Rooftop Equipment Curbs: A Critical Point of Failure in Commercial Roof Systems

Rooftop equipment supports, specifically engineered roof curbs, are foundational components of a commercial building’s waterproofing system, designed to integrate HVAC units, exhaust fans, and other penetrations without compromising the building envelope. As a fiduciary advisor responsible for capital asset preservation, you must view these elements not as simple fixtures, but as critical points of financial risk. An improperly installed or failing curb is a direct conduit for water intrusion, leading to catastrophic inventory damage, operational downtime, and tenant disruption. The lowest bid on curb installation is not a cost-saving measure; it is an accepted liability that invites predictable failure and future capital expenditure.

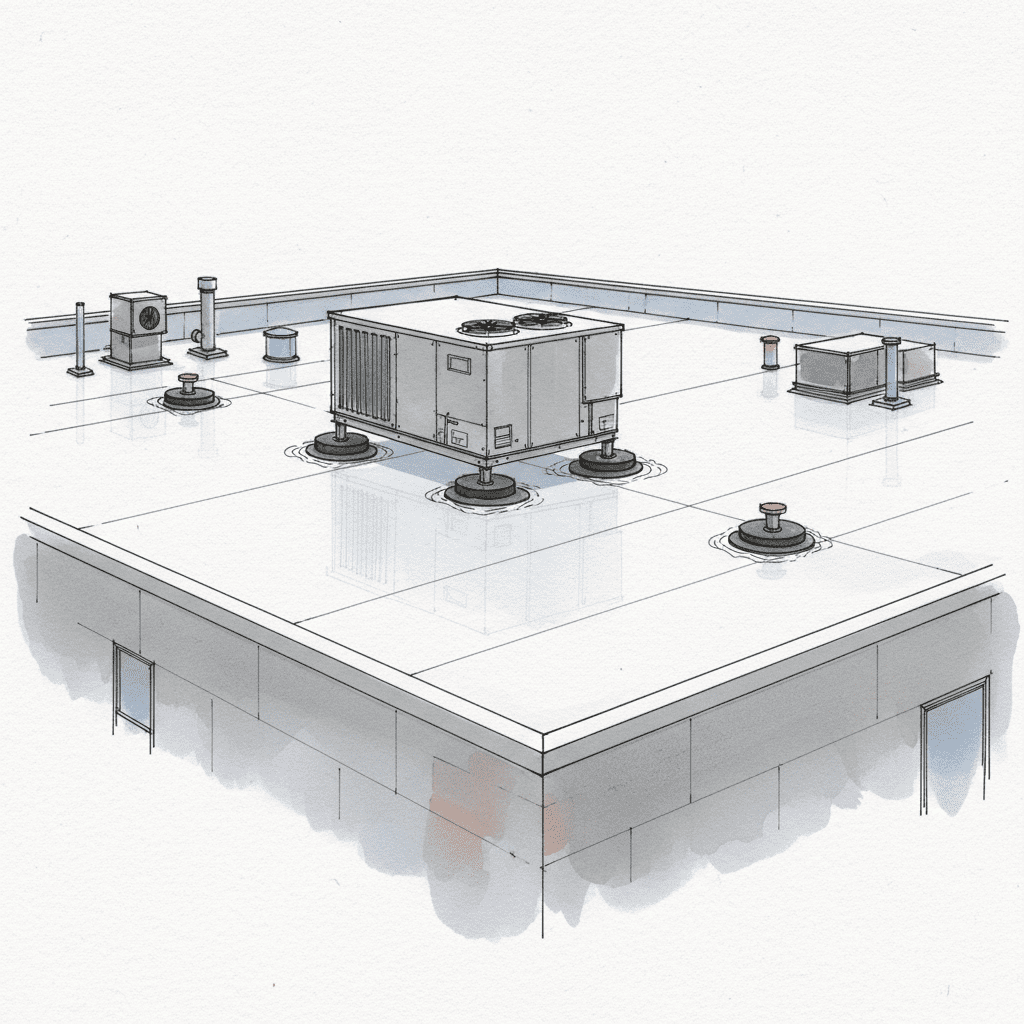

Defining the Roof Curb and its Function in Asset Protection

A roof curb is a raised metal or wood frame that elevates rooftop equipment above the surface of the roof membrane. This elevation is a fundamental engineering requirement for proper water drainage and flashing integration. Its primary function is to provide a stable, waterproofed structural mount that isolates the roof penetration from the primary roof field, thus protecting the building envelope. For the asset manager, a properly engineered HVAC curb is a non-negotiable component of risk mitigation. It is the demarcation line between a secure, dry interior and the direct financial consequences of water damage, including structural degradation of the roof deck and interior building components.

