An engineered roofing system is a cohesive set of integrated components designed to protect a building’s structure from environmental loads, manage thermal transfer, and control moisture migration. It functions as a complete solution where the performance of each layer directly impacts the effectiveness and longevity of the entire assembly. This approach contrasts with viewing a roof as a simple commodity, where individual parts are chosen based on cost rather than their role within a unified, high-performance system.

The Critical Distinction: Roofing as a Commodity vs. an Engineered System

The approach to a roof replacement project is dictated by one of two opposing mindsets. The first, and most common in the construction industry, is the commodity mindset. The second, which our entire operational model is built upon, is the engineered system mindset. The former invites chaos, unpredictability, and premature failure. The latter establishes order, predictability, and long-term asset protection.

The Commodity Mindset (The Industry Standard)

The commodity mindset defines a roof by its most visible component: the shingle. It treats a roofing project as a transactional purchase, where the primary objective is to secure the lowest possible price for a superficially acceptable installation. This perspective reduces a complex building science challenge to a simple line item on a budget, ignoring the interdependent functions of the underlying components.

The consequences of this approach are predictable and severe. They introduce significant risk and stress into the project.

- Vague, One-Line Quotes: Proposals often lack detail, bundling labor and materials into a single, opaque number. This makes it impossible for a homeowner to compare bids on an equivalent basis and hides where corners will be cut.

- Surprise Change Orders: The low initial bid is often a tactic. Once the old roof is removed, “unexpected” issues like rotted decking are discovered, leading to immediate, high-pressure demands for additional funds. The process was designed for this outcome.

- Poor Communication: Homeowners are left without a dedicated point of contact. Questions go unanswered, timelines shift without notice, and the job site operates without clear leadership. This is a direct result of a business model focused on volume, not project management.

- Material Substitution: To protect their thin margins, contractors using the commodity model may substitute specified materials for cheaper, lower-grade alternatives like thinner underlayment, inadequate flashing, or fewer fasteners.

- Catastrophic System Failure: The focus on the shingle ignores the critical roles of ventilation, underlayment, and flashing. An imbalanced system will fail, often within a fraction of its warrantied lifespan, regardless of the quality of the shingle itself.

- Ignored Structural Issues: A superficial inspection misses underlying problems like inadequate attic ventilation or structural deck degradation. Covering these issues with new shingles is not a solution; it is the concealment of a future failure.

The Engineered System Mindset (The RocStout Philosophy)

The engineered system mindset defines a roof as a single, integrated machine for asset protection. It acknowledges that the final weather-exposed layer is only as effective as the carefully specified and installed components beneath it. This philosophy prioritizes performance, longevity, and the predictable execution of a well-defined plan. It is a direct rejection of the chaos inherent in the commodity approach.

The principles of this mindset are rooted in established scientific and management disciplines.

- Building Science: We apply the principles of thermodynamics, hydrokinetics, and aerodynamics to design a system that actively manages heat, water, and air pressure. The goal is not just to shelter the home, but to improve its overall performance and efficiency.

- Material Science: Component selection is based on compatibility, durability, and specific performance characteristics required by the home’s design and local climate. We do not use a one-size-fits-all material list.

- Precision Installation: We adhere to, and often exceed, manufacturer specifications for every step, from fastener placement to flashing integration. The quality of the installation is more critical than the brand of the material.

- Systematic Project Management: The entire process is managed with the same rigor as a complex engineering project. This includes detailed initial assessments, logistical planning, daily progress reporting, and a formal quality assurance inspection.

Table: Commodity vs. System Comparison

| Attribute | Commodity Mindset | Engineered System Mindset |

|---|---|---|

| Primary Goal | Lowest initial price | Highest long-term value and asset protection |

| Focus | Superficial appearance (shingles) | Integrated performance of all components |

| Pricing | Opaque, one-line estimate | Transparent, itemized scope of work |

| Project Management | Reactive, often chaotic | Proactive, process-driven, predictable |

| Change Orders | Expected and frequent | Eliminated through forensic assessment |

| Outcome | Unpredictable lifespan, high risk of failure | Predictable performance, warrantied longevity |

| Client Experience | Stressful, uncertain, disorganized | Clear, controlled, stress-free |

Our Position: We Exclusively Design and Install Engineered Roofing Systems

We have made a conscious, strategic decision to operate exclusively within the engineered system framework. This is a declaration of who we are and, just as importantly, who we are not. Our processes, our team, and our standards are designed to serve a specific type of client who values precision and predictability above all else.

