A low-bid roof is a project delivery model that systematically prioritizes an artificially low initial price over the core protective functions of a roofing system. It is not a discount; it is a calculated omission of correct materials, certified labor, and necessary project controls. The result is a predictable cycle of premature failure, costly repairs, and significant financial liability. A roof is the top covering of a building, an engineered system designed to provide absolute protection against rain, snow, sunlight, extremes of temperature, and wind. Any bid that compromises these functions is, by definition, an unacceptable risk to your home’s structural integrity and value. If your primary decision-making metric is securing the absolute lowest price, RocStout is not the right partner for your project. Our process is designed for meticulous homeowners who understand that predictability, not price, is the true measure of value.

The Financial Fallacy: Deconstructing the True Cost of a Low Bid

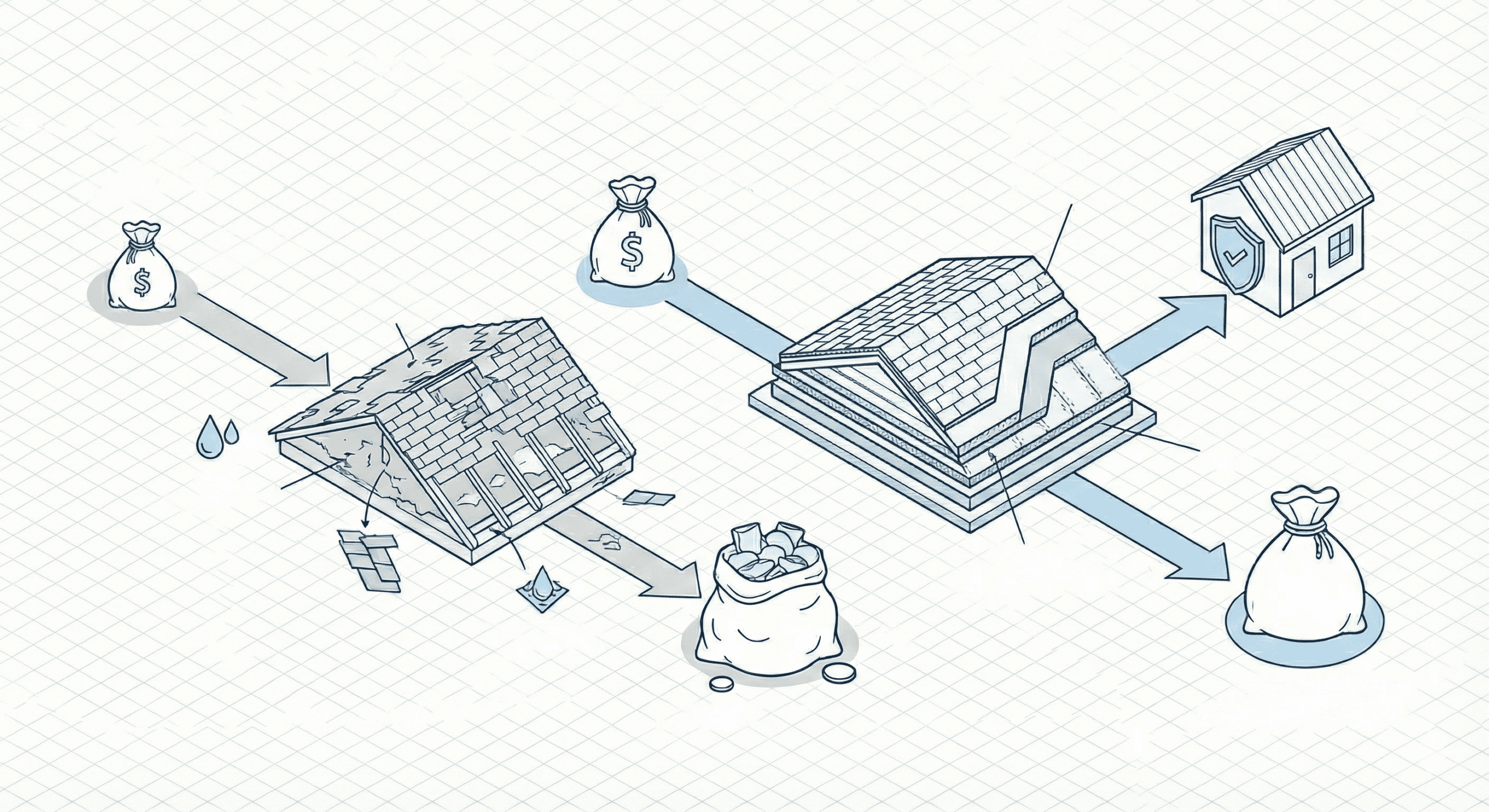

The initial number on a roofing estimate is merely one data point in a much larger financial equation. A low bid creates the illusion of savings while initiating a cascade of hidden costs and long-term expenses. The enemy is chaos, and a low bid is its entry point into your home and your finances. It guarantees a chaotic experience defined by surprise charges, missed deadlines, and eventual system failure.

