Ultraviolet (UV) degradation is the systematic breakdown of a commercial roofing membrane’s polymer structure, directly accelerating its failure and forcing unplanned capital expenditures. As a fiduciary advisor to facility managers and CFOs, we view this process not as a maintenance issue, but as a direct financial risk to your asset’s value and operational continuity. Ignoring the physics of photodegradation is equivalent to ignoring depreciation schedules on critical machinery; it guarantees a catastrophic, and entirely avoidable, fiscal event. Our methodology is engineered to replace reactive, costly repairs with proactive asset preservation, ensuring fiscal certainty in your capital planning.

The Physics of UV Degradation: Quantifying the Impact on Commercial Roofing Polymers

The integrity of your commercial roof is dictated by the strength of the polymer chains within its membrane. Ultraviolet radiation, specifically UVA and UVB wavelengths, acts as a constant, high-energy force that fractures these molecular bonds. This process, known as photodegradation, is not a linear event; it is an accelerating cascade that systematically compromises the material’s physical properties, turning a protective shield into a liability.

Photodegradation Mechanisms: How UV Radiation Fractures Molecular Bonds

At a microscopic level, UV radiation initiates two primary degradation mechanisms: chain scission and cross-linking. Chain scission is the direct breaking of the long polymer chains that give the membrane its flexibility and tensile strength. The result is a brittle, fragile material susceptible to thermal shock and mechanical damage. Cross-linking causes adjacent polymer chains to fuse, reducing elasticity and leading to shrinkage, surface crazing, and cracking. Both mechanisms result in a roof membrane that can no longer expand and contract with daily temperature fluctuations, guaranteeing seam failure and water ingress.

Material-Specific Vulnerabilities: TPO vs. EPDM vs. Modified Bitumen Analysis

Not all roofing systems are engineered with the same tolerance for UV exposure. The selection of a roofing membrane is a critical capital decision with long-term performance implications. Understanding the inherent vulnerabilities of each primary material type is fundamental to responsible asset management.

| Material System | Primary UV Vulnerability | Visual Indicator of Degradation | Financial Implication |

|---|---|---|---|

| TPO (Thermoplastic Polyolefin) | Surface erosion of the top polymer layer, exposing the scrim reinforcement. Dependent on the quality of the initial UV stabilizer package. | Fiberglass scrim visible, surface crazing, chalking. | Accelerated failure once scrim is exposed; loss of reflectivity increases energy costs. |

| EPDM (Ethylene Propylene Diene Monomer) | Carbon black, the primary UV protectant, erodes over time, leading to membrane thinning and loss of elasticity. | Chalking, shrinkage causing flashings to pull away from walls/curbs. | High risk of seam separation and flashing failure, leading to systemic leaks. |

| Modified Bitumen (Mod-Bit) | The asphaltic oils that provide flexibility are baked out, making the surface brittle. Granule loss exposes the asphalt to direct UV. | Bald spots (granule loss), alligator cracking. | Cracking allows water to penetrate the membrane, saturating the felts and underlying insulation. |

Accelerated Weathering vs. Real-World Performance Data

Manufacturers rely on accelerated weathering tests, governed by ASTM standards, to project a membrane’s service life. While these laboratory tests provide a baseline, they cannot fully replicate the complex interplay of UV radiation, thermal cycling, moisture, and atmospheric pollutants your asset endures. We place greater emphasis on real-world performance data and forensic analysis of existing roof systems. This approach allows us to model a more accurate asset lifecycle, moving beyond marketing claims to engineer a system that meets the specific environmental demands of your facility’s location, ensuring predictable, long-term performance.

Financial Exposure Analysis: Translating UV Damage into Balance Sheet Liabilities

UV degradation is not merely a physical condition; it is a financial variable that must be managed. The slow, silent erosion of your roofing membrane creates quantifiable liabilities that impact CapEx budgets, operational expenses, and overall asset valuation. A failure to proactively manage this risk represents a breach of fiduciary duty to the asset itself.

Calculating Premature Asset Failure and Unplanned Capital Expenditures

A roofing system is a depreciating capital asset with a predictable service life. When UV degradation is left unmanaged, that service life is drastically shortened, forcing a full replacement years ahead of schedule. This triggers an unplanned, multi-million-dollar capital expenditure that wreaks havoc on fiscal planning. Our role is to provide the diagnostic data and mitigation strategies that align your roof’s actual service life with its planned depreciation schedule, converting unpredictable risk into a managed expense.

Energy Inefficiency: The Link Between Reduced Reflectivity and Increased HVAC Load

For cool roofs, particularly TPO and PVC systems, the white, reflective surface is a functional component designed to lower energy consumption. As UV radiation degrades the surface, it begins to chalk and retain dirt, significantly reducing its Solar Reflectivity Index (SRI). This diminished reflectivity increases the roof’s surface temperature, which in turn elevates the building’s interior temperature and places a greater load on your HVAC systems. This translates directly to higher monthly operational expenses and a quantifiable erosion of the roof’s initial ROI.

