Choosing between TPO and EPDM roofing systems is a critical capital expenditure decision, impacting not just initial outlay but the total cost of ownership, operational continuity, and long-term asset value of your industrial or warehouse facility. This is not a choice between materials; it is a strategic decision about risk management and fiscal predictability. As your fiduciary advisor, our objective is to translate complex material science into a clear financial analysis, ensuring your capital is deployed to maximize ROI and minimize liability.

Opting for the lowest initial bid on a commercial roof is a well-documented path to financial liability. It prioritizes a short-term accounting entry over long-term asset preservation, inviting inventory damage from leaks, tenant disruption, and costly emergency repairs. We reject this reactive model. Our methodology is built on proactive asset preservation, ensuring your facility remains a productive, uninterrupted center of operations.

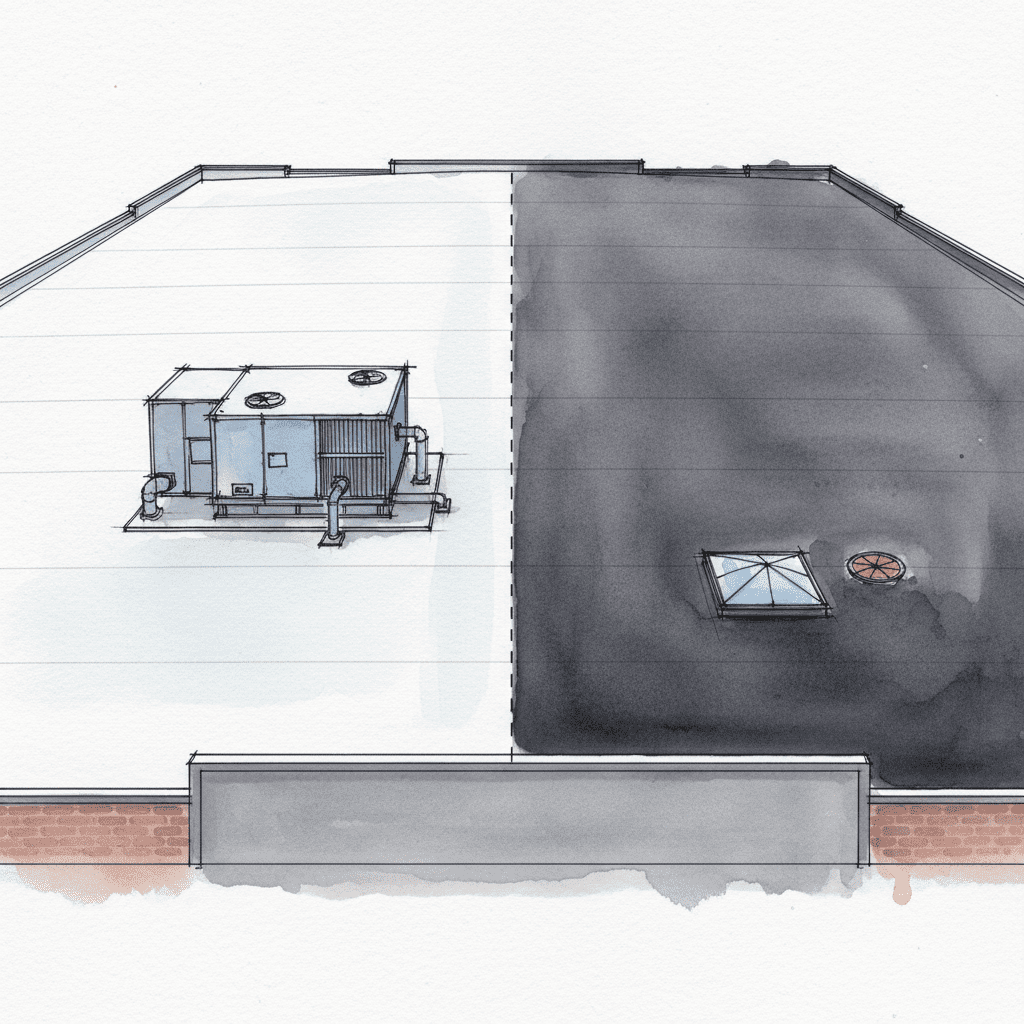

TPO vs. EPDM: A Comparative Framework for Capital Expenditure (CapEx) Planning

A responsible capital plan requires a clear-eyed assessment of both immediate costs and future financial obligations. The initial bid for a roofing system represents only a fraction of its total cost of ownership. A comprehensive analysis must account for the financial impact of the system over its entire service life.

