A roof cricket is a peaked, triangular structure built on the high-slope side of a roof penetration, specifically engineered to divert water around the obstruction. It functions as a small, secondary roof plane that divides the flow of water, preventing it from pooling against vertical surfaces like chimneys. This structure is an essential component of the roof, the primary covering that provides a building with protection against rain, snow, and wind. A properly constructed cricket ensures the roof system maintains its structural integrity at its most vulnerable points.

What Is a Chimney Roof Cricket? A Structural Necessity for Water Diversion

A roof cricket is not a cosmetic addition. It is a purpose-built structure designed to solve a fundamental hydrodynamic problem on a sloped roof: managing the flow of rain and snow melt. Its presence is a primary indicator of a correctly installed roofing system that prioritizes long-term water management over expediency.

Core Function: Protecting the Building Structure from Rain and Snow

The primary function of a roof cricket is to prevent water intrusion. A wide chimney acts as a dam on the roof plane. Without a cricket, rainwater and melting snow accumulate directly behind the chimney masonry. This standing water creates significant hydrostatic pressure against the flashing seams, exponentially increasing the probability of a leak. Over time, this constant moisture exposure leads to material degradation, flashing failure, and ultimately, water damage to the roof decking, attic, and interior of the home. The cricket redirects this water, preserving the integrity of the entire roof system and the building envelope it protects.

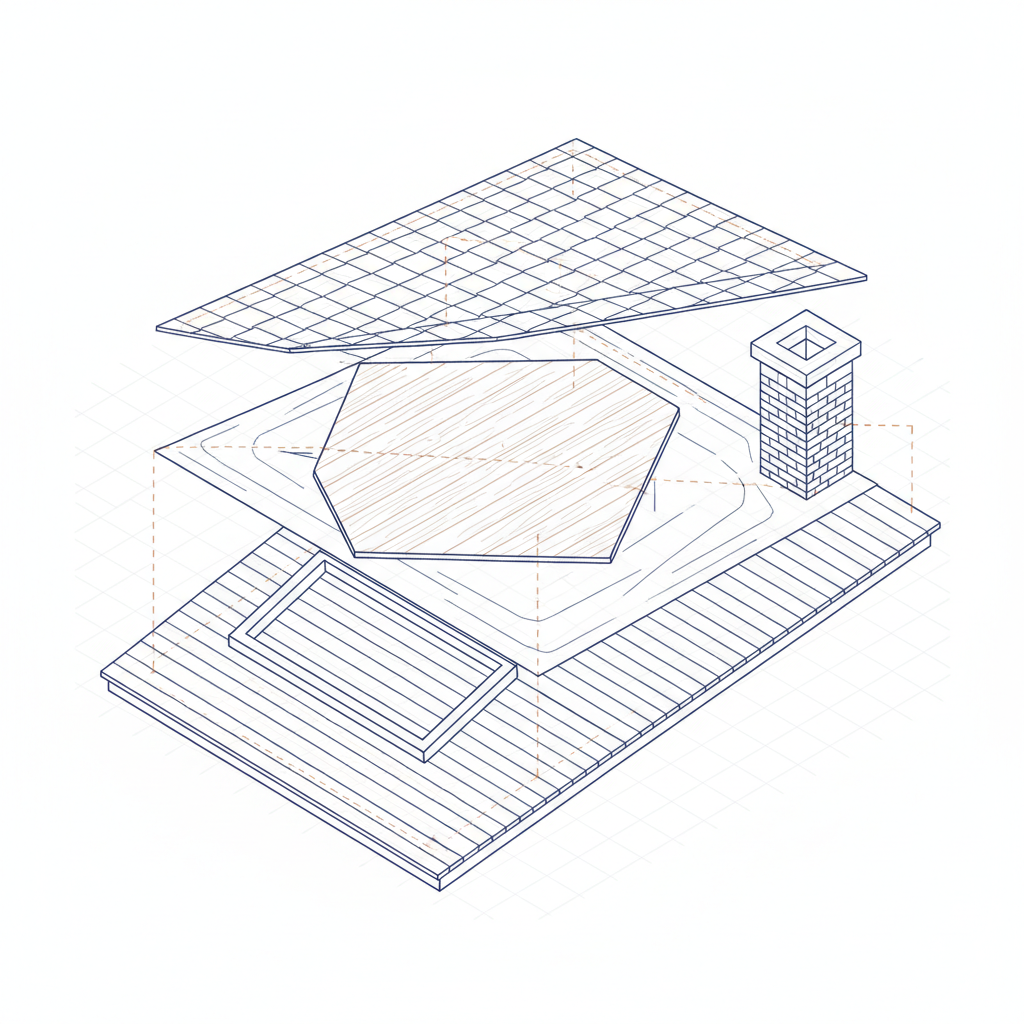

Diagram: Visualizing Water Flow With and Without a Cricket

The physics of water flow on a roof are simple. Water follows the path of least resistance. A chimney interrupts this path, creating a critical vulnerability point. The following diagram illustrates the difference in water flow dynamics.

