Defining FM Global Approval: A Framework for Asset Protection & Insurance Compliance

FM Global Approval is a third-party certification for commercial roofing materials and assemblies, signifying they have met some of the most rigorous loss-prevention engineering standards in the world. For a Facility Manager or CFO, this is not a mere product sticker; it is a critical component of your risk management strategy, directly impacting insurance underwriting, asset valuation, and operational continuity. It serves as documented proof that your roofing system is designed not just to shelter, but to withstand quantifiable catastrophic forces and protect the revenue-generating operations within your facility.

Beyond Building Code: How FM Standards Mitigate Catastrophic Financial Loss

It is a fundamental error to equate local building codes with the level of asset protection required by a fiduciary. Building codes establish the absolute minimum legal requirement to ensure life safety and prevent structural collapse. They are not engineered to prevent business interruption, inventory loss, or the significant financial damages that follow a major weather event. FM Global standards, by contrast, are born from over a century of property loss data. They are designed with a single purpose: to ensure business continuity by engineering systems that resist failure under extreme conditions. Adhering to these standards is a proactive declaration that your organization prioritizes long-term asset preservation over meeting a minimum legal threshold. This distinction is critical during insurance underwriting and is a core tenet of responsible fiscal management.

The Role of Property Loss Prevention Data Sheets (PDS 1-28, 1-29)

The technical specifications for achieving this level of resilience are codified in FM Global’s Property Loss Prevention Data Sheets, specifically PDS 1-28 for Wind Design and PDS 1-29 for Roof Deck Securement and Above-Deck Roof Components. These documents are not suggestions; they are engineering mandates. They provide the precise, data-driven calculations for determining wind uplift pressures based on geography, building height, and surrounding topography. They also dictate the required components—from the specific fastener and insulation board to the membrane seam strength—that must be used in a tested assembly to achieve a specific uplift rating. For your capital planning, these data sheets remove ambiguity and provide a clear, engineered pathway to a resilient, insurable, and defensible roofing asset.

The Financial Rationale: Translating FM Compliance into Long-Term ROI

Specifying an FM Approved roof assembly is a strategic capital expenditure, not an operational expense. The decision moves beyond material costs and installation labor, entering the realm of long-term financial performance. This investment directly influences insurance costs, property valuation, and the total cost of ownership over the asset’s lifecycle, delivering a measurable return on investment.

Quantifying the Impact on Commercial Property Insurance Premiums

Commercial property insurance underwriters are, fundamentally, risk assessors. An FM Approved roof system, with its verifiable engineering and third-party testing, presents a significantly lower risk profile than a non-compliant or minimally-coded roof. This lower risk can translate directly into more favorable insurance terms, including potentially lower premiums, reduced deductibles, or the elimination of specific policy exclusions related to wind or hail damage. By investing in a system that meets the stringent requirements of a major underwriter like FM Global, you are providing empirical evidence of proactive risk mitigation, which strengthens your negotiating position and can yield substantial long-term savings.

FM Approval as a Differentiator in Asset Valuation and Divestiture

During a due diligence process for a potential acquisition or divestiture, the condition and documentation of the roofing asset are scrutinized. An FM Approved roof assembly is a documented capital improvement with a clear engineering pedigree. This documentation simplifies the Property Condition Assessment, removes uncertainty for potential buyers, and can be leveraged to justify a higher asset valuation. Conversely, a roof with an ambiguous history or non-compliant installation introduces perceived risk, which can lead to demands for price concessions or capital escrow accounts. An FM-compliant roof is therefore not just a shield against weather; it is a marketable feature that enhances the liquidity and value of your commercial property.

| Financial Metric | Standard (Non-Compliant) Roof | FM Approved Roof Assembly |

|---|---|---|

| Insurance Premiums | Higher risk profile leads to standard or elevated premiums and less favorable terms. | Lower risk profile may lead to preferential rates, lower deductibles, and broader coverage. |

| Asset Valuation | Uncertain liability during due diligence; may require concessions or escrow. | Documented capital asset that can enhance marketability and support higher valuation. |

| CapEx Predictability | Prone to premature failure and unplanned emergency expenditures. | Engineered for longevity, allowing for predictable lifecycle costs and capital planning. |

| Risk of Loss | High risk of inventory damage, tenant disruption, and business interruption. | Engineered to mitigate catastrophic failure, protecting operations and revenue. |