A Statement on Price and Value

Our services are not for everyone. If your primary decision-making criterion is securing the absolute lowest bid, we are not the right contractor for you. This is not a judgment; it is a statement of fact based on the resources required to deliver a fundamentally different result. A low price is the primary indicator of the commodity mindset. It is mathematically impossible to provide a dedicated project manager, use premium-grade materials, conduct a forensic assessment, and maintain rigorous quality control while competing with contractors who omit these critical elements.

We do not compete on price. We compete on the elimination of chaos. Our clients choose us because they understand that the true cost of a roof includes the risk of premature failure, the stress of a disorganized project, and the financial impact of interior damage. They are purchasing a predictable outcome, not just a product.

Who We Serve

We are structured to serve the meticulous homeowner. Our clients are often engineers, lawyers, project managers, and other professionals who manage complex systems in their own careers. They understand that a successful project is the result of a robust process, not luck. They expect clear communication, detailed planning, and professional execution. They are unwilling to tolerate the disorganization, poor communication, and financial surprises that define the standard roofing experience. Our entire business is built to meet this standard.

The Non-Negotiable Elements of Our Process

Every RocStout project is built on a foundation of control and transparency. These are not optional add-ons; they are core components of our service delivery model.

- A Dedicated Project Manager: Every client has a single, accessible point of contact responsible for the project from start to finish. This individual is your advocate, information source, and quality control lead.

- A Detailed, Fixed-Price Proposal: Our proposals are comprehensive scopes of work that detail every material, every task, and every line-item cost. The price you are quoted is the price you will pay.

- Zero-Surprise Change Order Policy: Our forensic assessment process is designed to identify all potential issues, such as deck rot, before the project begins. We build the cost of these known repairs into the initial proposal, eliminating the industry’s most common and stressful tactic.

- Daily Digital Logs: You will receive a daily report from your project manager, including photos and a summary of work completed. You will never be left wondering about the status of your project.

- Meticulous Site Management: We implement a comprehensive plan for property protection, material staging, and daily cleanup. A clean, organized job site is a direct reflection of a well-managed, precise installation process.

