Infrared thermal imaging is a non-destructive diagnostic protocol used by fiduciary asset managers to identify subsurface moisture infiltration within commercial roofing systems before it manifests as a catastrophic failure. This engineering-based approach translates temperature differentials on the roof’s surface into a clear, quantifiable map of trapped water, allowing for data-driven capital expenditure decisions that preserve asset value and eliminate the risk of operational disruption. For the CFO or Facility Manager, it is not merely a leak detection tool; it is a core component of a proactive capital asset preservation strategy.

Quantifying the Financial Liability of Subsurface Moisture Infiltration

Unidentified moisture within a roof assembly is a depreciating entry on your balance sheet. It is a hidden liability that silently compromises the building envelope, escalates operational costs, and exposes the organization to significant legal and financial risk. Ignoring this subsurface threat is not a cost-saving measure; it is an explicit acceptance of future, and likely much larger, capital expenditures and potential business interruption. A proactive diagnostic approach is the only fiscally responsible standard of care for a commercial asset.

Degradation of Thermal Resistance and Escalating Energy Expenditures

The primary function of roofing insulation is to provide thermal resistance, measured as an R-value. When this insulation becomes saturated with water, its performance plummets. Water is a conductor, not an insulator. Entrapped moisture creates thermal bridges, allowing conditioned air to escape and exterior temperatures to infiltrate the building. The direct financial consequence is a measurable increase in utility costs as HVAC systems are forced to work harder to maintain interior climate control. An effective energy audit must begin at the roof level, as compromised insulation performance renders other efficiency initiatives moot. Escalating energy expenditures are often the first, albeit lagging, indicator of a critical failure in the building envelope.

Accelerated Deterioration of Roof Deck and Structural Components

Subsurface moisture initiates a chain reaction of structural degradation that severely shortens the asset lifecycle. For steel roof decks, chronic moisture exposure leads to corrosion and section loss, compromising the deck’s load-bearing capacity and the pull-out strength of roofing fasteners. In systems with wood or lightweight concrete decks, the result is wood rot and concrete spalling, respectively. This deterioration is not a cosmetic issue; it is a fundamental threat to the structural integrity of the building. Allowing this condition to persist transforms a manageable roof repair into a multi-trade, high-cost structural rebuild, representing a catastrophic failure in capital planning.

Mitigating Risk: Tenant Disruption, Inventory Loss, and Mold Proliferation

The ultimate cost of water ingress is measured in operational downtime. A ceiling leak that damages tenant spaces, destroys high-value inventory, or disrupts critical business operations represents a far greater financial loss than the cost of any roofing project. Furthermore, trapped moisture in a dark, enclosed space creates the ideal environment for mold proliferation, exposing the organization to significant health and safety liabilities. Proactive identification of water infiltration is therefore a primary risk management function, safeguarding operational continuity and protecting the health of building occupants, thereby insulating the enterprise from potential litigation and reputational damage.

