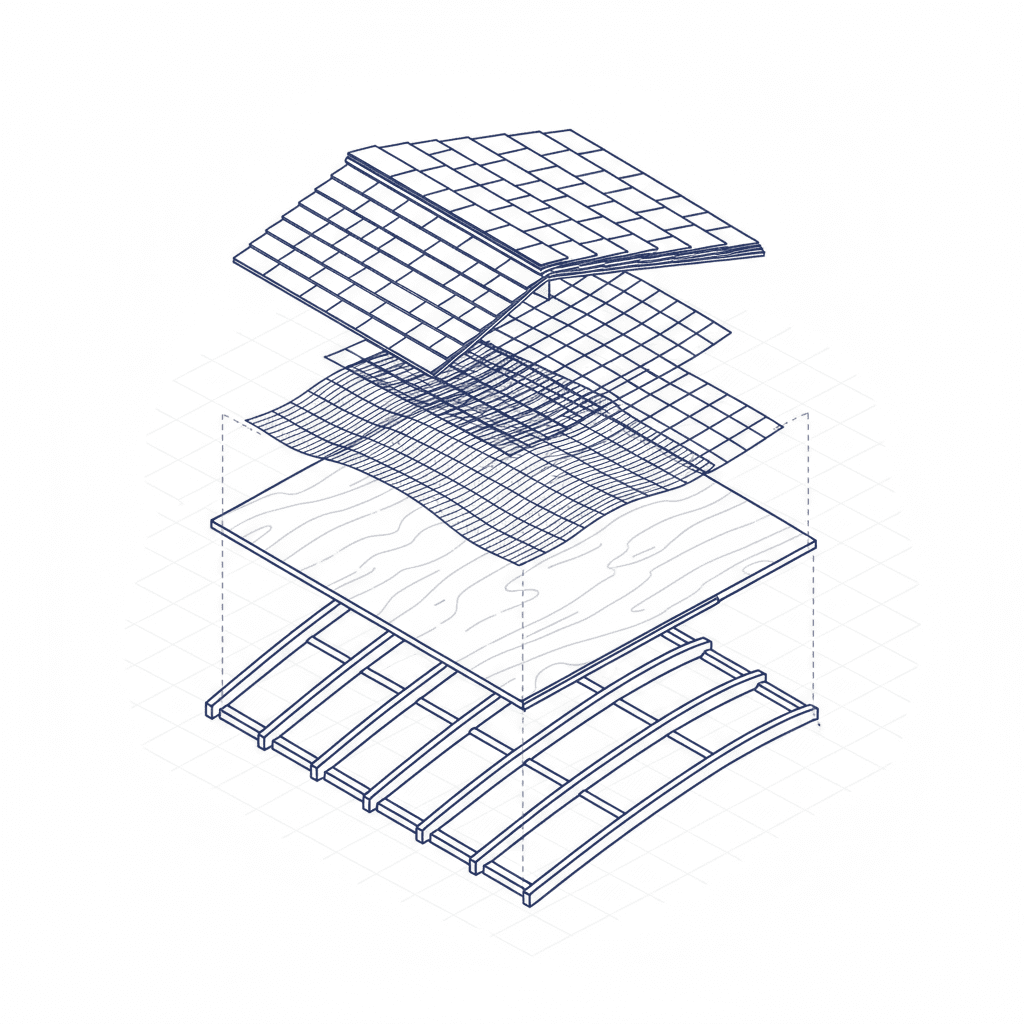

Roof underlayment is a water-resistant or waterproof barrier material installed directly onto a roof’s deck, beneath all other roofing materials. It functions as a critical component of the complete roof system, which is the total covering of a building designed to provide protection against rain, snow, sunlight, and wind. Underlayment serves as the secondary line of defense against water intrusion, protecting the building’s core structure if the primary roof covering is breached. The material science of this layer dictates the predictability and longevity of the entire system. Traditional asphalt-saturated felt introduces systemic vulnerabilities. Modern synthetic underlayment eliminates them.

The Critical Function of Underlayment in Total Roof Protection

The underlayment is not an optional accessory; it is an integral layer in the construction of a durable roof. Its performance directly impacts the structural integrity of the sheathing, rafters, and the interior of your home. It ensures the roof assembly can fulfill its primary mandate: to protect the building from environmental elements.

