TPO Seam Failure: A Critical Financial Liability for Commercial Assets

A Thermoplastic Polyolefin (TPO) roofing system’s performance is ultimately governed not by the membrane itself, but by the integrity of its heat-welded seams. These seams are the critical points where factory-produced membrane sheets are fused on-site into a single, monolithic barrier against water ingress. As a fiduciary advisor responsible for commercial asset preservation, it is imperative to understand that seam integrity is the primary predictor of your roof’s service life and the number one variable in managing long-term capital expenditures. A failure here is not a simple leak; it is the start of a cascading financial liability that threatens asset value and operational continuity.

Quantifying the Risk: From Inventory Loss to Tenant Disruption

Choosing a roofing contractor based on the lowest bid is a decision that directly invites financial liability. A compromised TPO seam initiates a sequence of events that extends far beyond the cost of a simple repair. The initial water intrusion leads to damaged inventory, compromised structural components like the roof deck and steel joists, and the potential for mold growth, creating significant health and legal liabilities. For facility managers and CFOs, the most damaging consequence is business interruption. Tenant operations are disrupted, critical equipment may be damaged, and the facility’s revenue-generating capacity is put on hold. This operational downtime, coupled with the unbudgeted capital expenditure of a premature roof replacement, represents a catastrophic failure in asset management.

Why Seam Integrity is the Primary Determinant of TPO System Lifespan

The TPO membrane arrives on-site as a highly engineered, quality-controlled product. The seams, however, are manufactured in the field, subject to variable conditions, equipment calibration, and technician skill. This makes the weld the system’s most significant point of vulnerability. A properly executed heat-welded seam creates a molecular bond stronger than the membrane itself, effectively turning multiple sheets into one. This monolithic membrane is the engineering goal. When workmanship is substandard, the seam becomes a weak point, destined to fail under the predictable stresses of thermal cycling and weathering. Therefore, the total cost of ownership and the functional lifespan of your roofing asset are decided not by the material you choose, but by the quality control protocol used to weld its seams.

Forensic Analysis of Weld Failures: Technical Causes and Financial Implications

Understanding the technical causes of TPO seam failure is essential for any asset manager focused on risk mitigation. These failures are almost never a result of deficient materials; they are overwhelmingly the product of installation error and a lack of rigorous, process-driven quality control. Each technical cause carries a direct and predictable financial consequence, transforming a preventable installation error into a significant balance sheet liability.

Installation Deficiencies: The Leading Vector for Premature Failure

The primary driver of premature TPO system failure is a lapse in workmanship during the welding process. This includes using unqualified labor, improper welder speed, and insufficient heat or pressure. A ‘cold weld,’ for instance, may appear sealed upon initial inspection but lacks the molecular bond to withstand thermal expansion and contraction, leading to failure within the first few years. Rushing the process by increasing welder speed prevents the thermoplastic materials from properly fusing. These are not unpredictable accidents; they are direct outcomes of inadequate training, supervision, and a contractor’s failure to adhere to manufacturer specifications—a quality control lapse that shifts future liability directly onto the building owner.

Environmental Stressors: UV Degradation and Thermal Cycling Effects

A commercial roof is a dynamic system under constant assault from environmental forces. Ultraviolet (UV) radiation slowly degrades the membrane surface, while thermal cycling causes daily expansion and contraction. A properly executed weld is engineered to accommodate this movement and resist weathering for decades. However, a substandard weld creates a point of cyclical fatigue. The constant stress concentrates at this weak point, leading to delamination and eventual failure. This is not a force majeure event; it is a predictable outcome when the installation process fails to account for the known operational stresses the asset will endure.

Substrate Contamination: How Debris and Moisture Compromise Weld Integrity

The integrity of a TPO weld depends on a pristine substrate. Dust, job site debris, and even microscopic amounts of moisture on the membrane surface during the welding process will prevent a complete molecular fusion. This creates a contaminated weld that may pass a cursory visual inspection but lacks the internal cohesion to perform long-term. This type of adhesion failure is a direct result of sloppy site management and a failure to follow standard operating procedures for surface preparation. It is a hidden defect that incubates for months or years before manifesting as a catastrophic leak, long after the negligent contractor has left the site.

Early Detection Protocols: Identifying Seam Vulnerabilities Before Catastrophic Failure

Proactive asset management requires a shift from reactive repair to proactive risk mitigation. Identifying seam vulnerabilities before they result in water ingress is fundamental to controlling the total cost of ownership of your roofing asset. Implementing a standardized inspection protocol provides the data necessary for intelligent capital planning and prevents minor deficiencies from escalating into major financial events.