Initial Installation Costs: Deconstructing Material and Labor Variables

The sticker price of a roofing project is influenced by material procurement, labor rates, and the specific attachment method (adhered vs. mechanically attached). TPO membranes are typically manufactured in wider rolls than EPDM, which can translate to fewer seams and a corresponding reduction in labor hours for installation. Furthermore, the robotic heat-welding process for TPO seams is often faster and less dependent on weather conditions than the manual application of adhesives and primers required for EPDM seams. However, the true cost is determined by a thorough pre-installation audit of the existing roof deck and structure. Any contractor who provides a price without this audit is not providing a bid; they are creating a future change order.

Beyond the Bid: Factoring in Long-Term Operational Expenditures (OpEx)

The most significant divergence in lifecycle cost between TPO and EPDM occurs in the operational budget. A roof is not a one-time purchase; it is a depreciating asset that requires a maintenance budget to ensure warranty compliance and prevent catastrophic failure. The engineering of the seam technology is the primary driver of these future costs. EPDM’s adhesive-based seams are a known maintenance liability, requiring periodic inspection and re-application of sealants. TPO’s heat-welded seams, which create a permanent molecular bond, effectively eliminate this category of repair expenditure, leading to a more predictable and lower long-term OpEx.

Material Engineering Analysis: Impact on Long-Term Asset Performance

The polymer chemistry of a roofing membrane dictates its performance under constant environmental stressors like UV radiation, chemical exposure, and physical impact. These ASTM-certified performance characteristics have direct financial consequences, influencing service life, repair frequency, and the overall resilience of your building envelope.

TPO (Thermoplastic) Profile: Heat-Welded Seams and Puncture Resistance

Thermoplastic Polyolefin (TPO) is an engineered material designed for durability and longevity. As a thermoplastic, it can be repeatedly softened with heat and hardened upon cooling without chemical change. This property is the foundation of its primary advantage: heat-welded seams. This process creates a monolithic, fused barrier that is stronger than the membrane itself. TPO’s formulation also provides superior puncture and tear resistance compared to non-reinforced EPDM, a critical risk mitigation factor for facilities with heavy rooftop HVAC traffic or in areas prone to hail.

EPDM (Thermoset) Profile: Adhesive Seams and UV Degradation Factors

Ethylene Propylene Diene Monomer (EPDM) is a thermoset material, meaning its molecular structure is permanently set—or cured—during manufacturing. It cannot be re-melted and welded. This synthetic rubber has a proven track record, but its performance is contingent on its primary vulnerability: the adhesive-based seams. These seams rely on primers and glues to bond two separate sheets, creating a point of weakness that EPDM systems lack elsewhere. Over time, these adhesives are susceptible to degradation from thermal cycling and UV exposure, creating a predictable need for maintenance and repair.

Seam Integrity Analysis: Mitigating Water Ingress and Inventory Loss

For any facility manager or asset owner, the single greatest threat is water intrusion. A seam failure is not an inconvenience; it is a direct threat to inventory, equipment, and operational continuity. The method of seam construction is therefore the most critical variable in your risk assessment.

Heat-Welded (TPO) Seams: A Monolithic Barrier Against Moisture Intrusion

The engineering of a heat-welded seam is designed to eliminate human error and material weakness. Using robotic welders that apply precise temperature and pressure, the overlapping TPO membranes are fused at a molecular level. The result is not a bond; it is a single, continuous piece of membrane material across the entire roof plane. This monolithic barrier presents no path for water infiltration, effectively engineering out the most common point of failure in commercial roofing systems. This is the gold standard for mitigating water infiltration liability.

Adhesive-Based (EPDM) Seams: Assessing Failure Points and Maintenance Liabilities

Adhesive seams represent a calculated risk. Their installation is highly dependent on technician skill and ideal weather conditions—temperature and humidity can compromise the bond. Over the asset’s lifecycle, thermal cycling causes the roof to expand and contract, placing constant shear stress on these glued seams. This stress, combined with adhesive degradation, inevitably leads to seam failure without a strict, recurring maintenance protocol. For a CFO, this translates to a permanent line item in the annual maintenance budget dedicated solely to inspecting and resealing seams.

Energy Efficiency Modeling: Impact on HVAC Load and Utility Expenditures

The roof is the largest component of the building envelope, and its surface properties directly influence your facility’s energy consumption. This is a quantifiable operational expenditure that must be factored into any legitimate Total Cost of Ownership analysis.

Solar Reflectance (SRI): Quantifying TPO’s Effect on Operating Costs

Standard white TPO is a highly reflective “cool roof” material, possessing a high Solar Reflectance Index (SRI). This means it reflects a significant portion of the sun’s thermal energy rather than absorbing it. A high SRI value directly translates to a lower roof surface temperature, which in turn reduces the heat transferred into your facility. This lessens the load on your HVAC systems, resulting in lower monthly utility costs and reduced peak energy demand charges. For asset managers in southern climates, this is a significant and predictable source of ROI.

