Commercial roofing warranties are not commodities; they are distinct financial instruments designed to protect a capital asset, and confusing their functions is a direct route to unbudgeted expenses and operational liability. A Material Warranty is a manufacturer’s promise regarding the physical integrity of their product, while a Workmanship Warranty is the contractor’s guarantee that the system was installed according to precise engineering standards. For the fiduciary responsible for asset preservation, understanding this division of liability is the first step in converting a roof from a reactive cost center into a predictable, managed asset.

Differentiating Warranty Instruments for Commercial Roofing Assets

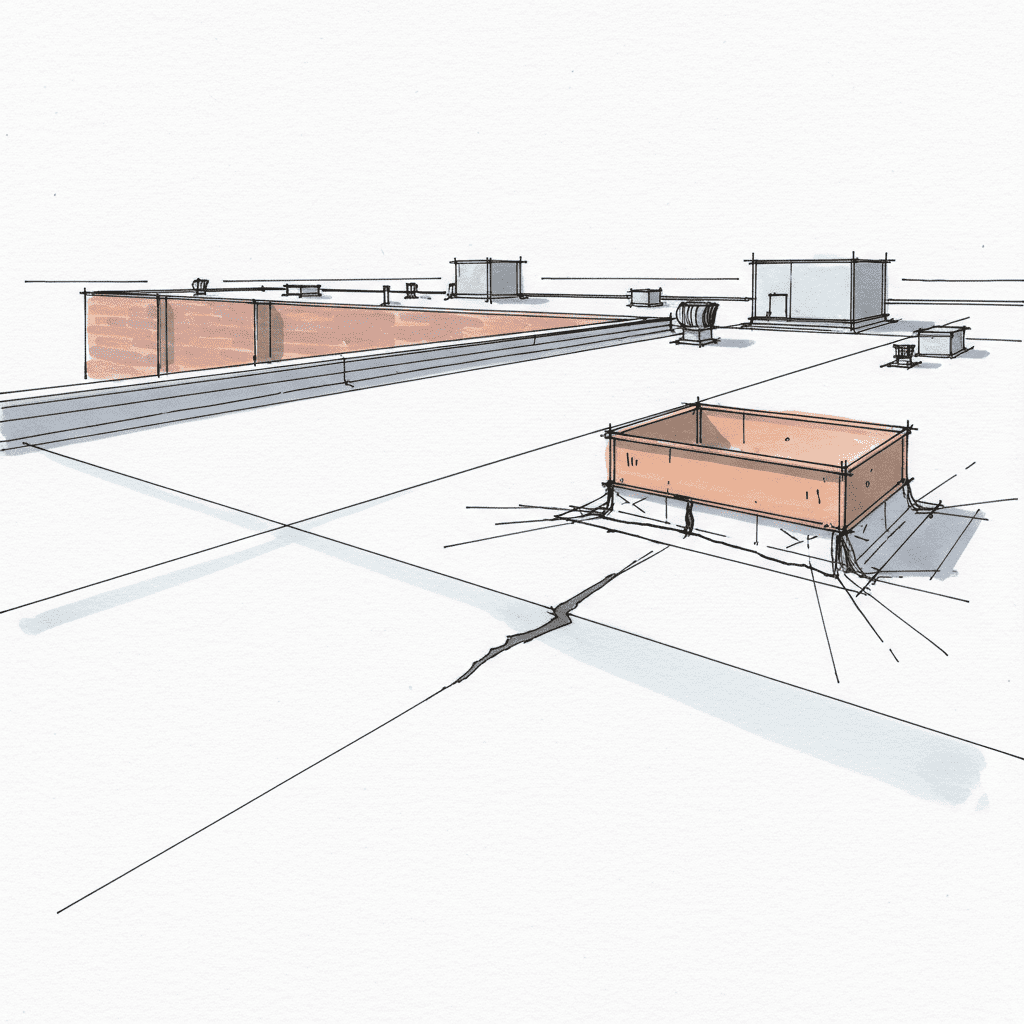

The successful performance of a commercial roof system depends on two distinct factors: the quality of the manufactured materials and the precision of the installation. Consequently, the warranty protecting this system is bifurcated. Misunderstanding where one policy ends and the other begins creates significant financial exposure. Your primary risk is not a material defect; it is the installation error that voids the material warranty, leaving your asset completely exposed.

