Exposed Fastener Systems: A Critical Assessment of Inherent Vulnerabilities

An exposed fastener metal roof system is a common capital asset whose performance is entirely dependent on the integrity of thousands of individual connection points. For a fiduciary asset manager, understanding these systems is not a matter of construction minutia; it is a core component of risk management. The fasteners are the primary line of defense for the building envelope, and their failure represents a direct and escalating threat to structural integrity, operational continuity, and the long-term value of the property.

Choosing the lowest bid for repair or installation on these systems is a well-documented financial liability. It prioritizes a short-term budget line item over the long-term preservation of the asset, inviting water infiltration, inventory damage, tenant disruption, and significant legal exposure. Our approach frames roofing not as a maintenance expense, but as a crucial element of your capital asset strategy.

The Role of Fasteners in System Integrity and Common Failure Points

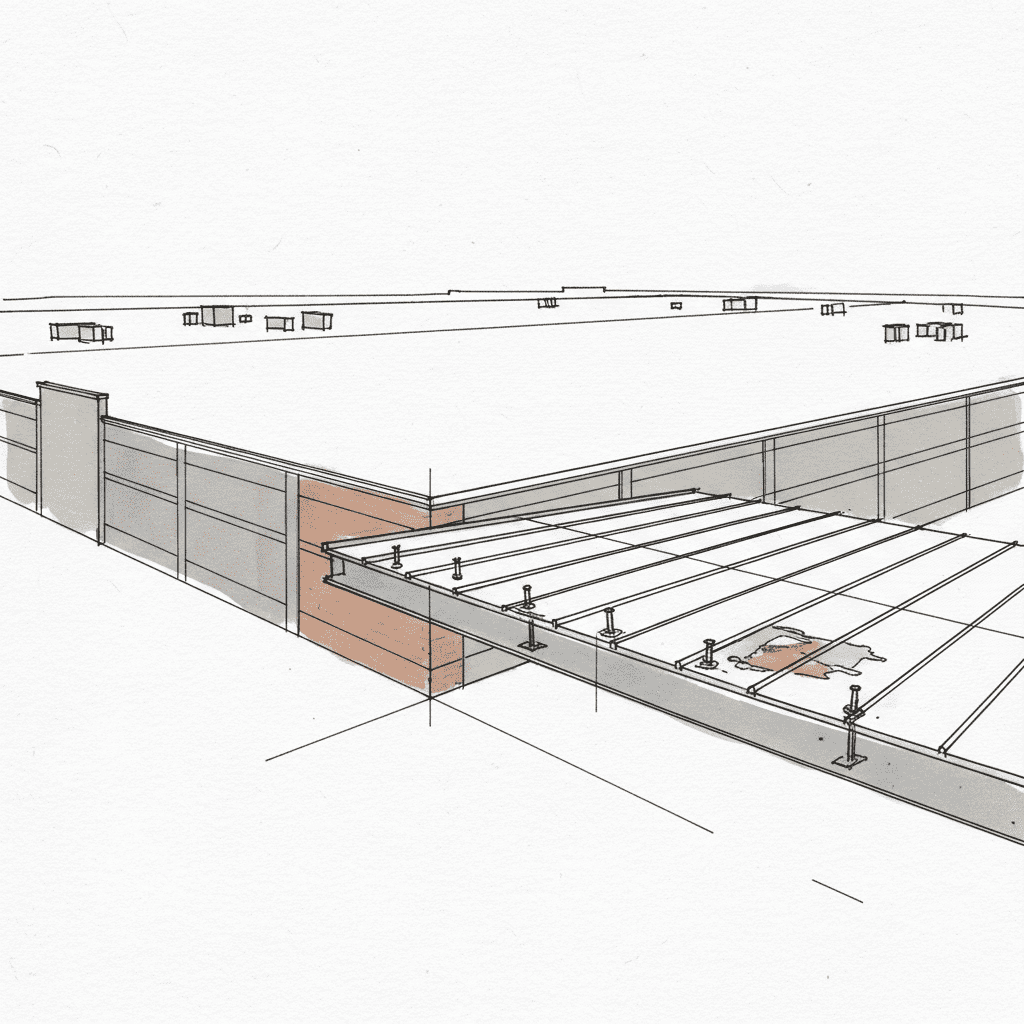

Each fastener is engineered to perform two critical functions: affixing the metal roof panels to the underlying structure and creating a watertight seal. The failure to perform either function compromises the entire system. The most common failure points are not catastrophic events but a gradual degradation that a trained eye can identify long before it impacts your operations. These include gasket degradation from UV exposure, fastener back-out from thermal cycling, and corrosion initiated by over-tightening, which fractures the protective coatings on the fastener head. These are not maintenance issues; they are leading indicators of future capital expenditure and potential operational crises.

