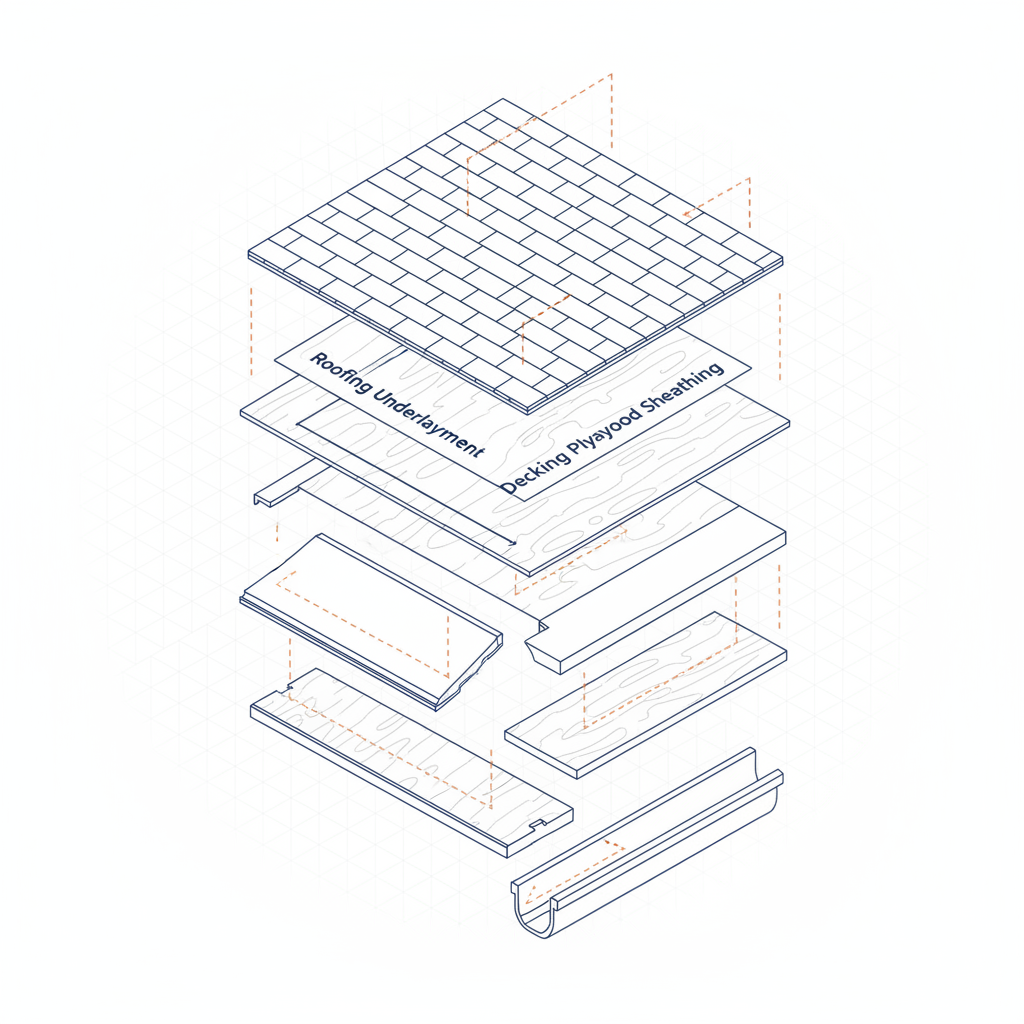

A roof drip edge is a non-corrosive, L-shaped metal flashing installed at the perimeter of a roof to direct water runoff away from the underlying fascia and into the gutter system. It functions as a critical component of the total roof assembly—a system of materials and constructions designed to protect a building against rain, snow, wind, and temperature extremes. Without a properly installed drip edge, the roof system fails at its most vulnerable point: the edge. Water adheres to the underside of the shingles through capillary action, saturating the wooden roof deck and fascia board. This moisture intrusion is the direct cause of wood rot, sheathing delamination, and eventual structural failure. The installation of a drip edge is not an aesthetic choice or a premium upgrade; it is a foundational engineering requirement for system longevity and the mitigation of preventable water damage.