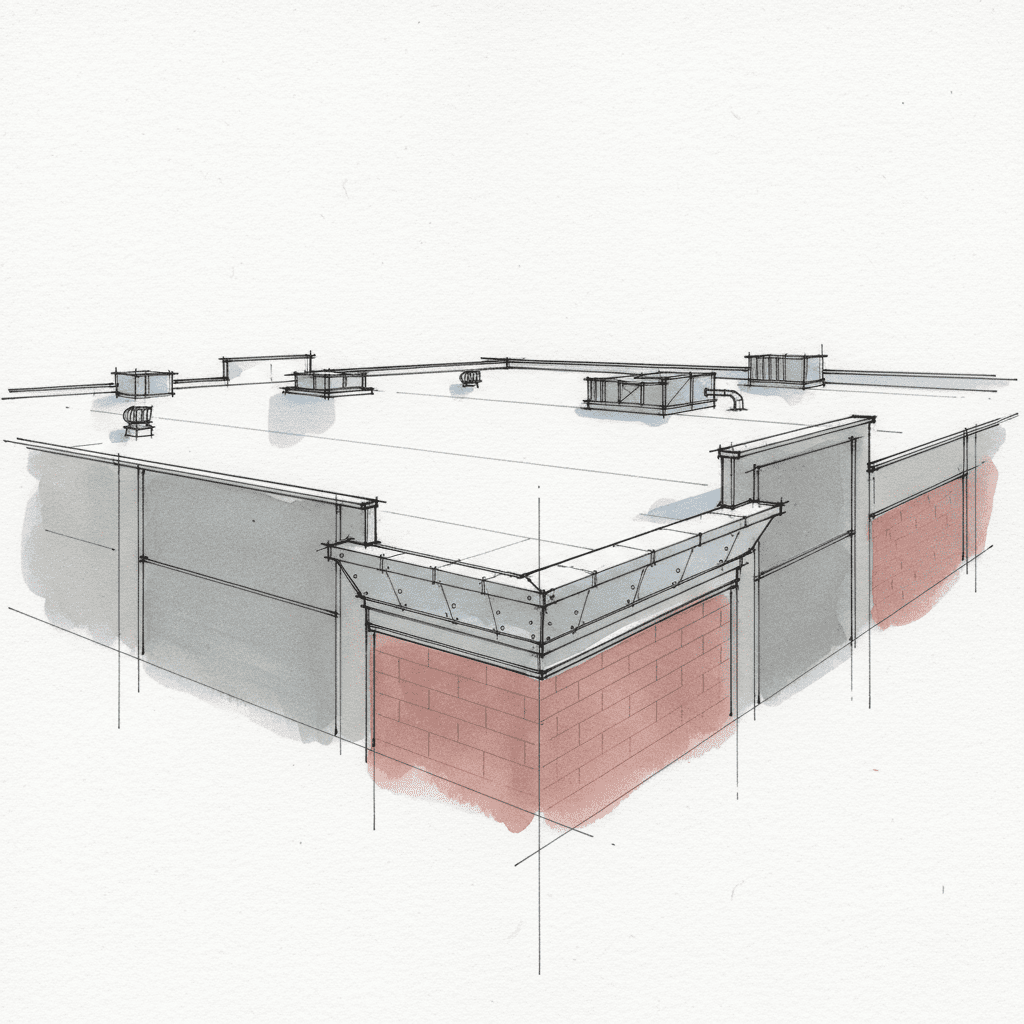

Wind Uplift Pressure Analysis: Engineering for Geographic and Structural Variables

Wind does not exert uniform pressure across a roof surface. Aerodynamic forces create significantly higher negative pressures (uplift) at the corners and perimeters of a building. A failure to engineer the roof assembly to withstand these concentrated forces is a primary cause of catastrophic roof failure. The FM Global methodology requires a precise analysis of these variables to specify a system capable of resisting calculated loads, measured in pounds per square foot (psf).

Mapping High-Risk Zones: Corner, Perimeter, and Field Uplift Ratings

A commercial roof is divided into three distinct zones for wind uplift calculations, each requiring a different level of securement. The interior section, or ‘field,’ of the roof experiences the lowest uplift pressure. The ‘perimeter’ experiences significantly higher forces, and the ‘corners’ endure the most extreme uplift pressures, often several times that of the field. A compliant installation involves increasing fastener density or adhesive application in these higher-risk zones according to precise engineering calculations from tools like FM Global’s RoofNav. A contractor who applies a uniform fastener pattern across the entire roof is not value engineering; they are demonstrating a fundamental and dangerous misunderstanding of basic building science, creating a massive liability for the asset owner.

The Critical Function of the Roof Deck in System-Wide Stability

The entire roof assembly’s ability to resist wind uplift is ultimately dependent on the structural integrity of the roof deck to which it is anchored. Whether it is a steel, concrete, or wood deck, its condition and load-bearing capacity are non-negotiable prerequisites for a compliant installation. This is why RocStout’s standard operating procedure explicitly advises against ‘overlay’ projects, where a new membrane is installed over an existing roof. This common cost-cutting measure hides the condition of the deck and its fasteners, creating an unknowable and unacceptable level of risk. A pull-out test must be conducted to verify the deck’s fastener retention capacity before the final assembly is specified. This establishes a baseline for system performance and ensures the entire capital investment is secured to a sound structural foundation.