WITHOUT A CRICKET

Water descends the roof slope directly toward the chimney.

Water impacts the back wall of the chimney, creating a dam. Water pools, debris collects, and hydrostatic pressure builds against the flashing.

Flashing seams fail under pressure. Water penetrates the roof deck, causing rot and leaks.

WITH A CRICKET

Water descends the roof slope and meets the cricket’s ridge.

The cricket’s two planes divide the water, directing it harmlessly to either side of the chimney.

No pooling occurs. Flashing remains effective. The roof decking and building interior are protected.

Distinguishing a Cricket from Standard Chimney Flashing

A cricket is a structural element, while flashing is a waterproofing material. They are not interchangeable; they are two distinct components of a complete roof waterproofing system that must work in concert.

- Flashing (Step, Counter, Apron): These are pieces of metal or specialized membrane that seal the joints where the roof plane meets a vertical surface. Step flashing is used along the sides, apron flashing on the low side, and counter flashing is embedded into the chimney masonry to cover the top of the other flashing pieces. Flashing is the primary seal against water penetration.

- Cricket: This is a wood-framed structure covered with decking and roofing materials. Its purpose is purely structural and hydrodynamic. It changes the geometry of the roof to manage water flow *before* it reaches the flashing.

A cricket does not replace flashing. A cricket requires its own complete, properly integrated flashing system to be effective. A contractor who suggests one can replace the other does not understand the fundamental principles of roofing.

Building Code Mandates for Roof Crickets: A Non-Negotiable Requirement

The construction of a roof cricket is not a roofer’s preference or a premium add-on. It is a mandatory safety and structural requirement dictated by national building codes. Its omission is not a cost-saving measure; it is a code violation that introduces significant risk and liability to the homeowner.

The 30-Inch Rule: Understanding IRC R1003.20

The International Residential Code (IRC) provides the baseline standard for residential construction in the United States. Section R1003.20 (previously R1001.11) explicitly addresses this issue. It states:

“A cricket or saddle shall be installed on the ridge side of any chimney or penetration more than 30 inches (762 mm) wide as measured perpendicular to the slope. The cricket or saddle shall be sheet metal or of the same material as the roof covering.”

This rule is unambiguous. Any chimney wider than 30 inches must have a cricket. This is not a recommendation. It is a mandate enforced by municipal building inspectors. A roofing project completed without a required cricket will fail inspection, creating costly delays and necessitating rework.

Calculating Required Cricket Dimensions Based on Roof Pitch

Code dictates the *existence* of a cricket, while physics dictates its *design*. For a cricket to function correctly, its slope must be equal to or greater than the slope of the main roof plane. A cricket with insufficient slope will slow water flow, trap debris, and fail to solve the pooling problem it was designed to prevent. Proper construction requires a dimensional analysis based on the roof pitch and chimney width to ensure the cricket’s ridge and valleys effectively channel water away from the chimney’s base.

Financial and Structural Consequences of Code Omission

Ignoring the IRC mandate is a costly error. The consequences extend far beyond a failed inspection.

- Catastrophic Water Damage: A missing cricket will inevitably lead to a leak. This leak will cause rot in the roof decking, damage to attic insulation and rafters, and eventually manifest as stains and mold on interior ceilings and walls. The cost of water damage restoration far exceeds the cost of building a cricket correctly in the first place.

- Homeowner Liability: If you sell your home, a home inspector will flag the missing cricket as a major defect. This can derail a sale or force you to make expensive, last-minute repairs.

- Voided Warranties: Most roofing material manufacturers will not honor their warranties if the roof system was not installed according to building codes. A missing cricket voids the warranty on the most vulnerable part of your roof.

Cricket Construction: Materials and Methods for Lasting Protection

A roof cricket must be constructed as a miniature roof. It is not an afterthought. It requires the same systematic, layered approach to framing, waterproofing, and finishing as the main roof structure to guarantee its performance and longevity. The goal is seamless integration with the building envelope.

Framing the Structure: Ridge Board and Decking Integration

The process begins with a structural frame. A wood ridge board is installed against the chimney, forming the peak of the cricket. Rafters are then run from this ridge board down to the main roof deck, creating the two new sloped planes. This frame is then covered with sheathing (decking), typically OSB or plywood, that matches the thickness of the existing roof deck. This creates a solid, contiguous substrate that is structurally sound and ready for waterproofing.