The Core Components of an Engineered Roofing System

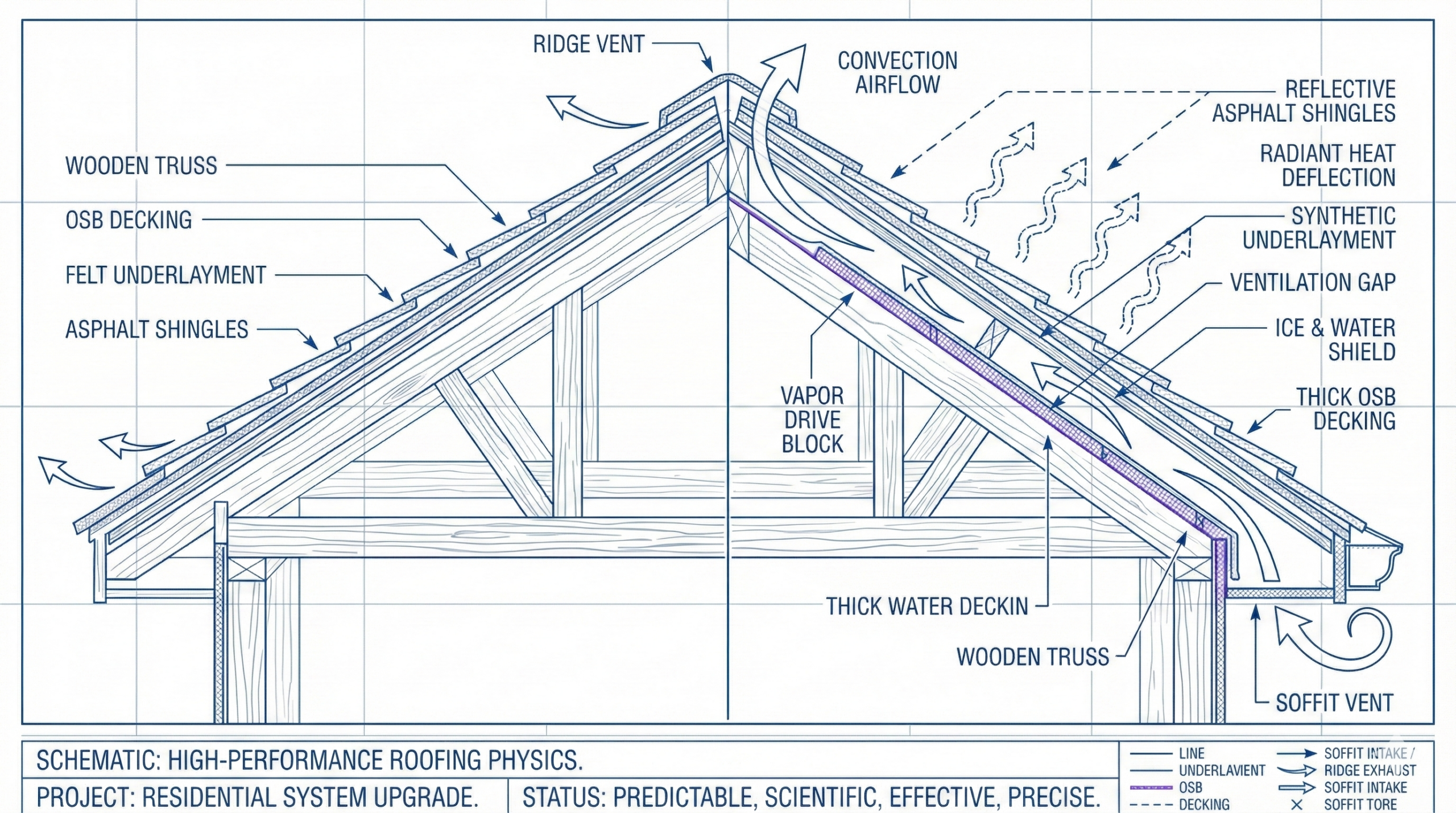

A high-performance roof is not a single entity. It is a system of five distinct, interconnected layers. The failure of any one of these components compromises the integrity of the entire system. Understanding their individual functions is critical to appreciating the engineered approach.

