A starter strip is a specialized asphalt roofing component installed at the eaves and rakes of a roof to provide the primary defense against wind uplift and water intrusion. It is a non-optional material engineered specifically to seal the leading edge of a shingle system, ensuring the top covering can fulfill its primary mandate: providing absolute protection against wind, rain, and temperature extremes. Its correct installation is a fundamental requirement for the structural integrity and longevity of the entire roof assembly.

Foundational Role of the Starter Strip in Roof Construction

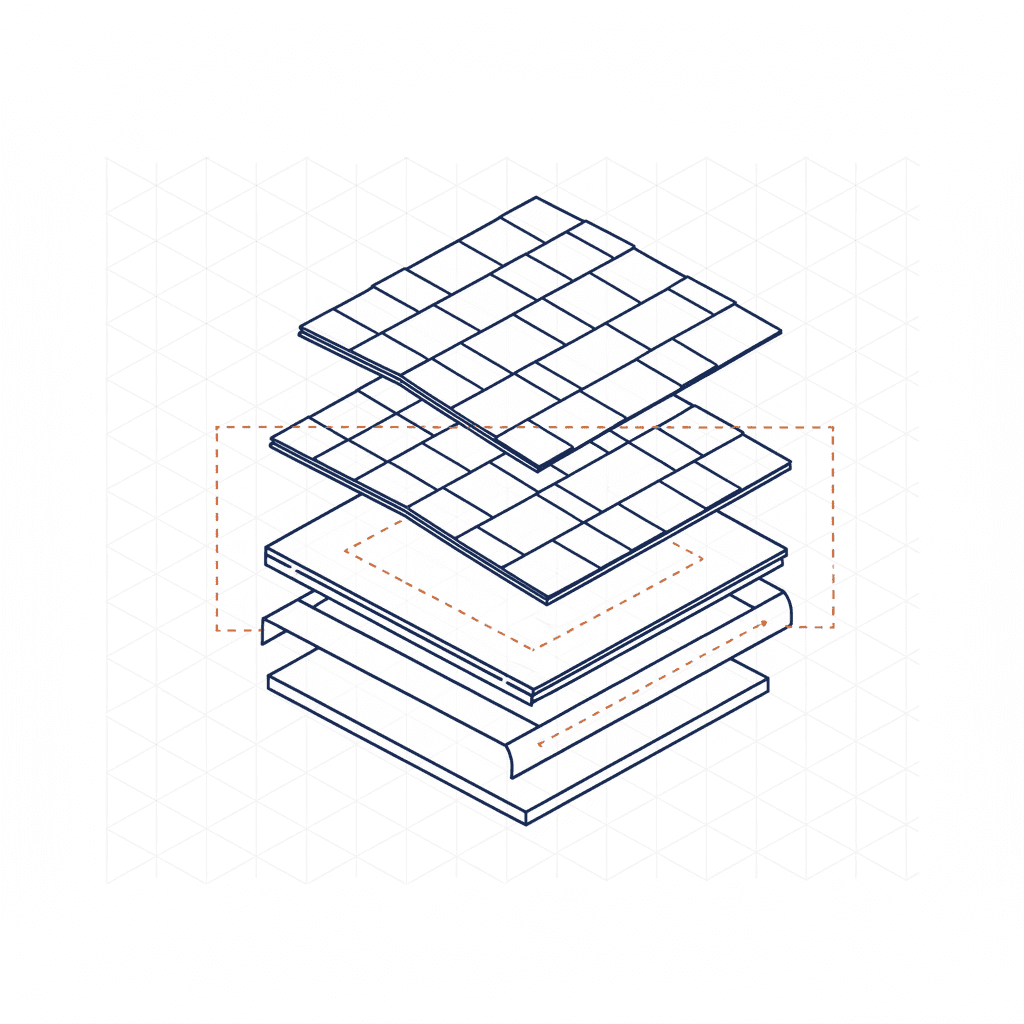

A roofing system is an assembly of interdependent components. The failure of one component compromises the entire system. The starter strip is the foundational component for the primary water-shedding layer—the asphalt shingles. It establishes the secure, sealed perimeter upon which all other shingles depend. Without it, the roof is vulnerable from the moment the first course is installed.