Calculating Total Cost of Ownership vs. Initial Price

Total Cost of Ownership (TCO) is a financial calculation that includes the initial capital expenditure plus all lifecycle costs, including repairs, maintenance, and eventual replacement. A low-bid roof maximizes the initial savings but creates an exponential increase in lifecycle costs. The math is simple and unforgiving.

A correctly installed roofing system is a 20- to 30-year capital expenditure with minimal, predictable maintenance. A low-bid roof, by contrast, becomes an operational expense, demanding frequent and costly repairs within the first 3-5 years. Leaks, shingle blow-offs, and flashing failures are not possibilities; they are statistical certainties. This increased repair frequency leads to a premature replacement cycle, forcing you to pay for a second complete roof replacement in half the expected time. This transforms an asset into a persistent liability.

Identifying Vague Scopes and Inevitable Change Orders

A low bid is structurally dependent on a vague scope of work. It is an intentional strategy. Ambiguity in the contract allows a contractor to substitute materials, cut corners on labor, and issue change orders for work that should have been included in the initial plan. A change order is a formal contract amendment, a document that proves the initial plan was incomplete. It is the primary mechanism for transforming a low bid into an expensive project.

Our process eliminates this risk by mandating a transparent, line-item estimate where every component and action is specified. There are no allowances or vague descriptions. You see precisely what you are paying for, which makes a true, apples-to-apples comparison possible. Predictability is the only antidote to the chaos of hidden fees.

| Low-Bid Vague Scope Item | RocStout Detailed Line-Item |

|---|---|

| “Install new shingles” | “Install GAF Timberline HDZ Shingles (Color: Charcoal) using a 6-nail pattern with 1.25-inch electro-galvanized roofing nails per manufacturer specification and local wind code.” |

| “Replace bad wood” | “Contingency: Replace up to 3 sheets of 1/2-inch CDX plywood decking at a fixed unit price of $XX per sheet, to be approved by homeowner before installation.” |

| “Install ice shield” | “Install GAF StormGuard ice and water shield from all eaves to a point 24 inches inside the interior wall line, and in all valleys per code requirements.” |

Material & Construction Failures: The First Point of Compromise

A roofing system is an assembly of components that must work in concert. A bid can only be lowered by compromising these components or the methods used to install them. This is not a matter of finding efficiencies; it is a matter of willful neglect of building codes, manufacturer specifications, and fundamental construction principles. The result is a system designed to fail.

Substandard Materials: An Analysis of Shingles, Underlayment, and Flashing

The first and easiest place for a low-bid contractor to cut costs is in material specifications. They rely on homeowner ignorance of the technical differences between products that appear visually similar.

- Asphalt Shingles: Cheaper shingles have less asphalt, lower fiberglass content, and fewer granules. This results in lower impact resistance, reduced UV protection, and a significantly shorter lifespan. They become brittle and crack years before a higher-quality product.

- Synthetic Underlayment: The underlayment is the roof’s secondary water barrier. Low-cost contractors use thin, non-breathable felt paper that tears easily during installation and can trap moisture, promoting deck rot. We use high-grade synthetic underlayment that is tear-resistant, waterproof, and breathable.

- Ice and Water Shield: This is a critical self-adhering membrane for eaves and valleys. Low-cost options have less effective adhesives and lower temperature tolerances, leading to leaks and ice dams.

- Flashing: Flashing protects the most vulnerable parts of your roof—chimneys, walls, and vents. Using thinner gauge aluminum or reusing old, failing flashing is a common cost-cutting tactic that guarantees water intrusion.

Deficient Construction: The Impact of Improper Nailing, Sealing, and Ventilation

Even with premium materials, a roofing system will fail if the construction methods are deficient. This is a function of poorly trained, low-wage labor and a lack of quality control—hallmarks of the low-bid model.

- Improper Nailing Pattern: Every shingle manufacturer specifies the exact number and location of fasteners required to meet wind warranty standards. Using too few nails, or placing them too high on the shingle (a common shortcut to speed up installation), voids the warranty and leads to shingle blow-off in moderate winds. This is not a mistake; it is a procedural failure.

- Lack of Sealing: All penetrations—vents, pipes, and skylights—require meticulous sealing. Rushing this process or using low-grade caulk results in immediate points of failure for water intrusion.

- Inadequate Roof Ventilation: A roof must breathe. An improperly ventilated attic traps heat and moisture, which cooks shingles from below, voids their warranty, and fosters mold growth on the roof decking. Calculating the correct balance of intake and exhaust ventilation is a science that low-cost installers ignore. This failure violates building codes and guarantees premature system degradation.

Systemic Failure: How Low Bids Compromise Core Protective Functions

A roof is not a cosmetic feature. It is a building’s primary defense system. Its sole purpose is to provide absolute protection from the elements. A low-bid installation compromises every single one of these protective functions, exposing the entire structure to risk.

Protection Against Rain: Analyzing Water Intrusion from Poor Workmanship

The most immediate failure of a cheap roof is its inability to provide protection against rain. Water intrusion is the direct result of deficient flashing details, improper shingle sealing, and incorrect fastener placement. A single roof leak can lead to catastrophic moisture damage inside the building envelope, including saturated insulation, stained drywall, and dangerous mold growth. The cost to remediate this interior damage will always exceed the initial savings on the roof bid.