Material Dynamics: Analyzing Thermal Expansion and Contraction Stresses

Metal roof panels are subject to constant thermal expansion and contraction. Throughout a single day, a metal panel can expand and contract significantly, placing immense shear and tensile stress on every fastener that holds it in place. This perpetual micro-movement elongates the fastener holes, fatigues the metal, and systematically breaks down the compressive seal of the washer. This is a predictable engineering challenge. An improperly engineered or installed system will fail prematurely, not due to defective materials, but due to a failure to account for these fundamental forces. This directly accelerates the depreciation of your roofing asset and shortens its viable service life.

Differentiating Cosmetic Blemishes from Actionable Structural Liabilities

An effective asset manager must distinguish between cosmetic issues and indicators of systemic failure. ‘Oil canning’—the visible waviness in the flat area of metal panels—is often a purely aesthetic issue with no impact on the roof’s performance. Conversely, the following are actionable liabilities requiring immediate engineering assessment:

- Surface Rust around Fastener Heads: Indicates a compromised protective coating and the onset of galvanic corrosion, which will degrade the fastener and the panel.

- Fastener Back-Out: A visible gap between the washer and the panel surface signals a loss of clamping force and a breach in the weatherproofing seal.

- Panel Distortion at Laps: Warping or separation at panel seams suggests excessive thermal movement or improper fastening, creating a direct path for water infiltration.

Prioritizing these structural liabilities over cosmetic blemishes is fundamental to a fiscally responsible maintenance strategy.

Diagnostic Analysis of Common Failure Modes and Their Financial Impact

A proactive approach to asset management requires a forensic understanding of how and why these systems fail. By identifying the specific failure mode, we can prescribe a corrective action that addresses the root cause, rather than merely treating the symptom (a leak). This methodology prevents minor operational expenses (OpEx) for repairs from escalating into major, unplanned capital expenditures (CapEx) for replacement.

Fastener Failure Forensics: Gasket Degradation, Back-Out, and Water Ingress Pathways

The neoprene or EPDM washers sealing the fasteners are the system’s weakest link. They are under constant compression and direct UV exposure. Over time, they harden, crack, and lose their compressive seal. This creates a microscopic pathway for moisture intrusion. Once water bypasses the washer, it is channeled directly into the building envelope, often traveling along purlins or decking before manifesting as a visible leak far from the point of origin. This hidden water damage leads to saturated insulation (reducing R-value and increasing utility costs), corrosion of the structural deck, and the potential for mold—a significant financial and legal liability.

Panel Corrosion and Rust-Through: Quantifying the Impact on Asset Lifespan

Modern Galvalume and coated steel panels are designed for longevity, but their protective coatings are microns thick. Improper installation techniques, such as using the wrong cutting tools or allowing metal filings to remain on the surface, create initiation points for corrosion. Cut-edge rust and galvanic corrosion around incompatible materials are not just cosmetic problems; they represent a quantifiable reduction in the asset’s lifespan. Every square foot of corrosion is a step closer to premature replacement, fundamentally altering the total cost of ownership for the roof and disrupting long-term capital planning.

To provide clear financial context, we have mapped common failure modes to their direct business consequences:

| Failure Mode | Technical Cause | Direct Financial Impact (OpEx/CapEx) | Indirect Financial Impact (Liability/Risk) |

|---|---|---|---|

| Gasket Degradation | UV exposure & compression set | Water damage to inventory/insulation, increased utility costs | Business interruption, tenant complaints, mold liability |

| Fastener Back-Out | Thermal cycling & vibration | Loss of wind uplift resistance, panel detachment (CapEx) | Catastrophic failure risk, increased insurance premiums |

| Panel Corrosion | Scratched coatings, cut edges | Premature panel replacement, structural repairs (CapEx) | Decreased property value, compromised structural integrity |

| Seam Sealant Failure | Improper installation, material aging | Persistent leaks, interior finish damage (OpEx) | Lost productivity, safety hazards (slip-and-fall) |

