Defining the Roof Cover Board’s Role in Commercial Asset Protection

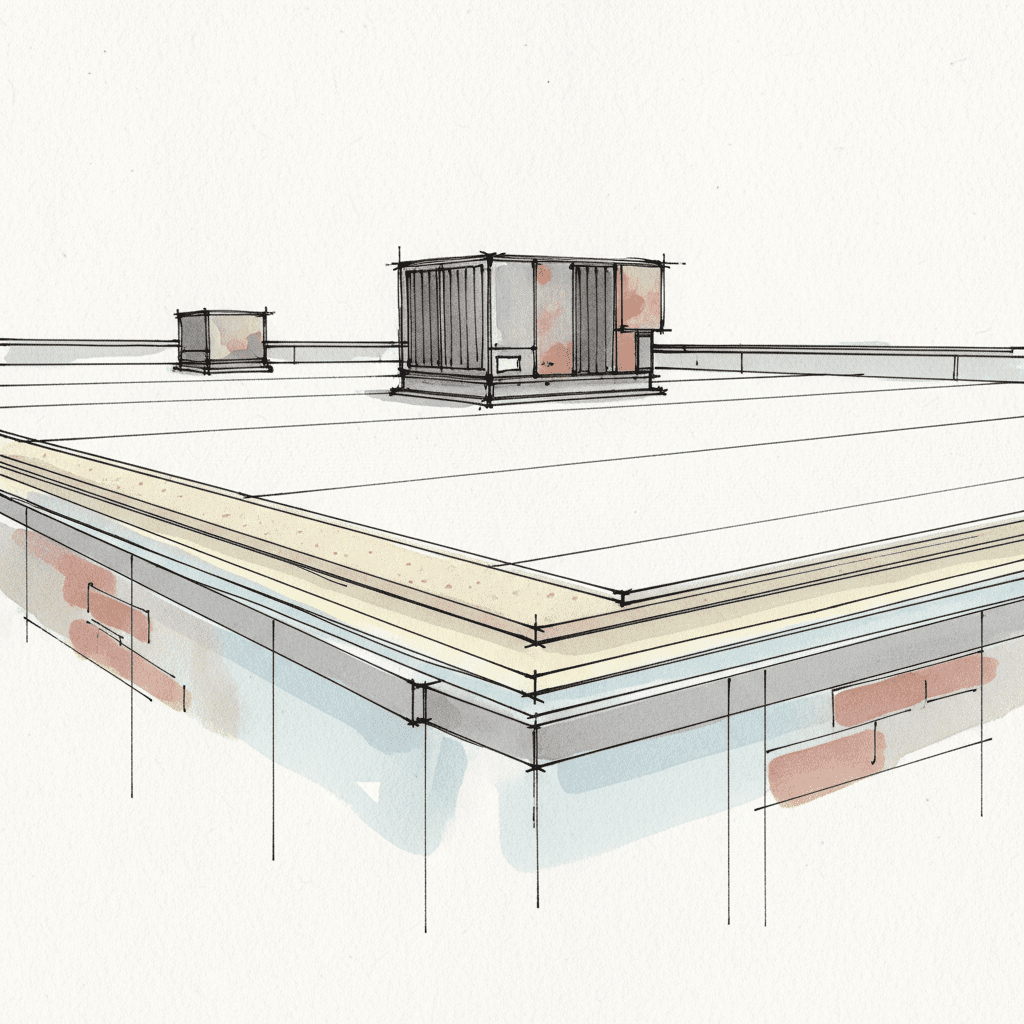

A high-performance roof cover board is a critical substrate engineered to protect the primary insulation and enhance the structural integrity of the entire commercial roofing system. For the fiduciary asset manager, it is not an optional upgrade; it is a fundamental component for long-term capital preservation, risk mitigation, and operational continuity. Its inclusion in a roofing specification directly translates to a more resilient building envelope and a predictable, lower total cost of ownership.