EPDM’s Thermal Absorption: Financial Implications in Various Climate Zones

Standard black EPDM has a very low SRI, meaning it absorbs a high percentage of solar radiation. This elevates roof surface temperatures far above ambient air temperature, increasing heat transfer into the building and placing a greater burden on HVAC systems. While ballasted systems or the application of reflective coatings can mitigate this, they add cost and complexity to the system. While a more absorptive roof can offer marginal benefits in very cold northern climates by reducing heating loads, this is typically outweighed by the increased cooling costs during summer months for most industrial and commercial facilities.

Total Cost of Ownership (TCO): A 30-Year Financial Lifecycle Projection

A fiduciary approach demands that we evaluate this capital project not on its initial price tag, but on its projected cost over a 30-year operational window. This TCO model provides the fiscal certainty required for effective long-range capital planning.

| Financial & Performance Metric | TPO (Thermoplastic Polyolefin) | EPDM (Ethylene Propylene Diene Monomer) |

|---|---|---|

| Seam Technology | Heat-Welded (Monolithic, Molecular Bond) | Adhesive-Based (Requires Primers/Glues) |

| Primary Failure Point | Improper Welding (Mitigated by QA/QC) | Adhesive Degradation at Seams |

| Projected Service Life | 20-30+ Years | 20-30+ Years (contingent on seam maintenance) |

| Energy Efficiency (SRI) | High (White/Light Colors) – Lowers HVAC OpEx | Low (Standard Black) – Increases HVAC OpEx |

| Puncture Resistance | Excellent (Reinforced Membrane) | Good (Can be punctured by dropped tools/fasteners) |

| Long-Term Maintenance Liability | Low (Routine inspections, minimal seam work) | High (Mandatory seam inspection and sealant re-application) |

Projected Service Life: TPO vs. EPDM Under Standard Environmental Stressors

Both TPO and EPDM systems, when properly specified and installed, can offer service lives exceeding 20-25 years. However, the projected service life of an EPDM roof is directly tied to a diligent maintenance program for its seams. A TPO system’s lifespan is less dependent on maintenance and more on the initial quality of installation. Its inherent resistance to degradation from UV exposure, ozone, and common chemical contaminants provides a more stable and predictable performance curve over time.

Maintenance and Repair Protocols: Forecasting Labor and Material Expenditures

Forecasting future expenditures is a cornerstone of responsible asset management. With a TPO system, repairs for punctures or modifications (e.g., adding a new curb) are executed by cleaning the area and heat-welding a new piece of TPO material, creating a permanent, monolithic patch. This is a fast and reliable process. Repairing EPDM requires extensive surface preparation, primers, patches, and sealants—a more complex and less permanent solution that introduces another potential point of failure. The labor and material expenditures for maintaining and repairing EPDM seams over a 30-year period are a significant, predictable, and avoidable cost.

Executing Your Capital Project with Fiscal Certainty and Zero Operational Disruption

The selection of the correct roofing system is only the first step. The true enemy of any facility manager is operational disruption. Delays, safety hazards, and poor communication from a standard contractor cost you money and damage tenant relationships. RocStout operates as a fiduciary partner, executing projects with a rigid methodology designed to eliminate disruption and provide absolute fiscal certainty.

Our Standard Operating Procedure (SOP) for System Specification and Installation

We do not install roofs; we execute engineered solutions according to a strict Standard Operating Procedure. This process-driven methodology is the only responsible way to manage critical building infrastructure and ensure predictable outcomes.

We conduct a comprehensive assessment of the existing substrate, core samples, drainage, and structural integrity. This eliminates unforeseen conditions and forms the basis of our ‘No Surprise’ billing guarantee.

Based on audit data, we engineer the optimal system—including membrane thickness, insulation R-value, and attachment method—to meet your specific asset performance and budget goals.

We develop a detailed project schedule, staging plan, and tenant communication protocol to ensure zero operational disruption. All work is governed by strict OSHA compliance.

Our certified technicians execute the installation, with daily progress reports and quality control checks. We adhere to a ‘water-tight-by-nightfall’ protocol to protect your asset at all times.

Mitigating Risk Through Proactive Project Management and Tenant Communication

We understand that time is money. Our project management is designed around your operational needs. We establish clear lines of communication with your facility team and tenants, providing daily progress reports and proactively managing logistics to keep your loading docks clear and your business running. Our commitment to OSHA compliance is non-negotiable, protecting your staff, our crews, and your corporate liability. This is the difference between hiring a contractor and retaining a professional services partner.

Partnering in Capital Planning: From Initial Audit to Multi-Year Asset Management

Your relationship with RocStout does not end when the project is complete. We provide all compliance documentation, detailed line-item reporting for your accounting department, and a proactive multi-year maintenance plan to preserve your capital investment. By viewing your roof as a financial asset, we help you transition from a cycle of reactive repair to a strategy of proactive asset preservation. This is how we provide fiscal certainty and become an integral part of your capital planning process.