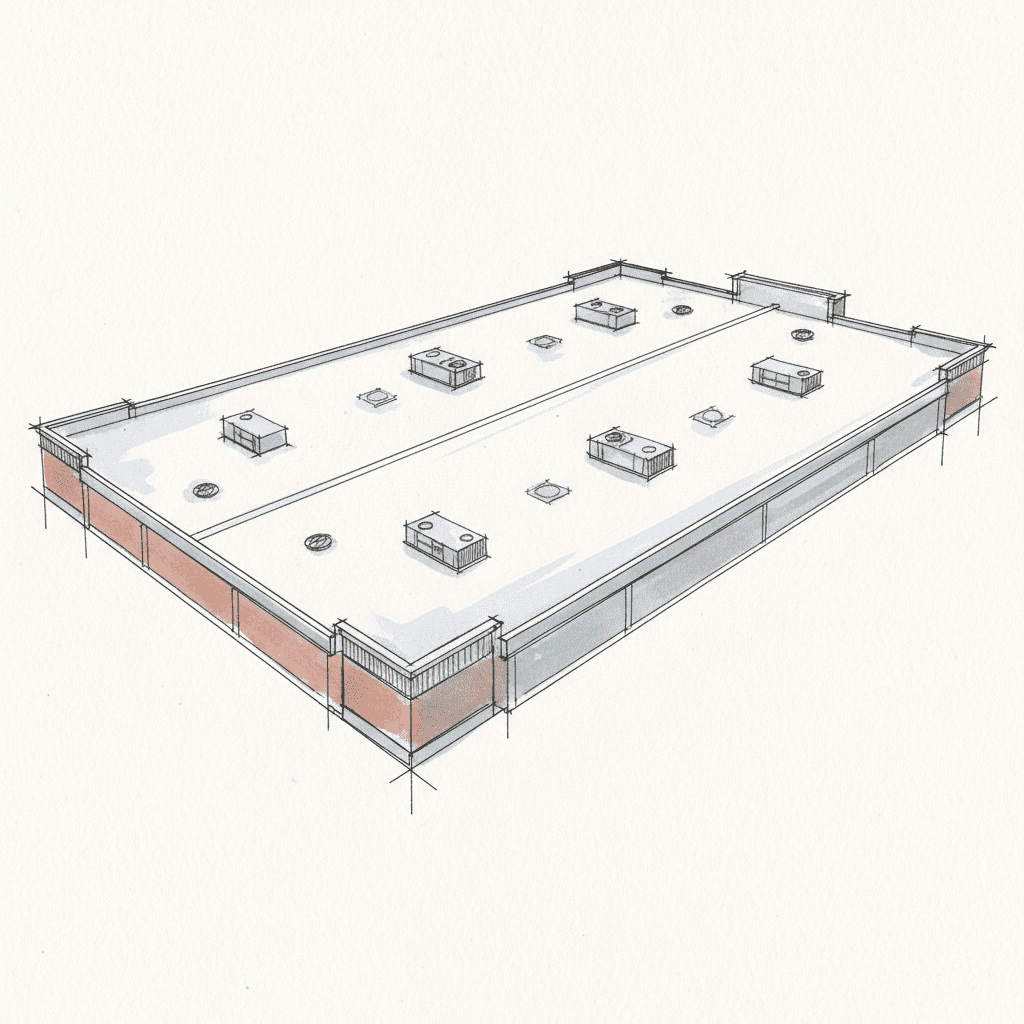

A TPO (Thermoplastic Polyolefin) roofing system is a single-ply reflective membrane engineered to reduce long-term operational expenditures and protect commercial assets from environmental liabilities. For the fiduciary asset manager, facility director, or CFO, the selection of a roofing system is not a maintenance task; it is a significant capital investment decision with direct consequences on building valuation, operational costs, and risk exposure. Choosing the correct system and, more importantly, the right installation partner is a function of responsible asset management. The industry default of selecting the lowest bid is a flawed strategy that mistakes price for cost, inviting operational disruption, tenant disputes, and premature system failure—all of which erode asset value.

TPO System Specification: A Financial & Performance Analysis for Asset Managers

A properly specified TPO roofing system is a strategic capital improvement that pays dividends over its service life. The technical specifications of the membrane are not merely engineering details; they are direct inputs into your building’s financial performance model. As fiduciaries, we analyze these specifications through the lens of total cost of ownership (TCO) and return on investment (ROI), ensuring the system enhances, rather than drains, your capital reserves.

Calculating Long-Term ROI Through Energy Efficiency & Reduced OpEx

The primary financial advantage of a white TPO membrane is its high solar reflectivity. This is not an abstract environmental benefit; it is a direct mechanism for reducing operational expenditures (OpEx). A highly reflective, ENERGY STAR-rated “cool roof” reflects a significant portion of solar radiation, preventing it from being absorbed as heat. This directly reduces the thermal load on your building, which in turn lowers the demand on your HVAC systems—one of the largest consumers of energy in a commercial facility. The result is a measurable decrease in utility costs, particularly during peak cooling seasons. This reduction in OpEx provides a clear and calculable return on the initial investment, shortening the payback period of the capital improvement.