Beyond a Substrate: The Cover Board as a Primary Protective Layer

Viewing a cover board as mere sheathing is a significant financial miscalculation. It functions as the primary protective layer for the most vulnerable component of your roof assembly: the insulation. The insulation dictates your building’s thermal performance and energy efficiency. Without a cover board, this soft material is directly exposed to foot traffic, hail, and the stress of the overlying roof membrane. The cover board acts as armor, distributing loads, resisting impacts, and providing a stable, uniform substrate. This protection is essential for ensuring the longevity of the entire roofing system and preventing the premature degradation of your capital asset.

Financial Justification: Moving from Optional Upgrade to Standard of Care

As a fiduciary, your responsibility is to maximize asset value and minimize liability. Opting for a roofing system without a high-performance cover board to reduce the initial capital expenditure (CapEx) is a classic example of false economy. This decision introduces unacceptable long-term risks, including crushed insulation (leading to higher energy OpEx), frequent punctures, and premature membrane failure. The incremental upfront investment in a proper cover board is a strategic risk mitigation measure. It secures the performance of the multi-hundred-thousand-dollar system it supports, ensuring the long-term value of your asset and aligning with your fiduciary responsibility to avoid foreseeable failures.

Performance Metrics: Quantifying the Impact on Operational Resilience

Engineering standards provide quantifiable data that directly informs financial outcomes. The performance metrics of a cover board are not abstract technical specifications; they are direct indicators of your roof’s ability to withstand common operational stressors and environmental threats, thereby protecting your revenue-generating activities from disruption.

Compressive Strength (PSI): Mitigating Damage from Foot Traffic and Equipment

Commercial roofs are not static environments. They are platforms for heavy HVAC units and are subject to routine maintenance traffic. Compressive strength, measured in pounds per square inch (PSI), quantifies a cover board’s ability to resist deformation under load. A low-strength assembly allows the underlying insulation to be crushed, creating depressions that lead to ponding water—a primary driver of leaks and membrane degradation. Furthermore, compressed insulation loses its thermal resistance (R-value), silently increasing your building’s energy consumption. Specifying a cover board with high compressive strength (e.g., 80-100 PSI for HD Polyiso) is a direct investment in system durability and predictable energy OpEx.

Impact & Puncture Resistance: Reducing Liability from Hail and Debris

A roof puncture is not a maintenance issue; it is a business continuity threat. Water ingress from a single puncture caused by a severe hail storm or a dropped tool can result in catastrophic inventory loss, damage to sensitive equipment, and operational downtime. High-performance cover boards are engineered and tested to stringent standards, such as those set by FM Global, to resist impact and puncture. This enhanced resistance is a critical liability control measure, reducing the probability of water damage and subsequent insurance claims that inevitably increase premiums. It is a calculated decision to harden the asset against predictable threats.

| Cover Board Material | Typical Compressive Strength (PSI) | Key Business Benefit |

|---|---|---|

| Standard Polyiso Insulation (No Cover Board) | 20-25 PSI | High risk of compression damage, reduced R-value, ponding water liability. |

| Glass-Mat Gypsum Board | 900+ PSI | Exceptional fire/moisture resistance; strong puncture barrier. Ideal for compliance-heavy assets. |

| High-Density (HD) Polyisocyanurate | 80-110 PSI | Balanced performance: adds R-value, provides robust traffic resistance, and is lightweight. |

Fire Resistance & Thermal Performance: Enhancing Code Compliance and Energy Efficiency

Compliance with building codes and industry standards, such as achieving a UL Class A fire rating, is a non-negotiable aspect of risk management. Many high-performance cover boards, particularly glass-mat gypsum products, are inherently non-combustible and contribute significantly to the overall fire resistance of the roof assembly. This is not just a regulatory hurdle; it is essential for ensuring occupant safety and maintaining insurability. Additionally, cover boards like HD Polyiso add a continuous layer of insulation over the primary insulation board joints, mitigating thermal bridging. This engineering detail prevents energy loss, enhances the effective R-value of the system, and contributes to lower, more predictable operational expenditures for heating and cooling.

System Compatibility: Maximizing Roof Membrane Lifespan and Performance

A roof is an integrated system, and the cover board is the critical interface that dictates the performance and longevity of the primary weatherproofing membrane (e.g., TPO, PVC, EPDM). Investing in a premium membrane without a compatible high-performance cover board is financially illogical.