Seam and Lap Deficiencies: How Improper Sealing Compromises the Building Envelope

The seams where metal panels overlap are critical points of defense. Failure here is almost always a function of improper installation. Insufficient sealant, incorrect lap orientation, or missing stitch screws create vulnerabilities. Water can be pulled into these compromised seams through capillary action, defying gravity and leading to persistent, hard-to-diagnose leaks. In colder climates, this trapped moisture can lead to ice damming, a destructive cycle of freezing and thawing that can physically pry seams apart and cause catastrophic damage to the roof and underlying structure.

Quantifying the Financial Ramifications of System Failure

As a fiduciary, your decisions must be guided by data and long-term financial modeling. A leaking roof is not an isolated event; it is a symptom of a failing asset with compounding financial consequences that extend far beyond the cost of a simple patch. Adherence to your fiduciary duty requires a clear-eyed assessment of these total costs.

Calculating the True Cost of Deferred Maintenance: A Lifecycle Cost Analysis

Reactive maintenance is the most expensive strategy for managing a roofing asset. Deferring the replacement of failing fasteners does not save money; it merely postpones and multiplies the expense. A proactive program to tighten and replace failing fasteners might represent a minor operational expenditure. Ignoring it guarantees a future where water has degraded the insulation and corroded the structural deck, transforming a minor repair into a full roof replacement—a major capital expenditure. A proper lifecycle cost analysis demonstrates that proactive asset preservation consistently delivers a higher ROI by maximizing the roof’s intended service life and preventing the compounding damage that accompanies neglect.

Operational Disruption Metrics: Quantifying Downtime and Tenant Impact

The true enemy of any commercial facility is operational disruption. A standard contractor who fails to manage a project effectively can cost you more in lost revenue and tenant goodwill than the entire value of their contract. Water on a manufacturing floor, leaks in a retail space, or cordoned-off areas in a logistics center all represent business interruption. Our project management methodology is built around a single mandate: zero disruption. We understand that time is money, and our protocols for scheduling, site containment, and tenant communication are designed to protect your revenue-generating operations at all costs.

Navigating Liability and Compliance: Building Codes and Insurance Mandates

A failing roof system is a significant liability. In the event of a catastrophic failure, your insurance carrier will conduct a forensic analysis of the roof’s maintenance history. A documented record of proactive inspections and professional repairs is your best defense against a denied claim. Furthermore, local building codes mandate specific performance standards for wind uplift and structural integrity. Willful neglect of a known roofing deficiency can open your organization to legal liability in the event of injury or property damage. Proper documentation and adherence to professional standards are non-negotiable components of risk management.

A Proactive Management Framework for Exposed Fastener Roof Assets

RocStout Commercial operates as a fiduciary partner, not a conventional contractor. Our entire methodology is designed to provide you with the fiscal certainty required to manage your building assets effectively. We replace guesswork with engineering, and unpredictable bills with planned, data-driven capital expenditures. This is our standard operating procedure for protecting your investment.

Retrofit vs. Replacement: A Data-Driven Approach to Capital Planning

Many contractors present full roof replacement as the only solution because it is the most profitable for them. This is often a breach of their advisory responsibility. In many cases of fastener failure, the roof panels themselves retain significant service life. A fluid-applied roof restoration system can address fastener and seam issues at a fraction of the cost of a full replacement, with significantly less disruption. This approach provides a new, seamless, and warranted membrane over the existing roof. We provide a clear cost-benefit analysis, allowing you to make a capital decision based on long-term value and predictable expenditure, not a contractor’s sales quota.

Executing a Zero-Disruption Project: Safety Protocols and Tenant Communication Mandates

The core promise of RocStout is fiscal and operational certainty. Our project management is built on this foundation. Before any work begins, we establish a comprehensive safety plan that meets or exceeds all OSHA compliance standards. We develop a detailed project schedule and logistics plan, which is shared and approved by your team. Most critically, we execute a proactive tenant communication plan to ensure all stakeholders are aware of the project timeline, creating a predictable environment that minimizes disruption. Our crews operate under a strict ‘water-tight-by-nightfall’ protocol, ensuring your facility is protected at the close of every workday. This process-driven methodology is the only responsible way to manage commercial infrastructure.