Roof pitch is the numerical measure of a roof’s steepness. It is a non-negotiable architectural variable that dictates the performance, material selection, and cost of the entire roofing system. A roof’s primary function is to serve as the top covering of a building, providing absolute protection against rain, snow, sunlight, and wind. The pitch of the roof is the primary factor governing how effectively it performs these duties.

What is Roof Pitch? A Non-Negotiable Project Variable

Understanding roof pitch is not an academic exercise; it is a fundamental requirement for a successful roofing project. This measurement defines the physical and geometric constraints within which all materials must perform and all labor must be executed. It is a fixed constant that informs every subsequent decision, from water drainage strategy to the type of fasteners used to secure the chosen material.

Defining Pitch vs. Slope: The Language of Precision

In construction, precision in language prevents costly errors. While ‘pitch’ and ‘slope’ are often used interchangeably, they have distinct technical meanings. Roof slope refers to the angle of the roof surface, typically expressed in degrees. Roof pitch is a ratio that expresses the same incline but in a standardized format for building trades. Pitch is the industry standard because it provides a clear, consistent instruction for framing and material layout without requiring complex angular calculations on site. For your project, we speak in terms of pitch. It is the language of execution.

The ‘Rise Over Run’ Formula: A Standardized Measurement

Roof pitch is calculated using the ‘rise over run’ formula. This formula establishes a simple ratio. The ‘run’ is a fixed horizontal distance, standardized in the United States at 12 inches (one foot). The ‘rise’ is the vertical distance the roof ascends over that 12-inch run. This relationship is expressed as a fraction, such as 4/12 or 9/12. A roof with a 4/12 pitch rises 4 inches for every 12 inches of horizontal distance. This system eliminates ambiguity. A 6/12 pitch is the same in Texas as it is in Maine, ensuring universal standards for material manufacturing and installation instructions.

System Performance: How Pitch Governs Protection

A roof is a system designed to manage environmental forces. Its pitch is the primary design element that determines its effectiveness against water, wind, snow, and sun. A failure to match the roofing material and installation method to the pitch results in systemic failure. It is not a matter of ‘if,’ but ‘when.’

Water & Snow Drainage Efficiency (Rain, Snow)

The primary function of pitch is to facilitate the shedding of water. On low-slope roofs (below 3/12), water moves slowly and is subject to ponding. This creates hydrostatic pressure, the force of standing water seeking ingress through the smallest seam or imperfection. Therefore, low-slope systems require monolithic, sealed membranes (like TPO or EPDM) to act as a waterproof barrier. As pitch increases, gravity becomes a more effective tool. Steeper roofs shed water and snow rapidly, minimizing the risk of water infiltration and the formation of destructive ice dams in colder climates. The roof moves from being a barrier to being an efficient drainage plane.

Wind Resistance & Uplift Forces (Wind)

Pitch directly influences how a roof interacts with wind. Low-slope roofs present a flat profile to the wind, which can create significant aerodynamic lift, similar to an airplane wing. This uplift force attempts to pull the roofing material and even the underlying structure off the building. Consequently, low-slope systems require robust fastening patterns and often full adhesion to the roof deck. Conversely, very steep roofs (above 9/12) present a larger vertical surface area, which must resist direct wind load. Shingles on conventionally sloped roofs are designed to overlap and seal, but their resistance to wind is highly dependent on correct fastening—a detail that is non-negotiable and dictated by the manufacturer based on pitch.

Sunlight Exposure & Material Longevity (Sunlight, Temperature)

The angle of the roof surface determines the intensity and duration of its exposure to ultraviolet (UV) radiation. A low-slope roof receives direct, perpendicular solar radiation for much of the day, accelerating the degradation of materials like asphalt. The protective granules on architectural shingles are worn away faster, and the material itself becomes brittle. Steeper pitches present an angle to the sun, reducing the intensity of UV exposure at any given point. This also affects thermal shock; the rapid heating and cooling cycles that cause materials to expand and contract. A pitch-appropriate material choice considers the expected solar reflectance and thermal stability required for long-term performance.

Material & Construction Constraints Dictated by Pitch

Material manufacturers invest millions in engineering roofing products to perform within specific pitch ranges. Ignoring these specifications is not a deviation; it is a guarantee of premature failure and a voided warranty. The laws of physics, not a contractor’s preference, dictate which materials can be used on your roof.

Low-Slope Systems (Below 3/12): Membrane & Built-Up Roofs

Roofs with a pitch between 1/4:12 and 3/12 cannot rely on gravity to shed water effectively. They require a fully sealed, waterproof membrane system. Shingles, tile, or metal panels are not options here; they are designed to overlap, not to form a monolithic seal, and will leak under these conditions.

