Flashing failure analysis is the systematic diagnostic process used to identify the root cause of water intrusion at the transitional points of a roof system. It is a methodical examination of materials, installation techniques, and environmental stressors that compromise the building envelope. The roof is the top covering of a building, a complete construction of materials designed to provide absolute protection against rain, snow, and extremes of temperature. Flashing is the component that ensures this protection is continuous, sealing the joints where the primary roof materials terminate or intersect with other structures like walls or chimneys. Its failure represents a critical breach in the roof’s core function.

Understanding this process is not an academic exercise. It is the only way to transition from a cycle of recurring leaks and temporary patches to a state of permanent resolution. For meticulous homeowners who value predictability, analyzing the ‘why’ behind a leak is more critical than simply addressing the ‘where’. It is the foundation of a durable, long-term solution versus a chaotic, temporary fix.

Foundational Principles of Roof Flashing Integrity

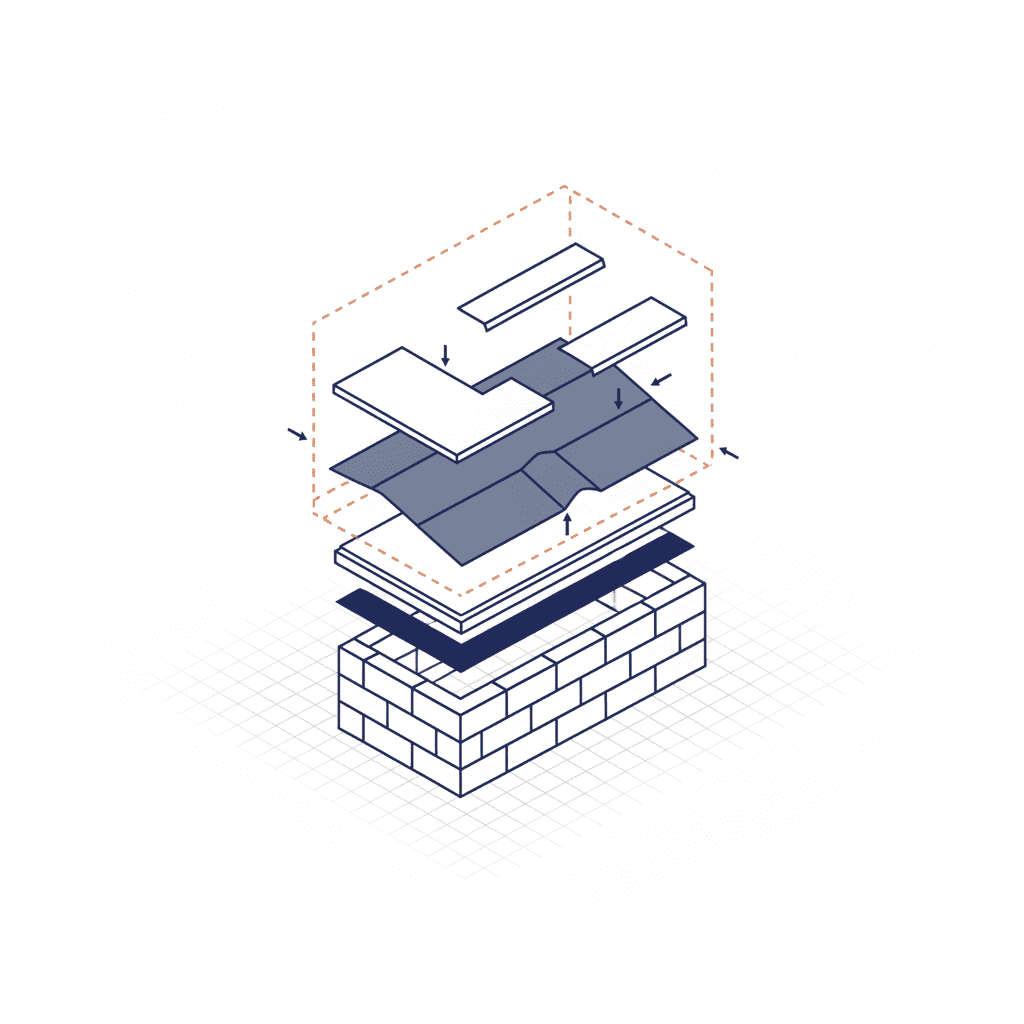

Roof flashing integrity is the measure of a flashing system’s ability to provide continuous, long-term waterproofing for the building envelope. This integrity depends on correct material specification, precise installation, and compatibility with the entire roof system, which consists of all materials and constructions necessary to support the top covering and protect the building from environmental factors.