The Engineering Principles of a Roof Drip Edge

A roof is a complete system, and its performance is dictated by the integrity of its weakest component. The perimeter is a primary point of failure, subjected to concentrated water flow and direct wind forces. A drip edge is engineered specifically to reinforce this perimeter, addressing multiple physical forces that lead to degradation. Its function is not singular; it serves as a multi-faceted defense mechanism for the entire building envelope.

Water Diversion: Protecting Structural Components from Moisture Intrusion

The primary function of a drip edge is to manage water flow at the roof’s eave and rake edges. Water possesses a property known as surface tension, which allows it to adhere to surfaces. When rainwater flows off the edge of a shingle, this property causes a portion of it to curl back and cling to the underside of the shingle and roof sheathing. This phenomenon, called capillary action, continuously exposes the wooden fascia board and the edge of the roof deck to moisture.

This constant saturation initiates a destructive cycle. The wood fibers absorb the water, creating an ideal environment for fungal growth, which is the biological process of wood rot. The plywood or OSB (Oriented Strand Board) roof sheathing begins to swell, delaminate, and lose its structural capacity. A drip edge provides a clean, impenetrable break. The metal flashing extends beyond the fascia, creating a physical edge from which water must drip, preventing it from curling backward. This simple diversion protects two of the roof’s most critical structural components from the certainty of moisture damage.

Wind Resistance: Securing the Roof Perimeter Against Uplift

A roof protects a building from wind by acting as a unified, aerodynamic surface. However, any gap or imperfection in this surface can allow high-velocity wind to create a pressure differential, resulting in uplift forces. The gap between the roof deck and the fascia board, directly beneath the edge of the first course of shingles, is a significant vulnerability. Wind-driven rain can be forced into this opening, but more critically, the wind itself can catch the shingle edge, peeling it back.

A drip edge seals this gap. It provides a smooth, continuous surface that deflects wind, preventing it from getting underneath the roof covering. By securing the perimeter, it reinforces the entire shingle field against uplift, drastically reducing the risk of shingles being torn off during severe weather events. This function is a direct contributor to the roof’s ability to withstand wind, a core requirement of its design.

Material Integrity: Sealing the Building Envelope Against Pests

The building envelope is the physical separation between the conditioned interior and the unconditioned exterior environment. Any breach in this envelope compromises the building’s integrity. The small, unsealed gap at the roof’s edge is a common entry point for insects, such as wasps and hornets, as well as small rodents seeking shelter. These pests can build nests within the soffit, attic, or wall cavities, causing damage to insulation, wiring, and structural members.

The drip edge acts as a physical barrier, closing this entry point. By integrating with the fascia and roof deck, it seals the building envelope at a critical junction. This aspect of weatherproofing is essential for maintaining the long-term health of the structure, preventing infestations that can lead to costly and disruptive remediation efforts.

System Longevity: Extending the Life of Your Roof Deck and Fascia

The functional lifespan of a roof system is determined by the durability of its constituent building materials. The premature failure of one component—such as the roof deck or fascia board—necessitates expensive, targeted repairs that compromise the system’s overall integrity. The installation of a drip edge is a direct investment in asset longevity.

By preventing chronic moisture exposure, the drip edge preserves the structural integrity of the wood components, preventing rot and decay. By sealing the perimeter against wind uplift, it protects the primary water-shedding layer—the shingles. By blocking pest intrusion, it safeguards the attic and wall assemblies. These combined functions ensure that the roof system degrades uniformly and predictably, reaching its maximum expected service life without premature failure at the edges. It is a small component that provides a disproportionately large return in terms of structural preservation.