Creating a Superior Substrate for Thermoplastic (TPO/PVC) Seam Welding

The integrity of a thermoplastic roofing system depends entirely on the quality of its heat-welded seams. These seams are the most common point of failure. A successful weld requires a perfectly smooth, rigid, and dimensionally stable surface. Attempting to weld a TPO or PVC membrane directly over softer insulation often results in inconsistent seams that are vulnerable to failure. A high-performance cover board provides the ideal substrate, ensuring consistent pressure and heat application during the automated welding process. This engineering control guarantees superior seam integrity and dramatically reduces the likelihood of leaks over the system’s lifecycle.

Improving Wind Uplift Performance and Fastener Pull-Through Resistance

During a severe wind event, the forces acting on a commercial roof are immense. The system’s ability to resist wind uplift is a function of its structural integrity, determined by factors like the fastener pattern and the substrate’s ability to hold those fasteners. A cover board provides a dense, fibrous medium that significantly increases fastener pull-through resistance compared to fastening directly into lower-density insulation. This robust connection is critical for meeting stringent building codes and mitigating the risk of catastrophic failure. For an asset manager, superior wind uplift performance is not a technical detail—it is a core component of liability management and asset preservation in the face of increasing weather volatility.

Material Analysis for Strategic Capital Planning

The selection of a cover board material is a strategic decision that should be aligned with the specific performance requirements and risk profile of your facility. It is a key input in any credible lifecycle cost analysis.

High-Density Polyisocyanurate (HD Polyiso): High R-Value and Compressive Strength

HD Polyiso is an engineered solution designed for high-performance applications. Its primary financial benefits are twofold: it contributes to the overall thermal resistance (R-value) of the assembly, directly reducing long-term energy costs, and its high compressive strength protects the system from damage. While its initial material cost is higher, a cost-benefit analysis often favors HD Polyiso for facilities where both energy efficiency and durability are primary drivers of value. It is a lightweight solution that provides a robust return on investment through both OpEx savings and extended system lifespan.

Glass-Mat Gypsum: Superior Fire, Moisture, and Mold Resistance

For mission-critical facilities such as data centers, pharmaceutical manufacturing, or food processing plants, the primary consideration is often risk elimination over thermal performance. Glass-mat gypsum boards offer a non-combustible core and inherent resistance to moisture and mold growth. This material provides an exceptional fire barrier and is the standard of care in high-humidity environments or where system cleanliness and compliance are paramount. The decision to specify a gypsum cover board is a strategic one, prioritizing asset protection, regulatory compliance, and the mitigation of specific operational risks over pure energy savings.

Specification & Installation: A Process-Driven Approach to Fiscal Certainty

The theoretical benefits of a high-performance cover board are only realized through meticulous specification and process-driven execution. This is where the standard contractor model fails and RocStout’s fiduciary approach provides absolute value. We eliminate the operational disruption and financial uncertainty that asset managers cannot afford.

RocStout’s System Engineering: Aligning Cover Board Selection with Asset Goals

RocStout operates as a partner in your capital planning process. We do not present a generic, one-size-fits-all bid. Our standard operating procedure involves a comprehensive analysis of your facility’s function to engineer a roofing system that aligns with your financial objectives. The selection of the cover board is a key decision point in this process. We model the lifecycle costs, project the ROI based on energy savings and reduced maintenance, and present a clear recommendation backed by performance data. This process provides the fiscal certainty required for effective capital planning and eliminates the risk of specifying an inadequate system.

Execution Protocols to Eliminate Tenant Disruption and Ensure OSHA Compliance

The true cost of any capital project includes the potential for operational disruption. This is the enemy. Our project management methodology is built around the principle of zero downtime for your operations. We develop detailed logistics and scheduling plans, establish clear lines of tenant communication, and enforce strict OSHA compliance to maintain a safe and orderly site. Our crews adhere to non-negotiable protocols, including a ‘water-tight-by-nightfall’ standard, to ensure your asset is protected at every stage. This process-driven execution is our commitment to you: we will protect your operations and your capital asset with the same professional authority you use to manage them.