Defining the Component: The First Line of Defense for Your Top Covering

A starter strip, also known as a starter shingle, is a pre-cut asphalt shingle product that has a continuous line of factory-applied tar sealant. It is specifically designed for installation along the eaves (the lower, horizontal edge of the roof) and the rakes (the sloped side edges). Unlike field shingles, which have cutouts or tabs, the starter strip is solid. This solid construction serves a critical purpose: it covers the joints and cutouts of the first course of shingles, preventing water from penetrating to the underlayment and roof deck. It is the first piece of the puzzle in a complete, integrated roofing system.

Primary Engineering Functions: Protection Against Wind and Rain

The starter strip performs two non-negotiable engineering functions. It anchors the shingle field against wind forces and provides a continuous waterproof barrier at the roof’s most vulnerable edges. Neglecting either function introduces a predictable point of failure into the system, transforming a minor weather event into a catastrophic expense.

Wind Resistance Mechanics: Analyzing the Tar Sealant Strip

The most critical feature of a starter strip is its aggressive adhesive strip. When field shingles are installed over the starter strip, their bottom edge aligns with this sealant. Over time, solar heat activates the sealant, chemically bonding the first course of shingles to the starter strip below. This creates a single, monolithic, and reinforced edge that wind cannot easily lift.

Without this bond, the edge of the first shingle course acts as a lever. Wind forces catch this unsealed edge, lifting it and placing immense stress on the fasteners. This leads to shingle blow-off, a common and entirely preventable failure. The starter strip’s sealant eliminates this leverage point, ensuring wind load is distributed across the bonded system rather than concentrated on a single, vulnerable edge.

Water Management: Ensuring a Continuous Waterproof Barrier at the Edge

Standard architectural or laminate shingles have gaps between their tabs, known as keyways. In the first course of shingles, these keyways would expose the underlayment or roof deck directly to wind-driven rain. The starter strip is installed beneath this first course to provide a solid, waterproof layer that covers these gaps completely.

It functions as an integral part of the water-shedding system, working in concert with the drip edge metal and the ice and water shield. Water running down the roof flows over the shingle, onto the starter strip, and then onto the drip edge, which directs it away from the fascia and into the gutter. This sequence ensures no water can migrate backward under the shingles at the roof’s edge, preventing wood rot and water intrusion.

Installation Analysis: Prescribed Methodology vs. Industry Shortcuts

The difference between a 30-year roof and a 5-year roof is not the quality of the materials alone; it is the precision of the installation methodology. The installation of the starter strip is a clear dividing line between professional contractors who adhere to manufacturer specifications and low-bid operators who rely on shortcuts. These shortcuts are the genesis of chaos.

Correct Placement at Eaves and Rakes for Maximum Structural Support

Manufacturer specifications and building codes are not suggestions. They are the minimum standards required for predictable performance. Correct installation follows a strict protocol:

The starter strip is placed along the eaves and rakes, overhanging the drip edge by ¼ to ¾ inch, as specified by the manufacturer. This overhang ensures water transitions correctly into the gutter system.

Fasteners are installed according to a prescribed nailing pattern, typically 3 to 4 nails per strip, placed 3 to 4 inches up from the eave. This secures the strip without impeding the sealant line.

The adhesive sealant strip must be positioned at the outermost edge to bond with the first course of field shingles.

This prescriptive method creates a locked, sealed, and structurally sound roof edge. It is the only way to achieve the wind ratings advertised by the shingle manufacturer.