Drip Edge Specifications: A Material and Profile Analysis

Selecting the correct drip edge is not arbitrary. The material and profile must be specified based on the local climate, roof design, and the type of roofing materials used. Meticulous planning at this stage prevents compatibility issues and ensures optimal performance.

Material Selection: Evaluating Aluminum, Steel, and Vinyl Options

The choice of material is a balance between corrosion resistance, strength, and cost. Each option has a designated application where it performs best.

| Material | Corrosion Resistance | Durability / Strength | Best Application |

|---|---|---|---|

| Aluminum | Excellent. Aluminum does not rust, making it ideal for coastal or high-humidity climates. | Good. It is lightweight and easy to work with but can be dented by impact (e.g., ladders). | The most common and reliable all-purpose choice for residential asphalt shingle roofs. |

| Galvanized Steel | Good to Very Good. The zinc coating (galvanization) protects the steel from rust, but scratches can compromise this protection over time. | Excellent. Steel is significantly stronger and more resistant to impact and bending than aluminum. | Regions with high winds, hail, or heavy snow/ice loads where superior strength is required. |

| Vinyl (PVC) | Excellent. Vinyl is a polymer and is completely impervious to moisture and rot. | Poor to Fair. Vinyl can become brittle over time due to UV exposure from sunlight and can crack under impact or in extreme cold. | Generally not recommended for long-term roofing systems. It is a low-cost option often used by budget-focused contractors. |

Profile Types: L-Style vs. T-Style and Their Designated Applications

Drip edge profiles are designed for specific locations on the roof. The two most common profiles are Type C (L-Style) and Type D (T-Style).

- L-Style (Type C): This profile features a simple 90-degree bend. It is typically used on the rake edges of a roof—the sloped sides. On the rake, the primary goal is to provide a clean edge for the shingles and prevent wind from getting underneath. The simpler profile is sufficient for this task.

- T-Style (Type D): This profile is shaped like a ‘T’ on its side, featuring a lower flange that extends outward from the fascia. This extended flange makes it the superior choice for the eaves (the horizontal bottom edge of the roof). The extension pushes water further away from the fascia and directly into the center of the gutter. This design provides an additional margin of safety against backsplash and water curling back onto the fascia board, which is especially important on low-slope roofs where water moves more slowly. For a comprehensive roofing system, Type D is the mandated standard for all eaves.

Code Compliance and Warranty: The Non-Negotiable Standard

For a process-driven organization, adherence to established standards is not optional. Building codes and manufacturer specifications exist to establish a baseline for safety, performance, and longevity. Ignoring them introduces unacceptable risk for the homeowner.

Analyzing International Residential Code (IRC) Mandates

The International Residential Code (IRC) is the model building code adopted by most municipalities in the United States. Its purpose is to ensure structures are built to a minimum standard of safety and durability.

Section R905.2.8.5 of the IRC explicitly mandates the installation of a drip edge at the eaves and gables (rake edges) of asphalt shingle roofs. The code specifies the material must be corrosion-resistant and outlines the precise installation method: the drip edge at the eaves must be installed under the roofing underlayment, while the drip edge on the rakes must be installed over the underlayment. This specific layering sequence is critical for proper water management.

A contractor who claims drip edge is ‘optional’ is either ignorant of fundamental building codes or is intentionally choosing to disregard them. This is a clear indicator of a high-risk, low-quality operation. Compliance is not a feature; it is the absolute minimum requirement for a legal and structurally sound installation.

How Incorrect Installation Voids Your Shingle Manufacturer’s Warranty

A shingle warranty is one of the most misunderstood documents in the construction industry. Homeowners often believe it is an unconditional guarantee. It is not. It is a limited warranty that is contingent upon the roofing system being installed precisely according to the manufacturer’s written specifications.

These specifications are detailed and exhaustive, covering everything from the type of nails used to the exact placement of every component, including the drip edge. Manufacturers require drip edge because they know its absence leads to edge failure.

