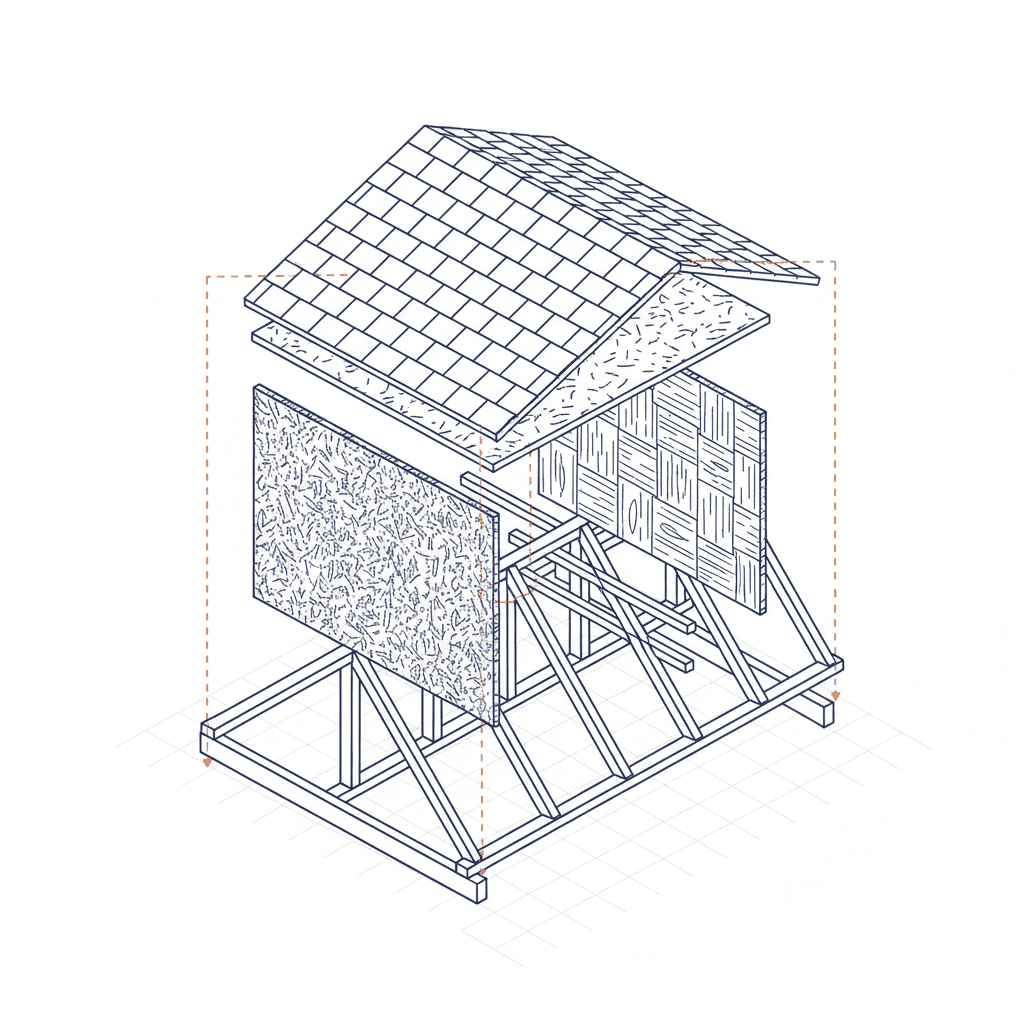

Roof sheathing is the layer of structural panels, commonly referred to as roof decking, that is fastened to the rafters or trusses of a building to form the primary support surface for the entire roofing system. It serves as the foundational plane upon which all subsequent materials—underlayment, flashing, and the final roof covering—are installed. The integrity of this single component dictates the performance, safety, and longevity of the complete roof, which functions as the building’s primary protection against rain, snow, sunlight, and wind.

Choosing the correct sheathing material is not a matter of preference; it is a critical engineering decision. The wrong material, or the correct material installed improperly, introduces systemic risk into your home. This is the first and most crucial step in preventing the chaos, leaks, and premature failures that define the standard roofing experience. Our process eliminates this risk through meticulous material specification and flawless installation protocols.

The Role of Sheathing in a Complete Roof System

The roof system is more than its visible surface. It is an integrated assembly of components, and the sheathing is its structural backbone. It unifies the roof structure, providing a solid, continuous surface that distributes loads and resists environmental forces. Without properly specified and installed sheathing, the most expensive shingles and advanced underlayments are rendered useless.

Defining Roof Sheathing as the Primary Structural Support

Roof sheathing, or the roof deck, consists of structural panels that bridge the space between roof rafters. Its primary function is to create a rigid diaphragm that ties the individual framing members together. This diaphragm action provides immense strength, preventing the roof structure from racking or shifting under lateral loads like high winds. It is the literal foundation for the roof covering, providing a solid substrate for securely fastening shingles, tiles, or metal panels. The stability of the entire roof assembly depends entirely on the strength and proper installation of these structural panels.