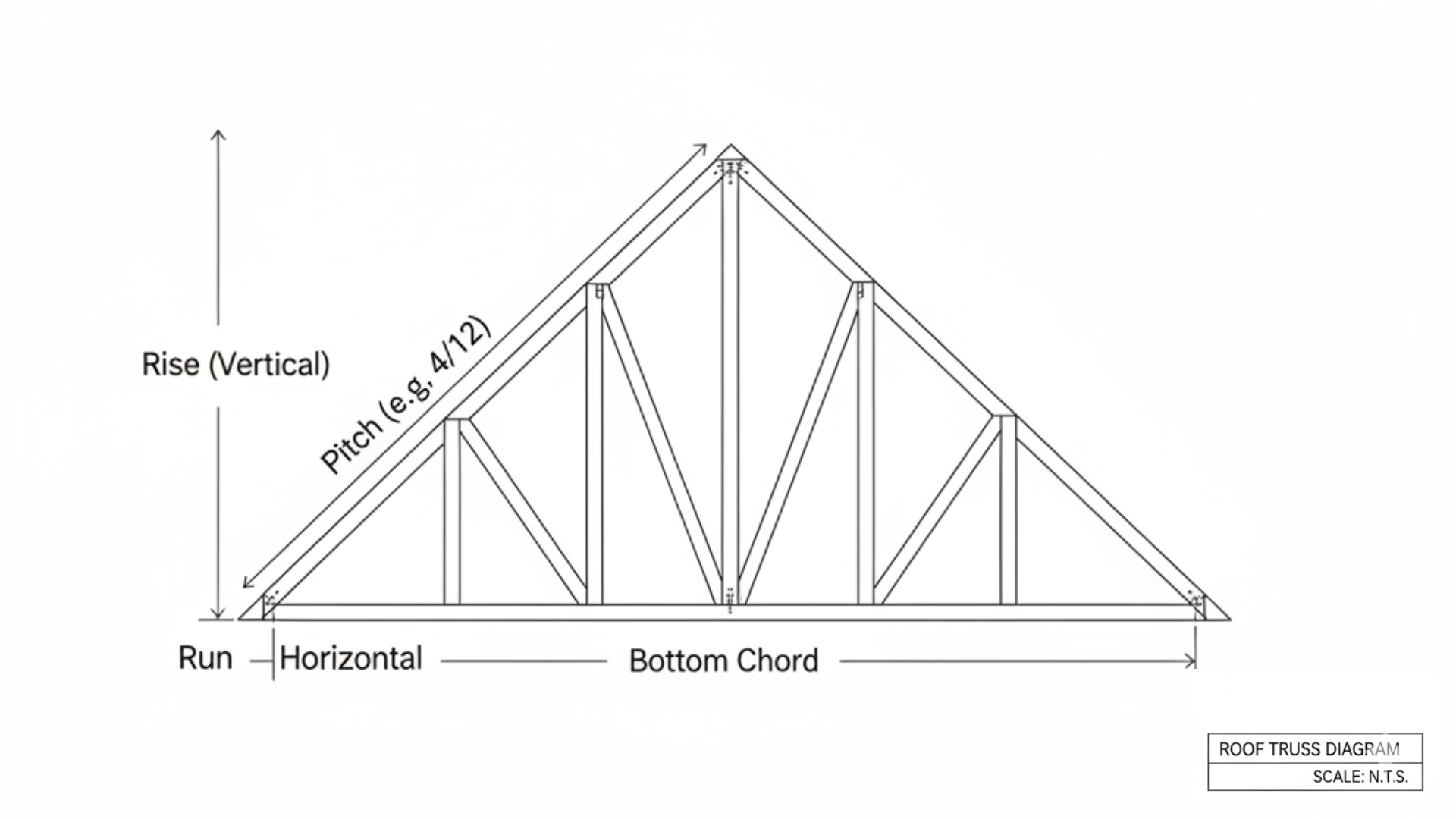

1. The Structural Deck

The structural deck is the foundation of the entire roofing system. It consists of the wood panels, typically plywood or OSB (Oriented Strand Board), that are fastened to the roof trusses or rafters. Its primary function is to provide a solid, stable substrate for all subsequent layers and to transfer loads (such as snow, wind, and the weight of the roofing materials) to the building’s frame.

A thorough system design begins with a rigorous inspection of the deck. We assess for water damage, rot, delamination, and inadequate fastener pull-out strength. Any compromised sections are identified and scheduled for replacement as part of the initial scope of work. Simply covering damaged decking is a guaranteed path to system failure.

2. The Underlayment System

The underlayment is the secondary water barrier. It is installed directly onto the structural deck, beneath the primary roofing material. While the shingles or metal panels are the first line of defense, they are not impervious. Wind-driven rain or water from ice dams can penetrate the primary layer. The underlayment’s function is to prevent this water from reaching the structural deck and entering the home.

Standard practice often involves using low-cost asphalt-saturated felt paper. We exclusively use high-performance synthetic underlayments. These materials offer superior tear resistance, water repellency, and UV stability. In critical areas prone to ice damming and heavy water flow, such as eaves, valleys, and around penetrations, we install a specialized self-adhering ice and water shield. This membrane seals directly to the deck and around fasteners, providing the highest level of protection against water intrusion.

3. The Ventilation System (Intake and Exhaust)

The ventilation system is the active-breathing component of the roof. Its function is to regulate temperature and moisture levels within the attic space. A properly balanced system creates a continuous flow of air, drawing cool, dry air in through intake vents and expelling hot, moist air through exhaust vents. This is not an optional feature; it is a fundamental requirement of building science.

The system operates on a physical principle known as the “stack effect.” Cool, dense air enters through intake vents located at the lowest part of the roof, typically the soffits. As this air is warmed by the sun-heated roof deck, it becomes less dense and rises. It then exits through exhaust vents located at the highest point of the roof, such as a ridge vent. For this system to function, there must be a 1:1 balance between the net free vent area of the intake and the exhaust.

An improperly ventilated system has severe consequences:

- Premature Shingle Failure: Trapped super-heated air in the summer literally bakes the shingles from below, accelerating the loss of their protective granules and causing them to become brittle.

- Ice Dam Formation: In the winter, heat escaping from the living space warms the underside of the roof deck, melting snow. This water runs down to the cold eaves and refreezes, forming a dam of ice that forces subsequent meltwater under the shingles.

- Mold and Mildew Growth: Moisture from the living space (from cooking, showers, etc.) rises into the attic. Without adequate ventilation to exhaust it, this water vapor can condense on the cool surfaces of the wood framing and decking, creating the ideal environment for mold growth.

4. The Flashing System

The flashing system is a set of components, typically made from metal like aluminum or galvanized steel, designed to waterproof the transitions and penetrations of a roof. A roof is not a flat, uninterrupted plane. It has valleys, chimneys, dormers, vents, and intersections with walls. These are the most vulnerable points for water intrusion. The flashing system’s sole purpose is to direct water away from these openings and back onto the surface of the primary roofing material.

