Roof replacement logistics refers to the systematic planning, execution, and management of all components required to deconstruct a failing roof system and install a new one that provides absolute protection against environmental forces. The process is not merely construction; it is a controlled project designed to protect the building’s primary function as a shelter from rain, snow, sunlight, and wind. A chaotic, poorly planned project compromises this function and introduces unacceptable risk. This checklist provides the framework for a predictable, orderly replacement process—the only methodology we consider valid.

If your primary goal is to find the lowest bidder, we are not the right company for you. Our process is engineered for meticulous homeowners who value clarity, predictability, and a flawless outcome. We eliminate the chaos inherent in the standard roofing industry.

Phase 1: A Systematic Assessment of Your Current Roof’s Protective Failures

A roof is the top covering of a building, engineered to shield the structure and its occupants from the environment. A replacement is necessary when this protective capability is compromised. The initial phase is a forensic audit to define the exact failure points of the existing system. This is not a casual glance from the curb; it is a data-gathering exercise that informs every subsequent decision.

Documenting Failures Against Rain, Snow, and Wind

The primary function of any roof is to manage water and resist wind. We begin by identifying all points of failure in this core function. This involves a granular inspection for signs of water intrusion, such as stains on interior ceilings, damp insulation in the attic, or daylight visible through the roof deck. We document the condition of shingles, looking for curling, cracking, or missing tabs that compromise the roof’s water-shedding surface. We assess snow load capacity by examining the structural support for any sagging or stress. Wind uplift resistance is evaluated by checking for loose shingles and improperly secured flashing, which are common entry points for high-velocity winds.

Analyzing Material Degradation from Sunlight and Temperature Extremes

Your roof exists in a state of constant environmental assault. Sunlight, specifically UV radiation, breaks down the chemical bonds in roofing materials, causing them to become brittle and ineffective. This is most evident in asphalt shingles through the loss of protective granules, which collect in your gutters. We analyze the extent of this material degradation. Additionally, thermal shock—the cycle of expansion and contraction from daily temperature fluctuations—stresses seams, seals, and fasteners. Our assessment quantifies this damage to specify materials for the new system that are resilient to our specific climate zone’s thermal extremes.