Risk Modeling for Water Ingress, Inventory Damage, and Business Interruption

The ultimate cost of a failed roof is never the repair itself. The true villain is operational disruption. A single leak resulting from a UV-compromised seam can lead to catastrophic consequences: damaged inventory, ruined equipment, and tenant displacement. These events introduce significant financial liabilities, from insurance claims and legal disputes to lost revenue and reputational damage. Choosing the lowest-bid contractor who uses inferior materials is a direct invitation for this type of liability. Our process is engineered around risk elimination, ensuring the integrity of the building envelope to protect the revenue-generating operations within it.

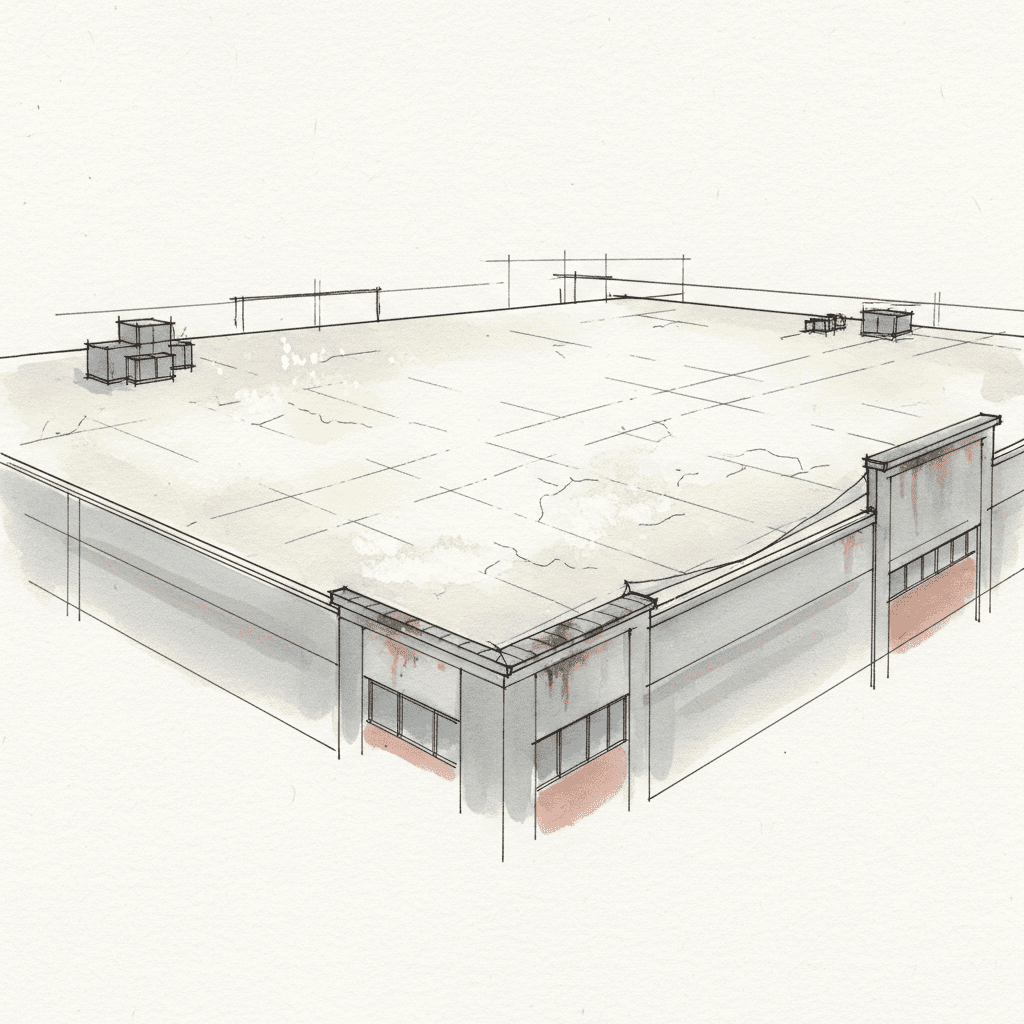

Diagnostic Protocols for Identifying Early-Stage UV Degradation

Effective asset management requires objective data, not guesswork. RocStout employs a multi-faceted diagnostic protocol to identify UV degradation in its earliest stages, allowing for proactive intervention before minor deficiencies escalate into systemic failures. This is not a simple walk-around; it is a forensic engineering assessment of your capital asset.

Visual Inspection Standards: Identifying Crazing, Chalking, and Embrittlement

Our field technicians are trained to identify the subtle but critical signs of UV damage. Chalking is the residue of depleted plasticizers and pigments. Crazing refers to a network of fine surface cracks that indicate the membrane is losing its flexibility. Embrittlement is the loss of pliability, most evident at seams and flashing details, which are the highest-stress areas of any roofing system. These are not cosmetic issues; they are objective evidence that the membrane is nearing the end of its functional service life.