Defining the Manufacturer’s Material Warranty Scope

A manufacturer’s material warranty covers defects in the roofing products themselves. This includes issues such as premature degradation of the membrane, manufacturing flaws in the insulation, or failure of factory-seamed components. This warranty certifies that the product, when it left the factory, met its specified performance criteria. However, it is fundamentally contingent on the product being installed exactly as the manufacturer dictates. It offers no protection against leaks caused by contractor error, which statistically account for the overwhelming majority of roof failures.

Defining the Contractor’s Workmanship Warranty Scope

The contractor’s workmanship warranty is your primary shield against leaks and operational disruption. This guarantee covers the quality of the labor and the integrity of the installation process. It addresses critical failure points such as improper seam welding, incorrect fastener patterns, faulty flashing details around penetrations, and poor adhesion. A reputable workmanship warranty is an explicit statement of liability from the installer, confirming their responsibility for the watertight integrity of the final assembly. It is the most critical performance guarantee for any facility manager or property owner.

The Critical Interdependence: Why One Warranty is Ineffective Without the Other

A material warranty is rendered useless if the contractor’s poor workmanship leads to a failure. The manufacturer will rightly deny the claim, citing installation that deviates from their required specifications. Conversely, even a perfect installation is compromised if the materials themselves are defective. The two warranties form an interlocking system of accountability. Selecting a contractor who lacks top-tier manufacturer certification is a direct financial risk; it severs this essential link and creates a liability gap that the asset owner will inevitably be forced to fill. This is a common but entirely avoidable error in capital planning.

| Attribute | Manufacturer’s Material Warranty | Contractor’s Workmanship Warranty |

|---|---|---|

| Issuer | The product manufacturer (e.g., GAF, Carlisle, Firestone) | The installing roofing contractor (e.g., RocStout) |

| Scope of Coverage | Covers product defects, premature UV degradation, blistering, and material failure. | Covers installation errors, seam failures, flashing leaks, and wind uplift due to improper fastening. |

| Primary Purpose | To guarantee the chemical and physical integrity of the roofing components. | To guarantee the watertight performance of the assembled roof system and prevent operational disruption. |

| Common Voids | Improper installation, unauthorized alterations, ponding water, lack of maintenance. | Negligence, third-party damage, failure to report issues in a timely manner as per the agreement. |

Manufacturer’s Material Warranty: A Critical Analysis of Coverage and Exclusions

The manufacturer’s warranty document is often viewed as the primary safety net for a roofing investment. However, for a fiduciary, it must be analyzed as a conditional legal document with specific exclusions that carry financial weight. Understanding these limitations is fundamental to effective risk management.

Scope of Coverage: Material Defect & Premature System Degradation

The core coverage of a material warranty addresses the performance of the specified products—typically membranes like TPO, EPDM, or PVC. The manufacturer guarantees that these materials will not fail due to a flaw in their production. This includes protection against issues like premature cracking from UV exposure or chemical breakdown under normal conditions. This is the extent of their liability; they are warranting the product, not the system’s overall performance.

Common Exclusions: Installation Deviations, Ponding Water, and Unauthorized Alterations

The exclusions section of a material warranty is where significant financial risk resides. Manufacturers will void coverage for failures caused by:

- Improper Installation: Any deviation from the manufacturer’s published engineering specifications—from the wrong fastener type to incorrect seam-welding temperatures—will nullify the warranty.

- Ponding Water: Most warranties exclude damage caused by water that stands on the roof for more than 48 hours. This places the onus for ensuring proper drainage squarely on the contractor and building owner.

- Unauthorized Repairs or Penetrations: Adding a new HVAC curb or allowing an uncertified contractor to perform a patch can void the entire warranty.

- Force Majeure: Damage from events like hurricanes, hail exceeding certain size thresholds, or other “Acts of God” is not covered.

Financial Impact of Prorated vs. Non-Prorated (NDL) Warranties on CapEx Planning

The financial structure of the warranty directly impacts long-term capital planning. A prorated warranty decreases in value over time. A failure in year 15 of a 20-year prorated warranty may only cover a small fraction of the replacement cost, creating a sudden, unbudgeted CapEx event. In contrast, a No Dollar Limit (NDL) warranty is the industry standard for fiduciaries. An NDL warranty commits the manufacturer to covering the full cost of repair or replacement to restore the roof to a watertight condition for the entire warranty period, without depreciation. This provides the fiscal certainty required for accurate lifecycle cost analysis and long-range capital asset planning.

