Saturated roof insulation is a hidden liability that silently transforms a building’s primary protective layer into a source of escalating operational expenditures and catastrophic structural risk. For the fiduciary asset manager, ignoring moisture intrusion within your roofing system is not a deferred maintenance issue; it is an active financial drain that compromises asset value, inflates utility costs, and exposes the organization to significant legal and structural liabilities. Choosing the lowest bid for a quick patch is a well-documented path to inventory damage, tenant disruption, and litigation. Our role as fiduciary advisors is to replace budgetary guesswork with engineering certainty, ensuring every capital decision serves the long-term preservation of your asset.

Financial Impact Analysis: Quantifying the True Cost of Saturated Roof Insulation

The moment water breaches the roofing membrane and saturates the insulation, a series of costly and compounding failures begins. This is not a single problem but a cascade of financial liabilities that must be professionally quantified to inform a responsible capital plan. We analyze these impacts not as maintenance items, but as direct threats to your balance sheet.

Degradation of Thermal Resistance (R-Value) and Resulting Energy Waste

Dry insulation is a financial asset; its specified R-value is a key component in controlling your building’s energy consumption. Wet insulation is a liability. Water is an excellent thermal conductor, and once insulation is saturated, it effectively becomes a thermal bridge, actively transferring energy through your building envelope. A mere 1% moisture content by volume can reduce a polyisocyanurate board’s thermal resistance by nearly 40%. This catastrophic loss in R-value places a direct and sustained load on your HVAC systems, forcing them to run longer and harder to maintain interior climate control. The result is a measurable and permanent increase in utility costs—an operational expenditure leak that will continue until the compromised materials are removed.