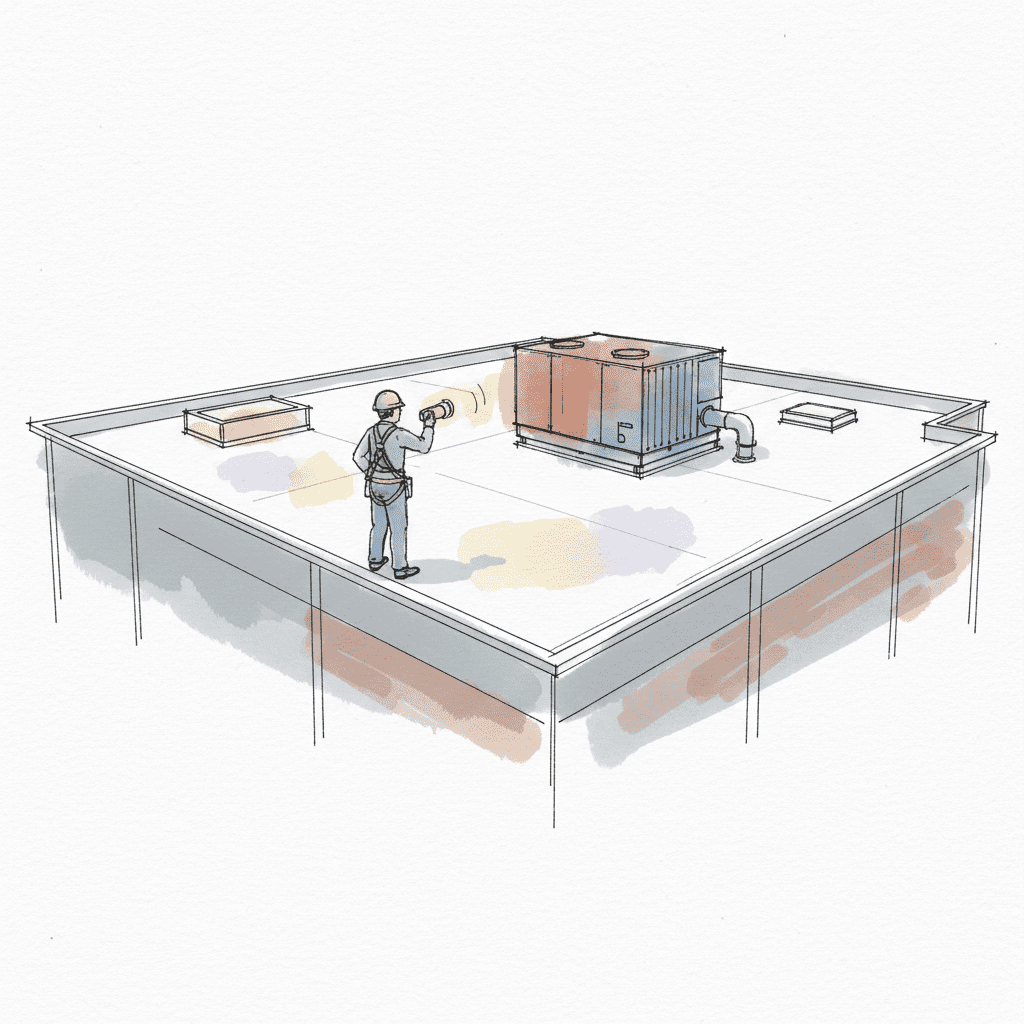

Infrared Thermography: A Non-Destructive Diagnostic Protocol for Commercial Roofs

Infrared thermography provides a forensic, non-destructive testing (NDT) method to assess the condition of a commercial roof system in accordance with engineering standards like ASTM C1153. By detecting minute temperature differentials across the roof surface, our certified thermographers can precisely identify areas of entrapped moisture. This protocol allows us to pinpoint latent defects without the need for extensive and destructive exploratory cutting. It replaces guesswork with verifiable data, forming the foundation of a responsible and financially sound asset management plan.

The Engineering Principles of Thermal Capacitance and Emissivity

The science behind infrared inspection is based on a simple principle: different materials absorb and release solar radiation at different rates. During the day, the entire roof system absorbs heat from the sun. After sunset, dry areas of the roof, with their lower thermal capacitance, cool down relatively quickly. However, areas with saturated insulation have a much higher heat capacity due to the entrapped water. These wet areas retain heat for longer, creating a distinct thermal anomaly that is invisible to the naked eye but clearly visible through a high-resolution infrared imager. The data captured is a direct representation of subsurface conditions, allowing for a precise diagnosis.

Standard Operating Conditions for Accurate Data Acquisition

Acquiring actionable, high-integrity data is not a casual process. It demands strict adherence to established protocols and precise environmental conditions. A valid thermographic survey must be conducted post-sunset, after a dry, sunny day, allowing for maximum thermal loading and subsequent temperature differentiation. The sky must be clear, as cloud cover can reflect heat back onto the roof and corrupt the data. The roof surface must be dry and free of debris. Any deviation from these standard operating conditions compromises data integrity and leads to flawed conclusions, which is why we reject any methodology that does not meet these stringent engineering requirements.

Comparative Analysis: Ground-Based vs. Aerial (UAV/Drone) Methodologies

While both ground-based and aerial platforms can be utilized, unmanned aerial vehicles (UAVs) represent the superior methodology for most commercial assets. Drones provide a comprehensive, top-down perspective that is safer, faster, and generates more consistent data resolution across large and complex roof surfaces. This approach minimizes risk to personnel and ensures complete coverage without disrupting site operations.

| Metric | Aerial (UAV/Drone) Inspection | Ground-Based (Walk-Over) Inspection |

|---|---|---|

| Efficiency & Speed | High. Capable of surveying hundreds of thousands of square feet per hour. | Low. Labor-intensive and time-consuming, especially on large facilities. |

| Safety & Risk | Minimal. Eliminates risks associated with walking on roofs at night. Full OSHA compliance. | High. Increased risk of falls and trips in low-light conditions. |

| Data Integrity | Excellent. Provides a complete, unobstructed orthomosaic view for precise moisture contour mapping. | Variable. Oblique angles and obstructions can lead to data gaps and interpretation errors. |

| Site Accessibility | Superior. Easily inspects inaccessible or unsafe roof areas without specialized equipment. | Limited. Restricted by roof pitch, obstructions, and safety hazards. |

Translating Thermographic Data into Actionable CapEx Intelligence

The value of an infrared scan is not in the thermal images themselves, but in their translation into a strategic financial document. RocStout’s process converts raw engineering data into a clear, fiduciary-grade report that empowers executive decision-making. We provide the intelligence necessary to move from reactive, emergency spending to proactive, planned capital expenditure, delivering fiscal certainty to your roof asset management program.

