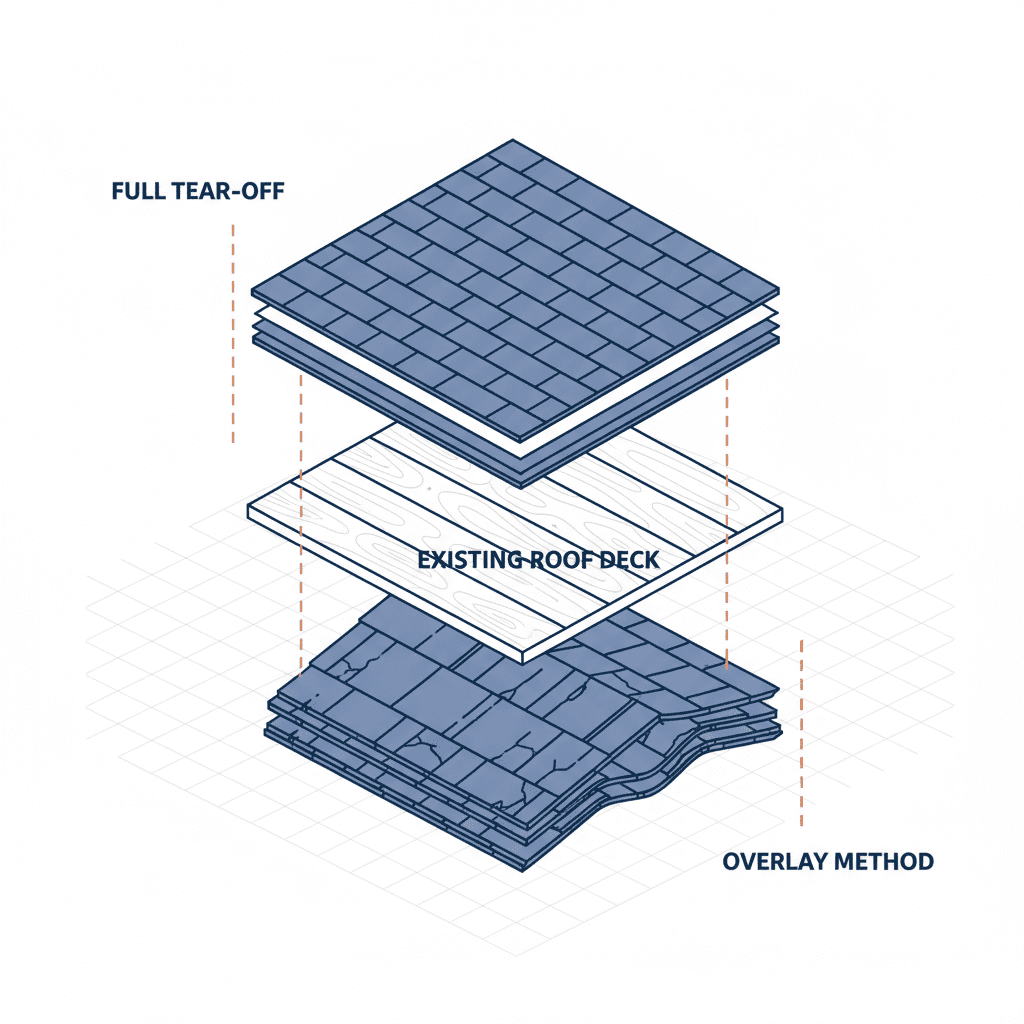

A roof replacement is a construction process that renews a building’s top covering, restoring its primary function to protect the structure against rain, snow, sunlight, extremes of temperature, and wind. This process is executed through one of two distinct methodologies: a complete roof tear-off or a roof overlay. The former is a systematic reconstruction; the latter is a superficial shortcut. At RocStout Roofing and Construction, we exclusively perform complete tear-offs. This is not a preference. It is a mandate dictated by our commitment to predictable outcomes and the elimination of chaos from your project.

Foundational Decision: Tear Off vs. Overlay Methodologies

The choice between a tear-off and an overlay defines the entire scope, risk profile, and long-term viability of a roof replacement project. One method is based on verifiable data and engineering principles, while the other is based on assumption and concealment. Understanding this distinction is the first step in mitigating the risks inherent in construction and ensuring the longevity of your investment.

The Complete Roof Tear Off (Reroof): A Systematic Approach

A complete roof tear-off is a methodical process of deconstruction and reconstruction. It involves the removal of all existing roofing materials, including shingles, flashing, and underlayment, down to the bare roof deck sheathing. This action creates a clean slate. It is the only method that allows for a thorough, physical inspection of the roof’s core structural integrity. The decking is the foundation for the entire roofing system; installing a new roof without verifying its condition is a critical engineering failure. A tear-off ensures every component, from the structural support to the final top covering, is new, correctly integrated, and functions as a complete, warrantable system.