Core Sample Analysis: Assessing Material Integrity and Substrate Condition

A core sample provides indisputable data about the roof’s composition and condition. It allows us to measure the remaining membrane thickness against manufacturer specifications and, most critically, to assess the condition of the underlying insulation. We explicitly advise against roof overlays without this analysis. Installing a new system over saturated insulation is a catastrophic financial error that traps moisture, accelerates deck corrosion, and voids manufacturer warranties. A core sample provides the fiscal certainty needed to make a sound capital decision.

Infrared Thermography for Detecting Compromised Insulation and Seams

Water that penetrates the membrane and saturates the insulation is invisible from the surface. However, this trapped moisture retains heat longer than dry insulation. An infrared thermographic survey, conducted after sunset, reveals these saturated areas as warm spots. This technology allows us to pinpoint the exact locations of subsurface leaks and compromised seams, providing a surgical map for repairs or quantifying the scope of a replacement. It is an essential tool for avoiding the unnecessary cost of replacing an entire roof when only a fraction is compromised.

Mitigation Strategies: Engineering UV Resistance for Long-Term Asset Protection

Identifying UV degradation is only the first step. The next is implementing a strategic plan to mitigate its effects, extend the asset’s service life, and protect your capital investment. These are engineering controls designed to defer costly replacements and maintain operational continuity.

Material Specification: Selecting Roofing Systems with Superior UV Stabilizer Packages

The most effective mitigation strategy begins before installation. Not all membranes are created equal. We guide our clients through the technical specifications of various roofing systems, focusing on the quality and quantity of the manufacturer’s UV stabilizer and fire retardant packages. A thicker membrane or a more robust chemical formulation may have a higher initial cost, but it provides a significantly longer service life and a lower total cost of ownership. This is a strategic procurement decision, not a simple bid process.

Protective Roof Coatings (Silicone & Acrylic) to Defer Capital Replacement

For a roof that is structurally sound but showing signs of surface degradation, a restorative coating is a powerful tool for capital deferment. A high-solids silicone or acrylic coating system forms a new, seamless, and highly reflective monolithic membrane directly over the existing roof. This process accomplishes three financial objectives: it immediately stops UV degradation of the underlying membrane, it seals minor leaks and cracks, and its high reflectivity dramatically lowers surface temperature, reducing HVAC load. This is not a ‘patch’; it is a strategic extension of your asset’s life, executed for a fraction of the cost of a full replacement.

Proactive Maintenance Programs: A Framework for Preserving Asset Integrity

A roofing asset requires regular, scheduled maintenance to perform as designed and to comply with warranty requirements. Our Proactive Maintenance Programs are built on the principles of asset management, not reactive repair. These programs include semi-annual inspections, debris removal, seam and flashing examination, and detailed reporting. This disciplined approach ensures small, manageable operational expenses prevent large, disruptive capital events. It is the only responsible method for managing commercial infrastructure.

The RocStout Methodology: Integrating UV Management into Capital Asset Planning

We operate as fiduciary partners, not contractors. Our entire methodology is designed to provide you with the data, analysis, and execution needed to manage your roofing system as a financial asset. We reject the industry’s standard of reactive fixes and low-bid liability. Our value is delivered through fiscal certainty, operational continuity, and risk elimination.

Lifecycle Cost Analysis: A Data-Driven Approach to Roofing CapEx

We move beyond the initial installation price to provide a comprehensive Lifecycle Cost Analysis. This financial model accounts for the initial investment, projected energy savings, anticipated maintenance costs, and the system’s expected service life. This data-driven approach allows you to compare roofing systems not by their upfront cost, but by their long-term value and predictable impact on your capital and operational budgets. It is the cornerstone of responsible capital planning.

Our Standard Operating Procedure (SOP) for UV-Resistant System Installation and Reporting

Excellence is not an accident; it is the result of a rigorous, documented process. Every RocStout project is governed by a strict Standard Operating Procedure that covers everything from material logistics and OSHA-compliant safety protocols to manufacturer-mandated installation details. We provide detailed, line-item reporting and photographic documentation at every project milestone. This commitment to process ensures quality assurance, transparent billing, and a final product that is engineered to perform, delivering the fiscal certainty you require.

Ensuring Zero Operational Disruption for Tenants and Facility Operations

We understand that our work site is your active place of business. The true enemy of any facility manager is operational disruption. Our project management methodology is built around a core principle of zero disruption. This includes meticulous logistics planning, clear and consistent tenant communication, designated safety zones, and a rigid adherence to project schedules. We enforce a ‘water-tight-by-nightfall’ protocol, ensuring your asset is protected at the close of every workday. This is not an added benefit; it is our standard operating procedure and the only professional way to conduct business.