Approved Materials:

- TPO (Thermoplastic Olefin): A single-ply white membrane known for its energy efficiency and heat-welded seams.

- EPDM (Ethylene Propylene Diene Monomer): A durable synthetic rubber membrane, often called a ‘rubber roof,’ with glued seams.

- Modified Bitumen: An asphalt-based system applied in layers, often with a torch-down or self-adhering application method.

Conventional-Slope Systems (3/12 to 9/12): Asphalt, Metal, Tile

This is the most common pitch range for residential construction in the United States. It provides an optimal balance, steep enough to shed water efficiently but not so steep as to require specialized installation equipment and techniques. This range allows for the widest variety of material choices.

Approved Materials:

- Asphalt Shingles (Architectural/Laminated): The dominant roofing material, designed to be installed in overlapping courses with specific nailing patterns.

- Standing Seam Metal: Metal panels with interlocking, raised seams that provide excellent water resistance and longevity.

- Clay and Concrete Tile: Heavy, durable materials that require a robust roof structure and specific underlayment protocols.

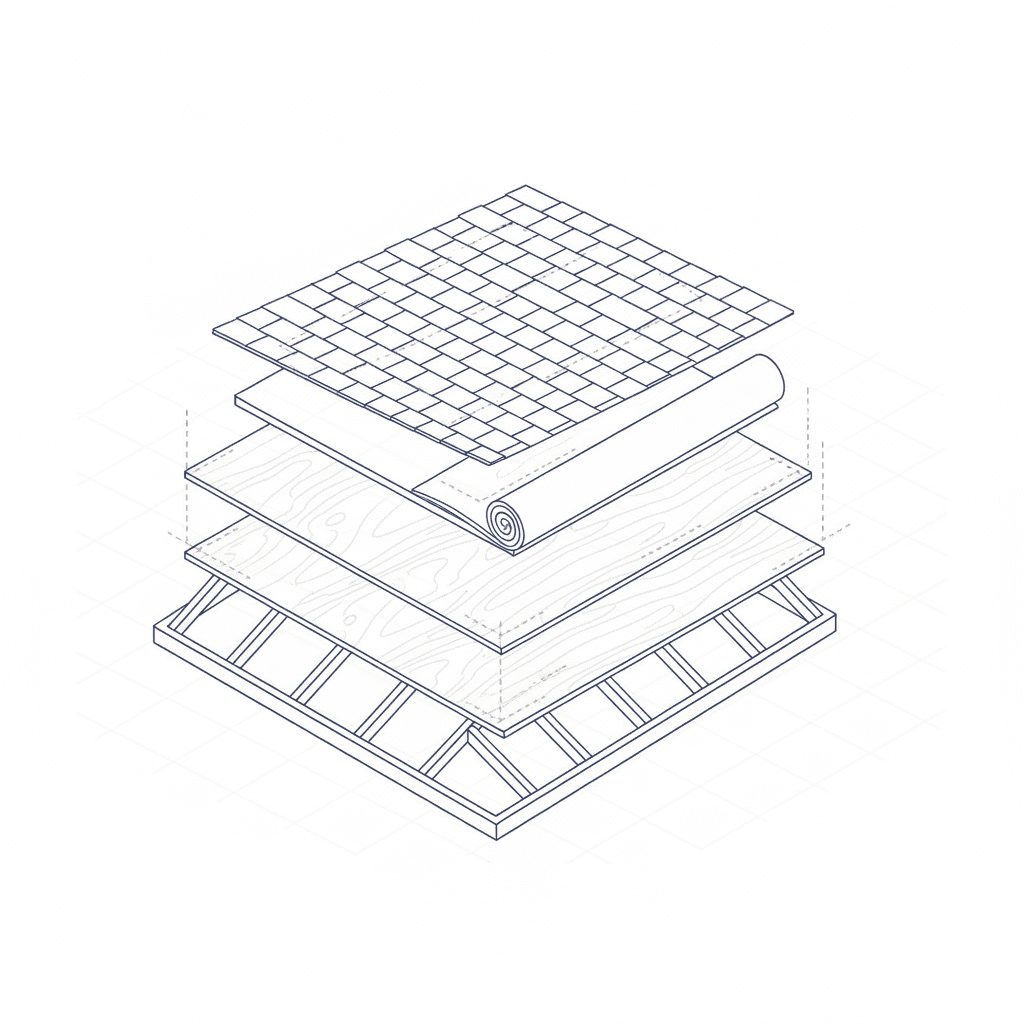

A high-quality synthetic underlayment is critical in these systems, acting as a secondary water barrier beneath the primary top covering.

