The Financial Rationale for Designated Roof Walkway Systems

A designated roof walkway pad system is a capital improvement engineered to protect a commercial roof membrane from mechanical damage, thereby preserving the asset’s warranty, reducing unscheduled repair liabilities, and ensuring safe, compliant access for authorized personnel. It transforms undefined roof surfaces into managed infrastructure, directly supporting the fiduciary responsibility of maintaining asset value and ensuring business continuity. For facility managers and CFOs, this is not a building accessory; it is a fundamental component of a comprehensive risk management strategy for your property’s primary weatherproofing asset. Choosing to omit this system is a direct acceptance of financial risk, positioning the lowest bid as a future liability rather than a present-day saving.

Mitigating Premature Membrane Degradation from Uncontrolled Foot Traffic

Your commercial roof is a financial asset with a defined service life. Uncontrolled foot traffic directly accelerates the depreciation of this asset. Every step taken by HVAC technicians, maintenance staff, or third-party vendors on an unprotected membrane introduces the risk of abrasion, punctures, and granular loss. This mechanical damage is not hypothetical; it is an inevitability that systematically undermines the roof’s waterproofing integrity. Scuffs from boots, dropped tools, and the grinding of small debris into the membrane surface create micro-abrasions that, under UV exposure and thermal cycling, become points of failure. A designated walkway system channels all foot traffic onto a sacrificial, high-durability surface, effectively isolating the primary roof membrane from this guaranteed wear and tear. This is not a repair strategy; it is a capital preservation strategy designed to maximize the asset’s functional lifespan and delay a multi-million-dollar replacement expenditure.

Quantifying the Cost of Punctures: From Water Ingress to Operational Downtime

The true cost of a roof puncture is never the price of the patch. That figure is trivial. The significant financial impact stems from the consequential damages of water ingress. A single, undiscovered puncture can introduce moisture into the insulation and roofing substrate, leading to saturated materials, reduced thermal performance, and the potential for structural deck corrosion. For the C-suite and facility manager, this translates into a cascade of unbudgeted liabilities: damaged inventory, ruined ceiling tiles, compromised electrical systems, and the development of mold. The ultimate cost is operational downtime and tenant disruption—the two most corrosive forces to a commercial property’s profitability. A walkway system is an investment in business continuity. By preventing the initial puncture, you eliminate the entire risk chain of subsequent damages and safeguard the operational capacity of the facility.

Preserving Manufacturer’s Warranty and Ensuring System Compliance

A manufacturer’s No-Dollar-Limit (NDL) warranty is one of the most valuable documents associated with your roof asset. However, it is a conditional agreement, not an unconditional guarantee. Most leading manufacturers explicitly stipulate that damage resulting from excessive or uncontrolled foot traffic is excluded from warranty coverage. A documented lack of protective walkways in high-traffic areas can be, and often is, used as grounds to deny a claim. Installing a professionally specified walkway system is a procedural safeguard that demonstrates fiduciary diligence. It preserves the integrity of your warranty, ensuring that this crucial financial backstop remains in full force. This action shifts the burden of proof, confirming that you have taken all necessary steps to protect the roofing system in accordance with industry best practices and manufacturer mandates, thereby securing your investment.

Engineering & Material Specifications for Walkway Pad Systems

The selection and specification of a walkway system are governed by engineering principles, not aesthetic preference. The material science, load distribution characteristics, and compatibility with the existing roof membrane are critical factors that determine the system’s effectiveness and long-term performance. A misapplication of materials or installation methods introduces new points of failure, negating the system’s intended purpose. RocStout’s methodology is to specify systems based on a forensic analysis of the existing roof, traffic patterns, and long-term performance requirements.

Material Composition Analysis: TPO, PVC, and Recycled Rubber Composites

The material composition of a walkway pad dictates its durability, UV resistance, and compatibility with the roof membrane. Each primary material type offers a distinct performance profile aligned with specific roofing systems. The choice is a technical decision, not a commodity selection. An incorrect specification can lead to delamination, chemical incompatibility, or premature degradation, creating a liability where an asset was intended.

| Material Type | Primary Application | Key Financial Benefit | Installation Method |

|---|---|---|---|

| TPO (Thermoplastic Polyolefin) | TPO Roofing Systems | Creates a monolithic, welded system with identical material properties, eliminating seam and adhesion risk. | Heat-Welded |

| PVC (Polyvinyl Chloride) | PVC Roofing Systems | Superior chemical and grease resistance; ideal for roofs with exhaust fans from commercial kitchens or industrial processes. | Heat-Welded |

| Recycled Rubber Composites | EPDM, Modified Bitumen, & various systems | High impact resistance and versatility. Can be adhered to multiple membrane types when direct welding is not feasible. | Adhered |