Defining Flashing’s Role in a Complete Roof Construction

Flashing functions as a water diversion mechanism. While the primary top covering of a roof—such as asphalt shingles or metal panels—sheds the majority of rainwater, it cannot form a waterproof seal at intersections, penetrations, or terminations. Flashing is installed at these points of geometric discontinuity. Its role is to intercept water that moves past the primary roof materials and direct it safely back onto the surface, preventing it from reaching the underlying structure. It is not an accessory; it is an essential component of the building’s total rainwater management system.

Systematic Classification of Flashing Types by Application

Flashing materials and designs are specified based on their location and function within the roof construction. Each type is engineered to manage water flow under specific conditions. Using the wrong type for an application is a direct cause of failure.

| Flashing Type | Application | Primary Function |

|---|---|---|

| Step Flashing | Where a sloped roof plane meets a vertical wall. | Individual pieces are woven into each course of shingles to divert water down the roof and away from the wall. |

| Counter Flashing | Used with step flashing, typically on chimney or wall intersections. | A second layer of flashing embedded into the masonry or wall siding that overlaps the step flashing, protecting the top edge from water entry. |

| Valley Flashing | Where two sloped roof planes intersect, forming a ‘V’ shape. | Creates a waterproof channel to handle high volumes of concentrated water flow from two converging roof surfaces. |

| Drip Edge | Applied along the eaves and rakes of the roof. | Directs water away from the fascia and into the gutters, preventing water from wicking back up under the roofing materials. |

| Chimney Flashing | A complex system at the base of a chimney where it penetrates the roof. | Combines step, counter, and apron flashing to create a multi-layered, watertight seal around a major roof penetration. |

Diagnostic Analysis of Common Flashing Failure Modes

A roof leak is a symptom. The failure mode is the disease. A diagnostic analysis identifies the specific mechanism of failure, which is the only way to prescribe a correct and permanent repair. Simply applying sealant to a visible gap is treating a symptom, guaranteeing the problem will return. We analyze the system to eliminate the cause of the failure.

Material Degradation: Quantifying Failure from Sunlight & Temperature Extremes

All exterior building materials degrade over time. The rate of degradation is predictable based on material choice and exposure. Flashing is particularly vulnerable to corrosion from acid rain, UV degradation from constant sunlight, and cracking from the extremes of temperature. Galvanic corrosion is a specific failure mode where two incompatible metals—such as aluminum flashing and steel fasteners—are in contact, creating an electrochemical reaction that rapidly destroys the weaker material. This is a failure of specification, not just wear and tear.

Installation Error: The Primary Source of Systemic Chaos

The vast majority of flashing failures are not material defects; they are a direct result of improper installation. This is the chaos that defines the standard roofing experience. Common contractor errors include using incorrect fasteners that back out over time, relying on sealant as the primary water barrier instead of mechanical diversion, improper lapping of flashing pieces, and cutting corners on integrating the flashing with the weather-resistive barrier. These are not minor mistakes. They are fundamental errors that build a future failure point directly into your roof system from day one.

Structural Movement: Assessing Stress Fractures from Thermal Cycling

A building is not a static object. It expands and contracts with thermal cycling and can experience minor settlement over time. Roof flashing must be installed to accommodate this movement between the roof deck and adjoining walls or structures. If flashing is fastened too rigidly, the constant stress will cause metal fatigue, leading to stress cracks and fractures. A proper installation accounts for this dynamic reality, ensuring the flashing can move with the structure without compromising the seal.

Mechanical Damage: Impact Analysis of Wind, Debris, and Foot Traffic

Flashing can be compromised by direct physical force. High winds can lift and bend flashing pieces, breaking the seal and creating an entry point for wind-driven rain. Hail damage can dent or puncture metal flashing. Falling debris, such as tree limbs, can cause significant impact damage. Even careless foot traffic from other trades performing work on the roof can bend or dislodge critical flashing components. A thorough inspection must assess for these mechanical damage vectors.