Verifying the Integrity of the Underlying Construction and Support

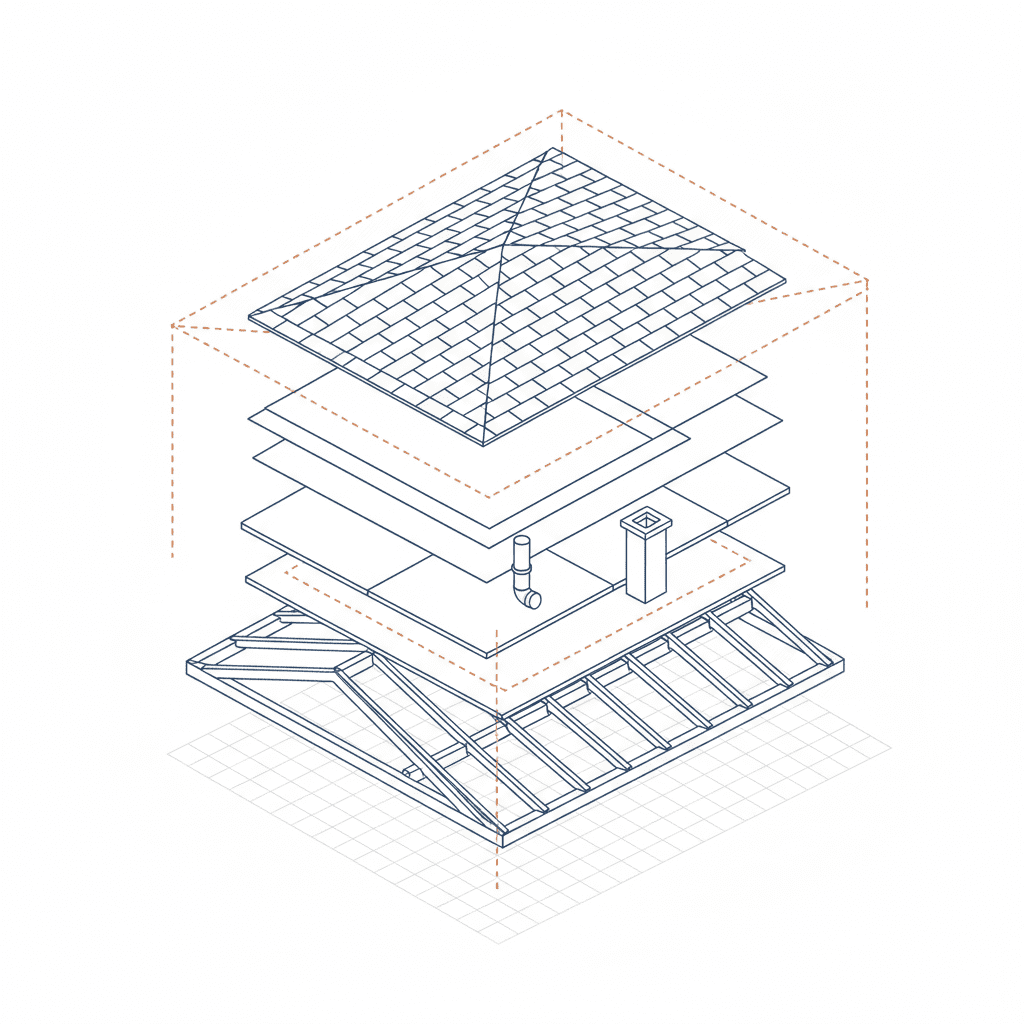

The shingles you see are only one component of a complex system. The true foundation is the roof decking and its structural support, including rafters and trusses. Our assessment includes entering the attic to directly inspect the underside of the roof deck for rot, water damage, or delamination. We verify that the decking is sound and capable of holding new fasteners securely. Any compromised sheathing represents a critical structural failure that must be included in the scope of work. Ignoring the underlying support structure is the most common and dangerous shortcut taken by low-bid contractors.

Phase 2: Material Specification for Absolute Environmental Defense

With a complete diagnostic of the old system’s failures, the next phase is to engineer a new system with materials specified to counteract those exact weaknesses. This is a technical selection process governed by building codes, material science, and the goal of long-term asset longevity. It is the opposite of choosing a shingle based on color alone.

Comparing Material Performance Against Rain and Snow

Effective waterproofing is the baseline requirement. We specify a multi-layered defense system. This starts with a high-performance synthetic underlayment that acts as a secondary water barrier. In climates prone to ice buildup, specifying a self-adhering ice and water shield along eaves, valleys, and penetrations is mandatory, not optional. It prevents water intrusion from ice dams. The primary covering, whether architectural shingles or standing seam metal, is then selected based on its documented water-shedding capabilities and interlocking design.

The table below outlines key performance indicators:

| Material System | Waterproofing Mechanism | Ice Dam Defense |

|---|---|---|

| Architectural Asphalt Shingle | Overlapping courses with bitumen sealant strips | Requires dedicated Ice & Water Shield underlayment |

| Standing Seam Metal | Mechanically seamed panels create a continuous waterproof barrier | High thermal conductivity helps melt snow; less prone to damming |

Selecting for Resilience to Sunlight and Temperature Fluctuation

To combat the degradation identified in Phase 1, we specify materials based on their solar reflectance and thermal emittance ratings. ‘Cool roof’ technology uses granules that reflect a higher percentage of solar radiation, keeping the roof surface cooler. This reduces thermal shock on the material itself and lowers the heat load on your home’s cooling system. Material stability across a wide temperature range is critical. We select products with a proven track record of performance in our specific climate zone, ensuring they will not become brittle in the cold or soft in the heat.

Mandating High Wind-Resistance Ratings for System Security

A roof system’s ability to resist wind uplift is not a matter of chance; it is an engineered outcome. We mandate shingles that meet the ASTM D7158 standard, Class H (rated for winds up to 150 mph) or Class G (120 mph). However, the rating is meaningless without correct installation. The specification must also define the fastener pattern—typically six nails per shingle in high-wind zones—and the precise placement of those fasteners. For homes in the most vulnerable areas, the scope may also include retrofitting hurricane clips to secure the roof trusses to the wall integrity, creating a continuous load path from the foundation to the roof’s peak.

Phase 3: Defining the Scope for the Complete Roof Construction

A roof is a system of integrated components. A proper scope of work defines the construction of this entire system, not just the visible surface. This phase translates the assessment and material specifications into a precise, step-by-step construction plan. Ambiguity in the scope is a direct invitation for chaos and cost overruns.

Underlayment and Decking: The Foundational Support System

The process begins at the base. The scope must detail the inspection and, if necessary, replacement of the roof decking or sheathing. This is the structural foundation for the entire system. Next, the scope specifies the type of underlayment. We mandate high-quality synthetic underlayment over standard felt paper for its superior tear resistance and water repellency. The scope must also explicitly detail the installation of a specialized ice and water shield in all critical areas, creating a waterproof seal that bonds directly to the decking.

Ventilation Strategy: Managing Temperature and Moisture

An unbalanced ventilation system traps super-heated, moist air in the attic. This raises cooling costs, promotes mold growth, and prematurely ages the entire roof system. A complete scope defines a balanced ventilation strategy. This includes detailing the installation of soffit vents for air intake and ridge vents for exhaust. The scope calculates the required net free vent area based on the attic’s square footage, ensuring the system meets or exceeds building code requirements for proper air exchange. This is a critical engineering component, not an afterthought.

Flashing and Sealants: Securing All Points of Penetration

Ninety percent of all roof leaks occur at points of penetration: chimneys, vents, skylights, and valleys. The scope of work must provide explicit detail on how these vulnerable areas will be secured. This means specifying new, pre-formed metal flashing, not reusing old, fatigued materials. It defines the use of high-grade sealants and the precise techniques for valley construction, such as a closed-cut or woven valley for shingles, or a custom-fabricated metal valley. A waterproof seal at these junctures is paramount to system integrity.