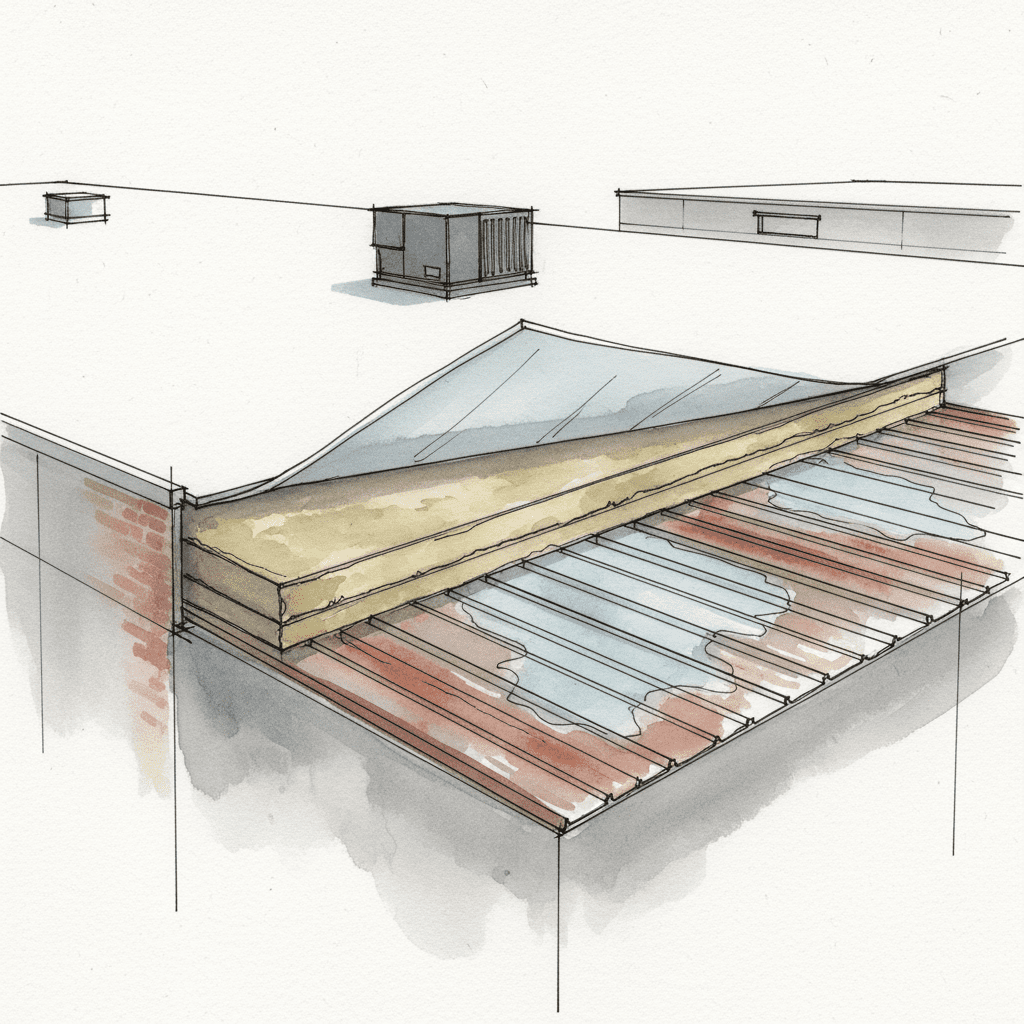

Accelerated Structural Decay: The Risk of Deck Corrosion and Failure

Entrapped moisture creates a highly corrosive microenvironment directly against your structural roof deck. For steel decks, this process of oxidation (rust) is relentless. It reduces the gauge thickness of the steel, fundamentally compromising its load-bearing capacity and leading to deflection or, in worst-case scenarios, failure. For concrete decks, freeze-thaw cycles can cause spalling and deterioration. This is not cosmetic damage; it is a direct depreciation of a core structural asset. A standard roofing contractor may offer to overlay this problem, hiding the corrosion under a new membrane. This is a financially irresponsible act that conceals a growing liability and complicates future capital repairs, driving up their eventual cost exponentially.

Liability Exposure: Mold Proliferation and Compromised Indoor Air Quality

Persistent moisture, combined with organic materials found in some cover boards and building dust, creates the ideal breeding ground for mold and microbial growth. This contamination poses a direct risk to tenants and employees, potentially leading to ‘sick building syndrome,’ increased absenteeism, and formal complaints. The financial consequences extend beyond tenant relations; they include costly mold remediation, potential insurance claims, and significant legal liability. Managing indoor air quality (IAQ) is a critical component of modern facility management, and a compromised roof system is one of its primary threats.

Diagnostic Methodologies for Assessing Insulation Moisture Content

To formulate a fiscally responsible remediation plan, we must first quantify the problem with precision. We replace assumption with data, employing a multi-faceted diagnostic process that is the standard operating procedure for professional asset management. This approach ensures that the scope of work is surgically defined, eliminating waste and preventing the unnecessary replacement of sound materials.

Infrared Thermography Scans: Non-Invasive Mapping of Saturated Areas

Our process begins with a non-invasive infrared thermography survey, executed in accordance with ASTM C1153 standards. Conducted after sunset, the thermal imager detects temperature differentials across the roof surface. Saturated insulation retains solar heat longer than dry insulation, appearing as warmer areas on the scan. This allows our certified thermographer to create a precise ‘moisture map’ of your entire roof, identifying the exact location and extent of subsurface water without a single disruptive roof penetration. This data forms the strategic foundation for all subsequent actions.

Nuclear Moisture Surveys and Capacitance Testing for Quantitative Analysis

While infrared thermography shows us *where* the moisture is, nuclear moisture gauges and electronic capacitance testing provide quantitative data on *how much* moisture is present. These non-invasive tools measure the density of materials beneath the membrane. Since water is significantly denser than dry insulation, we can cross-reference these readings with our infrared map to confirm saturation levels. This step provides the objective, verifiable data required for accurate budget forecasting and removes all ambiguity from the assessment process.