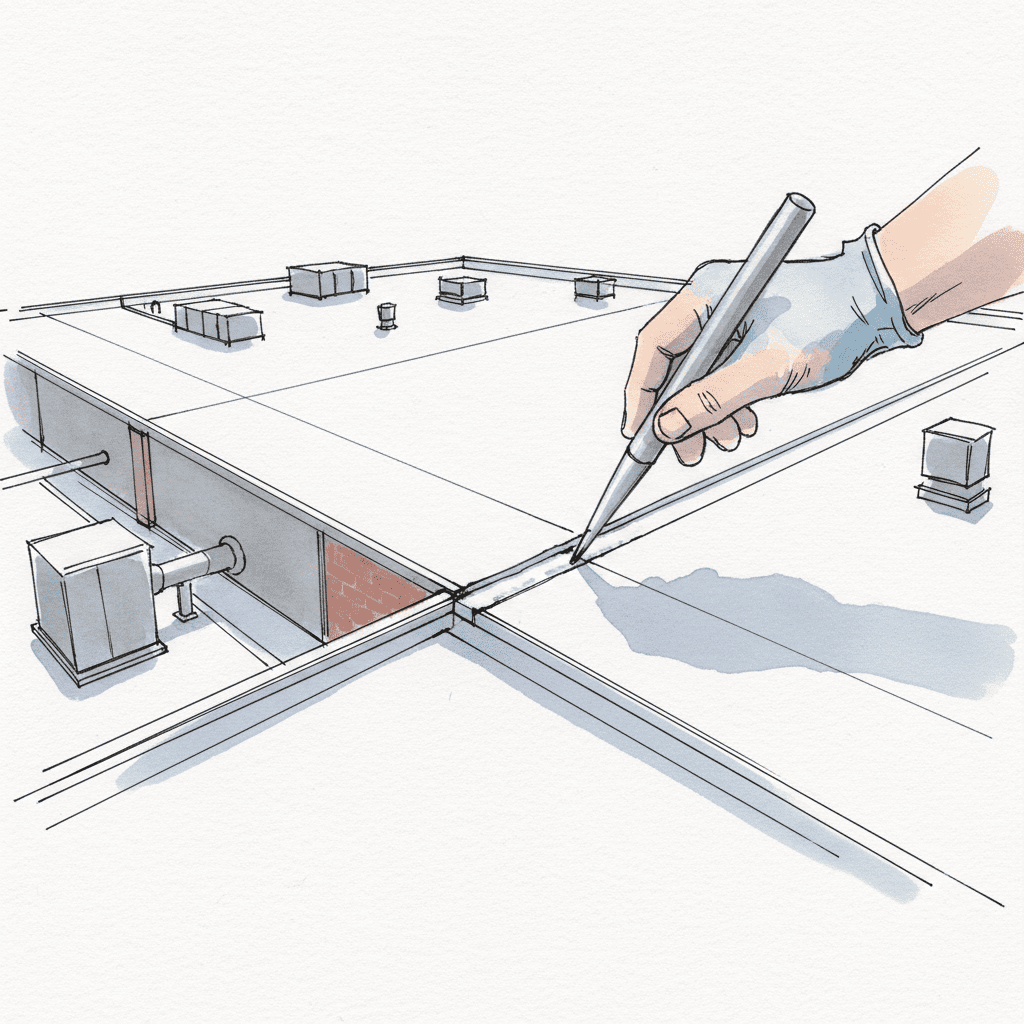

Standard Operating Procedure: Manual Seam Probing and Visual Inspection

The baseline for any effective roof asset management program is a disciplined, annual inspection that includes manual seam probing. Using a specialized tool, a trained technician methodically checks the entire length of every weld for imperfections. This tactile process identifies voids, ‘fishmouths’ (openings), wrinkles, and cold welds that are invisible to a casual observer. This is not merely a check-up; it is a data-gathering process that provides an accurate, real-time assessment of the system’s primary vulnerability. The findings form the basis for a preventative maintenance plan, allowing for targeted, low-cost repairs that avert widespread failure.