Anatomy of a Curb Flashing System: Key Components and Materials

A curb flashing system is an engineered assembly, and its integrity is dependent on the correct specification and installation of every component. Any deviation from manufacturer specifications or industry best practices invalidates warranties and guarantees premature failure. The core components include:

- Structural Curb: The foundational frame, typically constructed of pressure-treated wood (the wood nailer) or heavy-gauge galvanized steel, which provides structural support for the rooftop unit.

- Insulation: High-density polyisocyanurate or other rigid insulation is often integrated into the curb walls to maintain the thermal barrier of the building envelope.

- Membrane Flashing: The waterproofing layer, such as TPO, EPDM, or modified bitumen, that is meticulously wrapped up the vertical walls of the curb and heat-welded or adhered to the roof field membrane. This continuous, monolithic seal is the primary defense against water intrusion.

- Counter-Flashing: A secondary metal flashing installed over the primary membrane flashing. It serves as a protective shield against mechanical damage, UV degradation, and water ingress at the termination point, directing water down and away from the seam.

- Fasteners and Sealants: All components must be secured with corrosion-resistant, manufacturer-specified fasteners. High-grade sealants are used exclusively at termination bars and penetrations as a final line of defense, not as a primary waterproofing method.

Quantifying the Financial Impact of Curb Flashing Failure

The failure of a single roof curb flashing system can trigger a cascade of financial liabilities that far exceed the initial cost of a compliant installation. As a fiduciary, your risk analysis must account for both direct and indirect costs:

- Direct Costs: These include emergency repair services, replacement of saturated insulation and damaged roofing materials, and the costs associated with interior remediation, such as drywall, ceiling tile, and flooring replacement.

- Inventory and Asset Damage: For facilities in manufacturing, logistics, or data management, water intrusion can result in millions of dollars of damaged inventory, unsalvageable raw materials, or irreparable harm to sensitive electronic equipment.

- Operational Downtime: The most significant cost is often business interruption. A leak can shut down production lines, displace tenants, or render retail space unusable, resulting in lost revenue and broken service-level agreements.

- Increased Liability and Insurance Premiums: A documented history of roof leaks due to deferred maintenance or improper installation can lead to increased insurance premiums or, in severe cases, denial of coverage for related damages. It also introduces significant legal liability in tenant disputes.

Engineering Analysis of Common Curb Flashing Failure Modes

From a forensic engineering perspective, curb flashing failures are rarely sudden events. They are the predictable outcomes of specific installation errors, material incompatibilities, or the absence of proactive maintenance. Understanding these failure modes is critical to developing a capital plan that prioritizes asset preservation over reactive, high-cost repairs.

Membrane Seam and Weld Integrity: The Primary Vector for Water Ingress

For thermoplastic systems like TPO, the integrity of the heat-welded seams at the curb’s corners and base is paramount. Improper welding technique—incorrect temperature, speed, or pressure—results in a weak bond that will inevitably separate under thermal stress. These ‘cold welds’ are the most common point of failure and a clear indicator of a non-certified installer. Similarly, for EPDM systems, adhesive failure at seams or reliance on caulking in place of proper flashing techniques creates a guaranteed entry point for moisture.

Structural Deficiencies: Wood Nailer Rot and Mechanical Fastener Corrosion

The internal wood nailer provides the structural anchor point for the membrane and metal flashing. If this wood is not properly treated or becomes saturated due to a breach in the membrane, it will rot. Wood rot compromises the load-bearing capacity of the curb and causes fasteners to back out, creating new penetrations and pathways for water. Likewise, the use of non-galvanized or incorrect fasteners leads to corrosion, which weakens the entire assembly and stains the roof membrane, indicating an underlying moisture issue.

Improper Sealant Application at Terminations and Penetrations

Sealant is not a substitute for proper flashing. In a correctly engineered system, sealant is a final detail, not the primary waterproofing component. Contractors who rely on excessive caulking to seal corners or terminations are creating a short-term fix with a guaranteed long-term failure point. Sealants degrade under UV exposure, lose adhesion over time, and require frequent maintenance. A system reliant on sealant is a system designed to fail.

Thermal Expansion and Contraction: Assessing Material Stress and Fatigue

Every material on a rooftop expands and contracts with temperature fluctuations. A professionally engineered system accounts for this thermal stress by using compatible materials and ensuring the membrane is not under tension. When a flashing detail is installed too tightly (‘bridged’) at the transition from the horizontal roof plane to the vertical curb wall, the constant movement will cause fatigue cracking and membrane splitting, leading to a system failure that a simple patch cannot resolve.

Ensuring Code Compliance and Adherence to Manufacturing Specifications

Adherence to building codes and manufacturer specifications is not optional; it is the foundation of fiscal certainty in commercial roofing. Choosing a contractor who disregards these standards is a direct decision to accept unmanaged risk and void any potential for long-term asset protection through warranties.