Waterproofing Layers: A System-Based Approach to Sealing

This is the most critical phase. Simply nailing shingles onto the cricket frame is a recipe for failure. A multi-layered waterproof barrier is required.

- Ice & Water Shield: A self-adhered, waterproof membrane (commonly known as an ice and water shield) is applied directly to the cricket decking and the surrounding main roof deck. It must extend up the chimney wall several inches. This self-sealing membrane acts as the primary line of defense.

- Underlayment Integration: Synthetic roofing underlayment from the main roof field is then integrated and lapped over the ice and water shield to ensure a continuous, secondary water-shedding layer.

- Flashing System: A complete metal flashing system is installed at all cricket-to-roof and cricket-to-chimney junctions, including step flashing, counter flashing, and valley flashing.

Material Integration: Matching Shingles, Metal, or Tile

The final step is to install the roof covering. This material—whether asphalt shingles, standing seam metal, or tile—must be installed on the cricket and woven seamlessly into the main roof field. Cuts and seams must be precise to maintain both the aesthetic consistency of the roof and the final layer of water protection. This level of detail work is a clear differentiator between a craftsman and a standard installer.

Analyzing Common Cricket Failure Points: A Diagnostic Checklist

Even when a cricket is present, it can fail if improperly designed or installed. These failures are often subtle, leading to slow, hidden leaks that cause significant damage before they are detected. Diagnosing these issues requires understanding the common points of error.

Improper Sizing and Slope: The Primary Cause of Water Pooling

The most common design flaw is a cricket with a slope that is too shallow. As stated, the cricket’s slope must be at least that of the main roof. If it is less, water flow slows down, allowing leaves, pine needles, and other debris to accumulate in the cricket’s valleys. This debris forms a small dam, causing water to pool and creating the exact problem the cricket was meant to prevent. This is a direct result of an engineering miscalculation or simple installer oversight.

Flashing Integration Errors: The Most Common Leak Source

The perimeter of the cricket is lined with flashing, and these seams are the most likely source of a leak. Common errors include:

- Poor Seams: Relying on caulk or roof cement instead of properly overlapped and integrated metal flashing. Sealants degrade under UV exposure and thermal expansion, guaranteeing a future leak.

- Counter Flashing Gaps: Failing to properly cut a kerf into the chimney masonry to seat the counter flashing. If the flashing is simply sealed against the face of the brick, water will eventually get behind it.

- Incorrect Lapping: Flashing and underlayment must be installed from the bottom up, with each subsequent layer overlapping the one below it. Reversing this order creates a seam that channels water directly into the roof system.

Substrate Rot: The Unseen Consequence of a Minor Leak

The most insidious danger of a failed cricket is substrate rot. A small, persistent leak may not be visible inside the home for years. During that time, the water is slowly saturating the OSB or plywood roof decking beneath the cricket. This leads to wood rot, compromising the structural integrity of the roof and creating a breeding ground for mold. By the time the leak is discovered, the cost of repair has escalated from a simple flashing fix to a major structural rebuild of that roof section.

The Project Management Approach to Cricket Installation

The chaotic, unpredictable nature of the typical roofing project is unacceptable. A roof cricket installation, like any component of your roofing system, demands precision, clear communication, and a process that eliminates variables. The enemy is not a difficult installation; the enemy is the chaos born from a lack of planning.

Beyond ‘Good Enough’: A Process that Eliminates Installation Variables

Our methodology treats every cricket installation as a self-contained, critical-path project. It is governed by a standard operating procedure that defines every step, from code verification and material specification to waterproofing layer sequence and final inspection. We operate on a zero-defect policy. This is not about simply meeting code; it is about building a system that is engineered for zero failures. This process-driven approach is the only sane way to manage the complexities of roofing and deliver a predictable outcome.

A Note on Price: We Are Not the Lowest Bid. We Are the Most Predictable.

If your primary decision criterion is finding the absolute lowest price, RocStout is not the right partner for your project. This is a deliberate choice. Our pricing reflects the investment in project management, certified installers, and superior materials required to eliminate the chaos and costly rework common in this industry. Our clients are meticulous homeowners who understand that the true cost of a project includes the potential for delays, surprise charges, and premature failure. They are purchasing a predictable, stress-free experience and a guaranteed outcome. We deliver value, not bargains.

Your Project Plan: From On-Site Assessment to Final Sign-Off

We replace uncertainty with a documented plan. Your project is managed with the clarity you expect for any significant investment.

We conduct a full on-site inspection, measure the chimney and roof pitch, and verify all local code requirements.

You receive a detailed, transparent quote with a full material specification and a firm project schedule. There are no hidden costs.

Your dedicated project manager oversees a team that executes the plan with precision, providing you with daily progress updates.

We conduct a comprehensive quality control inspection against our checklist. The project is not complete until every item is verified and you sign off on the work.