A roofing site protocol is a systematic framework of procedures governing job site organization, material handling, debris management, and property protection. Its function is to ensure predictable and safe project execution. This methodology is the core difference between a controlled, professional installation and the chaotic, high-risk environment common in the residential roofing industry. For a meticulous homeowner, understanding this protocol is the primary tool for mitigating homeowner anxiety and protecting the value of your property. We operate on a foundation of order; this is our non-negotiable standard.

Job Site Organization: The Foundation of a Predictable Roofing Project

The physical organization of a roofing project site is a direct reflection of the contractor’s internal processes and commitment to quality. A disorganized site is not merely an aesthetic issue; it is a leading indicator of potential safety hazards, inefficient workflow, and substandard workmanship. Our methodology treats the job site as a controlled environment, engineered to protect your property and deliver a flawless final product.

Defining ‘Clean’: From Aesthetic Tidiness to Systemic Safety

In the context of a roofing project, ‘clean’ transcends simple tidiness. It refers to a state of systemic order where every tool, material, and piece of debris has a designated location and purpose. This level of organization is a functional requirement for safety and efficiency. It ensures compliance with OSHA standards, minimizing liability for both our team and you, the homeowner. A systematically clean site eliminates trip hazards, prevents cross-contamination of materials, and allows for unobstructed movement, which directly increases project efficiency. For the homeowner, this translates to tangible peace of mind, knowing the project is managed with professional precision.

The Direct Correlation Between a Messy Site and Poor Workmanship

Chaos is the enemy of quality. A messy, disorganized job site is the physical manifestation of a chaotic process. When a contractor fails to manage the site, it is a clear signal they lack the attention to detail required for a high-performance roof installation. Tools get lost, new materials are damaged before installation, and critical steps are overlooked in the rush to ‘get the job done.’ This environment fosters an acceptance of shortcuts and compromises. Hidden issues, like improperly fastened shingles or damaged flashing, are born from the same lack of discipline that leaves roofing nails scattered across a driveway. In the standard roofing industry, this chaos is often accepted as normal. At RocStout, it is eliminated by design.

Pre-Installation Site Protocol: Protecting Your Building and Landscape

The success of a roofing project is determined before the first shingle is removed. Our pre-installation protocol is a comprehensive defense system for your property. A roof exists to protect the building’s walls, windows, and interior from the elements; our process exists to protect those same components from the installation process itself. We do not begin work until your home and landscape are fully shielded.

Perimeter Assessment and Protective Material Deployment

Our process begins with a detailed perimeter assessment. We identify all assets at risk, from driveways and walkways to delicate flower beds and lawn areas. This is not a cursory glance; it is a logistical evaluation. We then deploy specific protective materials based on the assessment.

Plywood sheets are laid down in high-traffic areas to prevent damage to concrete or pavers from equipment and foot traffic.

Heavy-duty tarps and breathable covers are secured over flower beds, shrubs, and lawns to shield them from falling debris without suffocating the plant life.

Large tarps are hung from the roofline to the ground, creating a curtain that directs debris into a controlled zone and away from the building’s exterior.

Isolating Vulnerable Building Components (Walls, Windows, Siding, HVAC)

Your home’s exterior components are not designed to withstand the impact of falling debris. We systematically isolate these vulnerable components. Tarps or plywood shields are placed against the walls of the building, especially delicate siding materials. Window screens are protected or temporarily removed to prevent punctures. We build temporary, durable covers for all exterior HVAC units to shield them from dust, nails, and shingle granules that can cause mechanical failure. Every component that is not being replaced is fully protected.