Precision is paramount in flashing installation. We fabricate and install custom flashing for all critical areas, ensuring tight, mechanically fastened, and properly sealed transitions. This includes step flashing woven into shingle courses along walls, counter-flashing set into chimney mortar joints, and custom pans for skylights. This is a skilled, detail-oriented task that is often rushed or ignored in a commodity-focused installation.

5. The Primary Weather-Exposed Layer (Shingles, Metal, etc.)

This is the outermost, visible layer of the roof. It serves as the primary barrier against rain, snow, hail, and UV radiation. While material selection is important, the performance of this layer is almost entirely dependent on the precision of its installation. Even the highest-rated architectural shingle or standing seam metal panel will fail if installed improperly.

Our installation protocol focuses on the details that create a unified, wind-resistant surface. This includes a mandatory 6-nail fastening pattern for shingles in our region, correct nail placement to hit the manufacturer’s designated nail line, proper staggering of shingle courses to offset joints, and the use of dedicated starter strips at all eaves and rakes to secure the roof’s perimeter against wind uplift.

Diagram: The Interconnected Layers

The following diagram illustrates the relationship between these five core components. Each layer depends on the proper function of the layer beneath it.

Deflects bulk water and UV radiation

Protects transitions and penetrations

Provides a secondary water barrier

The foundation of the system

Building Science Principles Applied to Roofing

Building science is the study of the physical principles that govern how buildings perform. An engineered roofing system is a direct application of this science. We do not just nail on shingles; we design a system that actively manages the forces of nature that constantly act upon your home’s exterior envelope.

Water Management (Hydrokinetics)

Effective water management is the primary goal of any roofing system. We use a strategy known as the “Four D’s” to ensure your home stays dry.

- Deflection: The first line of defense. The shape and slope of the shingles or metal panels are designed to immediately deflect the vast majority of rainwater.

- Drainage: Water that is not deflected must be channeled off the roof. The slope of the roof, combined with properly installed flashing in valleys, creates a clear and unobstructed path for water to flow into the gutters.

- Drying: No system is perfectly waterproof forever. The ventilation system provides a mechanism for any incidental moisture that finds its way into the system to dry out before it can cause damage to the structural deck.

- Durability: Materials are selected and installed to withstand decades of exposure to water and UV radiation without degrading. This includes using non-corrosive metals for flashing and high-quality, tear-resistant synthetic underlayments.

Air Movement and Control (Aerodynamics)

Wind places significant stress on a roofing system, primarily through uplift forces. As wind flows over a roof, it creates a pressure differential, with lower pressure on the top surface and higher pressure underneath. This differential generates a lifting force that tries to pull the shingles off the deck.

Our system design directly counters these aerodynamic forces. We use dedicated starter strips with a factory-applied adhesive sealant along all eaves and rakes. This bonds the perimeter of the roof directly to the underlayment. We use a 6-nail fastening pattern, which increases the manufacturer’s rated wind resistance significantly. The precise placement of these fasteners ensures they engage the thickest part of the shingle and penetrate securely into the wood deck, creating a unified and wind-resistant assembly.

Thermal Management (Thermodynamics)

A roof must manage the transfer of heat. In the summer, it must minimize heat gain from solar radiation. In the winter, it must help minimize heat loss from the conditioned living space.

- Radiation: The primary source of heat gain is solar radiation. Lighter-colored or “cool-roof” shingles can reflect a significant portion of this energy. In some designs, a radiant barrier installed on the underside of the roof deck can further block radiant heat transfer into the attic.

- Convection: The primary mechanism for removing heat that does penetrate the system is convection. The ventilation system creates a continuous convective loop, carrying hot air out of the attic before it can conduct through the insulation into your home.

- Conduction: Heat also moves through solid materials. Proper attic insulation slows the conduction of heat from the attic into your living space in the summer, and from your living space into the attic in the winter. The roof ventilation and attic insulation work together as a complete thermal management system.

Moisture Control (Hygrothermics)

Hygrothermics is the study of heat and moisture movement. A significant amount of water vapor is generated inside a home. This vapor naturally moves from the warm, high-pressure interior to the colder, low-pressure exterior—a phenomenon known as vapor drive. In winter, this means moisture is constantly trying to move up into the attic.