Load Distribution and Slip-Resistance: OSHA Compliance and Personnel Safety

Walkway pads serve a dual purpose: protecting the roof and protecting personnel. Their engineered design distributes the concentrated load of footfalls and tool carts over a wider surface area, preventing pressure points that could damage the membrane or underlying insulation. Furthermore, their textured, non-slip surfaces are a critical component of a facility’s fall protection plan. OSHA regulations mandate that employers provide safe working surfaces. A properly installed walkway system helps meet this standard, reducing the risk of slip-and-fall incidents, which are a primary source of workplace injuries and subsequent liability claims. This transforms the walkway from a maintenance product into an integral part of your corporate safety and compliance framework.

System Compatibility: Heat-Welded vs. Adhered Application on TPO, EPDM, & Mod-Bit

The method of attachment is as critical as the material itself. For thermoplastic membranes like TPO and PVC, heat-welding is the superior method. It fuses the walkway pad directly to the roof membrane at a molecular level, creating a single, monolithic piece with no seams for water to penetrate. This eliminates the risk of adhesive failure over time due to weathering or chemical exposure. For thermoset membranes like EPDM or multi-ply systems like Modified Bitumen, a high-strength, chemically compatible bonding adhesive is required. Executing this requires stringent surface preparation and adherence to environmental conditions (temperature and humidity). Choosing the correct application method is a non-negotiable requirement for ensuring the long-term integrity of the entire roof asset.