Advanced Diagnostics: Infrared (IR) Scans and Vector Mapping for Moisture Detection

When there is reason to suspect subsurface moisture, advanced diagnostic tools are required to quantify the scope of the problem. Infrared thermography allows us to identify areas of saturated insulation, which retain heat differently than dry areas. This non-destructive testing method provides a clear map of subsurface moisture without invasive core cutting. For a more precise analysis, electronic leak detection (ELD) or vector mapping can pinpoint the exact location of membrane breaches. This level of data is critical for capital planning. It allows an asset manager to make a financially sound decision between targeted repair and full replacement, preventing the costly error of installing a new roof over compromised, wet insulation.

| Remediation Strategy | Initial Cost | Long-Term Financial Impact | Fiduciary Recommendation |

|---|---|---|---|

| Short-Term Patching (Sealants) | Low (Operational Expense) | High. Creates recurring maintenance costs, masks compounding subsurface damage, and increases liability. Leads to premature replacement. | Not Advised. A financial fallacy that defers and amplifies a capital liability. |

| Comprehensive Seam Restoration | Medium (Capital Repair) | Low. Extends the service life of the entire asset, restores monolithic integrity, and provides budget predictability under a long-term warranty. | Advised. A capital preservation mandate that maximizes ROI on the existing roof system. |

Remediation Strategies: Comparing Low-Cost Patches vs. Systemic Restoration

When seam deficiencies are identified, the asset owner is faced with a critical decision that will significantly impact future budgets. The choice is between a low-cost, temporary ‘band-aid’ fix and a systemic repair designed to restore the asset’s long-term performance. From a fiduciary perspective, the correct path is the one that prioritizes capital preservation and budget certainty over short-term savings.

The Financial Fallacy of Short-Term Patching and Sealants

Applying sealants or patches to failing TPO seams is a common practice driven by a desire to minimize immediate costs. This approach is a financial fallacy. These temporary repairs treat a symptom, not the underlying cause of systemic weld failure. Sealants degrade quickly under UV exposure, turning a one-time problem into a recurring operational expense. More dangerously, these patches can trap moisture or mask the continued slow ingress of water into the insulation below, allowing unseen damage to compound. This strategy converts a manageable repair into an inevitable and far more expensive premature roof replacement, representing a profound failure of fiscal management.

Comprehensive Seam Restoration: A Capital Preservation Mandate

The correct, fiduciary-minded approach is a systemic restoration of all compromised seams. This involves thoroughly cleaning the membrane and utilizing robotic welders to re-weld every deficient seam according to manufacturer specifications. This capital repair addresses the root cause of the problem, restores the roof to a single, monolithic system, and halts the progress of any underlying damage. While the initial outlay is higher than a simple patch, this strategy provides a significant return on investment by extending the asset’s functional lifespan by many years. It converts an unpredictable liability into a managed asset with a predictable budget and, when executed correctly, can be covered by a new long-term warranty.

The RocStout Protocol: Engineering Fiscal Certainty in TPO Roof Management

RocStout Commercial operates as a fiduciary partner, not merely a contractor. We have engineered a protocol that replaces the industry’s standard of variable workmanship with a system of verifiable quality control and predictable outcomes. Our methodology is designed to protect your capital asset, eliminate operational disruption, and provide the fiscal certainty required for effective long-range planning.

Standardized Quality Control for TPO Weld Application and Verification

We view TPO seam welding as a manufacturing process that happens to occur on your roof. Our standard operating procedure mandates that all projects are staffed by manufacturer-certified installers. Before any work begins, we perform test welds to calibrate our robotic equipment to the site’s specific ambient conditions. During installation, we conduct routine field pull-tests to physically verify that weld strength exceeds manufacturer specifications. This entire process is documented in detailed compliance reports, providing you with auditable proof that your capital investment is being executed to the highest engineering standards.

Executing with Precision to Eliminate Operational Disruption

The true cost of any major construction project includes the impact on your daily operations. Our primary enemy is operational disruption. Every RocStout project is managed with a logistics and safety plan designed to be invisible to your tenants and employees. This includes a proactive tenant communication plan, predictable scheduling that we adhere to rigidly, and strict site logistics to manage debris and equipment. Our unwavering adherence to OSHA safety protocols is not just about compliance; it’s about protecting your employees, your customers, and your organization from liability. Our goal is zero downtime for your business.

Lifecycle Asset Management: From Installation to Multi-Year CapEx Planning

Our engagement does not end when the project is complete. We provide our partners with a comprehensive preventative maintenance program designed to maximize the service life of your new roofing asset. You receive detailed, line-item reporting after every inspection, providing the data needed for accurate budget forecasting. This ‘No Surprise’ billing and reporting system transforms your roof from a reactive problem into a managed asset with a predictable, multi-year CapEx plan. By partnering with RocStout, you are not just buying a roof; you are investing in a system of capital asset preservation and fiscal certainty.