Systematic Roof Tear-Off Process

All existing shingles, fasteners, and underlayment are stripped from the roof.

The exposed wood decking is inspected for rot, water damage, or soft spots. Any compromised sheathing is replaced.

A new, integrated system of underlayment, flashing, and shingles is installed per manufacturer specifications.

The Roof Overlay (Roof-Over): Layering New Materials

A roof overlay, also known as a shingle-over, is the practice of installing a second layer of new asphalt shingles directly on top of the existing, failing layer. This approach avoids the labor and disposal costs of a tear-off. It is presented as a cost-saving measure, but it is a false economy. An overlay conceals, rather than corrects, underlying issues. It is an approach that violates the core principle of any complex project: you cannot build a stable new structure on a failing foundation. Most building codes prohibit installing more than two layers of roofing materials due to the unacceptable weight placed on the building’s support constructions.

Structural Integrity Analysis: Assessing the Roof’s Support System

A roof is more than its shingles; it is an engineered system of constructions designed to support a specific load and transfer it safely to the building’s walls. The overlay method fundamentally disregards this engineering. It introduces variables that compromise the entire system’s ability to manage weight and protect the home’s interior, especially from snow and water.

Why Decking Inspection is a Non-Negotiable Diagnostic Step

The roof deck, typically OSB or plywood sheathing, is the structural foundation for the shingles. It must be solid and secure to provide adequate nail-holding power. An overlay makes direct inspection impossible. Any existing water damage, rotted wood, or soft spots in the sheathing are simply covered up. Nailing new shingles into compromised decking is the equivalent of anchoring a ship to sand. The fasteners will not hold, leading to catastrophic failure during high winds. A tear-off is the only diagnostic step that verifies the integrity of this critical structural support.

Calculating Total Roof Weight and Load-Bearing Capacity

Asphalt shingles are heavy, weighing between 200 to 450 pounds per square (100 square feet). A second layer of shingles doubles this dead load—the static, permanent weight of the roof itself. This additional weight, often thousands of pounds, is transferred to the roof trusses and the building’s load-bearing walls. This added stress was not accounted for in the original structural engineering of your home. When combined with a live load, such as heavy snow, the total weight can exceed the structure’s design limits, posing a significant safety risk.

The Liability of Trapped Moisture Between Layers

An overlay creates a sealed cavity between the old and new shingle layers. Any moisture from a minor, pre-existing leak or condensation caused by extremes of temperature becomes trapped. This trapped moisture cannot evaporate. It sits directly on the old shingles and the underlying roof deck, creating a perfect environment for accelerated rot, mold growth, and material degradation. The roof deck rots from the top down, a silent process that goes unnoticed until a major structural failure or significant interior leak occurs. This negates the roof’s ability to protect against rain and temperature shifts.

Long-Term Performance: Protection Against the Elements

A roofing system’s performance is measured by its ability to provide unwavering protection against wind, rain, and sunlight over decades. An overlay compromises this performance from day one by creating systemic weaknesses at critical points of failure.

Wind Uplift Resistance: A Comparative Failure Analysis

Manufacturer wind ratings are contingent on proper installation. This means securing fasteners directly into solid wood decking. When nailing through an existing layer of shingles, the nail must penetrate the old, often brittle material before reaching the deck. This reduces its holding power. Furthermore, the uneven surface of the old shingles prevents the new layer from lying flat and sealing properly. This allows wind to get underneath the shingle edges, creating uplift forces that easily tear them from the roof during a storm. A tear-off ensures every nail has maximum penetration and every shingle has a flat, solid surface for optimal adhesion.

Water Intrusion & Leak Prevention: Analyzing Critical Failure Points

Effective water protection relies on a system of integrated flashing around penetrations like vents, chimneys, and skylights, as well as in roof valleys. Flashing must be installed directly against the decking and woven into the underlayment to create a seamless waterproofing membrane. An overlay makes this impossible. Contractors are forced to use caulk and tar around old, failing flashing, creating a temporary patch, not a permanent seal. These patches are notorious failure points, virtually guaranteeing future leaks and rendering the roof’s primary defense against rain ineffective.

Sunlight (UV) and Heat Impact on Layered Roof Systems

Sunlight and the heat it generates are primary causes of shingle degradation. An overlay exacerbates this process. The added layers trap significantly more heat, essentially cooking the shingles from both above and below. This intense heat accelerates granule loss, causes shingle curling, and shortens the lifespan of the new materials. Furthermore, the heat transfers directly into the attic space, increasing cooling costs and putting a strain on your home’s HVAC system. A properly installed roof on a clean deck, combined with adequate ventilation, is designed to manage heat transfer and protect the system from solar degradation.