Strategic Layout & Integration for High-Traffic Commercial Roofs

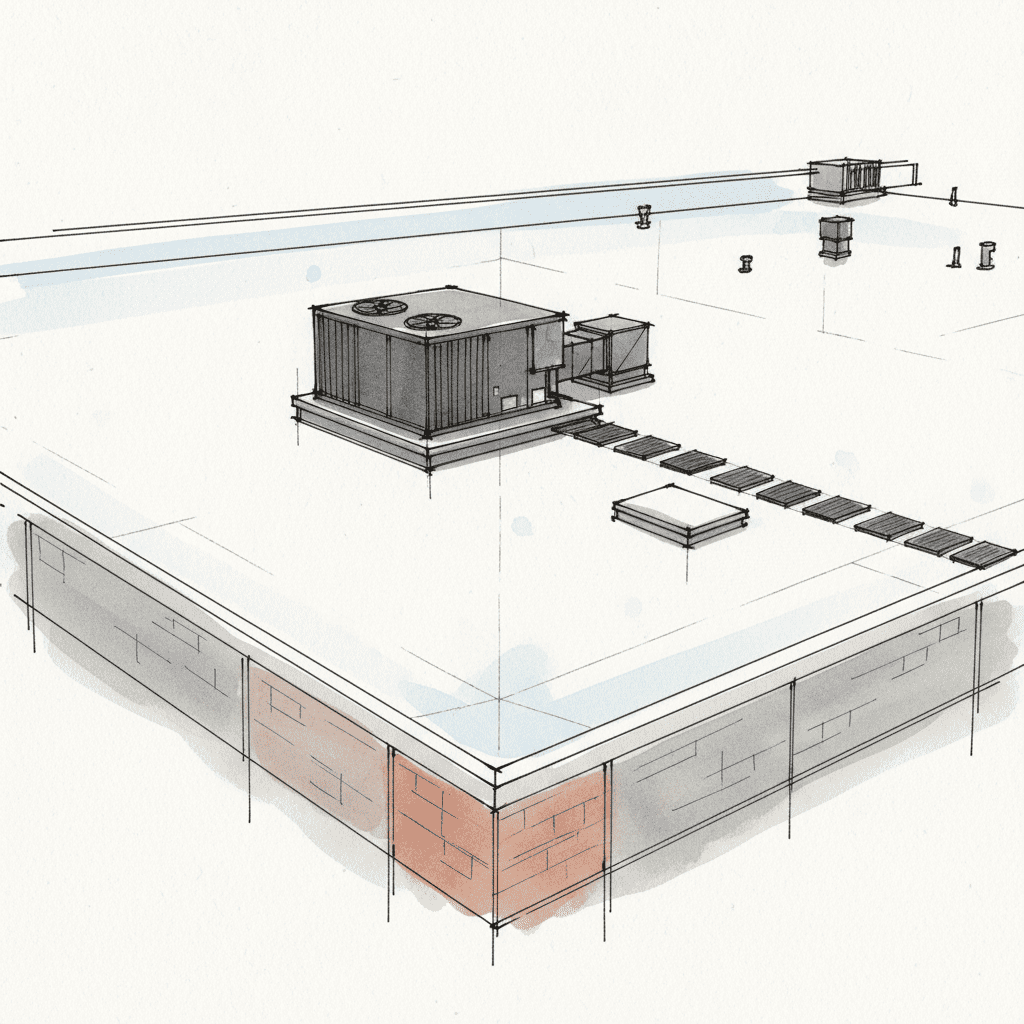

Effective walkway systems are not placed arbitrarily. Their layout is the result of a strategic analysis of rooftop operations. The goal is to create a clear, intuitive, and safe network of designated pathways that guide all traffic, from routine inspections to emergency repairs, thereby containing the impact of rooftop activity and protecting the vast majority of the roof surface.

Mapping High-Traffic Zones: HVAC Units, Drains, and Rooftop Access Points

Our process begins with a comprehensive analysis of rooftop traffic patterns. We identify all primary and secondary access points, such as roof hatches, ladders, and doorways. We then map the most direct and logical service routes to all rooftop equipment requiring periodic maintenance, including HVAC units, exhaust fans, communication arrays, and roof drains. By establishing clear, designated pathways between these points, we eliminate the random, meandering foot traffic that causes widespread membrane damage. This data-driven layout ensures that protection is allocated precisely where the risk is highest, maximizing the ROI of the installation.

Integration with Rooftop Safety Systems: Guardrails and Tie-Off Points

A walkway system is a component within a larger ecosystem of rooftop safety. Its layout must be integrated with existing or planned fall protection systems. Pathways should lead directly to guarded areas around the roof perimeter and provide clear access to certified fall arrest tie-off points. This holistic approach ensures that maintenance personnel are not only on a safe walking surface but are also within the compliant zones of the overall safety plan. This level of integrated planning demonstrates a commitment to safety that satisfies both OSHA requirements (under standard 1910) and corporate risk management protocols, significantly reducing liability exposure.

Walkway Installation Methods: Minimizing Disruption and Ensuring Membrane Integrity

The installation of any rooftop component carries inherent risks to the building’s watertight integrity. RocStout’s standard operating procedure is built around a zero-disruption, zero-defect principle. Our installation teams adhere to strict manufacturer specifications and our own rigorous quality assurance protocols. Every phase, from surface preparation to the final heat-weld or adhesive application, is executed to ensure a flawless bond without compromising the existing membrane. All projects operate under our ‘water-tight-by-nightfall’ guarantee, meaning your building’s interior is never exposed to the elements. This disciplined execution provides fiscal certainty that the solution will not create a new problem.

Lifecycle Cost Analysis: Walkway Pads as a Capital Asset Preservation Tool

Astute financial management of a facility requires a shift from evaluating upfront costs to analyzing long-term lifecycle value. A roof walkway system is a textbook example of a modest capital expenditure that generates substantial long-term savings by reducing the Total Cost of Ownership (TCO) of the primary roof asset. This aligns directly with the fiduciary duty to preserve and enhance the value of capital assets.

Calculating Total Cost of Ownership (TCO) vs. Initial Installation Expense

The initial expense of installing a walkway system is transparent and predictable. The alternative—leaving a roof unprotected—invites unpredictable and often escalating costs. A TCO model factoring in walkway pads would include the initial installation cost against a projected reduction in leak-related repair invoices, a lower probability of major water damage events, the preservation of the full warranty value, and an extended service life for the roof membrane, thereby deferring a major capital replacement project. When viewed through this financial lens, the ROI of a walkway system becomes immediately apparent. It is an investment in cost avoidance and budget stability.

Impact on Roof Inspection Frequency and Preventative Maintenance Schedules

Designated walkways improve the efficiency and effectiveness of preventative maintenance programs. They allow inspectors and technicians to navigate the roof safely and quickly, without causing inadvertent damage. This structured access allows for more consistent and accurate data collection during inspections, leading to better-informed maintenance decisions. By concentrating wear in predictable locations, it also simplifies the inspection process, allowing a technician to focus on the walkway’s condition as a leading indicator of overall rooftop activity. This operational efficiency translates to lower long-term maintenance labor costs and a more reliable predictive maintenance schedule, further reducing the overall TCO of the roof.

RocStout’s Standard Operating Procedure for Walkway System Integration

We do not operate as conventional contractors; we function as fiduciary partners in your capital asset management. Our process is designed to deliver fiscal certainty, operational continuity, and documented compliance. The installation of a walkway system is not merely a task; it is an engineered solution integrated into your facility’s long-term financial and operational plan.