A roof valley installation is the systematic process of waterproofing the intersection where two sloped roof planes meet. This juncture is the most critical point for managing water runoff and is a primary failure point in substandard roofing systems. The integrity of the valley dictates the performance of the entire roof, which functions as the primary top covering of a building, providing essential protection against rain, snow, sunlight, and extremes of temperature. A correctly executed valley protocol is not a detail; it is the foundation of a durable, weather-tight building envelope.

The Critical Role of Roof Valleys in Weather Protection

A roof valley channels the highest volume of water on any roof. Its proper construction is non-negotiable for system longevity and structural protection. Any flaw in design or installation introduces a significant, predictable risk of water intrusion.

Defining the Roof Valley: A Structural Overview

A roof valley is the geometric line formed by the intersection of two downward-sloping roof planes. This channel must collect water runoff from both planes and direct it safely to the roof’s edge. Structurally, it consists of several integrated layers: the roof decking, a waterproof underlayment (typically a self-adhered ice and water shield), and the final top covering, which may be shingles or metal flashing. The proper integration of these layers determines its capacity to function without failure.

Why Valley Failure Presents a Catastrophic System Risk

Valley failure is a systemic failure. Because it concentrates water flow, a breach in the valley’s waterproofing allows massive amounts of water directly into the roof structure and attic space. This leads to predictable and compounding problems: saturated insulation, damaged drywall, wood rot in rafters and decking, and the formation of destructive ice dams in cold climates. An improperly installed valley guarantees future leaks and negates the investment in the rest of the roofing system.