A Financial Framework: Comparing True Project Cost vs. Long-Term Value

A project budget should not be evaluated on initial outlay alone. A meticulous homeowner analyzes the total cost of ownership, including risks, maintenance, warranty coverage, and impact on property value. An overlay appears cheaper upfront, but this calculation is misleading and ignores significant long-term financial liabilities.

Initial Project Cost: A Line-by-Line Breakdown

An overlay saves money by eliminating the labor costs associated with removing the old roof and the fees for its disposal. This is its only financial benefit. A tear-off has higher initial costs in these two categories. However, it also eliminates the risk of surprise charges for hidden deck repairs and ensures the new investment is built on a sound foundation.

| Cost Factor | Roof Overlay | Full Tear-Off |

|---|---|---|

| Material Costs | Standard | Standard + Decking (if needed) |

| Labor Costs | Lower (Installation Only) | Higher (Removal + Installation) |

| Disposal Fees | None | Applicable |

| Warranty Validity | Often Voided | Fully Valid |

| Future Replacement Cost | High (Two-Layer Tear-Off) | Standard |

| Risk of Hidden Damage | High | Eliminated |

The Impact on Manufacturer Warranty Validity

This is a critical, non-negotiable point. Nearly every major shingle manufacturer states in its warranty documentation that their products must be applied to a smooth, clean deck surface. Installing new shingles over an old, uneven layer is considered an improper installation. This action voids the manufacturer’s material warranty from the moment of installation. Any potential savings from an overlay are instantly negated by the loss of this crucial long-term protection. You are paying for a 30- or 50-year product with zero manufacturer backing.

Resale Value and Home Inspection Implications

During a real estate transaction, a home inspector will immediately identify a roof-over. It is a red flag for deferred maintenance and hidden problems. This discovery reduces buyer confidence and introduces doubt about the overall quality of the home’s upkeep. It signals that a significant, more expensive roof replacement—the removal of two layers—will be required in the near future. This known liability can lead to demands for a lower sale price or kill a deal entirely. A new roof from a full tear-off is a major selling point that enhances property value and curb appeal.

The Chaos Variable: Why an Overlay Introduces Unpredictability

The standard roofing industry experience is rife with chaos: vague estimates, surprise charges, and unforeseen issues that derail budgets and timelines. An overlay is a wager that multiplies this unpredictability. It is a decision to proceed with a major construction project while willfully remaining ignorant of the most critical structural variable.

Exposing the Risk of Hidden Damages and Surprise Charges

A contractor who proposes an overlay is gambling with your money. They are betting that the decking beneath the old shingles is perfectly sound. If that bet is wrong—if they discover soft spots or rotted decking after the project has begun—the work must stop. The project scope suddenly changes, leading to unplanned expenses, change orders, and project delays. A tear-off eliminates this chaos. The decking is inspected at the start of the project. Any necessary repairs are identified, quoted, and approved before a single new shingle is installed, preserving budget integrity and timeline predictability.

The Inevitable Second Tear Off: Compounding Future Costs

An overlay does not prevent a tear-off; it only postpones and complicates it. When the second layer of shingles fails, you cannot apply a third. Building code and common sense forbid it. At that point, a tear-off of both layers is mandatory. This process is significantly more expensive than a single-layer tear-off. The labor is more intensive, and the disposal weight is doubled, leading to much higher landfill fees. The short-term savings of the initial overlay are completely erased by this compounded future cost.

The Process-Driven Mandate: Our Exclusive Commitment to Tear Offs

We have built our company to serve meticulous homeowners who value clarity, process, and predictable results. Our refusal to perform overlays is a direct reflection of that commitment. It is the only methodology that aligns with our core principle: eliminating chaos through a transparent, systematic process.

Our Guarantee: A Clean Slate for Total System Integrity

We guarantee a predictable outcome because our process starts with verifiable data, not assumptions. By tearing off the old roof, we gain complete knowledge of the existing structural conditions. This allows us to engineer a complete, integrated roofing system that performs exactly as designed and is fully backed by the manufacturer’s warranty. This is the only sane way to manage a project of this magnitude. It is the only way to provide our clients with the stress-free, professionally managed experience they deserve.

A Note on Price: We Are Not the Cheapest. We Are the Most Thorough.

If your primary decision-making factor is finding the lowest possible bid, RocStout is not the right partner for your project. Our process is designed for clients who prioritize long-term value, structural integrity, and a predictable, managed process over short-term savings. We do not compete with contractors who cut corners by layering over old problems. Our pricing reflects the comprehensive nature of our work, the quality of our materials, and our unwavering commitment to getting every detail right the first time. This focus allows us to deliver a superior result without compromise, providing an investment that protects your home for decades to come.