Function: Providing Protection Against Wind, Rain, and Snow

The sheathing is the first line of structural defense against weather. It bears the direct weight of snow and ice, distributing this dead load across the roof frame. In high-wind events, it resists uplift forces that attempt to peel the roof from the building. While the underlayment and shingles provide the primary water-shedding surface, the sheathing is the component that must endure incidental moisture from a breach without compromising its structural capacity. Its performance directly impacts the building envelope’s ability to provide absolute protection from the elements, the core function of any roof.

Material Analysis: Oriented Strand Board (OSB)

Oriented Strand Board (OSB) is an engineered wood product widely used as a structural panel in residential construction. It is recognized for its uniformity and cost-effectiveness, but its performance characteristics, particularly concerning moisture, require careful consideration. A decision to use OSB must be based on a clear understanding of its inherent vulnerabilities.

Manufacturing Process and Composition

OSB is manufactured from rectangular wood strands, which are essentially engineered wood chips. These strands are arranged in cross-oriented layers, mixed with waterproof resins and wax, and then cured under immense heat and pressure. This process creates a dense, consistent panel without the natural knots or voids found in plywood. The result is a building material with predictable and uniform structural properties from sheet to sheet, which simplifies engineering specifications but also introduces a consistent vulnerability to moisture.

Technical Specifications: Strengths and Vulnerabilities

OSB’s primary strength is its high shear value relative to its cost. It is a strong, consistent, and cost-effective structural panel. However, its significant vulnerability is its reaction to moisture. The wood strands used in its composition readily absorb water, causing the panel to swell, particularly along the edges. This edge swelling is often irreversible and can telegraph through the shingles, creating a visibly uneven roof plane. More critically, when saturated, OSB loses a significant portion of its structural strength and nail-holding power, creating a failure point within the roof system. It does not dry out efficiently, trapping moisture and creating conditions for rot.

Material Analysis: Plywood

Plywood is a structural panel constructed from thin layers of wood veneer that are glued together under heat and pressure. Its cross-grained construction provides it with distinct performance advantages, particularly in impact resistance and moisture tolerance. For projects where long-term durability is the only metric that matters, plywood is the superior material.

Manufacturing Process and Composition

Plywood is made by laminating thin sheets of wood veneer, with the grain of each adjacent layer turned at a 90-degree angle. This cross-graining process is the source of plywood’s strength and dimensional stability. It distributes strength in both directions, resists splitting, and provides exceptional nail and screw holding power. The layers, or plies, are bonded with strong, water-resistant adhesives, creating a solid, stiff panel that functions as a superior structural element in demanding applications like roof construction.

Technical Specifications: Strengths and Vulnerabilities

Plywood’s greatest strength is its superior moisture tolerance. When exposed to water, it swells less than OSB and, crucially, it returns to near its original dimensions as it dries. This ability to withstand and recover from moisture exposure is a critical risk mitigation feature. It also possesses higher impact resistance and greater stiffness than OSB of the same thickness, making it more resilient to foot traffic during installation and point loads from heavy, wet snow. Its primary vulnerability is a higher initial cost and the potential for delamination or internal voids if manufacturing quality is substandard—a risk eliminated by sourcing from reputable suppliers.

Head-to-Head Comparison: Key Performance Metrics

The choice between OSB and plywood is a choice between upfront cost savings and long-term asset protection. A direct comparison of their performance metrics reveals a clear hierarchy of value. This is not about finding the cheapest option. It is about specifying the correct material for a predictable, durable outcome.

If your decision-making process is driven by achieving the absolute lowest initial price, RocStout is not the right partner for your project. Our process is designed for homeowners who understand that short-term savings often create long-term chaos and expense. We select materials based on performance, not price.

| Performance Metric | Plywood | Oriented Strand Board (OSB) |

|---|---|---|

| Moisture Tolerance | Superior. Swells less, dries faster, and returns to near-original dimensions. Retains structural integrity after wetting. | Poor. High moisture absorption leads to significant and often permanent edge swelling. Loses structural strength when wet. |

| Structural Integrity (Stiffness) | Higher stiffness and impact resistance. Better performance under point loads (e.g., heavy snow, foot traffic). | Slightly more flexible than plywood of the same thickness. Adequate shear strength but less resistant to impact. |

| Nail Holding Power | Excellent. Cross-grain structure provides a superior grip on fasteners, which is critical for wind uplift resistance. | Good when dry. Significantly reduced when panels become wet, compromising the entire system’s wind resistance. |

| Dimensional Stability | High stability. Less prone to swelling and warping, resulting in a flatter, more uniform roof plane over time. | Lower stability. Prone to irreversible edge swelling that can create ridges visible through the shingles. |

| Cost-Value Analysis | Higher initial material cost. Represents a superior long-term investment by mitigating risk of moisture-related failure. | Lower initial material cost. The savings introduce a significant risk of costly future repairs if any moisture intrusion occurs. |

Structural Integrity and Wind Load Capacity

Both plywood and OSB are rated by building codes to meet minimum structural performance requirements for shear and wind uplift. However, plywood’s superior stiffness and nail holding power provide a greater margin of safety. In a high-wind event, the force is transferred from the shingles, through the fasteners, to the sheathing. Plywood’s ability to grip those fasteners more tenaciously provides a more robust defense against wind-related failures. This is not a theoretical advantage; it is a practical enhancement to the security of your home.