Core Sampling: Verifying Saturation Levels and System Composition

The final diagnostic step is strategic core sampling. Based on the data from our non-invasive scans, we take a limited number of physical cores from the roof. This destructive testing serves two critical functions: it provides absolute verification of moisture content and allows for a laboratory analysis of the existing roof system’s composition. We confirm the types and thicknesses of all materials, the condition of the substrate, and the method of attachment. This ground-truth data ensures our line-item estimate is precise and that the final capital project plan is engineered for flawless execution with no surprises.

Deconstructing the Capital Expenditure: Key Variables in Wet Insulation Replacement Costs

A credible capital expenditure plan requires a transparent breakdown of all cost drivers. We provide line-item reporting not just as an invoice, but as a tool for your capital planning process. Understanding these variables allows for informed decision-making and a cost-benefit analysis grounded in operational reality.

Material Costs: Polyisocyanurate (Polyiso) vs. EPS/XPS Insulation Boards

The choice of insulation is a long-term financial decision. While Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) may present a lower initial material cost, high-density Polyisocyanurate (Polyiso) insulation typically offers a superior R-value per inch and higher compressive strength, making it more resilient to foot traffic and impact. We analyze the specific needs of your facility—from foot traffic requirements to desired energy efficiency—to recommend the material that delivers the optimal Total Cost of Ownership.

| Insulation Attribute | Polyisocyanurate (Polyiso) | Extruded Polystyrene (XPS) | Fiduciary Consideration |

|---|---|---|---|

| R-Value per Inch | R-5.7 to R-6.5 | R-5.0 | Higher R-value achieves energy codes with less material thickness, reducing associated labor and fastener costs. |

| Compressive Strength | 20-25 PSI (Standard) | 15-100 PSI (Varies widely) | Higher strength (HD Polyiso) prevents compression damage under HVAC units and foot traffic, protecting the membrane. |

| Moisture Performance | Closed-cell, but facer can trap moisture if damaged. | Closed-cell, highly resistant to moisture absorption. | While XPS has superior moisture resistance, the primary defense is always a 100% waterproof membrane. The system must work in concert. |

Labor & Logistics: Tear-Off, Disposal, and Staging Complexity

The physical removal of saturated, heavy roofing materials is a significant cost driver. This includes the manual labor for the tear-off, crane rental for hoisting materials, and debris disposal fees, which are calculated by weight. A key component of our process is meticulous site logistics planning. We establish clean, safe, and efficient staging areas to minimize our footprint and ensure zero interference with your daily operations, from deliveries to employee parking.

Compliance & Safety Overheads: OSHA Requirements and Permitting Fees

For RocStout, safety is not a cost center; it is a non-negotiable component of professional execution that protects your organization from liability. Our pricing includes all necessary overheads for strict adherence to OSHA 1926 standards, including fall protection, material handling protocols, and site-specific safety plans. We also manage the entire building permit process with local authorities, ensuring the project is fully compliant with all relevant building codes.

Operational Impact: Factoring in Business Interruption and Tenant Coordination

The true villain of any capital project is operational disruption. The cost of downtime, tenant complaints, and logistical headaches far outweighs any marginal savings from a low-bid contractor who lacks a sophisticated project management process. Our planning phase includes the development of a detailed Tenant Communication Plan. We coordinate with you to schedule loud work during off-hours, manage building access, and provide clear, proactive updates to all stakeholders. This is a core component of our service, designed to preserve business continuity.

Cost Modeling: Per-Square-Foot Estimates for Wet Insulation Remediation

To facilitate accurate capital planning, we model remediation costs based on the percentage of saturation identified during our diagnostic phase. These scenarios provide a budgetary framework for your asset management team.

Scenario 1: Localized Replacement (<25% Saturation)

When moisture is confined to small, well-defined areas, a surgical approach is the most fiscally prudent. This operational expenditure (OpEx) involves removing only the saturated insulation and membrane, ensuring the surrounding deck is clean and dry, and patching in new materials to match the existing system. This infrared-guided repair strategy extends the life of the roof asset without the cost of a full replacement.