Steep-Slope Systems (Above 9/12): Slate, Wood Shake & Specialty Metals

Once a roof’s pitch exceeds 9/12, the project’s complexity and safety considerations increase exponentially. The structural load of the materials, the method of fastening, and the safety of the installation crew become paramount. These are not standard roofing jobs; they are specialized construction projects.

Approved Materials:

- Slate Roofing: A natural stone product that can last over a century but requires skilled artisans for installation and specialized fasteners to prevent cracking.

- Cedar Shake: A natural wood product that provides a distinct aesthetic but requires specific ventilation and fastening techniques to prevent rot.

- Specialty Metals (e.g., Copper): Premium materials often used for accent roofs or historic restorations, requiring expert fabrication and installation.

Workers on these roofs require advanced fall protection, and materials must be staged and secured with extreme care.

Analyzing the Financial Impact of Your Roof’s Pitch

The pitch of your roof is a primary driver of the final project cost. A steeper roof is more complex, more dangerous, and more time-consuming to work on than a low-slope or conventional-slope roof. This is a logistical reality that directly impacts the bottom line of any legitimate, insured, and safety-compliant roofing contractor.

Calculating Increased Material & Labor for Steeper Roofs

A 12/12 pitch roof requires significantly more material to cover the same square footage of attic space than a 4/12 pitch roof. This is calculated using a ‘pitch factor’—a multiplier applied to the base area to determine the actual roof surface area. For example, a 12/12 pitch has a factor of approximately 1.414, meaning it requires 41.4% more material than a flat roof covering the same footprint. Labor costs increase in parallel. Every task, from loading materials to installing shingles, takes longer and requires more physical effort on a steep slope. This increase in labor hours is a direct and unavoidable cost.

| Roof Pitch | Pitch Factor (Multiplier) | % Increase in Material |

|---|---|---|

| 4/12 | 1.054 | 5.4% |

| 6/12 | 1.118 | 11.8% |

| 9/12 | 1.250 | 25.0% |

| 12/12 | 1.414 | 41.4% |

Safety Protocols & Equipment: A Non-Negotiable Cost

For any pitch over 6/12, standard work procedures are insufficient. OSHA compliance and basic risk management demand specialized safety equipment. This includes full-body harnesses, anchor points, roof jacks (toe boards), and in some cases, scaffolding. This equipment represents a hard cost. Furthermore, our insurance and workers’ compensation premiums are calculated based on the risk profile of our work. Steep-slope roofing is classified as a high-risk activity. Any contractor who does not factor these costs into their proposal is either not using the required equipment, not properly insured, or both. This exposes you, the homeowner, to unacceptable liability.

Our Methodology: A Predictable Process in an Industry of Chaos

The standard roofing experience is an exercise in chaos: vague estimates, shifting timelines, poor communication, and a job site left in disarray. This is unacceptable. Our entire business is structured to be the antidote to that chaos. We operate on a foundation of process, transparency, and predictability. We believe this is the only sane way to manage a significant investment in your home.

Step 1: Precise Pitch Verification for Ironclad Quotes

Our process begins with data, not guesswork. We conduct a thorough on-site measurement of your entire roofing system, including precise verification of every roof plane’s pitch. This data is cross-referenced with digital and aerial measurements to build a complete project model. This meticulous approach allows us to generate an ironclad scope of work and a fixed-price quote. There are no surprise charges. There are no last-minute additions. What we quote is what you pay. This is the foundation of a predictable, stress-free project.

Our Position on Price: We Are Not the Cheapest Option

We must be clear: If your primary decision criterion is finding the absolute lowest price, we are not the right company for you. This is intentional. Our pricing reflects the true cost of a professionally managed project executed with premium materials, skilled and insured labor, and an unwavering commitment to safety and communication. Chasing the lowest bid inevitably leads to cut corners in materials, safety, or both. We have built our reputation by serving meticulous homeowners who understand that long-term value is more important than short-term savings. Our clients choose us because they want the project done right, once.

The Only Sane Approach to Your Roofing Project

We replace the typical industry chaos with a managed, predictable process. This is how we ensure your peace of mind and protect your investment.

Based on precise measurements of pitch, area, and complexity. No vague allowances or hidden fees.

You receive a single point of contact responsible for your entire project, from material delivery to final inspection.

You will receive a communication at the end of each workday detailing progress made and outlining the plan for the next day.

Your property is protected, and the site is cleaned daily. We use magnetic sweeps to collect stray fasteners.

The project is not complete until you and our project manager have inspected every detail and confirmed it meets our exacting standards.