If the attic is cold and poorly ventilated, this warm, moist air will cool and condense on the cold surfaces of the roof deck and framing. This condensation is a primary cause of mold, mildew, and wood rot. A balanced ventilation system is the only way to safely exhaust this moisture from the attic before it can condense and cause damage. It ensures the air in the attic stays close to the outside ambient temperature and humidity, preventing the conditions necessary for condensation to occur.

The RocStout Process: Engineering Predictability into Your Project

The quality of our finished product is a direct result of the rigor of our process. We have systematically engineered every potential point of failure, miscommunication, and surprise out of the client experience. Our process is our promise of a predictable, stress-free project. It is the tangible delivery of order over chaos.

Phase 1: Forensic Assessment & System Design

This initial phase is the most critical. We do not provide a simple “estimate.” We conduct a comprehensive, data-driven assessment of your existing roof and attic.

- Attic Inspection: We enter the attic to directly observe the condition of the structural deck, identify any existing leaks or moisture issues, and measure the adequacy of the current ventilation and insulation.

- Roof Surface Inspection: We conduct a full physical inspection of the roof surface, documenting the condition of all components, including shingles, flashing, pipe boots, and gutters.

- Precise Measurements: We use satellite imagery and on-site measurements to create a precise digital model of your roof, ensuring material calculations are exact.

- System Design & Proposal: The data collected is used to design a complete, integrated roofing system tailored to your home. The output is a detailed, fixed-price scope of work that clearly specifies every material, every procedure, and the logic behind our recommendations.

Phase 2: Pre-Construction & Logistical Planning

Once you approve the proposal, we transition to meticulous planning. This phase is about preparing for a smooth, efficient, and clean execution.

- Material Procurement & Staging: All materials for your project are ordered and scheduled for delivery. We coordinate a specific staging location on your property that minimizes disruption.

- Property Protection Plan: We deploy protective coverings for landscaping, siding, windows, and driveways. This is not an afterthought; it is a planned, systematic part of our process.

- Crew Briefing: Your dedicated project manager briefs the installation team on the specific scope of work, unique challenges of your property, and our quality standards.

Phase 3: Precision Execution & Project Management

This is the installation phase, governed by constant oversight and communication.

- On-Site Project Management: Your project manager is on-site daily to supervise the crew, enforce safety protocols, and ensure every detail of the installation conforms to our engineering standards and the manufacturer’s specifications.

- Systematic Installation: The crew follows a precise sequence of operations, from tear-off and deck inspection to underlayment, flashing, ventilation, and final shingle installation.

Phase 4: Quality Assurance & System Commissioning

A project is not complete until it has been verified and all documentation has been delivered.

- Multi-Point Final Inspection: Your project manager conducts a comprehensive final inspection using a detailed checklist to verify that every aspect of the installation meets our quality standards.

- Final Site Cleanup: The property is swept with magnetic rollers to collect stray fasteners, and all debris is removed. We leave your property cleaner than we found it.

Diagram: The Four-Phase Project Lifecycle

This diagram shows the linear, controlled progression of every RocStout project.

Forensic Assessment & System Design

Pre-Construction & Logistical Planning

Precision Execution & Project Management

Quality Assurance & System Commissioning

Asset Protected

Conclusion: A Roof is Not a Purchase. It is a Capital Investment in Asset Protection.

The central argument of this document is a call to shift your perspective. A new roof should not be viewed through the lens of a necessary, expensive repair. It must be viewed as a long-term capital investment in the single most important function of your home: keeping the structure, its contents, and its occupants safe and dry.

The True Cost of a “Cheap” Roof

The commodity mindset, with its relentless focus on the lowest initial price, is fiscally irrational. A poorly designed and installed roof, even if it costs 20% less upfront, carries enormous hidden liabilities. The true cost includes the near-certainty of premature failure, the high probability of interior water damage to ceilings, walls, and possessions, a quantifiable loss in property value, and the immense, unquantifiable stress of managing an avoidable crisis.

The Return on a System-Based Approach

An investment in an engineered roofing system yields tangible returns. It provides decades of reliable performance, directly protecting the value of your largest financial asset. A properly ventilated and insulated system can contribute to lower energy bills. Most importantly, it provides certainty. It is the purchase of peace of mind, backed by a predictable process and a robust warranty. It is the conversion of a chaotic, high-risk expense into a controlled, high-value investment.

If you view your home as a critical asset and demand a process defined by precision, transparency, and predictability, then our philosophy and methodology are aligned with your goals. We invite you to schedule a consultation to begin the process of designing a permanent solution for your home.