Scenario 2: Sectional Replacement (25-50% Saturation)

For more widespread moisture, a phased capital repair may be indicated. We can isolate large sections of the roof for partial tear-off and replacement. This approach allows the project to be broken into phases to align with your capital budget cycles and minimize operational impact on specific areas of the facility at any one time. This is a strategic effort to preserve the viable portions of the asset while addressing the compromised sections.

Scenario 3: Full System Tear-Off and Replacement (>50% Saturation)

When saturation exceeds 50% or is widespread across the entire roof plane, a full replacement is often the only responsible financial path forward. Attempting to save small, isolated sections becomes inefficient and provides a poor return on investment. A full down-to-deck restoration is a major capital project that restores the integrity of the entire building envelope, resets the asset’s lifecycle clock, and provides the best long-term value and warranty coverage.

Mitigating Future Liability: Integrating Roof Health into Capital Asset Planning

Treating a roof replacement as a one-time capital expense is a flawed strategy. A new roof is a long-term asset that requires a proactive management plan to maximize its service life and financial return. We partner with you to shift from a reactive repair cycle to a proactive asset preservation model.

Total Cost of Ownership (TCO) vs. Initial Bid Price

A low initial bid is the most common indicator of high long-term costs. Contractors who cut corners on materials, use undertrained labor, or carry inadequate insurance expose you to premature failure, ongoing repair costs, and significant liability. We urge our clients to analyze the Total Cost of Ownership, which factors in the initial investment, expected service life, annual maintenance costs, energy savings, and the financial strength of the manufacturer’s warranty. A properly engineered and installed roof system from a certified partner provides a lower TCO and a higher Net Present Value (NPV) for your asset.

Developing a Proactive Maintenance Protocol to Prevent Reoccurrence

Upon project completion, we deliver not just a warranty, but a strategic maintenance protocol. This simple, cost-effective plan includes scheduled semi-annual inspections, comprehensive drain and gutter cleaning, seam and flashing examination, and debris removal. This proactive approach allows for the early detection of minor issues before they can escalate into major capital problems, ensuring your roof asset performs as designed for its entire warrantied life.

Executing with Fiscal Certainty: The RocStout Standard Operating Procedure

Our commitment is to deliver predictable capital expenditures and eliminate operational disruption. This is achieved not through promises, but through a rigid, process-driven methodology that governs every phase of our engagement. We are not just roofing contractors; we are partners in your capital planning process, and we operate with the discipline that fiduciary duty requires.

We provide detailed, line-item reporting and a strict change order protocol. Our ‘No Surprise’ billing ensures your approved budget is the final budget.

Our pre-construction meetings and critical path scheduling, supported by a proactive tenant communication plan, are designed to make our presence invisible to your operations.

We execute every project with a site-specific safety plan, quality control checklists, and comprehensive compliance documentation, delivering a complete project closeout package that protects your liability.

Line-Item Reporting for Transparent Capital Expenditure Management

You will receive a proposal and subsequent invoices that detail every facet of the project—from material quantities and labor hours to logistics and compliance fees. This financial transparency provides you with the documentation necessary for internal budget tracking and capital planning. Our change order protocol is rigorous; no additional work is ever performed without a formal, pre-approved authorization, guaranteeing fiscal certainty from start to finish.

Project Scheduling Engineered to Eliminate Operational Disruption

Before any team member arrives on site, we deliver a comprehensive project schedule using the critical path method, often visualized with a Gantt chart. This schedule is developed in coordination with your facility management team during a mandatory pre-construction meeting. We identify your operational constraints—critical delivery times, sensitive tenant areas, noise restrictions—and build our plan around them. Our goal is operational invisibility.

A Process-Driven Approach to Safety Compliance and Risk Mitigation

Our Standard Operating Procedure (SOP) for project execution is built on a foundation of proactive risk mitigation. Every project begins with a site-specific safety plan and is monitored through a series of quality control checklists at critical milestones. We view adherence to OSHA standards as the bare minimum. Our process-driven approach ensures that compliance is documented and verifiable, providing you with a complete project closeout package that serves as a permanent record of a safely and professionally executed capital improvement.