Incorrect Specification: Material Incompatibility in Roof Constructions

Choosing the wrong flashing material for the roof construction is a guarantee of premature failure. For example, using a thin-gauge aluminum flashing in a high-movement area or in contact with alkaline masonry will lead to rapid degradation. Similarly, selecting a flashing material that is incompatible with the primary asphalt shingle material can cause chemical reactions that damage both components. Proper specification requires a technical understanding of material compatibility, anticipated lifespan, and environmental conditions. It is a calculated decision, not a commodity choice.

Risk Assessment: The Consequences of Flashing System Failure

A flashing failure is never a localized problem. It is the start of a progressive cascade of damage that amplifies over time. The consequences extend far beyond a simple water stain, affecting structural integrity, indoor air quality, and the financial value of your property. Ignoring a small leak is accepting an unacceptable level of unpredictable risk.

Water Intrusion Pathways: Tracing Leaks from the Roof Covering to Interior Walls

Water does not travel in a straight line. A leak originating from a failed chimney flashing can travel down rafters, along ceiling joists, and finally appear as a stain on an interior wall many feet away from the initial entry point. Effective leak detection requires tracing these pathways from the symptom (the stain) back to the source (the breach). This often involves using diagnostic tools like moisture meters or thermal imaging to map the extent of moisture saturation within the structure, ensuring the full scope of the problem is understood before any repair is planned.

Compromised Support Structures: Identifying Rot and Mold Proliferation

Once water bypasses the flashing and saturates the underlying roof sheathing and trusses, a more serious threat emerges. Persistent moisture creates the ideal conditions for wood rot and mold growth. Rot compromises the structural integrity of the roof deck and framing, turning solid wood into a soft, spongy mass. Mold proliferation releases spores into the attic and living spaces, creating a significant health hazard. This type of damage is hidden from view and progresses silently, compounding the cost and complexity of the eventual repair.

The Unpredictable Costs of Delayed Remediation

The primary enemy in homeownership is the surprise expense. A minor flashing repair, addressed systematically, has a predictable cost. A flashing failure left unaddressed metastasizes into a project with unpredictable costs. The scope expands from a simple flashing replacement to include sheathing replacement, truss repairs, insulation replacement, mold remediation, and interior drywall and paint work. Delay transforms a manageable, planned expense into a chaotic, costly emergency. It directly erodes property value and introduces significant financial risk.

The Systematic Approach to Flashing Repair and Replacement

We do not patch leaks. We execute a systematic process to diagnose the root cause of failure and engineer a permanent solution. This methodology eliminates the chaos, stress, and unpredictability that homeowners have been forced to accept as standard. It is a process built on precision, transparency, and accountability.

A point of clarity: if your primary decision criterion is the lowest possible price, we are not the right company for you. Our process is designed for homeowners who understand that the true cost of a roof repair includes the elimination of future risk and chaos. We invest in high-performance materials and meticulous project management to deliver a predictable outcome, not a low bid.

Our Process-Driven Flashing Inspection Protocol

Our work begins with a rigorous, data-driven assessment. We do not guess. We diagnose. This protocol ensures every variable is accounted for, leading to a precise and comprehensive scope of work. There are no surprises.

A comprehensive examination of all flashing components, fasteners, and sealants to identify obvious signs of degradation, damage, or installation error.

Use of calibrated moisture meters and optional thermal imaging to map the extent of water intrusion within the roof assembly without unnecessary destructive testing.

Delivery of a detailed diagnostic report with photographic evidence, identifying the specific failure mode(s) and defining the precise scope of work required for a permanent solution.

A transparent, fixed-price proposal based on the diagnostic report. The price is the price. There are no hidden fees or surprise charges.

Material Specification: Mandating Predictable Performance Over Low Cost

We specify materials based on their lifecycle cost and predictable durability, not their upfront price tag. We select high-performance flashing metals, compatible fasteners, and premium underlayments that are engineered to work as a system. This approach aligns with manufacturer warranties and ensures the repair will last. Investing in quality materials is a non-negotiable component of risk mitigation. It is the only way to ensure the longevity of the repair and the protection of your home.

Zero-Defect Installation: Eliminating Chaos Through Methodical Execution

Our installation methodology is the antidote to the typical contractor experience. Every step is planned, communicated, and executed with precision. You are assigned a dedicated Project Manager who is your single point of contact. You receive frequent, scheduled project updates. Our technicians are trained to follow specific, documented installation procedures that exceed manufacturer requirements. We maintain an organized, clean job site to minimize disruption to your life. This is not a promise; it is our process. It is the only sane way to manage a roofing project and deliver the predictable, stress-free outcome you deserve.