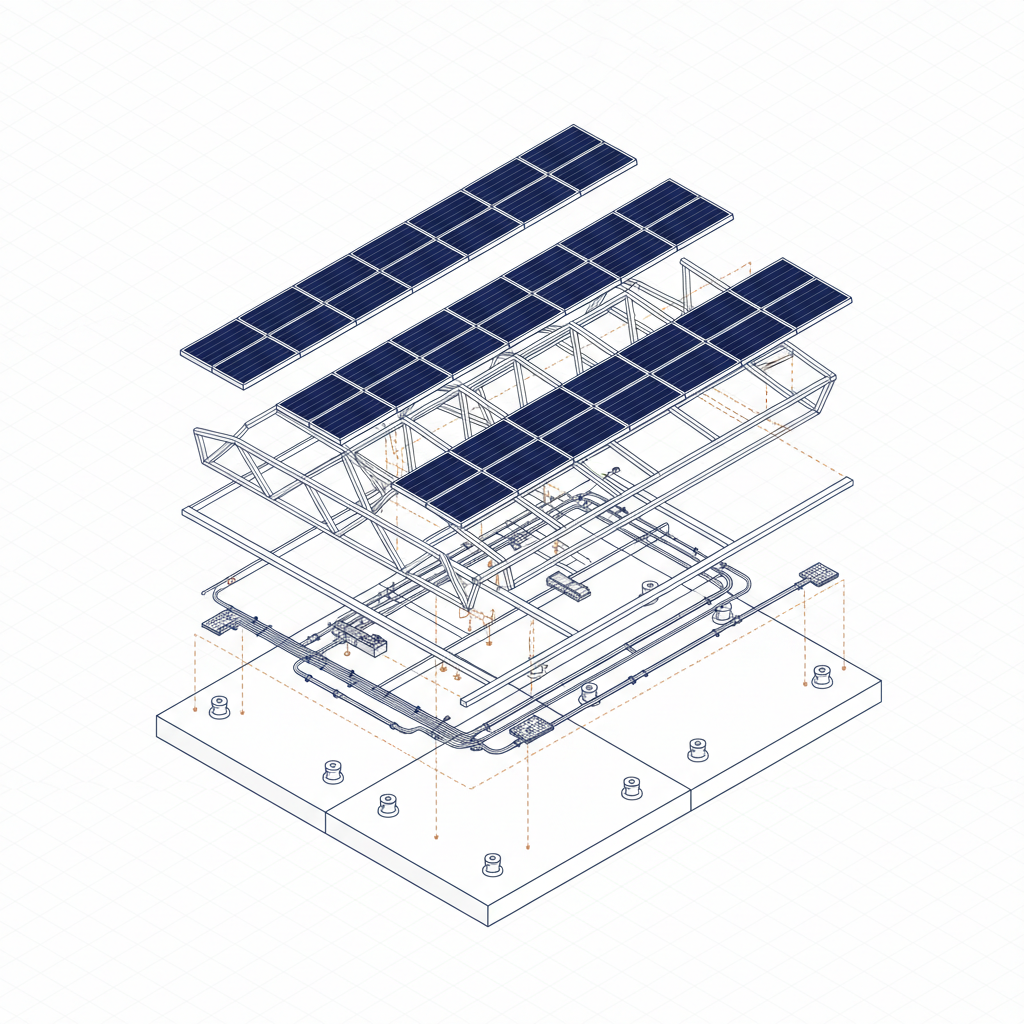

Establishing Designated Material and Debris Staging Zones

Efficient site flow is critical for safety and quality. We establish clearly defined staging areas before any work commences. New materials are placed in a clean, dry, and accessible location, away from the primary debris path. A separate, designated zone is established for dumpster placement, ensuring debris is contained immediately. This logistical planning prevents the commingling of old and new materials, protects your property from unnecessary traffic, and ensures our team can work efficiently without obstruction.

Systematic Removal of Old Roofing Materials

The roof tear-off phase presents the greatest risk for property damage and debris contamination. Our process transforms this potentially chaotic demolition into a controlled, systematic disassembly. The objective is not just to remove the old shingles, but to do so with minimal impact on your property and to perform a forensic analysis of the underlying roof decking.

Controlled Demolition: Minimizing the Spread of Shingles and Underlayment

We work in manageable sections, removing old asphalt shingles and underlayment in a sequence that limits the amount of exposed roof decking at any given time. This controlled roof demolition minimizes the uncontrolled spread of debris. All removed materials are funneled directly from the roof into the designated disposal area using tarps or a debris chute. As each section is cleared, we conduct a thorough roof decking inspection to identify and address any rot or damage before the new system is installed. This is a critical quality control checkpoint that is impossible to perform on a chaotic site.

Continuous Magnetic Sweeping for Nail and Metal Debris Control

Loose roofing nails are a significant hazard. They can cause flat tires and pose a serious risk to children and pets. Our protocol mandates continuous magnetic sweeping throughout the entire project. This is not a task saved for the end of the day. As our team works around the perimeter, high-powered magnets are constantly run over lawns, driveways, and walkways to capture stray fasteners as they fall. This proactive approach drastically reduces the accumulation of hazardous metal debris.

The Role of Specialized Equipment (e.g., Equipter) in Protecting Property

For qualifying job sites, we utilize specialized debris management equipment like the Equipter RB4000. This self-propelled, raisable container acts as a mobile dumpster that can be positioned directly at the roofline. It catches shingles and debris before they ever touch the ground, virtually eliminating impact on landscaping, flower beds, and siding. This investment in technology is a direct investment in property protection and is a clear differentiator from contractors who rely on throwing materials to the ground and hoping for the best.