Defining the Secondary Water Barrier: Your Roof’s Last Line of Defense

The primary roof covering, such as shingles or metal panels, is designed to shed the vast majority of water. However, no primary system is infallible. Wind-driven rain, ice damming, or damage to a shingle can allow water to bypass this first layer. The underlayment’s function is to intercept this water before it reaches the wood roof deck. It channels the moisture down to the eaves and away from the structure, preventing rot, mold, and catastrophic leaks. A failure at this layer means a complete system failure.

System Integration: How Underlayment Supports the Entire Roof Construction

A roof is a complete system of integrated parts, not a collection of materials. The underlayment must function in concert with the deck, shingles, flashing, and ventilation. It provides a uniform surface for shingle installation, preventing irregularities in the wood decking from telegraphing through. During construction, it offers temporary protection to the roof deck, allowing work to proceed in a controlled manner even if weather interrupts the project. A stable, durable underlayment is the foundation upon which a predictable, long-lasting roofing project is built.

Technical Assessment: Asphalt-Saturated Felt (Traditional Method)

Asphalt-saturated felt paper, commonly called tar paper, is a legacy material. Its composition and performance characteristics are products of a bygone era of material science. From a modern engineering perspective, its continued use introduces unacceptable levels of risk and unpredictability into a roofing project.

Material Composition: Organic Fibers Saturated in Asphalt

Felt underlayment consists of a base mat of organic materials—typically cellulose fibers from recycled paper and wood pulp—that is saturated with asphalt. It is produced in two common weights: 15-pound and 30-pound, designations referring to their weight per 100 square feet. This organic composition is its fundamental flaw. It is, by its very nature, a porous, absorbent material coated in a water-resistant substance, not an inherently waterproof one.

Performance Analysis: Water Resistance vs. Water Absorption

The core deficiency of asphalt felt is its hydrophilic nature. While the asphalt provides initial water resistance, the underlying organic fibers will absorb moisture upon prolonged exposure. This absorption causes the felt to wrinkle and buckle. These wrinkles can telegraph through the shingles, creating an aesthetic issue and, more critically, creating channels where water can be trapped. The material wicks moisture, meaning it can draw water into the roof deck rather than shedding it away. This behavior directly contradicts the primary function of a secondary water barrier.

Exposure Limitations: UV Degradation and Temperature Sensitivity

Asphalt felt is highly susceptible to environmental degradation. Exposure to sunlight causes the volatile oils in the asphalt to evaporate, making the material brittle and prone to cracking. This severely limits the acceptable window for installation; a roof deck covered in felt cannot be left exposed to the elements for long without compromising the material. Furthermore, in cold temperatures, felt becomes stiff and difficult to install correctly, while in high heat, it can soften and scuff under foot traffic, creating weak points.

Technical Assessment: Non-Asphalt Synthetic Underlayment (Modern Standard)

Synthetic underlayment is the engineered solution to the inherent failures of asphalt felt. It is a product of advanced material science designed specifically for superior strength, water repellency, and installation stability. It represents the modern standard for any roofing project where predictability and long-term performance are the primary objectives.

Material Composition: Woven Polymer Fabrics and Advanced Coatings

Synthetic underlayments are typically manufactured from polypropylene or polyolefin, which are polymers. These materials are spun into exceptionally strong woven or non-woven fabrics. Unlike the organic mat of felt, this polymer base is inherently water-resistant and inert. The fabric is then coated with specialized layers that enhance water repellency, provide UV protection, and create a high-traction, slip-resistant surface for installer safety. The entire construction is lightweight, dimensionally stable, and engineered for performance.

Performance Analysis: Superior Water Repellency and Strength

The defining characteristic of synthetic underlayment is that it is hydrophobic—it repels water. It does not absorb moisture, so it will not wrinkle, buckle, or transmit moisture to the roof deck. Its tensile strength, a measure of its resistance to tearing, is exponentially higher than that of asphalt felt. This durability is critical. It withstands the rigors of installation, including high foot traffic and fastener penetration, without compromising its integrity. It functions as a true water-shedding barrier, ensuring any moisture that gets past the shingles is directed safely off the roof.