The ‘Flipped Shingle’ Fallacy: A Critical Point of Failure Driven by Low Bids

The most common and destructive shortcut is to create a makeshift starter strip by cutting a standard three-tab shingle. Roofers using this method will cut the tabs off a shingle and install it with the factory sealant strip facing *up* the roof, away from the edge. This is a deliberate, cost-cutting measure that introduces a catastrophic flaw into the system.

Why is this done? To save the cost of one or two bundles of dedicated starter shingles. This decision, made to produce a lower bid, guarantees two things:

- No Edge Sealant: The factory sealant, which is the primary defense against wind uplift, is now in the wrong place. The leading edge of your roof has no adhesive bond. It is completely exposed.

- Voided Manufacturer Warranty: Every major shingle manufacturer explicitly forbids this practice. Using a ‘flipped shingle’ as a starter course immediately voids the material warranty for the entire roofing system. The predictable failure that results is entirely the homeowner’s liability.

This is not a clever trick; it is a calculated omission that invites chaos. It is a bet against physics that the homeowner will always lose.

Risk Assessment: The Predictable Failures of a Compromised System

An improperly installed starter strip—or the absence of one—does not create a potential risk. It creates a mathematical certainty of premature failure. Sunlight, temperature cycles, and wind will exploit this weakness, leading to systemic damage that cascades across the entire roof.

How an Improper Starter Strip Leads to Systemic Shingle Delamination

The failure process is predictable. Without the edge sealant, wind gets under the first course of shingles and begins to lift them. This constant fluttering, even in moderate winds, subjects the shingles and their fasteners to repeated stress cycles. The nails loosen their grip in the roof decking. The shingle’s asphalt layers begin to separate under the strain, a process called delamination. Granules are shed at an accelerated rate, exposing the asphalt to UV radiation and accelerating its decay. This process of premature aging and material stress migrates up the roof, course by course, as each row is compromised by the failure of the one below it.

Identifying Missing or Incorrect Starter Strips During a Roof Inspection

You can often identify this defect from the ground or with a ladder at the gutter line. A correctly installed system has a clean, solid, and sealed edge. An improperly installed system will show signs of vulnerability:

- Visible Shingle Tabs: Look under the edge of the first course of shingles. If you can see the cutouts or tabs of another shingle underneath, a ‘flipped shingle’ was likely used.

- Lifted Edges: The shingles along the eaves may appear loose or slightly curled upwards, as there is no adhesive holding them down.

- Exposed Decking or Underlayment: You may be able to see gaps between the shingles in the first course that look directly through to the underlayment.

A professional roof inspection will identify this immediately as a critical flaw requiring immediate correction.

Our Protocol: Eliminating Chaos Through Process Control

If your primary objective is securing the lowest possible price for a roof replacement, we are not the right company for you. Our entire operation is engineered to eliminate the chaos, ambiguity, and surprise costs that define the standard roofing experience. We achieve this through an unwavering commitment to process, and that process begins with using the right materials, correctly, every time.

A Non-Negotiable Standard for Every Roof We Construct

The use of manufacturer-specified starter strips on all eaves and rakes is a non-negotiable line item on our installation checklist. It is not an upgrade or an option. It is the required foundation for a RocStout roof. Our project managers verify this step during our quality control inspections. Our clients receive clear communication and photographic documentation of our process, so you see for yourself that every component, from the starter strip to the ridge cap, is installed to precise specifications. We build roofing systems, not just shingle coverings.

Why We Reject Shortcuts: A Commitment to Predictable Outcomes

Shortcuts like the ‘flipped shingle’ method are symptoms of a business model focused on volume and speed, not on quality and longevity. That approach introduces variables that lead to unpredictable outcomes for the homeowner. Our process-driven methodology is designed to do the opposite: we eliminate variables to produce a predictable, durable, and stress-free result.

Your roof is a significant investment in the protection of your home. We honor that investment by refusing to compromise on the fundamental engineering principles that ensure its performance. A dedicated starter strip is a small material cost that provides a massive return in system integrity and peace of mind. For us, and for our clients, that is the only sane way to conduct a construction project.