Navigating IBC Standards for Minimum Curb Height and Clearances

The International Building Code (IBC) mandates minimum curb heights (typically 8 inches above the finished roof surface) to prevent water from breaching the flashing during heavy rain or snow accumulation. This is not an arbitrary number; it is an engineering standard designed to ensure proper drainage and protect the penetration. A contractor who installs a shorter curb to save on material cost is introducing a code violation and a permanent design flaw into your building envelope, making your asset non-compliant and vulnerable.

Manufacturer Warranty Invalidation: The High Cost of Non-Compliant Installation

A manufacturer’s No-Dollar-Limit (NDL) warranty is a powerful financial tool that protects your capital investment. However, this warranty is contingent upon installation by a certified applicator in strict accordance with published specifications. Any deviation—from using non-approved fasteners to improper welding techniques—voids the warranty instantly. The ‘savings’ from a low-bid, non-compliant installation are insignificant compared to the multi-million dollar liability you assume when that system fails without a warranty to back it.

| Financial Metric | Compliant Installation (RocStout Standard) | Non-Compliant ‘Low Bid’ Installation |

|---|---|---|

| Manufacturer Warranty | Valid NDL Warranty (15-30 Years) | Immediately Voided |

| Asset Lifespan | 20+ Years with Proactive Maintenance | 5-7 Years before Major Failures |

| Liability Exposure | Mitigated by Warranty and Compliant System | Owner Assumes 100% of Risk |

| Total Cost of Ownership | Predictable; Limited to Planned Maintenance | High; Driven by Unplanned Emergency Repairs |

OSHA Regulations and Rooftop Safety Protocols During Installation

The enemy of your timeline and budget is operational disruption caused by an unsafe contractor. Strict adherence to OSHA regulations for fall protection, material handling, and site security is a non-negotiable component of our standard operating procedure. A contractor who disregards safety is not only a danger to their crew but a direct liability to you as the property owner. An OSHA shutdown or a worksite accident creates significant project delays, legal exposure, and a complete loss of control over your capital project timeline.

Proactive Maintenance and Lifecycle Planning for Curb Flashing Systems

A commercial roof is a depreciating asset that requires active management. We reject the industry’s reactive repair model in favor of proactive asset preservation. This approach transforms roofing expenditures from unpredictable emergencies into planned, budgeted items within your capital plan.

Implementing a Standardized Inspection Protocol for Early Defect Detection

Our standard is to conduct semi-annual inspections of all roof penetrations, including curb flashing systems. Using a detailed checklist and technologies like infrared thermography, we identify early signs of failure such as sealant deterioration, fastener back-out, or seam deficiencies. This data is logged and tracked, allowing for minor preventative repairs that eliminate the risk of major system failure and provide the data needed for long-term financial planning.

Integrating Curb Maintenance into Your Capital Expenditure (CapEx) Plan

The data from our inspections provides the fiscal certainty required for effective CapEx planning. Instead of reacting to a sudden, costly leak, we provide a multi-year forecast detailing the expected lifecycle of your curb systems and a corresponding budget for their maintenance or eventual replacement. This transforms your roof from a source of financial anxiety into a managed asset with a predictable total cost of ownership.

Retrofit vs. Replacement: A Cost-Benefit Analysis for Aging Systems

When a curb system is nearing the end of its functional life, we provide a detailed cost-benefit analysis comparing a retrofit against a full replacement. A retrofit may offer a lower initial cost, but a full replacement provides a new, long-term warranty and eliminates underlying issues like saturated insulation or rotted wood nailers. Our recommendation is always based on maximizing long-term ROI and minimizing your future liability, providing the clear financial data you need to make the most prudent capital decision.

The RocStout Methodology: Engineering Fiscal Certainty into Rooftop Penetrations

We operate as fiduciary partners, not contractors. Our entire methodology is built to eliminate the operational and financial risks that building owners and facility managers associate with commercial roofing. We do not compete on price; we compete on fiscal certainty and operational continuity.

Our Standard Operating Procedure (SOP) for Curb Flashing Installation & Remediation

Our process is rigid, documented, and engineered to deliver a predictable outcome. Every curb flashing project follows a strict SOP that guarantees compliance, quality, and long-term performance, turning a common failure point into a reliable component of your building asset.

Minimizing Operational Disruption: A Phased Approach to Live Environments

We understand that time is money. Our project management team is dedicated to a ‘zero disruption’ policy. This is achieved through meticulous pre-construction planning, clear tenant communication protocols, and strict schedule adherence. We establish clean and secure work zones, manage all logistics to avoid interference with your daily operations, and adhere to a ‘water-tight-by-nightfall’ protocol. Our job is to protect your asset and your revenue stream, not to disrupt it.

Line-Item Reporting and Lifecycle Forecasting for Predictable Asset Management

Our commitment to fiscal certainty is absolute. You will receive detailed, line-item reporting throughout the project, ensuring complete transparency and ‘No Surprise’ billing. Upon completion, we provide lifecycle forecasting data that integrates directly into your asset management software or financial planning tools. With RocStout, you are not just purchasing a roof repair; you are investing in a predictable, managed capital asset.