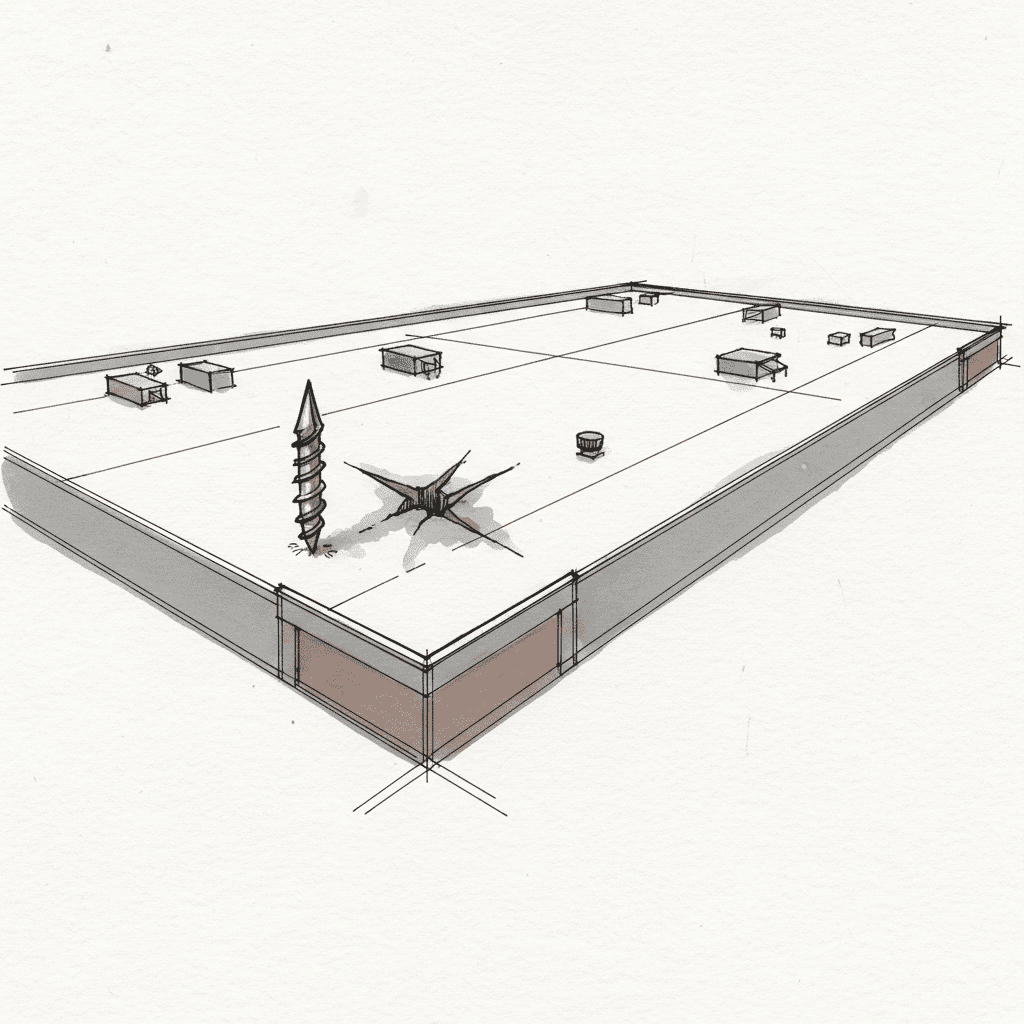

A puncture in a Thermoplastic Polyolefin (TPO) roofing system is not a minor maintenance issue; it is a financial liability that compromises your building’s structural integrity, thermal performance, and overall asset value. For the fiduciary asset manager, viewing this breach as anything less than a direct threat to capital preservation is a critical oversight. It initiates a sequence of degradation—from saturated insulation to corroded structural decking—that exponentially increases future capital expenditures and operational risks.

TPO Puncture Diagnostics: Assessing Financial Liability and Structural Compromise

A responsible capital plan requires precise data, not guesswork. Our diagnostic protocol is engineered to move beyond locating a leak and instead quantify the full financial scope of the damage. This forensic approach is the first line of defense against compounding liabilities and ensures every repair decision is based on a clear understanding of the asset’s condition.

Identifying the Puncture Vector: From HVAC Traffic to Weather-Related Debris

Determining the puncture source—whether from dropped fasteners during HVAC servicing, unauthorized foot traffic, membrane abrasion from storm debris, or simple material fatigue—is critical for liability assessment and preventative strategy. Identifying the vector allows you to address root causes, potentially holding service vendors accountable and implementing protocols to mitigate future occurrences. This is not about placing blame; it’s about controlling variables that impact your asset’s lifecycle and operational budget.

Sub-Surface Moisture Analysis: Quantifying Insulation Saturation and R-Value Degradation

Once moisture breaches the TPO membrane, it saturates the polyisocyanurate insulation, rendering it thermally useless. This is a direct attack on your operational expenses. Saturated insulation no longer provides its specified thermal resistance (R-value), leading to significant energy loss as your HVAC systems work harder to maintain climate control. We utilize non-destructive infrared thermography to map moisture saturation across the entire roof field, supplemented by targeted core sampling for absolute verification. This data provides a clear picture of energy waste and the potential for widespread substrate damage.