Moisture Tolerance and Dimensional Stability (Rain & Snow)

This is the most critical point of divergence. A roof leak is a matter of ‘when,’ not ‘if,’ over the 20-30 year lifespan of a roofing system. A minor breach from a failed flashing or a wind-driven rain event can introduce water onto the sheathing. Plywood tolerates this incidental exposure, dries out, and maintains its integrity. OSB absorbs this moisture like a sponge, swells, weakens, and creates a small problem that can rapidly escalate into a catastrophic failure requiring a complete roof replacement. Choosing plywood is an investment in resilience.

Cost-Value Analysis for Long-Term Roof Performance

The initial cost difference between OSB and plywood for an average-sized roof is negligible when viewed in the context of the total project cost and the value of the asset being protected. Opting for OSB to save a few hundred dollars introduces a level of risk that is disproportionate to the savings. The lifecycle cost of an OSB-sheathed roof is potentially much higher due to its vulnerability. The true value is found in specifying the material that provides the most predictable and durable long-term performance. That material is plywood.

Climate-Specific Material Selection Protocols

A process-driven approach to roofing demands that material selection is not arbitrary. It must be dictated by objective factors, primarily the regional climate. Environmental conditions exert constant pressure on the roof system, and the sheathing must be specified to withstand those specific pressures without degradation.

Material Specification for High-Humidity Environments

In coastal areas or regions with high ambient humidity, moisture management is the primary challenge. These environments create a constant vapor drive that can lead to condensation within the roof assembly. OSB’s low permeability and high moisture absorption make it a dangerously unsuitable choice. It traps moisture, promoting mold growth and rot. Plywood is the only logical specification. Its greater permeability allows the roof assembly to breathe and dry out, and its inherent water tolerance makes it far more resistant to the damaging effects of constant humidity.

Load-Bearing Requirements for Heavy Snow Regions

Regions with heavy snowfall place extreme dead loads on a roof structure. This is often not a uniform load; drifts and ice dams can create significant point loads. Plywood’s superior stiffness and strength-to-weight ratio make it the more robust choice for these conditions. It is less likely to deflect or sag under concentrated weight, maintaining the structural integrity of the roof plane and preventing damage to the roofing materials installed above it. This is a non-negotiable aspect of structural engineering for winter conditions.

Beyond Materials: The System for a Predictable Outcome

The debate between OSB and plywood is important, but it is secondary to a more critical variable: installation quality. The most advanced material in the world will fail if installed incorrectly. Contractor error is the primary source of project chaos and premature roof failure. It is the enemy we have engineered our entire process to eliminate.

Installation Error: The Primary Source of Sheathing Failure and Project Chaos

The roofing industry is plagued by rushed, subpar workmanship. Sheathing failures are almost always a direct result of installation errors that compromise the material’s designed function. Common, catastrophic errors include:

- Improper Nailing: Using the wrong fasteners, incorrect spacing, or over-driving nails, which reduces wind uplift resistance to near zero.

- Incorrect Panel Spacing: Failing to leave the required 1/8-inch gap between panels for expansion, causing panels to buckle and warp.

- Lack of H-Clips: Omitting required edge support clips between rafters, leading to a weak, sagging roof deck.

- Ignoring Manufacturer Specifications: Disregarding the explicit, tested installation protocols provided by the material manufacturer, which voids all warranties and guarantees failure.

These are not minor details. They are fundamental errors that transform a multi-thousand-dollar investment into a liability.

Our Methodology: Mandating Precision for a Chaos-Free Project

We do not leave outcomes to chance. Our process replaces the standard industry chaos with absolute predictability. We achieve this by treating your roof replacement not as a construction job, but as a managed project with zero tolerance for deviation.

Before any work begins, we develop a comprehensive plan detailing every material, every fastener, and every installation step. There is no ambiguity and no on-the-fly decision-making.

Our certified installation team executes the plan precisely, adhering to all building codes and manufacturer specifications. A dedicated project manager conducts multiple quality assurance checks daily.

You are never in the dark. You receive proactive updates from your project manager, have access to a direct line of communication, and are kept fully informed. There are no surprise charges and no unanswered questions.

Ultimately, selecting the right sheathing is a simple technical decision. Plywood offers superior performance for a negligible increase in total project cost. But the real decision is choosing a partner whose entire business model is built on eliminating the chaos and uncertainty that define the roofing industry. You are not just buying a roof; you are investing in a predictable, stress-free outcome.