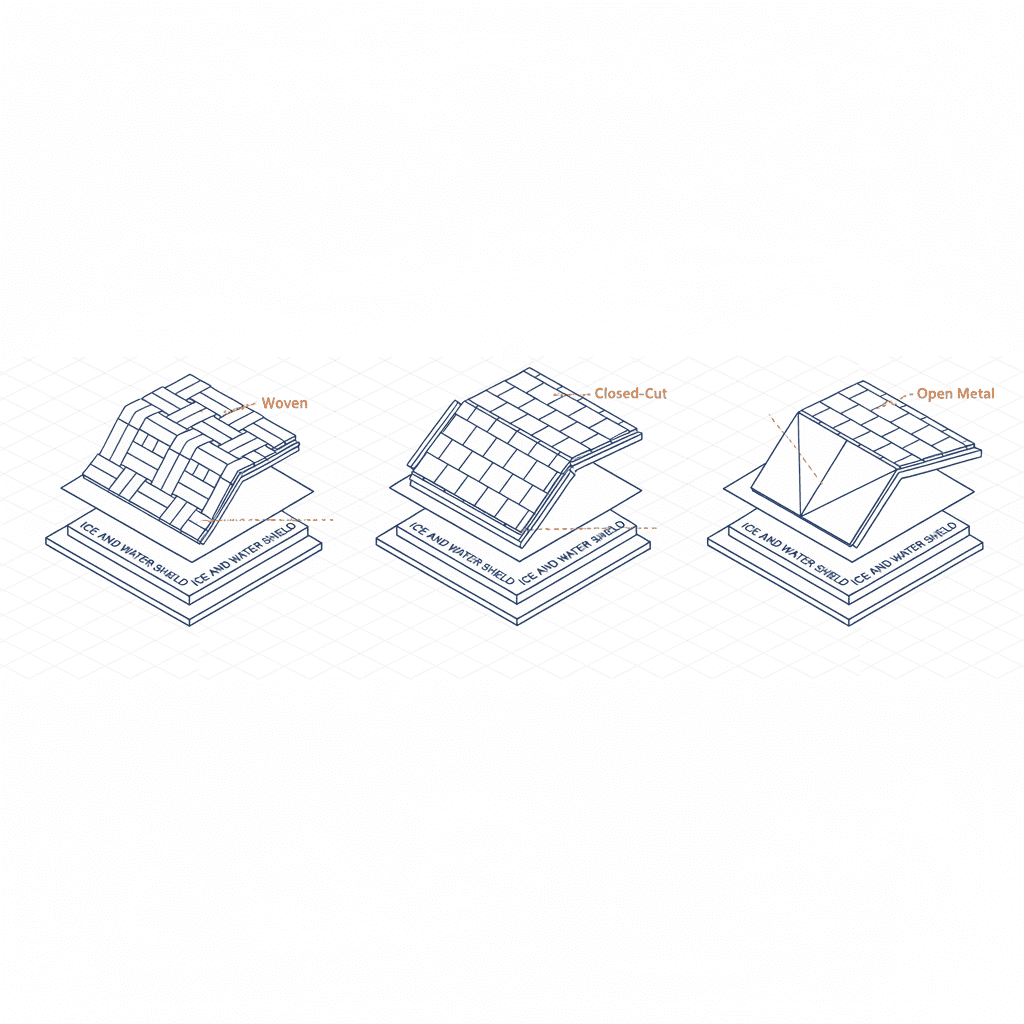

Comparative Analysis: Three Primary Valley Installation Methods

There are three recognized methods for finishing a shingle roof valley. Their selection impacts aesthetics, cost, and, most importantly, long-term performance. While other contractors may present these as equivalent options, they are not. The performance data is unequivocal.

| Method | Description | Performance Grade | Key Risk |

|---|---|---|---|

| Woven Valley | Shingles from both roof planes are interlaced through the valley, creating a continuous, woven pattern. | Poor | High friction impedes debris and water flow, leading to premature granule loss and leaks. Difficult to repair. |

| Closed-Cut Valley | Shingles from one plane are run through the valley. Shingles from the adjacent plane are laid over them and cut in a straight line 2 inches from the centerline. | Acceptable | Nails are placed close to the valley centerline, creating potential leak points. The cut edge can be vulnerable to water intrusion. |

| Open Metal Valley | A pre-formed metal flashing channel is installed over the underlayment. Shingles are trimmed and sealed along the edges of the metal, leaving the channel exposed. | Superior | Requires skilled installation; higher material cost. When executed correctly, risk is negligible. |

Method 1: The Woven Valley Installation Process & Specifications

The woven valley is achieved by running asphalt shingles from both roof planes through the valley and interlacing them. This creates a continuous visual pattern favored for certain historic aesthetics. However, this method is functionally obsolete. The interlaced shingles create excessive friction, trapping debris like leaves and pine needles, and impeding the rapid shedding of water. The constant stress on the woven shingles leads to premature granule loss and cracking, creating a high probability of leaks within years of installation. It is a labor-intensive method that produces a fragile result.

Method 2: The Closed-Cut Valley Installation Process & Specifications

In a closed-cut valley, the shingles from the first roof plane are installed completely through the valley line. Then, the shingles from the second, intersecting plane are laid over the first layer and trimmed in a straight line approximately two inches from the valley’s centerline. While more effective than a woven valley, this method still places a seam of cut shingles directly in a high-flow water channel. It also requires fasteners to be placed perilously close to the valley centerline, increasing the risk of water intrusion over time as sealant fails.

Method 3: The Open Metal Valley Installation Process & Specifications

The open metal valley is the superior installation protocol. It begins with the installation of a self-adhered ice and water shield. A pre-formed, W-shaped metal flashing, typically galvanized steel or copper, is then centered in the valley and secured. Shingles are installed over the metal and trimmed back on each side, leaving a 2- to 4-inch channel of exposed metal. This smooth, frictionless water channel allows water and debris to be shed rapidly and completely. It moves all seams and fasteners far away from the center of the valley, minimizing points of potential failure. This is the only method that provides a truly redundant, long-term waterproofing system.

Material Specifications for Long-Term Environmental Durability

The materials used within the valley system are as critical as the installation method. Using substandard components is a false economy that guarantees premature failure. A roof must provide protection against extremes of temperature and wind; the valley materials bear the brunt of this work.