Exposure Advantages: High UV Stability and Wind Resistance

High-quality synthetic underlayments are engineered with UV inhibitors that allow them to be exposed to sunlight for extended periods—often 6 to 12 months—without degradation. This creates a massive advantage in project management, eliminating the chaos caused by weather delays. A ‘dried-in’ roof using synthetic underlayment is protected, allowing other trades to work without the urgent pressure to install the final covering. Its superior tear strength also provides exceptional resistance to wind uplift, both during and after construction, keeping the roof deck protected in high-wind events.

Comparative Analysis: A Decision Matrix for Meticulous Homeowners

The choice between underlayment materials is not a matter of preference. It is a calculated decision based on empirical data. For a homeowner who values order, predictability, and long-term asset protection, the data points to a single, logical conclusion.

| Performance Metric | Asphalt-Saturated Felt (Unacceptable Risk) | Synthetic Underlayment (Modern Standard) |

|---|---|---|

| Moisture Protection Efficacy | Water Resistant / Water Absorbent. Prone to wicking moisture into the roof deck. Wrinkles when wet, creating water traps. | Waterproof / Hydrophobic. Actively repels and sheds water. Dimensionally stable; will not wrinkle or buckle. |

| Durability & Tear Strength | Very low tear strength. Easily damaged by foot traffic, high winds, or around fasteners. | Extremely high tear strength. Withstands heavy foot traffic and resists tearing from fasteners and wind uplift. |

| Installation & Safety | Heavy, brittle in cold, soft in heat. Often slippery. Fewer square feet per roll increases installation time and seams. | Lightweight and flexible across all temperatures. Engineered slip-resistant surface. More coverage per roll reduces seams and installation time. |

| UV & Exposure Stability | Degrades rapidly in sunlight (days to weeks). Forces rushed project timelines and introduces weather-related risk. | Stable in sunlight for 6-12 months. Allows for predictable project scheduling and protects the structure during delays. |

| Long-Term Value | Lower initial material cost. Higher risk of premature failure, deck rot, and costly secondary repairs. A liability to the system. | Higher initial material cost. Provides superior long-term protection, supports system warranty, and minimizes total cost of ownership. An asset to the system. |

Financial Calculation: Initial Cost vs. Long-Term Asset Value

A roofing system is a significant capital investment. Focusing solely on the initial material cost of one component is a flawed financial calculation. While felt paper is cheaper per roll, it introduces a high probability of future costs: premature shingle failure, deck replacement due to rot, and interior water damage. Synthetic underlayment’s slightly higher upfront cost is an investment in risk mitigation. It ensures the longevity of the entire roof assembly, protecting the far more expensive components and the structure of your home itself. This is the difference between a short-term expense and a long-term asset.

Our Protocol: System Integrity is Non-Negotiable

At RocStout, our entire business model is built on eliminating the chaos and unpredictability that defines the standard roofing industry experience. This philosophy dictates our choice of materials, our installation procedures, and our client interactions. We do not offer a menu of good, better, and best options. We offer one option: the correct one.

Why We Mandate Synthetic Underlayment: Eliminating Project Chaos

We use synthetic underlayment on every project. This is not an upgrade; it is our baseline standard. It is a non-negotiable component of our process. By mandating a superior, predictable material, we remove an entire category of potential failures and delays from the project equation. It allows our project managers to provide you with a reliable timeline. It ensures our installers can work safely and efficiently. It guarantees that your home is protected from the moment we begin work. This is project control.

Rejecting the Low-Bid Mentality for Predictable, Warrantied Results

We must be clear. If your primary objective is to secure the absolute lowest price for your roofing project, RocStout is not the right contractor for you. Our process is designed for meticulous homeowners who understand that value is a function of total cost of ownership, not initial price. The low-bid contractor relies on cutting corners with materials like felt paper to reduce their price. This approach is fundamentally incompatible with our commitment to providing a warrantied, stress-free, and predictable result. We confidently serve clients who prioritize process, communication, and certainty over a marginal upfront saving.

A Process-Driven Approach to Roof Construction

Your peace of mind is the ultimate metric of a successful project. Our methodology is designed to provide it through absolute transparency and predictability. Mandating superior materials like synthetic underlayment is just one step in a comprehensive, system-wide protocol.