Structural Deck Inspection: Evaluating the Risk of Corrosion and Load-Bearing Failure

The final and most critical stage of degradation is damage to the structural deck. Persistent moisture trapped beneath the membrane will aggressively corrode a steel deck or cause spalling in concrete. This corrosion compromises the deck’s load capacity and weakens the bond of roofing fasteners, leading to a risk of fastener pull-out during a high-wind event. A compromised roof substrate is a precursor to catastrophic failure, turning a manageable repair into an emergency replacement and a significant, unplanned capital expenditure.

TPO Puncture Repair Protocols: Engineering a Permanent Watertight Seal

Executing a repair that merely stops a leak for the current fiscal quarter is a financial disservice. The industry standard often involves improper patches that fail within months, inviting litigation and exacerbating the original problem. Our repair methodology is based on ASTM standards and manufacturer specifications, designed not as a patch, but as a permanent, monolithic restoration of the membrane’s integrity.

Surface Preparation and Membrane Cleaning: A Prerequisite for Weld Adhesion

A successful hot-air weld is impossible on a contaminated surface. Dirt, oils, and environmental pollutants interfere with the thermoplastic fusion process, leading to adhesion failure and a compromised seam. Our standard operating procedure mandates a rigorous, multi-step cleaning process using manufacturer-specified TPO cleaner. This ensures the membrane is chemically prepared to accept a permanent, molecular bond, guaranteeing the long-term integrity of the repair.

Material Compatibility Verification: Selecting OEM-Specified Patches and Sealants

Using incompatible materials is a common shortcut taken by low-bid contractors and a primary cause of repair failure and warranty invalidation. We verify the exact TPO formulation of your existing roof to select the correct, OEM-specified non-reinforced membrane for the patch. All components, from the patch material to the edge sealant, are matched to manufacturer specifications to ensure chemical compatibility and maintain full compliance with your existing system warranty.

Hot-Air Welding vs. Adhesives: A Comparative ROI and Longevity Analysis

While solvent-based adhesives may seem like a quick fix, they are a poor long-term investment. Thermoplastic welding with a professional-grade Leister heat gun creates a molecular bond as strong as the original membrane itself. This method offers superior tensile strength and longevity, providing a far greater return on investment by eliminating the need for future repairs at the same location. The choice is between a temporary seal and a permanent, engineered solution.

| Metric | Hot-Air Welding (Engineered Standard) | Solvent-Based Adhesives (Substandard Fix) |

|---|---|---|

| Seam Integrity | Creates a permanent, monolithic bond with tensile strength equal to the original membrane. | Surface-level bond that degrades under UV exposure and thermal cycling, leading to premature failure. |

| Long-Term ROI | High. A permanent solution that eliminates repeat service calls and protects the asset’s lifecycle. | Negative. Leads to compounding damage and requires frequent, recurring repairs, increasing total cost of ownership. |

| Warranty Compliance | Maintains manufacturer warranty when performed by a certified contractor. | Often voids the manufacturer warranty, shifting all future liability to the building owner. |

| Chemical Resistance | Impervious to most chemical exposures, same as the parent TPO sheet. | Susceptible to breakdown from oils, greases, and common rooftop chemical contaminants. |

Post-Repair Integrity Testing: Infrared and Electric Field Vector Mapping for QA

A repair is not complete until it is verified. Our quality assurance protocol includes meticulous seam probing of every linear inch of the weld. For critical facilities, we deploy non-destructive testing methods like post-repair infrared scans or Electric Field Vector Mapping (EFVM), also known as holiday testing. This provides absolute, data-backed certainty that the repair is 100% watertight and the breach has been permanently resolved.

The Financial Ramifications of Substandard TPO Puncture Repair

Choosing the lowest bid for a commercial roof repair is a decision to accept unmanaged risk. It is a direct contradiction of fiduciary responsibility. A substandard patch is not a solution; it is the beginning of a much larger, more expensive problem that threatens your budget, your tenants, and your asset’s structural health.

Manufacturer Warranty Invalidation: A Costly Consequence of Non-Certified Repairs

An unauthorized repair performed by a non-certified contractor using improper methods instantly invalidates your manufacturer’s material and workmanship warranty. This action transfers the entire financial liability for the roofing system—an asset valued in the hundreds of thousands or millions of dollars—onto your balance sheet. A single misguided attempt to save a few hundred dollars on a patch can forfeit decades of warranty protection.

Compounding Damage: How Improper Patches Lead to Premature Roof Replacement

A failed patch acts as a funnel, directing water into the roofing system and accelerating the degradation process. This progressive water damage saturates insulation far beyond the original puncture point and allows corrosion to spread unchecked across the structural deck. This deferred maintenance guarantees a premature, full roof replacement, forcing a massive, unplanned capital expenditure years ahead of schedule and destroying the asset’s projected lifecycle.

Operational Disruption: Quantifying the Cost of Tenant and Inventory Impacts

The true cost of a recurring leak is measured in operational disruption. For a facility manager, this means dealing with tenant complaints, damaged inventory, slip-and-fall liabilities, and potential business interruption. These internal damages carry a cost that far exceeds the price of an engineered repair. Maintaining operational continuity is paramount, and a reliable roof assembly is the foundation of that stability.

The RocStout Standard Operating Procedure: From Puncture to Permanent Resolution

We operate as fiduciary partners, not contractors. Our process is engineered to deliver fiscal certainty and eliminate operational disruption. Every step is documented, transparent, and designed to protect the value of your capital asset. This is not just roofing; it is a rigid, process-driven methodology for infrastructure management.