From Raw Thermal Data to a Quantified Moisture Map

Our process begins by stitching hundreds or thousands of individual radiometric thermal images into a single, high-resolution orthomosaic map of your entire roof asset. This composite thermogram is then analyzed by a certified thermographer who performs a meticulous delineation of all thermal anomalies. The final deliverable is not just a picture, but a scaled architectural drawing overlaid with a precise moisture contour map. This visual report quantifies the exact square footage and location of suspected subsurface moisture, providing an unambiguous foundation for the scope of work.

The Mandate for Ground-Truth Verification via Core Sample Analysis

A thermal anomaly indicates a high probability of moisture, but it is not definitive proof. The only responsible next step is physical verification. Our standard operating procedure mandates that we take minimally invasive roof core samples from representative anomalous and dry areas. This forensic analysis validates the thermographic data by confirming the presence and saturation level of moisture in the insulation and substrate. This ground-truthing process is non-negotiable; it eliminates assumptions and ensures that every dollar of your capital budget is allocated with precision and certainty.

Developing a Data-Driven Scope of Work: Surgical Repair vs. Full Replacement

Armed with a verified moisture map, we can develop a scope of work (SOW) that is both technically sound and financially optimized. If the data indicates that moisture is localized and affects less than 25-30% of the roof area, a surgical restoration—removing only the wet sections and restoring the membrane—may be the most prudent investment. This targeted approach preserves the value of the remaining dry sections and extends the asset’s service life at a fraction of the cost of a full replacement. This data-driven strategy prevents over-spending on a full tear-off when it is not required, directly improving your return on investment.

Integrating Infrared Analysis into a Long-Term Asset Preservation Strategy

A one-time infrared scan is a valuable diagnostic tool, but its true power is realized when integrated into a recurring, long-term asset management program. This approach shifts your posture from reactive repair to proactive preservation, transforming the roof from an unpredictable liability into a managed asset with a predictable lifecycle and budget. This is the cornerstone of achieving fiscal certainty in your facility management operations.

Establishing a Baseline Condition for Proactive Maintenance Protocols

The initial comprehensive infrared survey establishes a definitive baseline of your roof’s condition. Subsequent annual or biennial scans are then compared against this baseline, allowing for powerful trend analysis. We can monitor the performance of past repairs, identify new areas of potential moisture infiltration at their earliest stages, and proactively address minor issues before they escalate. This performance monitoring protocol provides a clear Roof Condition Index, enabling you to forecast capital needs with a high degree of accuracy and avoid budgetary surprises.

Leveraging Infrared Reports for Warranty Claims and Insurance Documentation

A professionally executed infrared survey, complete with certified analysis and core sample verification, is an invaluable piece of third-party documentation. In the event of a premature failure, this report serves as objective, scientific evidence to substantiate a manufacturer warranty claim. Similarly, following a storm or other damage event, it provides the indisputable proof required by insurance carriers to process a claim efficiently and fairly. This level of due diligence is a critical component of risk management and protects your organization’s financial interests.

RocStout’s Standard Operating Procedure for Infrared Roof Diagnostics

We do not simply offer infrared scans; we provide a turnkey, fiduciary-grade diagnostic solution designed to protect your capital asset and ensure operational continuity. Our process is rigid, compliant, and transparent, culminating in a report that equips your executive team to make informed financial decisions. We manage the entire process, from logistics to final reporting, to eliminate any burden on your internal resources.

Phase I: Pre-Scan Asset Review and Logistical Coordination

Every engagement begins with meticulous planning. We conduct a thorough review of all asset documentation, including existing warranties and maintenance records. A detailed project management and safety plan is developed, outlining flight paths, timelines, and communication protocols. We coordinate directly with facility management to ensure our operations are seamless and create zero disruption for tenants or site personnel. This pre-scan phase is critical to ensuring safe, efficient, and compliant data acquisition.

Phase II: Compliant On-Site Data Acquisition and Verification

Our on-site execution is governed by strict compliance and safety protocols. All aerial surveys are conducted by an FAA Part 107 certified UAV pilot who is also a certified thermographer. An on-site safety manager oversees the operation to ensure adherence to all OSHA standards. Following the thermal data collection, our technicians perform the mandated core sampling for ground-truth verification. This two-step process guarantees the quality control and integrity of the data we collect.

Phase III: Fiduciary-Grade Reporting for Executive Decision-Making

The final deliverable is a comprehensive diagnostic report designed for a business executive, not a roofing technician. It includes a concise executive summary, the detailed moisture contour map, and photographic documentation of the core samples. Most importantly, it provides clear capital budget recommendations based on a lifecycle cost analysis of various scenarios—from surgical repair to full replacement. The report includes a prioritized repair schedule and a risk assessment matrix, providing everything your organization needs to confidently authorize and execute the most fiscally responsible course of action.