Underlayment Selection Based on Climate & Temperature Extremes

The standard felt paper is inadequate for a roof valley. A high-temperature, self-adhered membrane (ice and water shield) is the mandatory first layer. This bitumen-based product adheres directly to the roof deck, creating a waterproof gasket around every fastener that penetrates it. In climates with snow and ice, this membrane is the primary defense against ice damming, where melting snow refreezes at the eaves and forces water back up under the shingles. The membrane must be rated for high temperatures to resist degradation from sunlight and attic heat.

Metal Flashing Gauge and Type: A Technical Specification Guide

The choice of metal for an open valley directly impacts its durability. We mandate a minimum of 24-gauge, Kynar-coated galvanized steel. Lighter gauge aluminum (26 or 28-gauge) is often used by low-cost providers, but it is highly susceptible to damage from hail, ladders, and thermal expansion. 24-gauge steel provides superior structural rigidity and corrosion resistance. Copper is a premium alternative offering unparalleled longevity and aesthetic value, but steel provides the necessary performance characteristics for a predictable, long-term outcome.

Common Installation Errors That Lead to Systemic Failure

The roofing industry is plagued by a lack of adherence to manufacturer specifications and building codes. These are not suggestions; they are minimum requirements for system function. Deviating from them introduces chaos and predictable failure.

Nail Placement Analysis: The Most Common Point of Water Intrusion

The single most common error is improper nailing. Nails must never be placed within 6 inches of the valley centerline. In a closed-cut or woven valley, this rule is frequently violated out of necessity or carelessness. Each misplaced nail is a potential leak point. In an open metal valley, a nailing strip is provided far from the center channel. Adhering to the nailing pattern specified by the shingle manufacturer is a basic requirement for waterproofing integrity.

Inadequate Underlayment and Flashing Integration

Another frequent error is the improper layering of materials. The underlayment must be installed before the metal flashing. Shingles must overlap the flashing correctly, and the edge must be sealed with a high-grade, urethane-based sealant, not cheap silicone caulk. Any bridging or gaps in the system create channels for water to bypass the waterproofing layers. These errors, often hidden from a homeowner’s view, are the direct result of a chaotic process that prioritizes speed over precision.

A Process-Driven Approach vs. The Industry Standard of Chaos

The typical roofing project is defined by vague timelines, poor communication, and a focus on completing the job as quickly as possible. This approach is incompatible with the precision required for critical details like valley installation. We have built our company as the antidote to this industry-standard chaos.

Why We Mandate Open Metal Valleys for Superior Protection

RocStout Roofing does not offer woven or closed-cut valleys. We exclusively install open metal valleys. The performance data is clear: they provide superior longevity, exceptional debris management, and a significantly reduced risk of leaks. Mandating this best practice removes a variable that often leads to failure. It is a non-negotiable component of our quality control system. This is not an upsell; it is the correct way to build a roof that provides lasting protection against rain and snow.

Our Commitment: A Documented, Predictable Installation Process

A predictable outcome requires a predictable process. Our installation protocol is documented, transparent, and executed without deviation on every project.

You receive a detailed project timeline. All materials, including 24-gauge metal and high-temp underlayment, are confirmed against the project specifications.

Your dedicated Project Manager provides daily progress reports with photos. Critical junctures, like valley waterproofing, are documented and inspected.

We conduct a final inspection using a comprehensive checklist. We do not consider the project complete until every item meets our standard. There are no surprise charges.

Is Our Meticulous Methodology Right for Your Project?

We are not for everyone. Our process is meticulous, our material specifications are uncompromising, and our communication is constant. This level of control and predictability requires a greater investment than a standard roofing job. If your primary decision driver is the lowest possible price, we are not the right fit for your project. Our clients are organized, detail-oriented homeowners who understand that the true cost of a roof includes the risk of chaos, stress, and premature failure. They choose us because they are making an investment in a predictable, stress-free outcome and the long-term value of their home.