Maintaining Order During New Roof Construction

The installation of new roofing materials requires the same level of discipline and order as the demolition phase. A roof’s primary function is to provide protection against rain, snow, sunlight, and extremes of temperature. To fulfill this function for decades, the materials must be handled and installed to precise manufacturer specifications, which requires a clean and organized work environment.

Protecting New Materials from Weather (Rain, Sunlight, Temperature)

New roofing materials are not impervious to damage before installation. Bundles of shingles left exposed to direct sunlight can cause premature adhesive activation. Underlayment exposed to rain can become compromised. Our protocol requires that all new materials remain covered and protected from the elements until the moment of installation. This diligence ensures the material integrity is maintained and that your new roof will perform exactly as designed by the manufacturer.

Waste Minimization: Efficient Shingle Cutting and Material Logistics

A designated cutting station is established to manage material modifications cleanly and efficiently. This minimizes the spread of shingle granules and small off-cuts across the roof surface and the ground. By planning our layout and logistics, we minimize material waste, which is a mark of skilled craftsmanship and contributes to overall cost efficiency. A well-managed site generates less waste and ensures every piece of material purchased for your project is used effectively.

End-of-Day Cleanup Procedures and Progress Reporting

Our commitment to order does not end when the work stops. At the conclusion of each day, a mandatory cleanup procedure is executed. The site is swept, tools are secured, and all materials are stacked and protected against wind and overnight weather. Your dedicated Project Manager will provide a concise progress report, ensuring you remain fully informed and confident in the project’s trajectory. You will never be left with a messy, unsecured site or uncertainty about the status of your project.

The Final Inspection: Restoring Your Property to Pre-Project Condition

Our job is not complete until your property is returned to its original state, with the sole exception of a perfectly installed new roof. The final inspection is a meticulous, multi-point process designed to leave no trace of our work behind. This is the final verification of our commitment to cleanliness and order.

Multi-Point Ground, Landscaping, and Gutter System Sweep

The final cleanup is a comprehensive sweep of the entire property. We walk every square foot of the grounds, checking for debris. We gently rake landscaping to restore its appearance and remove any hidden material fragments. Critically, we clear all gutters and downspouts of any granules or debris generated during the installation, ensuring your water management system functions correctly. If necessary, we will pressure wash driveways or walkways to remove any residual dust or scuff marks.

High-Powered Magnetic Rolling: The Definitive Nail Check

After the visual sweep is complete, we perform the definitive nail check. We use a high-powered magnetic roller—far stronger than a simple hand-held sweep—across every inch of your lawn, driveway, garden beds, and walkways. This final nail sweep is a systematic process governed by a checklist to ensure complete coverage. Our standard is zero nails left behind. This is a non-negotiable step for property safety.

Client Walkthrough and Site Cleanliness Sign-Off Protocol

The final step is a formal walkthrough with you, the client. We will inspect the roof, the grounds, and all protected areas together. This is your opportunity to review our work and confirm that our standard of cleanliness meets your expectations. The project is only considered complete upon your final approval and sign-off. This transparent process ensures total client satisfaction and holds us accountable to our promises.

Our Non-Negotiable Standard for Job Site Cleanliness

A clean, orderly job site is not a premium feature or an optional upgrade. It is the bedrock of the RocStout process. It is the physical proof of our core philosophy: that a roofing project can and should be a predictable, stress-free experience for the discerning homeowner.

Why the Lowest Bid Guarantees a Chaotic Job Site

Let us be direct. If your primary decision-making factor is finding the absolute lowest price, we are not the right company for you. The lowest bid is mathematically guaranteed to come from a contractor who cuts corners, and the first corner cut is always disciplined site management. A low price necessitates rushing, which creates chaos. This chaos leads to property damage, safety hazards, poor communication, and ultimately, a subpar roof. Those ‘savings’ are a down payment on future problems and hidden costs. We have structured our entire business to serve clients who understand the profound difference between price and value.

Our Process: The Antidote to Industry Chaos

The typical roofing experience is an exercise in managing chaos. Our process is the antidote. Predictability is our weapon. It is built through a step-by-step methodology that includes a dedicated Project Manager you can always reach, transparent pricing with no surprises, and constant communication. This system is designed to eliminate the anxiety and frustration that define our industry. We do not react to problems; our process prevents them from occurring in the first place.

A Clean Site Isn’t a Feature—It’s a Foundational Requirement

We do not view a clean site as a ‘nice to have.’ It is a foundational requirement for quality work. It is an indicator of respect for you, your family, and your property. It is the only sane, logical way to manage a complex construction project on a residential property. A commitment to order is a commitment to excellence. This is the RocStout way. It is the only way we work.