If your roof is installed without a drip edge and a leak develops at the perimeter, the manufacturer has clear grounds to void your warranty coverage. The failure was not caused by a material defect in their shingle; it was caused by a workmanship error—the contractor’s failure to install a complete roofing system. By omitting a required component, the contractor transfers all future risk of failure directly to you, the homeowner. This is an unacceptable compromise.

Execution: Our Process vs. The Chaotic Industry Standard

The decision to install a drip edge is a litmus test for a roofing contractor’s entire operational philosophy. It reveals whether their priority is delivering a low initial price or a predictable, long-term outcome. There are two fundamentally different approaches to a roofing project. One invites chaos. The other eliminates it.

The Common Method: How ‘Bargain’ Bids Create Long-Term Failures

The standard roofing experience is defined by ambiguity and a focus on cutting costs to win a bid. Contractors operating this way view components like drip edge as expendable line items that can be removed to make their price appear lower.

This approach is the root of project chaos.

- The Deceptive Bid: The initial quote is artificially low because it omits necessary components. This is the first step in a process that will inevitably lead to surprise charges or a substandard final product.

- The Cascade of Failures: Without a drip edge, moisture begins to attack the fascia and decking within the first few years. The paint on the fascia peels, the wood softens, and leaks may appear inside the soffit.

- The Warranty Black Hole: When you attempt to file a warranty claim, you discover the installation did not meet manufacturer specifications, leaving you with no recourse.

- The Expensive Repair: You are now forced to hire another contractor to repair the rotted wood and correctly install the flashing that should have been there from the start.

This cycle of hidden fees, premature failure, and project stress is the direct result of choosing a contractor whose primary value proposition is a low price. It is a preventable, self-inflicted chaos.

Our Methodology: Mandating Drip Edge for a Predictable, Controlled Outcome

We have a different philosophy. Our entire operation is built to deliver a predictable, stress-free experience for meticulous homeowners who value order and clarity. Our process is not a collection of services; it is a system designed to eliminate variables and control outcomes.

Your project proposal details every component, including code-mandated items like drip edge. Pricing is transparent and comprehensive.

Your dedicated Project Manager oversees installation, ensuring every detail is executed to IRC and manufacturer standards.

We confirm total compliance, ensuring your manufacturer’s warranty is valid and your asset is protected.

This system is built on a non-negotiable principle: we build to code and manufacturer specifications, without exception. Drip edge is not an upgrade; it is a mandatory part of every RocStout roof.

- Transparent Pricing: The cost of all required components, including drip edge, is included in your proposal from the beginning. There are no surprises and no corners cut to create an artificially low price.

- Dedicated Project Management: Your dedicated project manager is responsible for quality assurance. They verify that every detail, from the layering of the underlayment to the fastening of the drip edge, is executed flawlessly.

- Asset Protection: For the meticulous homeowner, a roof is a significant investment in the protection of their primary asset. Our methodology treats it as such. We make decisions based on engineering principles and long-term performance, not short-term cost savings.

If your primary objective is to secure the lowest possible bid for your roofing project, we are not the right company for you. Our process is intentionally designed for a different type of client: one who understands that the true cost of a project includes the risk of failure and the stress of a chaotic process. We offer a controlled, predictable, and correct outcome. That is our value.

A roof drip edge is a small, inexpensive component that performs an outsized role in the protection of a building. It is a critical piece of engineering designed to defend the roof’s perimeter against the persistent threats of water intrusion, wind uplift, and pest infestation. Its presence is mandated by building codes and required by manufacturers for a reason: a roofing system without it is incomplete and structurally compromised.

The choice to include it is a clear indicator of a contractor’s commitment to quality. The industry standard often treats it as optional, a corner to be cut in pursuit of a lower price, which ultimately exposes the homeowner to the chaos of premature failure and voided warranties. At RocStout Roofing and Construction, our process eliminates that risk. We mandate the correct installation of a drip edge on every project, ensuring your roof is a complete, compliant, and durable system. The outcome is not just a new roof; it is the predictable, stress-free protection of your investment.