Component-Level Requirements for an FM Approved Roof Assembly

An FM Approved rating is not granted to individual products in isolation. It is awarded to a complete roof assembly in which every component—from the deck screw to the membrane—has been tested to work together as a cohesive system. Substituting a single, unapproved component invalidates the entire system’s rating and exposes the property owner to significant liability.

Fastener and Adhesive Specification: Securing the First Line of Defense

Mechanical fasteners and bonding adhesives are the primary components transferring wind uplift loads from the membrane and insulation to the structural deck. For an FM assembly, these components are specified based on their tested pull-out resistance and bonding strength. The installation must adhere to a precise fastener pattern, which, as noted, will be denser in perimeter and corner zones. The choice of fastener type, length, and plate is an engineering decision, not a contractor’s preference. This precision ensures the system’s first line of defense against uplift is quantifiable and reliable.

Insulation and Cover Board Integrity Under Uplift Stress

Roof insulation and cover boards in an FM assembly must do more than provide thermal resistance. They must possess sufficient compressive strength and dimensional stability to withstand uplift forces without crushing, fracturing, or delaminating. FM-approved polyisocyanurate insulation and high-density cover boards are tested to ensure they maintain their integrity under the suction forces of high winds. A failure at this layer would cause the membrane to billow and detach, leading to a catastrophic system failure, even if the membrane itself remains intact.

Membrane Performance: Seam Strength and Puncture Resistance Criteria

The roof membrane (e.g., TPO, PVC) is the primary waterproofing layer, but its performance in an FM assembly is equally judged on its structural integrity. The seams, whether heat-welded or adhered, are a critical focus. They must be tested to ensure the weld is stronger than the membrane field itself, preventing the roof from ‘unzipping’ under wind load. Furthermore, the membrane must meet stringent standards for puncture and hail resistance, ensuring that the system can withstand not just wind, but a combination of environmental threats that could compromise the building envelope.

Financial Liabilities of Non-Compliance and Improper Installation

Engaging a contractor who lacks the discipline or expertise to execute an FM-specified assembly is a direct assumption of financial liability. Installation errors and non-compliant material substitutions create latent defects that will inevitably manifest as operational disruptions, unbudgeted capital outlays, and potential legal challenges.

Analyzing Common Failure Points: From Fastener Pull-Out to Seam Delamination

The most common points of failure in commercial roofing systems are directly addressed by FM Global standards. Fastener pull-out due to incorrect specification or deck corrosion, seam failure from improper welding techniques, and membrane detachment from adhesive failure are all preventable installation errors. Each of these failures leads to immediate water ingress, resulting in damaged inventory, lost revenue from operational downtime, and severe disruption to tenants. These are not roofing problems; they are business problems that originate with poor contractor selection and a lack of process controls.

The High Cost of Value Engineering: Why the Lowest Bid Creates the Greatest Risk

The commercial roofing industry is rife with contractors who win projects by offering the lowest bid, often achieved through so-called ‘value engineering.’ This practice is a euphemism for substituting non-specified materials, reducing fastener densities, or taking shortcuts in surface preparation. This approach transfers all long-term performance risk from the contractor to you, the asset owner. The initial savings are invariably consumed by future change orders, costly leak repairs, and the catastrophic cost of a premature roof failure. Choosing the lowest bid is not a fiscally prudent decision; it is a gamble against proven engineering principles, and it is a liability that no responsible fiduciary should accept.

RocStout’s Protocol for FM Global Specification & Execution

We operate as fiduciary partners in your capital planning process, not as transactional contractors. Our methodology is engineered to translate FM Global’s rigorous standards into a seamless, predictable, and financially transparent project execution. We do not compete on price; we compete on delivering fiscal certainty and ensuring absolute operational continuity for your facility.

Our Mandate: Zero Operational Disruption and Total Fiscal Certainty

Your core business is not managing roofing projects. Our Standard Operating Procedure is built around the primary objective of protecting your revenue-generating activities. This is achieved through rigid schedule adherence, proactive tenant and staff communication, and obsessive safety protocols that exceed OSHA requirements. We provide detailed, line-item reporting and operate on a ‘No Surprise’ billing principle. This methodology provides the predictable capital expenditure that is essential for effective financial management and eliminates the operational chaos common to commercial construction projects.

The RocStout Process: From Engineering Review to Final Certification

Our process is designed to deliver a compliant, high-performance roofing asset, not just a completed project. It begins with an engineering-led review to define the precise technical requirements. We then manage the complex submittal and approval process, ensuring every component meets the specification. Throughout installation, our quality assurance protocols document every critical step, from fastener placement to seam welding integrity. The process concludes not when the last tool is packed, but when you have the final compliance documentation and warranty in hand, securing the long-term value of your capital investment.