Protection Against Wind: Calculating Uplift Risk in Low-Cost Systems

A roof system must provide protection against wind. Wind uplift is the force that pulls shingles from the roof deck. A system’s resistance to this force is determined by its materials and, more critically, its installation method. Low-cost systems fail due to an incorrect nailing pattern. Meeting the ASTM D7158 standard for high-wind resistance requires a specific number of nails in a specific location. By deviating from this, low-bid contractors create a roof that will fail and cause widespread shingle blow-off during a storm, exposing the underlayment and decking to direct rainfall.

Protection Against Snow & Temperature: The Science of Ice Dams and Thermal Failure

A roof’s function is to provide protection against snow and extremes of temperature. This is achieved through a balanced system of insulation and ventilation. Low-bid projects neglect this calculation, leading to ice dams. An ice dam is a ridge of ice that forms at the edge of a roof and prevents melting snow from draining. The water backs up behind the dam and, through improperly sealed seams, leaks into the home. This is a direct consequence of thermal failure, where heat loss from the attic melts snow unevenly. It is a preventable engineering problem that low-cost models ignore.

Protection Against Sunlight: Quantifying Accelerated UV Degradation

A roof must also provide protection against sunlight. The ceramic-coated granules on an asphalt shingle serve one primary purpose: to block damaging ultraviolet (UV) radiation. Low-quality shingles used in cheap bids have fewer granules and weaker adhesion. They experience accelerated asphalt granule loss, exposing the underlying asphalt to direct sunlight. UV radiation makes the asphalt brittle, leading to cracking and systemic failure. This premature aging is a quantifiable result of choosing substandard materials.

Structural Risk: When a Bad Roof Threatens the Entire Building

The failure of a low-bid roof is not contained to the shingles. It transmits risk directly to the structural components of your home. A compromised roof is a threat to the integrity of the entire building, from the walls down to the foundation.

The Unseen Damage: Overlooking Rotted Decking and Compromised Supports

A common practice among low-bid contractors is to install a new roof directly over existing, rotted roof decking. This is called a \”roof-over.\” It hides a critical structural defect. The sheathing, or decking, is what the shingles are nailed to; if it is soft or rotted, the fasteners have no holding power. The structural load of the roof system is supported by trusses and rafters. If water intrusion from the previous failing roof has compromised these supports, covering them up creates an immense liability. Our process mandates a full tear-off and a thorough inspection of the roof deck. Any compromised sheathing is replaced. This is a non-negotiable step for ensuring the longevity and safety of the support structure.

Liability and Insurance: The Financial Exposure of Unlicensed or Underinsured Contractors

Choosing a contractor based on the lowest bid exposes you to severe financial liability. These contractors often operate with inadequate or non-existent insurance coverage.

- General Liability Insurance: If the contractor damages your property (e.g., a falling ladder breaks a window or damages siding), their policy should cover it. Without it, you are responsible for the repairs.

- Workers’ Compensation: If a worker is injured on your property and the contractor does not have workers’ compensation insurance, you can be held liable for their medical bills and lost wages. This can result in a lawsuit against you as the homeowner.

Furthermore, a workmanship guarantee or manufacturer warranty is only as good as the company that backs it. A low-bid contractor who cuts corners on installation will not be in business to honor a warranty claim five years later. A valid warranty requires both certified installation and a stable, reputable company to service it.

The Antidote to Chaos: A Process-Driven Framework for Predictable Outcomes

The chaos of the typical roofing project is not inevitable. It is the direct result of a flawed process. The solution is to replace that chaos with a system built on transparency, communication, and quality control. We have engineered a project management framework that delivers a predictable, stress-free outcome. This process is the reason we cannot and will not compete on price alone.

Mandating Clarity: The Non-Negotiable Elements of a Project Plan

A successful project is determined before the first hammer is swung. Our pre-construction process mandates absolute clarity, eliminating the ambiguities that low-bid contractors exploit. This is our blueprint for predictability.

A line-item proposal specifies every material by brand and model, and every action to be taken. There are no vague allowances.

You meet your dedicated Project Manager to review the project timeline, material data sheets, and establish the communication protocol.

Your Project Manager is on-site daily, providing updates via a client portal and ensuring all work meets our quality assurance standards.

A multi-point final inspection is completed with you. The project is not finished until you sign off on every detail.

Why Our Process Disqualifies Low-Bid Contractors

Our methodology is fundamentally incompatible with a low-cost business model. The investment in a dedicated project manager, a client communication portal, rigorous quality assurance checks, and comprehensive insurance is substantial. These are non-negotiable costs required to produce a predictable, high-quality result for a meticulous homeowner.

Low-bid contractors operate by eliminating these exact controls. They cannot afford a dedicated project manager. Their business model depends on vague communication and avoiding the scrutiny of a final inspection. They build chaos into their system. We have engineered it out of ours.

The decision to replace your roof is not a choice between a high price and a low price. It is a choice between a controlled, predictable process and a guaranteed liability. It is a choice between asset protection and systemic chaos. For the organized homeowner who values clarity and long-term performance, the decision is clear.