Durability and Puncture Resistance: Quantifying the Impact on Asset Longevity

A commercial roof’s primary function is to protect the asset and its revenue-generating operations from water intrusion. The durability of a TPO membrane, defined by its thickness and polyester reinforcement, is a key variable in its ability to resist punctures, tears, and impacts from foot traffic, hail, or dropped equipment. A thicker membrane (e.g., 60-mil or 80-mil) offers superior puncture resistance compared to a standard 45-mil sheet. This specification directly correlates to a lower probability of leaks, reduced need for reactive maintenance calls, and an extended roof lifecycle. Compliance with ASTM standards for material strength is the baseline for performance. By specifying a more robust membrane, you are engaging in proactive risk management, safeguarding inventory, tenant operations, and the structural integrity of the building itself.

| Membrane Thickness | Primary Application | Financial Justification |

|---|---|---|

| 45-Mil TPO | Low-traffic roofs, budget-constrained projects | Meets minimum code; lower initial CapEx but higher lifecycle risk. |

| 60-Mil TPO | Standard commercial, distribution centers, manufacturing | Balanced cost and performance; the standard for responsible asset preservation. |

| 80-Mil TPO | High-traffic areas, roofs with significant equipment, hail-prone regions | Highest puncture resistance; minimizes long-term repair costs and liability. |

Navigating Building Code Compliance & Wind Uplift Classifications

Building codes and wind uplift ratings are not bureaucratic hurdles; they are critical risk mitigation frameworks. Adherence to standards like ASCE 7 and classifications from entities such as FM Global ensures the roofing system is engineered to withstand local weather events, particularly high winds. A failure to meet these standards exposes the asset to catastrophic failure, invalidates insurance coverage, and creates significant legal liability. A proper wind uplift calculation, based on building height, location, and topography, dictates the specific attachment method required. This is a non-negotiable component of our engineering protocol, insulating your asset from predictable and preventable risks.

TPO Installation Methodology: A Framework for Mitigating Structural & Financial Risk

The highest quality TPO membrane is rendered worthless by improper installation. The enemy of asset preservation is the contractor who cuts corners, ignores manufacturer specifications, and treats the building envelope as a simple surface. Our methodology is a rigid, process-driven framework designed to eliminate installation error and mitigate the financial risks associated with a compromised building envelope.

Substrate & Insulation Integrity: The Foundation of TPO System Performance

A TPO system’s performance is entirely dependent on the integrity of the substrate beneath it. Installing a new membrane over a wet, deteriorated roof deck or saturated insulation is financial malpractice. It traps moisture, accelerates structural decay, and guarantees premature system failure. Our standard operating procedure mandates a thorough substrate analysis, often including core sampling and infrared moisture detection. We verify the structural soundness of the deck and the thermal performance (R-value) of the polyisocyanurate (polyiso) insulation. Addressing these foundational issues is the only responsible path to ensuring the new system performs as engineered and meets energy code requirements.

System Attachment Analysis: Mechanically Attached vs. Fully Adhered Systems

The method used to secure the TPO membrane is a strategic decision based on the building’s structure, wind exposure, and budget.

- Mechanically Attached Systems: Utilize fasteners and plates to secure the membrane to the structural deck. This method is often more cost-effective and faster to install, making it suitable for many steel or wood deck applications.

- Fully Adhered Systems: Use bonding adhesives to glue the membrane directly to a suitable substrate. This creates a smooth, monolithic surface with superior wind uplift resistance, making it the required specification for concrete decks and buildings in high-wind zones.

The choice is not arbitrary. It is an engineering decision that balances cost, performance, and long-term risk mitigation for your specific asset.

Seam Integrity Assurance: The Criticality of Thermoplastic Heat-Welding

The seams are the most vulnerable component of any roofing system. TPO’s key advantage is that its seams are not glued but are heat-welded with hot air to create a monolithic, permanent bond. This process fuses the overlapping panels into a single, continuous membrane that is stronger than the sheet itself. This thermoplastic weld eliminates the reliance on adhesives and tapes that degrade over time when exposed to UV radiation and weathering. A properly welded seam is the ultimate defense against water ingress, protecting your facility from inventory loss, equipment damage, and the severe operational disruption that a single leak can cause.

Project Execution & Operational Continuity Management

The true cost of a roofing project is not limited to the invoice; it includes the hidden costs of operational disruption, tenant complaints, and safety liabilities. The standard commercial contractor is often the greatest source of this disruption. Our project management protocol is built around one central principle: protecting your business operations and insulating your asset from liability.

OSHA-Compliant Safety Protocols: Insulating Your Asset from Liability

An unsafe job site is a direct financial liability to the property owner. A contractor with a poor safety record exposes your asset to lawsuits, project delays, and increased insurance scrutiny. RocStout operates under a strict, non-negotiable safety protocol that meets or exceeds all OSHA compliance standards. This includes mandatory fall protection, clear site security and access plans, and daily safety briefings. Our commitment to safety is not a line item; it is a core component of our risk management service provided to you.

A Logistics-Driven Installation Plan to Minimize Tenant & Business Disruption

We understand that time is money and that your facility must remain operational. Our process begins with a comprehensive logistics plan designed for absolute minimal disruption. This includes carefully planned material staging areas, defined access routes for our crews, noise and odor abatement strategies, and a proactive tenant communication schedule. We coordinate with your facility management team to schedule the most disruptive work during off-peak hours whenever possible. Our goal is to execute the project with such efficiency and professionalism that your tenants and employees are barely aware of our presence. This is the essence of business continuity.

The RocStout Protocol: A Standard Operating Procedure for Fiscal Certainty

We reject the reactive, price-driven model of the roofing industry. Our clients require fiscal certainty and predictable capital planning. The RocStout Protocol is our proprietary, three-phase methodology that transforms a roofing project from an unpredictable expense into a managed, transparent capital expenditure.

This protocol is the only responsible way to manage commercial roofing infrastructure. It replaces uncertainty with engineering, and financial risk with predictable ROI. As your fiduciary partner, we believe this is the standard of care you should demand.