Phase 4: Contractor Qualification—A Vetting Process for Predictability

Choosing a contractor is not a search for the lowest price. It is a qualification process to find a partner capable of executing a complex project with precision and predictability. The goal is to eliminate risk and chaos. The contractor’s documentation and communication protocols are direct indicators of their on-site discipline.

Analyzing the Granularity of the Proposal and Bill of Materials

A professional proposal is a detailed technical document, not a one-page sales slip. It must contain a line-item bill of materials that specifies the exact manufacturer and product name for every component—from the shingles down to the type of nails used. The scope of work should be broken down into discrete, verifiable steps. A vague proposal that hides details is a clear signal of impending chaos, surprise charges, and material substitutions. If the primary feature of a proposal is its low price, it is by definition an incomplete and high-risk document.

Mandatory Verification: Licensing, Insurance, and Certifications

This is a non-negotiable due diligence step. You must verify that the contractor holds a current, valid state license. You must request and receive a certificate of insurance that shows both general liability and workers’ compensation coverage. Do not accept the contractor’s word; call the insurance agency to confirm the policy is active. Furthermore, top-tier contractors hold manufacturer certifications (e.g., GAF Master Elite®, Owens Corning Platinum Preferred). These certifications are not marketing ploys; they indicate the crew has been trained to install the system to the manufacturer’s exact specifications, which is a prerequisite for the best warranties.

Evaluating Communication Protocols and Project Oversight

Chaos thrives in a communication vacuum. Before signing any contract, you must understand the company’s communication plan. Who is your single point of contact? Will you have the direct cell phone number of a dedicated project manager, or will you be routed through a call center? How will you receive progress updates? What is the documented process for handling unexpected issues, like the discovery of rotted decking? A professional firm will have clear, pre-defined answers to these questions. The absence of a structured communication protocol guarantees a stressful, reactive, and disorganized project.

Phase 5: Executing the Pre-Installation Site Protection Plan

Your home is the primary asset to be protected during construction. A detailed site protection plan is the hallmark of a process-driven contractor. This plan is executed before a single old shingle is removed, transforming the work area from a potential chaos zone into a controlled and protected environment.

Securing Landscaping, Driveways, and Building Exteriors

Our process begins with comprehensive property protection. This includes deploying heavy-duty tarps to cover all landscaping, shrubs, and flower beds near the home’s perimeter. We lay down plywood sheets to protect driveways from the weight of debris containers and material delivery trucks. Siding, windows, and doors are shielded from falling debris. Air conditioning units are covered to prevent dust and nails from damaging sensitive fins. This is standard operating procedure, not an optional add-on.

Establishing Clear Zones for Material Staging and Debris Removal

A well-defined logistics plan is essential for efficiency and safety. We establish a designated area for material delivery and staging, ensuring it does not obstruct access to your home. A debris container is placed in the most logical and least obtrusive location. We define clear pathways for our crew to move materials and remove debris, minimizing foot traffic on your lawn. The result is a clean job site that operates with predictable efficiency, not a disorganized mess that spills across your property.

Communicating the Work Schedule to All Stakeholders

Predictability requires communication. We provide you with a clear work schedule, including start and estimated end times. We advise on mitigating noise disruptions and ensuring pet safety during the most active construction phases. As a courtesy, we believe in notifying your immediate neighbors of the upcoming work, which helps manage expectations regarding noise and vehicle traffic. A transparent project timeline ensures all stakeholders are informed, eliminating surprises and anxiety.

Our Methodology: The Only Antidote to Industry Chaos

The standard roofing experience is broken. It is defined by vague communication, fluctuating prices, and a general sense of disorder. Our entire business is built as a direct response to that failure. We do not offer a better version of the chaotic standard; we offer a completely different, process-driven methodology. It is the only sane way to manage a significant investment in your home.

Your Dedicated Project Manager: A Single Point of Contact, Not Excuses

Upon project commencement, you are assigned a dedicated Project Manager. This individual is your single point of contact for the duration of the job. You will have their direct contact information. They are responsible for overseeing the logistics, managing the crew, and providing you with proactive daily updates. There is no call center, no confusing chain of command, and no ambiguity about who is accountable for your project’s success.

The Price We Quote is The Price You Pay. Period.

Our proposals are meticulously detailed for a reason. They allow us to provide a fixed-price quote for the defined scope of work. The price you see on your contract is the price you will pay. We do not engage in the common industry tactic of low-bidding a project and then creating profit through a series of unexpected change orders. The only exception is for a change in scope that you request or for the discovery of significant, previously concealed structural damage, which is handled through a transparent, pre-agreed-upon process.

A Final Inspection Checklist That Guarantees Perfection

Our work is not complete until it passes a multi-point final inspection. Your Project Manager will walk the property with you, referencing a detailed punch list to verify that every component has been installed to specification and that your property has been cleaned to a state better than we found it. This includes a magnetic sweep of the entire perimeter to find stray nails. We do not consider the project finished until you have signed off, confirming your complete satisfaction. This process is backed by our comprehensive workmanship warranty, a guarantee of our commitment to predictable, high-quality outcomes.