The Contractor Workmanship Warranty: Your Primary Defense Against Operational Disruption

While the material warranty protects against product failure, the workmanship warranty protects against business failure. Water infiltration from installation errors is the direct cause of damaged inventory, tenant disputes, safety hazards, and operational shutdown. The lowest bid often comes with a worthless workmanship warranty, transferring the cost of that disruption directly to you.

Scope of Coverage: Installation Errors, Flashing Failures, and Seam Integrity

A robust workmanship warranty from a fiduciary partner like RocStout explicitly covers the most common points of failure. This includes ensuring the absolute integrity of all seams, whether welded or adhered, and guaranteeing the complex flashing details around pipes, vents, walls, and curbs are permanently watertight. It further covers proper fastener patterns to meet specified wind uplift ratings, preventing catastrophic failure during severe weather events. This is not just a promise to fix leaks; it is a guarantee of operational continuity.

Contractor Certification Levels: The Financial Risk of Uncertified Installers

Manufacturers offer tiered certification levels to contractors based on training, financial stability, and a proven track record of quality installations. An uncertified or low-level certified installer cannot offer the most comprehensive NDL material warranties. Choosing such a contractor to save on initial outlay is a critical error. It restricts your access to the best protection and signals a higher probability of installation errors that will lead to future costs far exceeding any initial savings. RocStout maintains elite-level certifications with major manufacturers, a non-negotiable standard for protecting our clients’ assets.

Response Time and Remediation Protocols: Quantifying the Cost of Downtime

A warranty’s value is also measured in response time. A leak during a critical production run or in a fully leased commercial space accrues costs by the minute. Our workmanship warranty is backed by a strict Service Level Agreement (SLA) that defines emergency response protocols. This isn’t a vague promise to “get back to you.” It is a documented process for leak detection, temporary remediation to ensure the building is water-tight-by-nightfall, and permanent repair scheduling that minimizes tenant or operational disruption. This is a core component of risk management.

Warranty Voidance: A Forensic Review of Common Points of Failure

A warranty is not an unconditional guarantee; it is a contract that requires adherence to specific protocols. Failure to comply, often due to contractor negligence, is a primary source of financial loss for building owners. As your fiduciary advisor, our process is engineered to eliminate these points of failure.

Improper Substrate Preparation and Its Cascade Effect on System Performance

A roofing system is only as strong as its foundation. A contractor who fails to conduct a thorough moisture survey of the existing substrate, or who installs new insulation over a contaminated or unsound roof deck, is guaranteeing future failure. Entrapped moisture will cause insulation to lose its R-value, fasteners to corrode, and adhesives to fail. This cascade effect will lead to system failure that will be correctly identified by the manufacturer as an installation error, voiding all material coverage.

Deviations from Manufacturer Engineering Specifications: A Liability Multiplier

Every manufacturer publishes extensive technical manuals detailing the exact requirements for system installation. These are not suggestions; they are engineering mandates. Using the wrong number of fasteners per board, failing to prime surfaces correctly, or using incompatible materials are all common shortcuts taken by low-bid contractors. These deviations create a massive liability for the building owner, as they immediately invalidate the manufacturer’s warranty and make the contractor the sole guarantor—a contractor who has already demonstrated a disregard for industry standards.

Negligent Maintenance Protocols and the Forfeiture of Coverage

Both material and workmanship warranties require the building owner to perform routine preventive maintenance. Failure to do so is considered negligence and can be grounds for voiding coverage. This includes regular inspections, removal of debris from drains and scuppers, and prompt reporting of any damage. A contractor focused on short-term transactions will not mention this. A fiduciary partner, however, integrates a proactive maintenance plan as a standard operating procedure to preserve your warranty and maximize the asset’s lifecycle.

RocStout’s Integrated Warranty Management: A Framework for Fiscal Certainty

RocStout operates on a simple principle: we deliver fiscal certainty. We reject the transactional model of the roofing industry in favor of a long-term partnership in asset management. Our process is engineered to not only provide a high-performance roof but also to ensure the absolute integrity of your warranty protection from day one through the end of its service life.